High-Performance Plastic Pellets Empower Dental Devices

2025-09-15Introduction The dental equipment industry places extremely high demands on material performance: devices must be resistant to high-temperature sterilization, chemical corrosion, mechanically strong, and reliable over the long term. Plastic pellets, as the core raw material for dental equipment, directly determine product qualification rates, service life, and market competitiveness.However, many buyers face challenges in select...

Global Plastic Raw Material Market Insights H2 2025 | Juyuan

2025-09-11Introduction In the second half of 2025, the global plastic raw materials market was impacted by multiple factors, including policy, trade, supply and demand, technological innovation, and environmental regulations. Prices and supply chains for general-purpose plastics such as PET, polyethylene, and ABS, as well as engineering plastics and bio-based materials, fluctuated. This article summarizes developments in six key are...

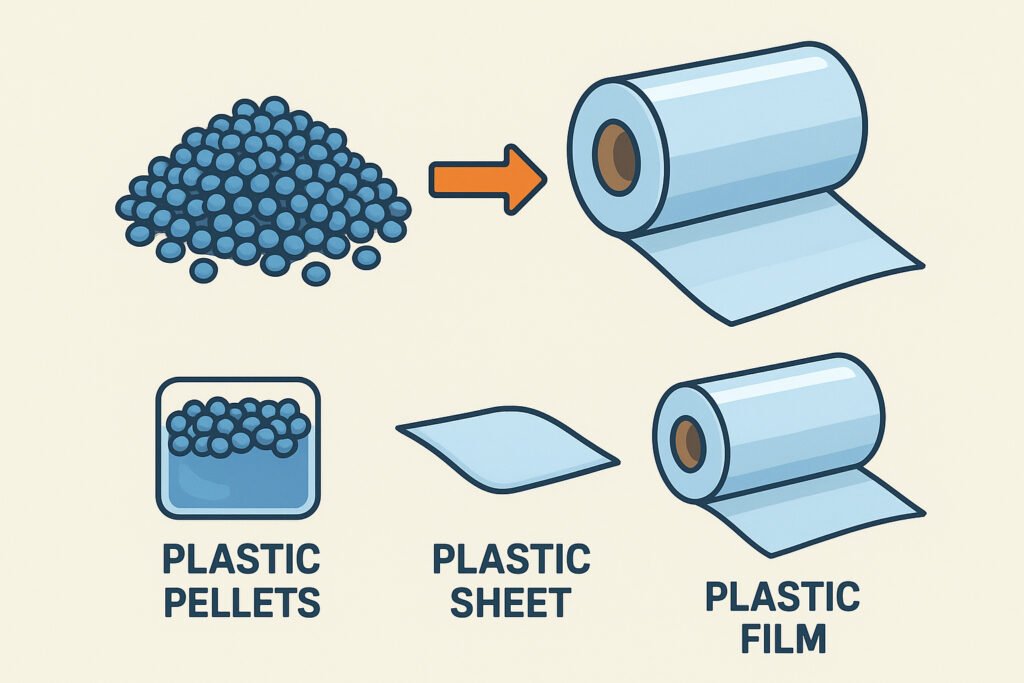

From Plastic Pellets to Films: A Complete Guide from Material Selection to Applications

2025-09-111. Introduction Plastic films are widely used in fields such as food packaging, industrial protective films, agricultural mulching films and functional films. The performance, transparency, toughness and barrier properties of the film largely depend on the type and performance of the raw material particles. Understanding the relationship between raw material particles and film processing is the key to producing high-qualit...

A Panoramic Analysis and Procurement Guide of China's Plastic Raw Material Pellets Industry

2025-09-10With the rapid development of China's manufacturing industry, demand for plastic raw material pellets continues to grow. From basic general-purpose plastics to high-performance engineering plastics, and finally to specialized functional materials, the Chinese market presents a diverse supply landscape. For buyers, understanding the characteristics and supply chain advantages of various companies will help achieve efficient procuremen...

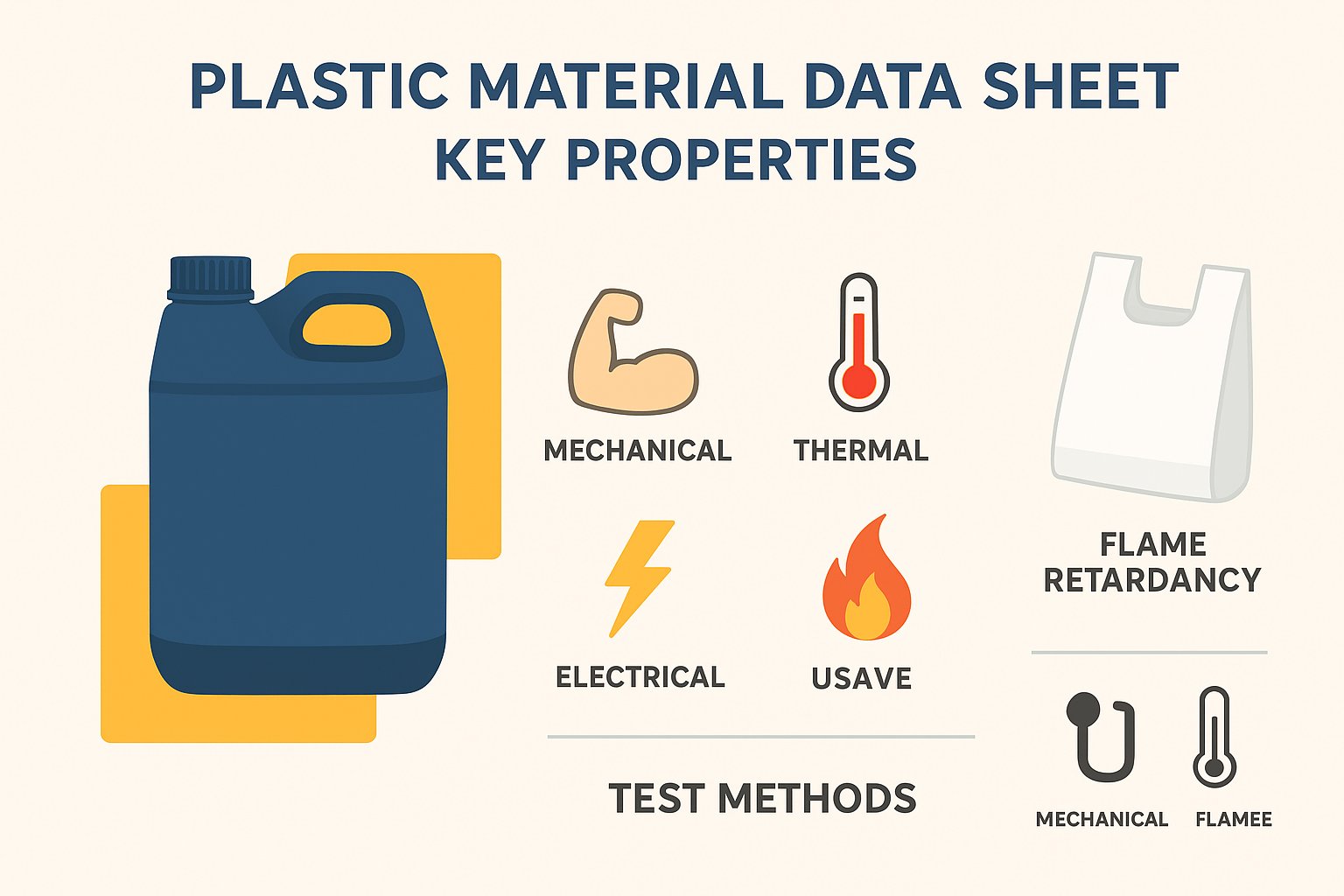

Plastic Material Data Sheet Explained: Key Properties, Test Methods & Value Guide

2025-09-08In the procurement and application of plastic raw materials, the physical property sheet (Datasheet) is the most intuitive reference tool. It not only demonstrates the performance parameters of the material, but also determines whether the product can meet the requirements of strength, heat resistance, electrical insulation and flame retardancy.However, when many purchasers are confronted with a dense list of physical properties,...

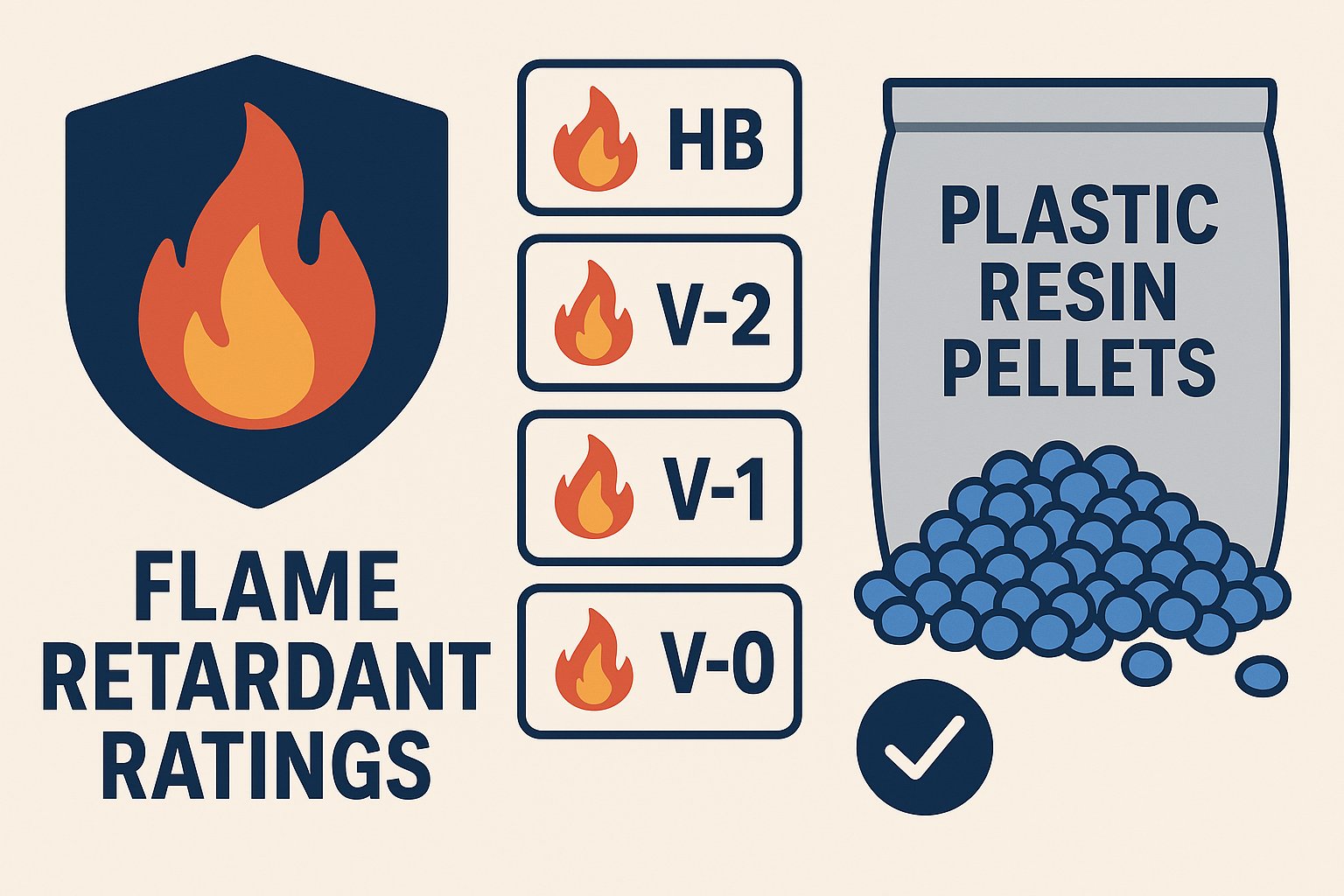

Flame Retardant Plastics Guide | Juyuan Resin Supply

2025-09-04Introduction In the physical property table of plastic raw materials, Flame retardancy Rating (flame Retardant Rating) is one of the indicators that purchasers pay the most attention to. It directly determines the safety, compliance and market access of materials in applications. Whether it is electronic appliances, automotive parts, or medical devices, flame retardant performance is an important basis for material selecti...

Plastic Material Selection & Procurement Guide for Machinery | Juyuan

2025-09-03As the global machinery and equipment industry continues to upgrade, buyers' demand for plastic raw materials has evolved beyond simply considering strength. They are now focusing on durability, supply stability, process adaptability, and cost control. In markets such as Europe, the US, Southeast Asia, and the Middle East, machinery manufacturers are generally considering how to reduce lifecycle costs through more rational material s...

Plastics for Power Tools: Selection & Procurement Guide | Juyuan

2025-09-02Introduction With the rapid development of the global power tool market, the durability, safety and user experience of products have become the key to competition. Whether it is an electric drill, an Angle grinder or an electric saw, plastic raw materials all play a significant role in them. The reliability of the casing, gears, battery case and electrical components directly determines the lifespan of the tool and its use...

5G Telecommunication Plastics Selection and Procurement Guide | Juyuan

2025-09-01Introduction With the accelerating adoption of 5G technology, the global communications industry is entering a new growth cycle. Compared to 4G, 5G's breakthroughs in transmission speed, low latency, and massive connectivity place higher demands on lightweight, weather-resistant, and stable equipment materials. Plastic raw materials, with their excellent insulation properties, mechanical strength, and processing flexibilit...