PRODUCTOS

TECASON® P MT XRO® PPSU: Medical-Grade Multi-Color Plastic

Estructura del producto

What is TECASON® P MT XRO®

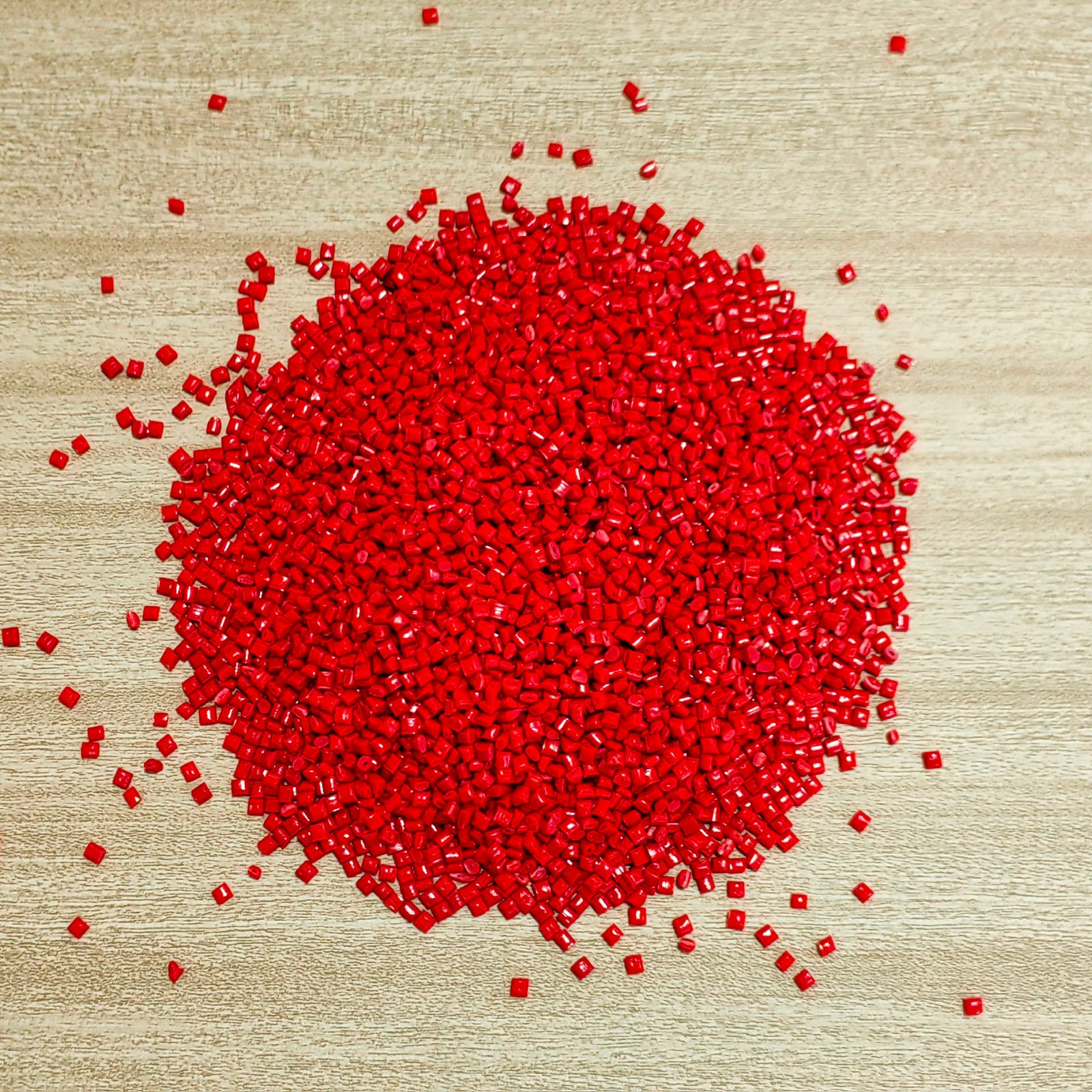

Material selection is crucial in medical devices and high-end industrial applications. Ensinger's TECASON® P MT XRO® PPSU series is a high-performance engineering plastic specifically designed for the medical industry. This series not only offers excellent heat resistance, hydrolysis resistance, impact resistance, and biocompatibility, but also offers a variety of color options (blue, red, green, gray, yellow, and black) for both aesthetics and safety, providing customers with innovative solutions that balance function and design.

01 | Material Highlights and Core Features

Medical-Grade Quality: Medically certified, it meets the high purity and safety requirements of surgical instruments and re-sterilized equipment.

High-Temperature and Hydrolysis Resistance: It offers long-term stable operation under high temperatures and pressures, making it particularly suitable for repeated high-temperature steam sterilization (autoclave) environments.

Color Variety: A wide range of color options not only facilitates the identification and management of medical devices, but also enhances product recognition and aesthetics in real-time.

Mechanical Strength and Toughness: A combination of high strength and toughness ensures the reliability of devices under frequent use and impact.

Filler Enhancement: Barium sulfate filler improves the material's detectability and stability.

02 | Applications

Surgical instruments and operating room accessories: Such as handles, clamps, and catheter components, they withstand repeated sterilization and high-intensity handling.

Medical diagnostic equipment: Housings and functional components ensure stability and durability during frequent operation.

Dental instruments and nursing tools: They meet the requirements of durability, comfort, and easy cleanability.

Other demanding industrial sectors: They also demonstrate excellent performance in some electronic and fluid control systems.

03 | TECASON® P MT XRO® Red Data Sheet

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Descanso 23°C | Norma ASTM D638 | 35 | % | |||

| Resistencia a la compresión | 23℃ 1% Strain | Norma ASTM D695 | 1.750 | psi | |||

| Resistencia a la compresión | 23℃ 10% Streain | Norma ASTM D695 | 13.700 | psi | |||

| Compressive Modulus | 23℃ | Norma ASTM D695 | 225.000 | psi | |||

| Resistencia a la flexión | 23℃ | Norma ASTM D790 | 18.000 | psi | |||

| Impacto de muesca Izod | 23℃ | Norma ASTM D256 | 1.6 | ft-lb/pulgada | |||

| Resistencia a la tracción | Rendimiento 23°C | Norma ASTM D638 | 11.500 | psi | |||

| Módulo de tracción | 23℃ | Norma ASTM D638 | 420.000 | psi | |||

| Módulo de tracción | 23℃ | 350.000 | psi | ||||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| Operating temperature | long | 300 | ℉ | ||||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Absorción de humedad | 23℃ 24 horas | Norma ASTM D570 | 0.19 | % | |||

| Dureza | Condición | Estándar | Valor | Unidad | |||

| Dureza Rockwell | M Scale 23℃ | Norma ASTM D785 | 92 | ||||

| Dureza Rockwell | R(Scale) 23°C | Norma ASTM D785 | 126 | ||||

04 | Processing and Processing Advantages

TECASON® P MT XRO® PPSU is available in various forms including sheet, rod, and tube, suitable for various processing routes, including injection molding, machining, and precision forming. Its excellent dimensional stability and ease of processing enable manufacturers to quickly manufacture complex components.

05 | Innovation and Competitive Advantages

Compared to traditional medical-grade plastics, the TECASON® P MT XRO® series not only offers more balanced performance but also offers breakthroughs in design freedom:

・Multiple color options address the issues of easy mix-up and difficult tracking of medical devices in hospitals.

・Made by the internationally renowned brand Ensinger, it offers competitive advantages in material certification, traceability, and regulatory compliance.

・Reliable, long-term supply guarantees peace of mind for customers during bulk purchases and project development.

06 | Customer Feedback

Feedback from medical device manufacturers indicates:

・"Multiple color options make device management more efficient."

・"Performance remains stable even after long-term high-temperature sterilization."

・"The smooth processing process reduces losses in the production process."

07 | FAQ

Q1: Can this material withstand repeated high-temperature steam sterilization?

A1: Absolutely. Long-term use will not affect mechanical properties or color stability.

Q2: Does the variety of colors mean a difference in performance?

A2: No. TECASON® P MT XRO® PPSU in different colors has identical performance data; it is only differentiated and identified by application scenario.

Q3: Does it meet medical industry certification requirements?

A3: Yes, the material is certified for medical applications and suitable for direct use in medical device manufacturing.

08 | Our advantage - reliable foreign trade suppliers

As a long-term plastic raw material supplier serving global customers, we not only offer genuine Ensinger medical-grade plastics from the original factory channels, but also bring you:

・A wide range of products are available in stock with fast delivery.

・Flexible procurement solutions for small and large batches to meet the needs of different customers.

・Professional technical support and application guidance to assist customers in achieving the optimal design and processing solutions.

・A global logistics network ensures safe and efficient cross-border transportation.

Choosing us means choosing stable supply, professional service and all-round support.

【Recomendaciones relacionadas】

What is PEEK Material? Definition, Properties, Applications and Market Insights Más información>

RTP Lubricated PPSU: Strength, Heat Resistance & Precision Más información>

QUADRANT PPSU Series: Heat Resistance, Chemical Durability Más información>