PRODUCTOS

Solvay Ketaspire™ KT 820 — Sterilizable PEEK Raw Material

Estructura del producto

What is PEEK Raw Material

Ketaspire™ KT 820 is a flame-retardant PEEK raw material from Solvay and is a member of the high-purity polyetheretherketone system. It combines thermal stability, radiation sterilization resistance and structural strength. It can maintain good mechanical integrity and dimensional stability even in extreme environments, making it particularly suitable for engineering applications that require long-term heat exposure and high-intensity operations.

One of its features lies in the V-0 flame retardant grade (thickness ≥1.5mm), and it can still reach V-1 under thin-walled conditions. While meeting the requirements of lightweight structure, it ensures the fire safety of the parts.

01 | Main Performance and Structural Characteristics

Ketaspire™ KT 820 adopts a modified PEEK-FR formula, with an efficient flame retardant system and lubricating additives introduced internally, achieving a balance among mechanical, thermal and electrical properties of the material.

・Outstanding high-temperature resistance: The long-term operating temperature can reach 260°C, and RTI (electrical/structural) demonstrates stable resistance to thermal aging.

・Outstanding flame retardant performance: With an oxygen index of 37%, it still achieves V-0 flame retardancy even in a halogen-free formula, meeting the safety standards for electronic and medical devices.

・Multi-sterilization compatibility: It can withstand steam, high pressure, ethylene oxide, gamma rays and electron beam sterilization without performance degradation.

・Combining mechanical strength with toughness: The tensile strength can reach up to 124 MPa, the elongation at break exceeds 200%, while maintaining a good fatigue life.

・Stable electrical insulation: Dielectric constant 3.1, volume resistivity as high as 2.6×10¹⁶ Ω·cm, suitable for use in precision electrical components.

・Dimensional stability and chemical corrosion resistance: Low water absorption rate (0.5%) and low linear expansion coefficient (4.3×10⁻⁵ cm/cm/℃) ensure that the parts do not deform during thermal cycling.

02 | Campos de aplicación típicos

With its unique heat resistance and sterilization performance, Ketaspire™ KT 820 is widely used in:

・Medical and nursing equipment: surgical instrument handles, dental applications, implant device housings, reusable sterilizable components.

・In the field of electronics and electrical engineering: connectors, coil bobbins, precision insulating components.

・Aviation and automotive industry: lightweight heat-resistant structural components, fuel system parts, sealing rings, pump and valve accessories.

・Industry and Energy: Oil and gas sealing components, high-temperature wear-resistant gears and pump body parts.

03 | Ketaspire™ KT 820 Data Sheet

| UL | Condición | Estándar | Valor | Unidad | |||

| CTI | IEC 60112 | 4 | SOCIEDAD ANÓNIMA | ||||

| GWFI | 0.87mm | IEC 60695-2-12 | 960 | ℃ | |||

| GWFI | 1,5 mm | IEC 60695-2-12 | 960 | ℃ | |||

| GWFI | 3,0 mm | IEC 60695-2-12 | 960 | ℃ | |||

| GWIT | 0.87mm | IEC 60695-2-13 | 850 | ℃ | |||

| GWIT | 1,5 mm | IEC 60695-2-13 | 825 | ℃ | |||

| GWIT | 3,0 mm | IEC 60695-2-13 | 850 | ℃ | |||

| Hola | NC BK 3,0 mm | UL 746A | 1 | SOCIEDAD ANÓNIMA | |||

| Alta Velocidad | UL 746A | 3 | SOCIEDAD ANÓNIMA | ||||

| HWI | NC BK 3,0 mm | UL 746A | 1 | SOCIEDAD ANÓNIMA | |||

| Resistencia al arco | ASTM D495 | 6 | SOCIEDAD ANÓNIMA | ||||

| Clasificación de llama | NC BK 3,0 mm | UL94 | V-0 | ||||

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Flow Yield 25μm | Norma ASTM D882 | 6.8 | % | |||

| Alargamiento | Flow Yield 50mm/min 150μm | Norma ASTM D882 | 5.5 | % | |||

| Alargamiento | xFlow Yield 25μm | Norma ASTM D882 | 6.7 | % | |||

| Alargamiento | xFlow Yield 50mm/min 150μm | Norma ASTM D882 | 5.4 | % | |||

| Alargamiento | xFlow Break 50mm/min 150μm | Norma ASTM D882 | 210 | % | |||

| Resistencia a la tracción | Flow Yield 25μm | Norma ASTM D882 | 75.8 | MPa | |||

| Resistencia a la tracción | Flow Break 25μm | Norma ASTM D882 | 109 | MPa | |||

| Resistencia a la tracción | xFlow Break 50mm/min 150μm | Norma ASTM D882 | 123 | MPa | |||

| Tear strength | 125μm | Norma ASTM D1004 | 10.0 | cN | |||

| Tear strength | 125μm | ASTM D1922 | 320 | gramo | |||

| Módulo secante | Flow 25μm | Norma ASTM D882 | 2050 | MPa | |||

| Módulo secante | xFlow 150μm | Norma ASTM D882 | 2540 | MPa | |||

| Drop-dart impact | 50 μm | ASTM D1709 | 1300 | gramo | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| Coeficiente de conductividad térmica | ASTM E1530 | 0.24 | W/(m·K) | ||||

| HDT | Annealing 1.80MPa 3.20mm | Norma ASTM D648 | 157 | ℃ | |||

| Temperatura de fusión | Norma ASTM D3418 | 340 | ℃ | ||||

| Temperatura de transición vítrea | Norma ASTM D3418 | 150 | ℃ | ||||

| CLE | Flow -50.0~50℃ | Norma ASTM E831 | 4.3E-5 | cm/cm/℃ | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Absorción de agua | 24 horas | Norma ASTM D570 | 0.50 | % | |||

| Densidad | Norma ASTM D792 | 1.30 | gramos/cm³ | ||||

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |||

| Constante dieléctrica | 1 kHz | Norma ASTM D150 | 3.10 | ||||

| Resistividad volumétrica | Norma ASTM D257 | 2.6E16 | Ω.cm | ||||

| Rigidez dieléctrica | 0.05mm | Norma ASTM D149 | 150 | kilovoltios/mm | |||

| Resistividad superficial | Norma ASTM D257 | 1.9E17 | Ω | ||||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Índice limitante de oxígeno | Norma ASTM D2863 | 37 | % | ||||

| Clasificación de llama | NC BK 0.75mm | UL94 | V-1 | ||||

| Clasificación de llama | NC BK 0.87mm | UL94 | V-1 | ||||

| Clasificación de llama | NC BK 1,5 mm | UL94 | V-0 | ||||

| Clasificación de llama | NC BK 3,0 mm | UL94 | V-0 | ||||

04 | Process Compatibility and Processing Suggestions

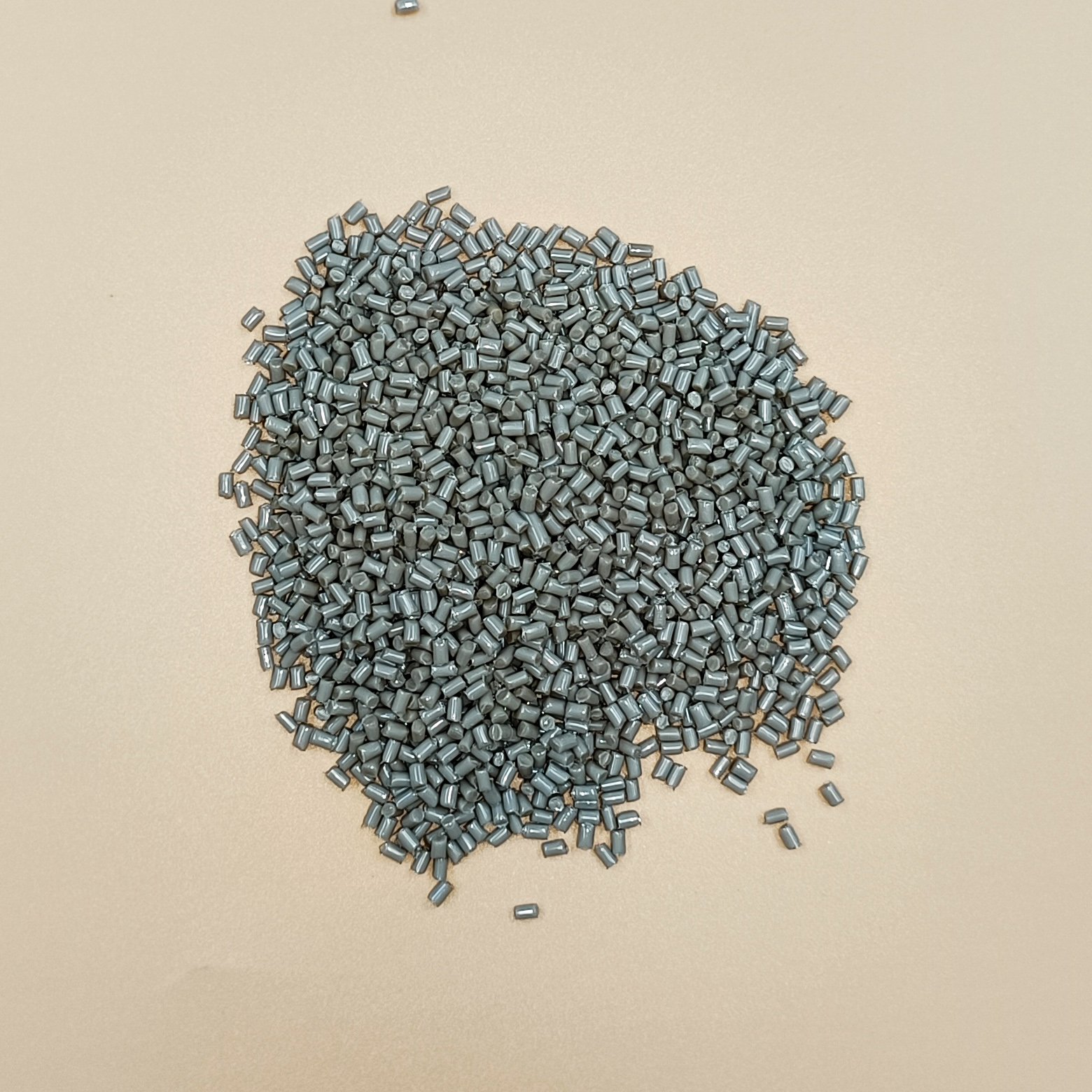

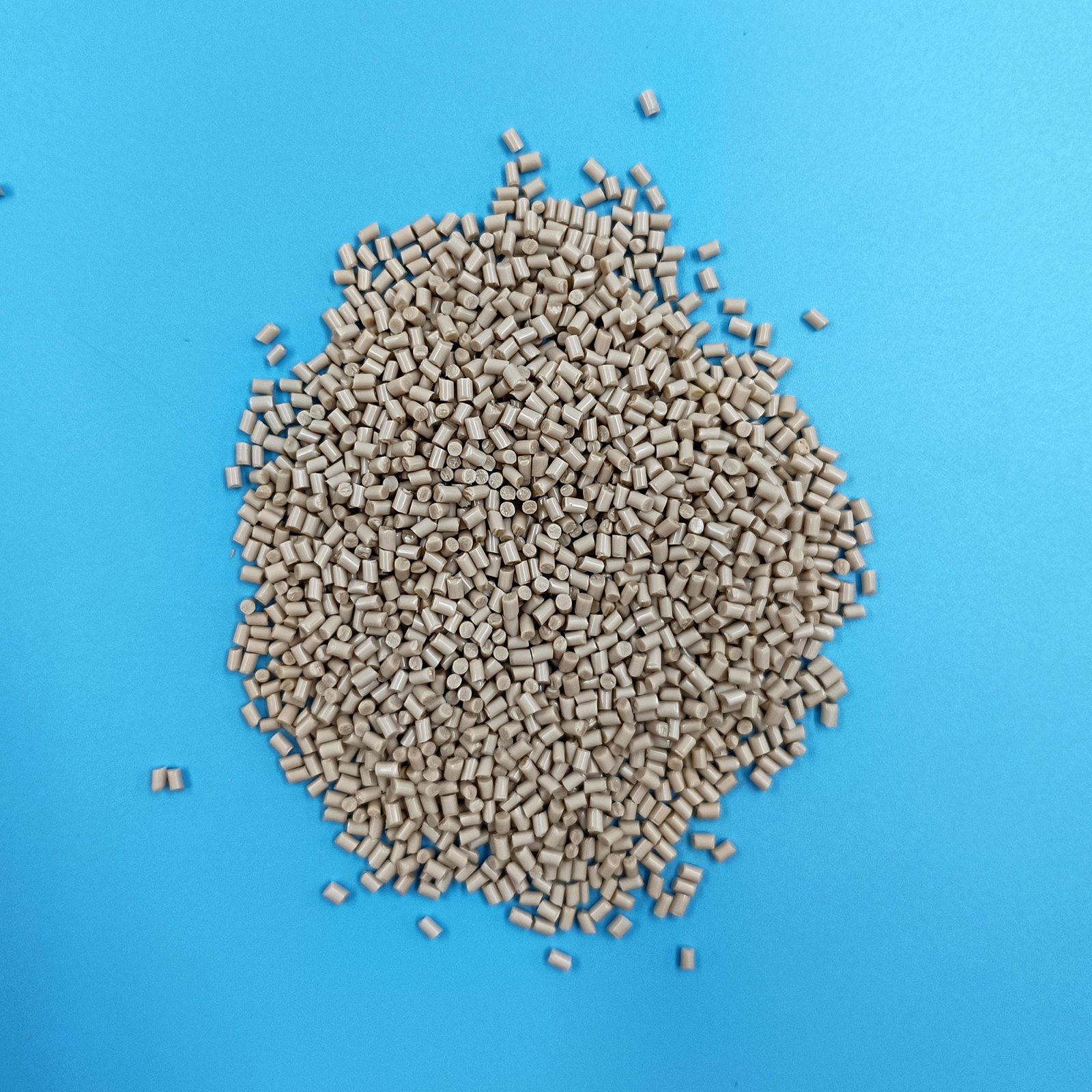

The particle form of Ketaspire™ KT 820 is convenient for a variety of thermal processing techniques:

・Injection molding: Suitable for batch manufacturing of high-precision components, the mold temperature needs to be controlled at approximately 180°C.

・Extrusion molding: It can be made into films, pipes and profiles. The melting temperature is approximately 340°C.

・Hot press forming: Suitable for the preparation of medical films or industrial separators.

Thanks to its excellent fluidity and thermal stability, the material maintains uniform molding at high shear rates, reducing problems such as bubbles, stress concentration and dimensional deviations in the workpiece.

05 | Industry Performance and Compliance Standards

・Passed UL94 V-0/V-1 flame retardant certification.

・Complies with UL 746B long-term thermal aging grade (RTI 260°C).

・The electrical, mechanical and thermal performance data all comply with the ASTM/IEC international standard test methods.

・Medical-grade specifications are available to meet the requirements of biocompatibility and multiple disinfection uses.

These characteristics enable it to demonstrate stable expected lifespan and reliability in highly demanding medical devices and industrial systems.

06 | Same Series Recommendations (Ketaspire™ KT 820 Family)

The Ketaspire™ KT 820 series includes a variety of formula models to meet different processing and performance requirements:

| Grade | Densidad | Resistencia a la tracción | Alargamiento | Mold Shrinkage | Módulo de tracción | HDT | Notched Izod Impact Strength | Módulo de flexión | Unnotched Izod Impact Strength | Resistencia a la flexión |

| KT-820 | 1.30 g/cm³ | 75.8 MPa | 6.8 % | 157 ℃ | ||||||

| KT-820 NT | 1.3 g/cm³ | 95 MPa | 25 % | 1.10~1.30 % | 3500 MPa | 157 ℃ | 91 J/m | 3700 MPa | 146 MPa | |

| KT-820 GF30 BK95 | 1.53 g/cm³ | 158 MPa | 2.7 % | 0.20~0.40 % | 10500 MPa | 315 ℃ | 110 J/m | 10300 MPa | 960 J/m | 261 MPa |

| KT-820 CF30 | 1.41 g/cm³ | 217 MPa | 2.0 % | 0.0~0.20 % | 19700 MPa | 315 ℃ | 69 J/m | 17500 MPa | 750 J/m | 317 MPa |

| KT-820 BK | 1.29 g/cm³ | 94.5 MPa | 5.2 % | 3500 MPa | 157 ℃ | 100 J/m | 3700 MPa | 145 MPa | ||

| KT-820UFP | 1.30 g/cm³ | 96.5 MPa | 5.2 % | 3650 MPa | 157 ℃ | 69 J/m | 3860 MPa | 152 MPa | ||

| KT-820 GF30 BG20 | 1.53 g/cm³ | 158 MPa | 2.7 % | 0.20~0.40 % | 10500 MPa | 315 ℃ | 110 J/m | 10300 MPa | 960 J/m | 261 MPa |

| KT-820SFP | 1.30 g/cm³ | 96.5 MPa | 5.2 % | 3650 MPa | 157 ℃ | 69 J/m | 3860 MPa | 152 MPa | ||

| KT-820 GF13 BG20 | 1.38 g/cm³ | 117 MPa | 3.9 % | 5900 MPa | 213 °C | 9.28 kJ/m² | 5600 MPa | 102.04 kJ/m² | 203 MPa | |

| KT-820 SL10 | 1.35 g/cm³ | 88.0 MPa | 5.2 % | 1.2~1.4 % | 3600 MPa | 155 ℃ | 170 J/m | 3500 MPa | 134 MPa | |

| KT-820 BK95 | 1.3 g/cm³ | 95 MPa | 25 % | 1.10~1.30 % | 3500 MPa | 157 ℃ | 91 J/m | 3700 MPa | 146 MPa | |

| KT-820 NL | 1.30 g/cm³ | 96.0 MPa | 5.2 % | 1.5 % | 3500 MPa | 157 ℃ | 91 J/m | 3700 MPa | 146 MPa | |

| KT-820 SL30 | 1.45 | 150 | 2.8 | 0.10~0.30 | 11000 | 291 | 69 | 10500 | 530 | 221 |

| KT-820 SL45 | 1.50 | 197 | 1.5 | 0.0~0.20 | 18300 | 299 | 69 | 16600 | 530 | 265 |

| KT-820FP | 1.30 g/cm³ | 96.5 MPa | 5.2 % | 3650 MPa | 162 ℃ | 69 J/m | 3860 MPa | 152 MPa | ||

| KT-820 GF15 NT | 1.40 g/cm³ | 124 MPa | 5.0 % | 6100 MPa | 218 °C | 9.0 kJ/m² | 74 kJ/m² | 205 MPa |

07 | Choose Juyuan as your PEEK supply partner

As an international plastic raw material trader with 24 years of experience, Juyuan offers original imported peek raw material and provides customers with:

✅ multiple brands of PEEK series (Solvay, Victrex, LATI, etc.) raw materials are in stock and available for custom purchase

✅ technical selection support and process optimization suggestions

✅ stabilize international supply chain and export packaging services

✅ quick-response pre-sale and after-sale team

Juyuan is committed to helping customers select the most suitable PEEK raw material under high temperature, high strength and medical safety requirements, in order to achieve better product reliability and cost efficiency.

【Recomendaciones relacionadas】

Foaming Molding Process & Common Defects Analysis | Plastic Resin Supply Más información>

LARPEEK 10K/40, 10G/30 Material Comparison & Processing Tips Más información>

LUVOCOM® Polyether Ether Ketone Compounds for Bearings & Gears Más información>