PRODUCTOS

Solvay PEEK MS NT1 AM Filament PEEK Material 3D Printing

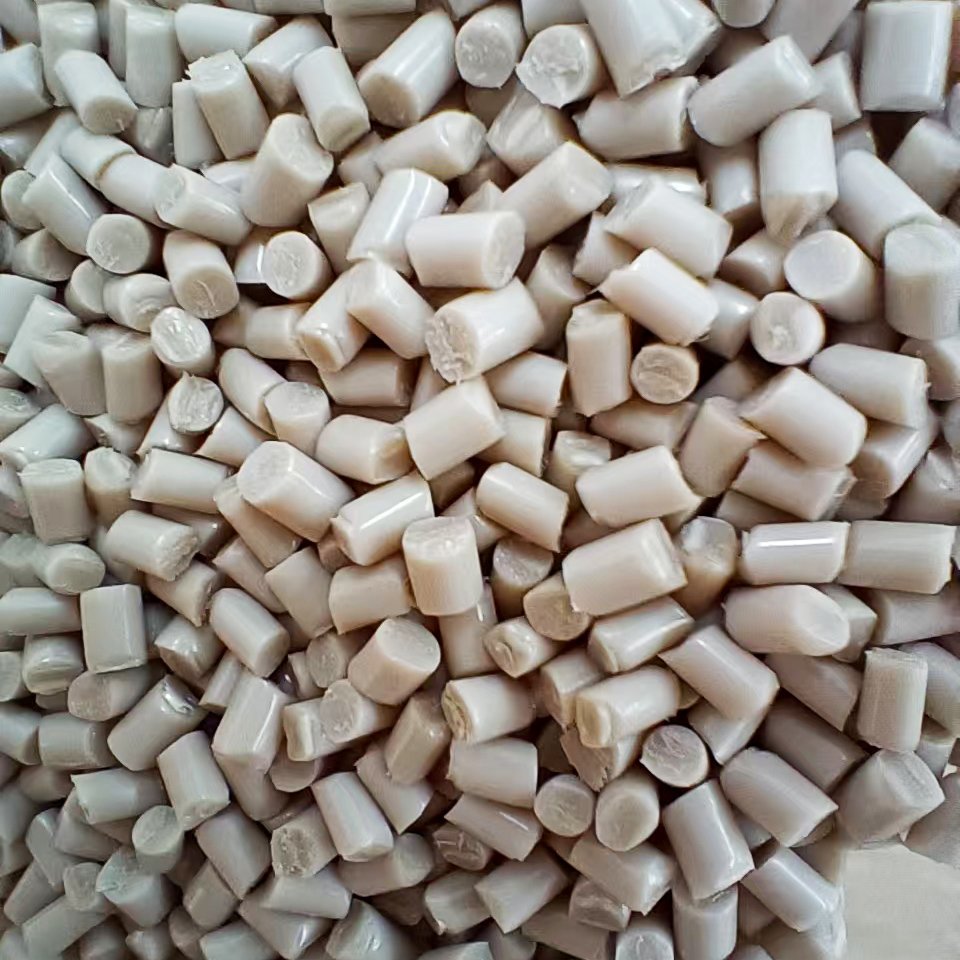

Estructura del producto

1. The Integration of PEEK Material and 3D Printing

At present, when 3D printing (Additive Manufacturing, AM) is gradually moving towards the production of functional terminal parts, material properties have become the key to determining the feasibility of industrialization.

PEEK (polyetheretherketone) has become a new generation of polymer material that can replace metals due to its high heat resistance, high strength, and chemical corrosion resistance.

With the maturity of PEEK material 3D printing technology, manufacturers can rapidly achieve lightweight, complex structures and small-batch production without sacrificing performance.

El PEEK MS NT1 AM Filament launched by Solvay is precisely a high-performance flame-retardant PEEK material optimized for industrial-grade 3D printing.

2. Product Overview: Flame-retardant PEEK filament specifically optimized for 3D printing

MS NT1 AM Filament adopts a flame-retardant PEEK-FR resin system with a filamentous structure, specifically designed for fuse manufacturing (FDM) 3D printing.

This material, while maintaining the high heat resistance and high strength of traditional PEEK, has been deeply optimized for rheological properties, interlayer adhesion and thermal shrinkage.

Its launch has made the performance of 3D printed parts closer to that of injection-molded parts, meeting the strict requirements of the aviation, automotive, oil and energy industries.

3. Key Performance Data

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Producir | Norma ASTM D638 | 7.0 | % | |||

| Alargamiento | Romper | Norma ASTM D638 | 21 | % | |||

| Impacto de muesca Izod | Norma ASTM D256 | 480 | j/m | ||||

| Resistencia a la tracción | Producir | Norma ASTM D638 | 62.0 | MPa | |||

| Resistencia a la tracción | Romper | Norma ASTM D638 | 42.0 | MPa | |||

| Módulo de tracción | Norma ASTM D638 | 2000 | MPa | ||||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| Temperatura de transición vítrea | DSC | MÉTODO INTERNO | 220 | ℃ | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Densidad | Norma ASTM D792 | 1.29 | gramos/cm³ | ||||

Performance Analysis

・Excellent ductility: Elongation at break is 21%, with outstanding crack resistance.

・Structural stability: A modulus of 2000 MPa ensures the dimensional accuracy of parts.

・High temperature resistance: 220℃ glass transition temperature, suitable for extreme environments.

・Flame retardant and chemically resistant: Meets oil and gas as well as aviation standards.

MS NT1 AM Filament has established its benchmark position in the field of PEEK material 3D printing with outstanding data performance.

4. Print Compatibility and Process Advantages

PEEK material is renowned for its high melting point, but this also makes the threshold for its 3D printing extremely high. Solvay has achieved through customized design of molecular structure and rheological properties:

✅ Stable fluidity: smooth extrusion in the range of 360-400℃;

✅ Tight interlayer bonding: significant increase in Z-direction strength;

✅ Low warpage rate: controlled cooling shrinkage, suitable for large parts;

✅ Smooth surface: can meet industrial requirements without complex post-treatment.

These characteristics make PEEK material 3D printing no longer limited to research and development experiments, but become a realistic solution for mass production.

5. Typical Application Fields

| Application Industry | Typical Use | Replacement / Added Value |

| Aerospace | Duct supports, mounting fixtures | Replaces aluminum, reduces weight by 30–50% |

| Automotive | High-temperature supports, electrical insulation components | High heat resistance, excellent insulation |

| Oil & Gas | Sealing rings, downhole structural parts | Corrosion-resistant, flame-retardant |

| Medical & Energy | Precision testing components | Supports rapid small-batch iteration |

With the transformation of manufacturing towards lightweighting and intelligence, PEEK material 3D printing has become an important driving force for high-end engineering applications.

6. Industry Trends: From Metal Substitution to Intelligent Manufacturing

Global manufacturing is accelerating its transformation towards lightweighting and sustainability.

In the aviation, automotive and energy industries, engineers are increasingly using PEEK material 3D printing to replace some aluminum alloy or stainless steel parts.

Compared with traditional metal processing, 3D printed PEEK has the following significant advantages:

| Item | Metal Parts | PEEK 3D Printed Parts |

| Weight | Heavy | Over 50% lighter |

| Cost | Requires mold | No mold needed, flexible customization |

| Production Cycle | Several weeks | Several hours to a few days |

| Chemical Resistance | Prone to corrosion | Resistant to acids, bases, oils, and solvents |

| Thermal Conductivity | Alto | Controllable, suitable for insulating structures |

This means that from design verification to functional testing to mass production, PEEK printed components can bring higher efficiency and lower risks to the manufacturing industry.

7. FAQ: Common Questions About PEEK Material 3D Printing

Q1: What are the differences between PEEK MS NT1 AM Filament and traditional PEEK filament?

A1: MS NT1 is specifically optimized for 3D printing, featuring stronger interlayer adhesion and printing stability. It can directly print large functional parts, while traditional PEEK filaments are mostly used for experimental or prototype printing.

Q2: Does printing PEEK require special equipment?

A2: Yes. PEEK printing requires an industrial-grade FDM printer with a high-temperature nozzle (≥400℃) and a heating chamber (≥120℃) to ensure the material is fully melted and interlayer bonded.

Q3: Which metal parts can PEEK material 3D printing replace?

A3: It can replace aluminum, stainless steel or titanium alloy components in high-temperature, corrosive or insulating requirements scenarios and is commonly found in hot zones of aviation, energy and automobiles.

Q4: Does Juyuan provide printing process parameters or technical guidance?

A4: Provided. Juyuan can provide customers with Solvay's official printing parameter references, spline testing support and application optimization suggestions, helping customers achieve complete implementation from raw materials to terminal components.

8. Similar Recommendations

| Modelo de producto | Descripción | Peso específico | Resistencia a la tracción | Alargamiento | Módulo de tracción | Izod Notched Impact |

| CF10 HC AM Filament | Compliance: ISO 10993Material Características: High strength • Biocompatible • Chemical resistance • Ductility • Dimensional stability • High impact • Heat resistance | 1.33 g/cm³ | 140 MPa | 1.70% | 11000 MPa | 89 J/m |

| CF10 LS1 AM Filament | Material Features: High strength • Chemical resistance • Ductility • Dimensional stability • High impact • Heat resistance Aplicaciones: Automotive components • Aerospace applications • Oil & Gas industries | 1.33 g/cm³ | 140 MPa | 1.70% | 11000 MPa | 89 J/m |

| NT1 HC AM Filament | Compliance: ISO 10993 Material Features: Heat resistance • Biocompatible • Chemical resistance • Ductility • Dimensional stability • High impact Aplicaciones: Medical devices • Healthcare products | 1.29 g/cm³ | 85.0 MPa | 4.80% | 3120 MPa | 81 J/m |

9. Juyuan: Providing material connectivity for Global 3D Printing Manufacturing

As an enterprise with 24 years of international experience in plastic raw material trade, Juyuan is dedicated to connecting the world's high-quality supply chains and providing customers with stable and reliable PEEK 3D printing materials.

Reasons to choose Juyuan

✅ Original Source: Authorized Solvay supplier;

✅ Global Distribution: Covering the European, Southeast Asian, and Middle Eastern markets;

✅ Technical Support: Providing printing parameters, material selection, and process consulting;

✅ Ongoing Partnership: Helping customers develop the next generation of lightweight structural parts.

Juyuan believes that From Material to Possibility, every innovation stems from the correct selection of materials.

【Recomendaciones relacionadas】

Import Substitution vs. International Brands: Which Offers Better Value? Más información>

Ensinger PEEK 450 CF30 black 9579 | A Carbon Fiber Reinforced Polyetheretherketone Más información>

DOMO PEEK 3350R30: Engineered PEEK Polyetheretherketone Más información>