From raw materials to strategy

In today's packaging industry, plastic granules are no longer just "manufacturing materials", but core resources that affect product performance,regulatory access, carbon footprint management and brand image.

Faced with carbon neutrality, regulatory upgrades and global consumers' attention to environmental protection, a new battle on "what granules can win the future market" has begun.

1. A quick look at technology trends: three strategic transformations of plastic granules

From general formulas → customized blended materials

Brands are no longer satisfied with "just being able to form", but need:

・More tolerant heat sealing: adapt to high-speed packaging lines

・Optimized optical properties: cater to brand vision

・Integration of anti-fog/anti-oxidation/anti-tear functions: reduce film layers and improve efficiency

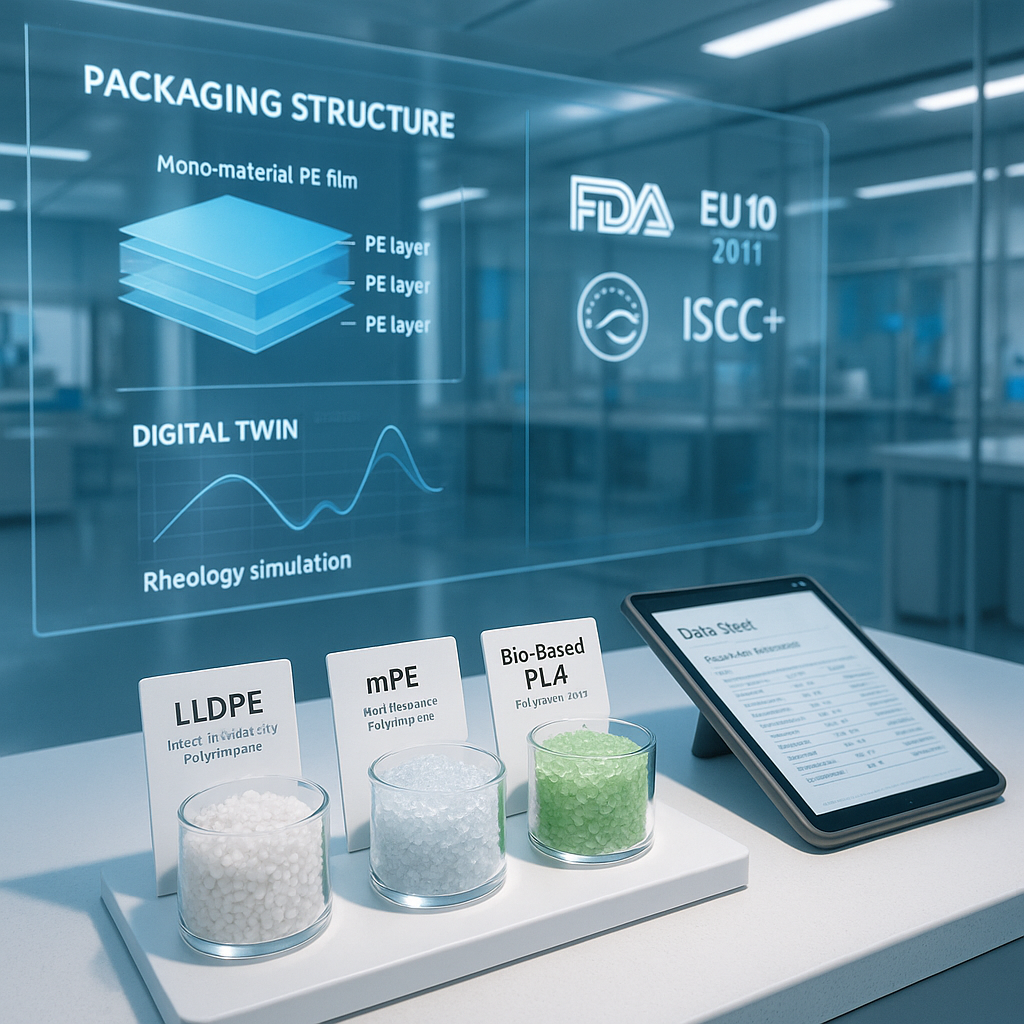

☑ Typical solution: LLDPE + mPE + functional masterbatch blending → single-structure packaging film

From multi-layer composites → single-material structure

In response to recyclable regulations and brand environmental protection commitments, PE/PE and PP/PP structures are gradually replacing traditional aluminum foil/nylon/coated film structures.

・Processing-friendly LLDPE copolymers enable multi-functions to be realized through a single material

・Metallocene polymers (mPE)** promote thinning by 20~30%, achieving "lightweight carbon reduction"

From molding to data-driven design

Pellets are no longer "hard attributes", but a link in the entire data chain.

・Digital twin modeling: material rheological parameters enter the design simulation system

・Particle parameters and equipment joint adjustment: improve production line stability and quality control consistency

2. Don't Just Choose the Expensive—Choose the Most Suitable Four Key Selection Criteria

We recommend that packaging brands evaluate pellet suitability based on the following four dimensions:

| Evaluation Criteria | Key Questions | Example Materials |

| Performance Fit | Does it meet physical strength, sealing range, transparency, etc.? | LLDPE 218WJ, 2426K |

| Equipment Compatibility | Is it compatible with your current blown film/cast/injection/thermoforming lines? | mPE, PP-R |

| Sustainability & Compliance | Does it meet FDA, EU10/2011, ISCC+ certifications? Is it recyclable? | ISCC+ LDPE, PBAT |

| Brand Strategy Alignment | Does the material support your brand’s eco-commitments or product differentiation? | Bio-based PLA, TPE |

3. Real-World Use Cases: How Pellets Can Be Redefined in Client Projects

| Industry | Original Material Structure | Upgraded Solution | Impacto |

| FMCG Beverages | PET bottle + PVC label | OPP film label + PP bottle | Easier for overall recycling |

| Household Detergents | Multilayer composite film (PE + PA + PET) | PE-PE monomaterial film with mPE modification | Lower carbon footprint & improved processing speed |

| Cold Chain Meat | Traditional high-barrier PA film | PE copolymer + EVOH co-extrusion barrier structure | Extended freshness, easier processing |

| Coffee Export | Aluminum foil + PET capsule | PLA + PBAT biodegradable capsule | Compostable certified, improved export compliance |

4. It is not about product material selection, but about material reconstruction product strategy

The material selection of an enterprise not only affects cost and performance, but also determines:

・Market entry speed

・Whether the brand complies with environmental protection regulations

・Whether it can be recognized by consumers

Today, when "functional particles" + "sustainable labels" have become part of brand communication, material selection is the first step in product design.

5. As a particle trader, we not only sell particles, but also participate in the future design of your products

Ofrecemos:

・Trend judgment support: Which materials have good prospects for export to Europe? Which can replace multi-layer composite structures?

・Blending suggestions and formula optimization: provide practical blending granule solutions that can be mass-produced

・Regulatory adaptation and matching: pre-select FDA, REACH, and ROHS certified materials

・Quick sample delivery: fast proofing, testing, and technical docking

If you are looking for a more suitable plastic granule solution for the future, we are willing to work with you to start from raw materials and explore the next possibility of the product.

📩 Welcome to contact us for technical information and sample support.