PRODUCTOS

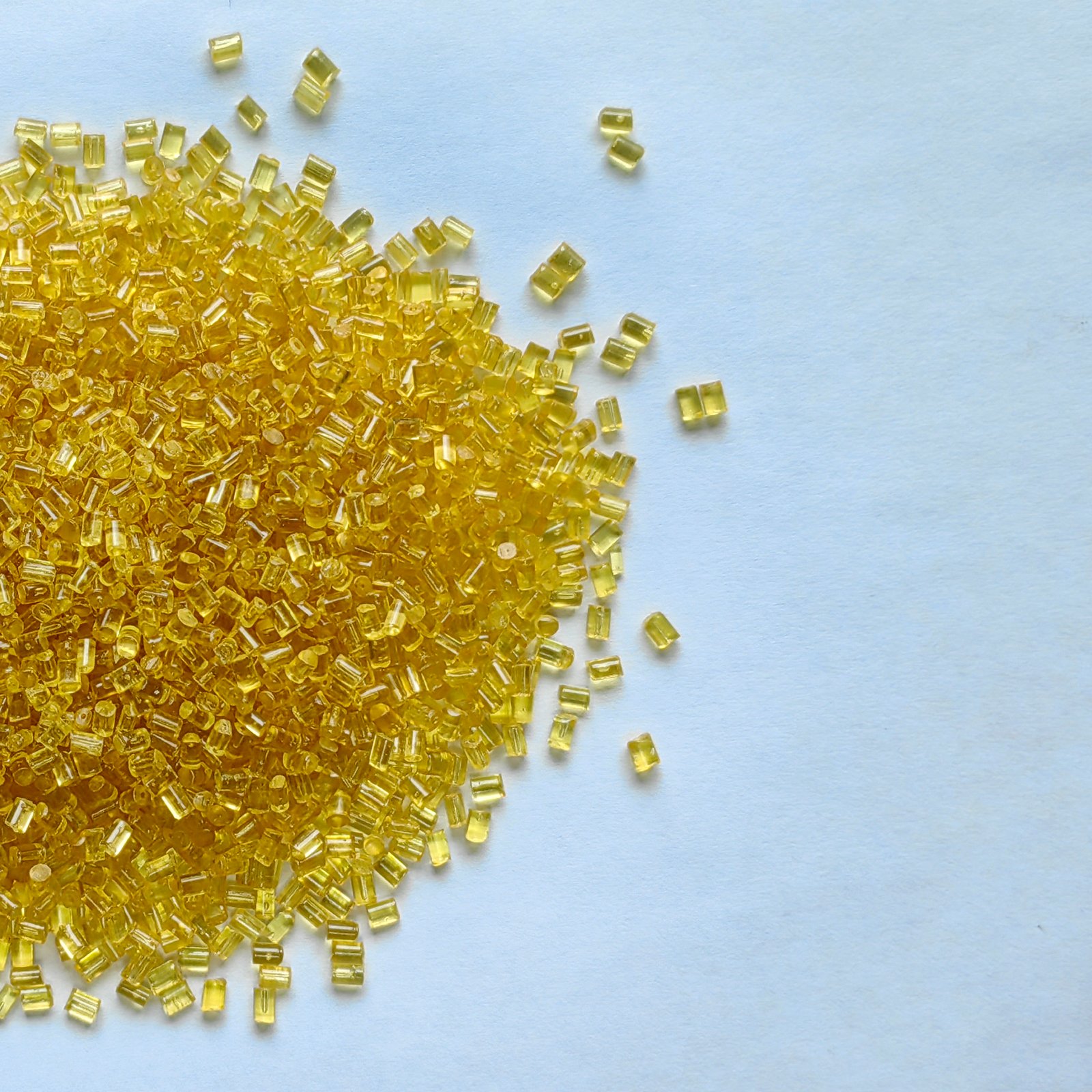

Solvay Polyphenylsulfone PPSU R-5000 NT for Medical Devices

Estructura del producto

What is Polyphenylsulfone PPSU

Today, with the continuous emergence of high-demand application scenarios, from operating rooms to food factories to advanced manufacturing industries, traditional plastic materials can no longer meet the comprehensive needs of heat resistance, corrosion resistance, and long-term stability. Solvay PPSU R-5000 NT, a colorless and transparent polyphenylsulfone PPSU, was born in response to this industry call. With its excellent thermal stability, broad-spectrum sterilization compatibility, and mechanical strength performance, it has become the "ideal choice" in the high-end field.

It not only passed the V-0 and 5VA flame retardant certifications, but also met the composite standards of medical grade, food contact grade, drinking water grade, electronic grade, etc., opening up new space for design freedom and safety boundaries.

01 | Polyphenylsulfone properties: not only heat-resistant and steam-resistant, but also radiation-resistant and sterilization-resistant

Compared with ordinary engineering plastics such as PES and PEI, R-5000 NT is almost full in terms of performance dimensions:

・Extreme heat resistance: HDT is as high as 207°C, glass transition temperature is 220°C, and it will not become brittle or deform even if exposed to high-temperature steam environment for a long time;

・Broad-spectrum sterilization compatibility: It supports multiple sterilization methods such as ethylene oxide, gamma rays, electron beams, and high-temperature steam, and is the first choice for multiple sterilization medical products;

・Chemical and hydrolytic stability: It is acid-resistant, alkali-resistant, and detergent-resistant, and is not afraid of harsh cleaning agents and repeated hot water cycles;

・Dimensional stability and stress crack resistance: The linear expansion coefficient is small, and the shrinkage rate is only 0.70%, which can cope with high-precision instrument processing without worries;

・Excellent toughness and impact resistance: The cantilever beam notch impact value is as high as 690 J/m, and it can remain unbroken even in low-temperature environments;

・Good electrical and wireless transmission compatibility: Good insulation (volume resistivity 9E15 Ω.cm), suitable for wireless sensing environments such as smart medical equipment;

・Transparency and optical refractive index: The refractive index reaches 1.672, supporting visualization needs and aesthetic design.

✅ At the same time, the material properties cover multiple specifications such as flame retardant, film, sheet, profile, thermal stability, and medical, truly realizing one material for multiple uses and adapting to diverse manufacturing systems.

02 | Application direction: In which industries does Polyphenylsulfone PPSU R-5000 NT stand out?

・Medical devices: Suitable for surgical instrument handles, dialysis connectors, respiratory masks, pipe connectors and other parts that are repeatedly sterilized at high temperatures;

・Dental and nursing consumables: such as dental tool housings, saliva suction tube components, and nursing needle and tube equipment;

・Food service field: coffee machine components, baby bottles, insulation equipment and other high-temperature food contact components;

・Automobile and rail transportation: used for heat-resistant and anti-aging components such as engine compartment hot zones, electrical connectors, and smart sensor housings;

・Surgical diaphragms and smart conductive parts: devices that have both structural strength and electrical performance requirements in medical electrical products.

03 | PPSU material data sheet

| Rendimiento óptico | Condición | Estándar | Valor | Unidad | |||

| Índice de refracción | Norma ASTM D542 | 1.672 | |||||

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Yield 3.2mm | Norma ASTM D638 | 7.2 | % | |||

| Alargamiento | Break 3.2mm | Norma ASTM D638 | 60~120 | % | |||

| Resistencia a la flexión | 5.0%Strain 3.2mm | Norma ASTM D790 | 91.0 | MPa | |||

| Módulo de flexión | 3,2 mm | Norma ASTM D790 | 2410 | MPa | |||

| Impacto de muesca Izod | 3,2 mm | Norma ASTM D256 | 690 | j/m | |||

| Resistencia al impacto por tracción | 3,2 mm | Norma ASTM D1822 | 399 | kJ/m² | |||

| Resistencia a la tracción | 3,2 mm | Norma ASTM D638 | 69.6 | MPa | |||

| Módulo de tracción | 3,2 mm | Norma ASTM D638 | 2340 | MPa | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| HDT | Unannealed 1.8MPa 3.2mm | Norma ASTM D648 | 207 | °C | |||

| Temperatura de transición vítrea | ASTM E1356 | 220 | °C | ||||

| CLE | Flujo 3,2 mm | Norma ASTM D696 | 5.6E-5 | cm/cm/°C | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Absorción de agua | 24 horas | Norma ASTM D570 | 0.37 | % | |||

| Absorción de agua | Balance | Norma ASTM D570 | 1.1 | % | |||

| Contracción | Flujo 3,2 mm | Norma ASTM D955 | 0.70 | % | |||

| Densidad | Norma ASTM D792 | 1.29 | gramos/cm³ | ||||

| Índice de fusión | 365°C 5kg | Norma ASTM D1238 | 14~20 | g/10min | |||

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |||

| Constante dieléctrica | 60Hz 3.2mm | Norma ASTM D150 | 3.44 | ||||

| Resistividad volumétrica | Norma ASTM D257 | 9E15 | Ω.cm | ||||

| Rigidez dieléctrica | 0.025mm | Norma ASTM D149 | 200 | kilovoltios/mm | |||

| Rigidez dieléctrica | 3,2 mm | Norma ASTM D149 | 15 | kilovoltios/mm | |||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Clasificación de llama | NC 0.36mm | UL94 | V-0 | ||||

| Clasificación de llama | Todos los colores 0,75 mm | UL94 | V-0 | ||||

| Clasificación de llama | Todos los colores 1,5 mm | UL94 | V-0 | ||||

| Clasificación de llama | Todos los colores 3,0 mm | UL94 | V-0 | ||||

04 | Process adaptability: multiple molding methods are covered in one net

Polyphenylsulfone PPSU R-5000 NT has excellent processing compatibility and is suitable for a variety of thermoplastic processing methods:

・Injection molding: suitable for high-precision injection molding of small and large shells of complex medical devices;

・Extrusion molding: can produce continuous products such as highly transparent films, plates, and strips;

・Blow molding: widely used in hollow products such as milk bottles and containers;

・Thermoforming & CNC cutting: suitable for customized medical structural parts, laboratory components, functional sample proofing, etc.

Its melt index is in the range of 14~20 g/10min (365°C, 5kg), with good flowability and high molding efficiency, which is conducive to the production of thin-walled products and complex cavity parts.

05 | Compliance and Standard Testing

Polyphenylsulfone PPSU R-5000 NT not only has excellent performance, but also has strong regulatory endorsement and testing and certification support:

・Flame retardant grade: UL94 V-0 (full color thickness 0.36mm~3.0mm all meet the standard)

・Passed FDA, NSF, ISO 10993 and other food and medical contact certifications;

・Multiple ASTM test standard verification: mechanical, electrical, and thermal data are complete;

・Biocompatibility evaluation, RoHS and REACH compliance reports are available.

📄 As the standard material for mainstream medical and food-grade products in the world, PPSU R-5000 NT fully supports the technical documentation required for international market entry and medical regulatory registration.

06 | Similar material recommendation: more extensive selection suggestions

According to different performance requirements, you can refer to the following similar Polyphenylsulfone PPSU models:

| Fabricante | Product Name | Modelo de producto | Densidad | Melt Flow Rate | Resistencia a la tracción | Alargamiento | Contracción | Módulo de tracción | HDT (Heat Deflection Temp.) | Módulo de flexión | Notched Izod Impact Strength | Coefficient of Linear Thermal Expansion | Resistencia a la flexión |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Solvay | PPSU | R-5100BK937 | 1.3 g/cm³ | 17 g/10min | 69.6 MPa | 7.2% | 0.7% | 2340 MPa | 214 ℃ | 2410 MPa | 690 J/m | 5.6×10⁻⁵ cm/cm/℃ | 91 MPa |

| Solvay | PPSU | R-5800NT | 1.29 g/cm³ | 24 g/10min | 69.6 MPa | 7.2% | 0.7% | 2340 MPa | 207 ℃ | 2410 MPa | 690 J/m | 5.6×10⁻⁵ cm/cm/℃ | 91 MPa |

If you have customized requirements, you can also contact us for more color matching, modification or compounding solutions.

07 | FAQ

Q1: How many times can PPSU R-5000 NT be repeatedly sterilized with high-temperature steam?

A: It can withstand more than 1,000 121°C steam sterilization cycles without obvious physical degradation.

Q2: Does this material contain bisphenol A (BPA)?

A: It is completely BPA-free and suitable for the high safety standards of baby products and medical products.

Q3: How does it perform compared with PEEK?

A: PPSU's heat resistance is slightly lower than PEEK, but it performs better in terms of cost-effectiveness, sterilization resistance and processing friendliness.

Q4: Which Impresión 3D or CNC custom equipment is suitable for?

A: Due to its high dimensional stability and mechanical strength, it is very suitable for high-temperature FDM equipment and five-axis CNC machining scenarios.

08 | Conclusion: Why choose us as your Polyphenylsulfone PPSU supplier?

We are not only a material provider, but also your material selection consultant and solution partner.

✔ We have been deeply involved in the trade of high-performance engineering plastics for many years and are familiar with the landing needs in multiple fields such as medical, food, and automobiles;

✔ We provide original technical information, compliance documents, sample support, and processing consultation;

✔ Flexible small batch orders, spot supply, and fast cross-border delivery.

📦 Welcome to inquire about Solvay PPSU R-5000 NT, get a quote and technical docking solution, and we will provide you with customized support with professionalism.

【Recomendaciones relacionadas】

PESU 2010 MR:High Flow & Flame-Retardant PESU Polymer Más información>

What is PPSU Material? A Panoramic Analysis and Market Opportunities of PPSU Engineering Plastics Más información>

BASF PPSU 3010 NAT: Heat-Resistant Injection Grade Plastic Más información>