PRODUCTOS

RTP PSU EMI 961 Polysulfone Plastic for EMI & ESD Protection

Estructura del producto

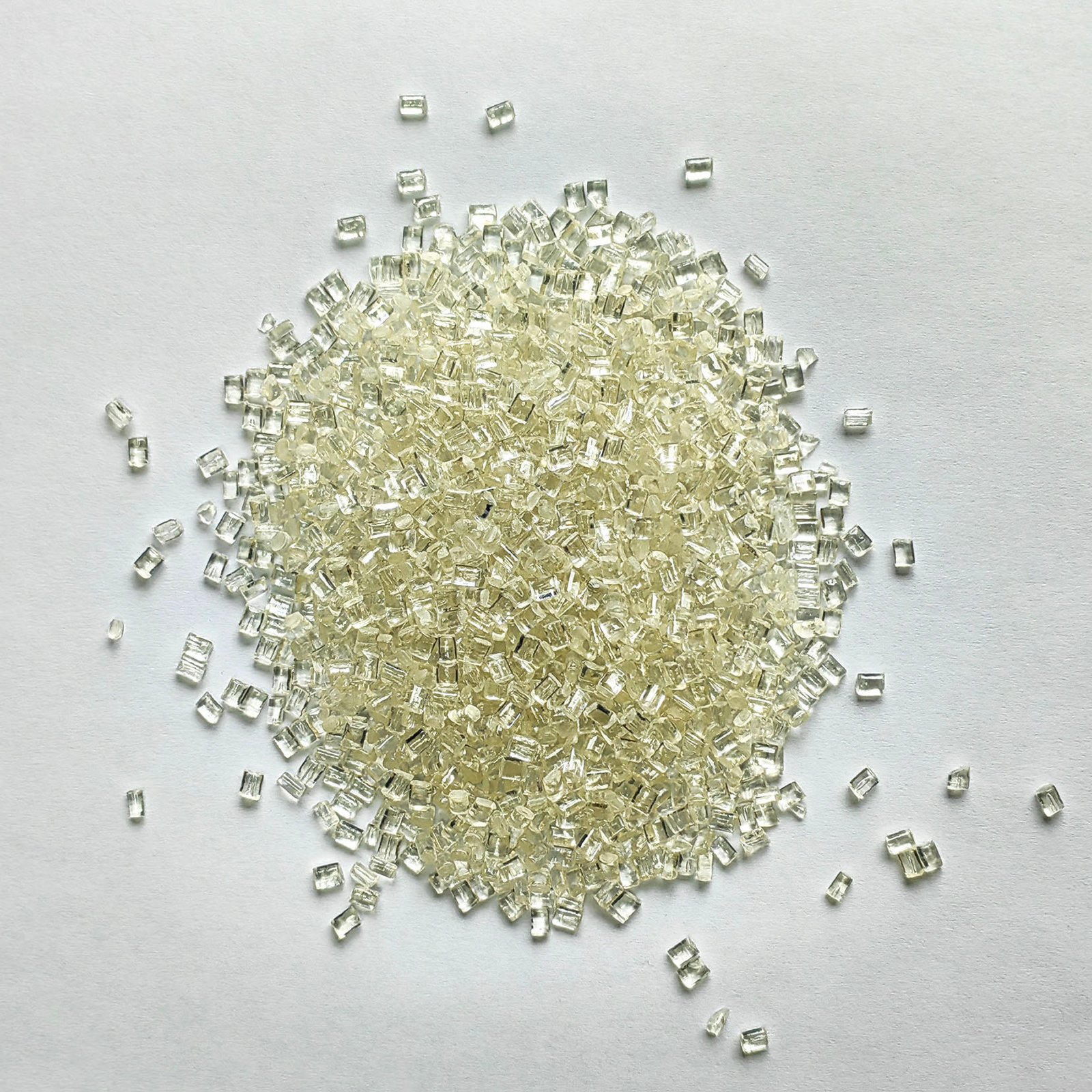

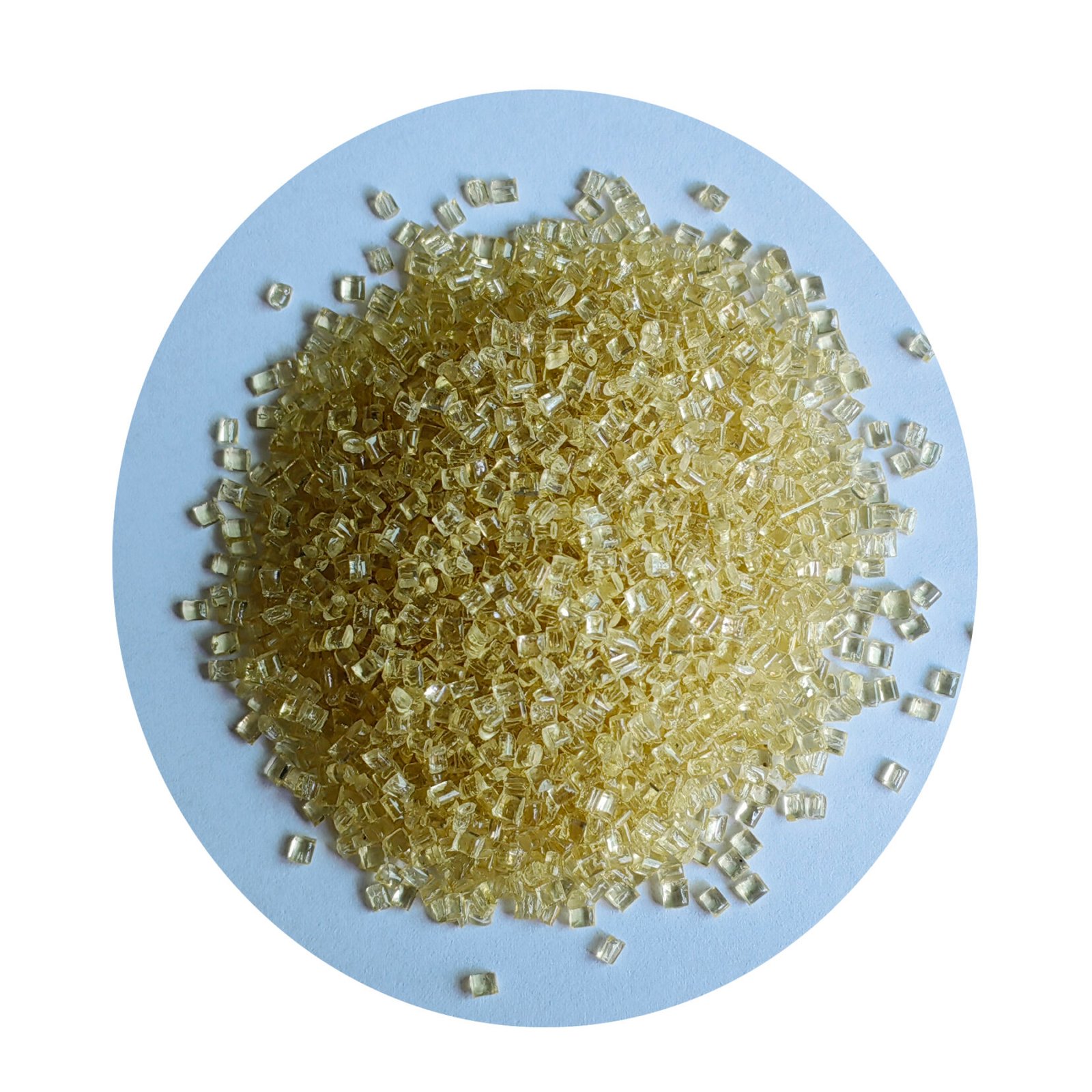

What is Polysulfone Materials

RTP Company PSU EMI 961 is a specialty engineering polysulfone plastic based on polysulfone (PSU) reinforced with 10% stainless steel fiber. Its design focuses on electromagnetic shielding, radio frequency shielding, and electrostatic protection, making it suitable for applications with stringent requirements for both electrical performance and mechanical strength. The material combines excellent mechanical properties with excellent electrical conductivity, providing stable structural support and electromagnetic safety for electronics, communications, and industrial equipment.

01 | Material Highlights and Procurement Value

Electromagnetic Shielding and Radio Frequency Protection

・Surface resistance: 10⁴–10⁵ Ω; volume resistance: approximately 10² Ω·cm.

・Effectively shields EMI/RFI interference, meeting the protection requirements of 5G, medical electronics, and industrial control applications.

Static Discharge and Safety Protection

・Passes ASTM D257 and ESD STM11.11 tests, enabling rapid static discharge.

・Effectively reduces the risk of failure in semiconductors and precision circuits during assembly and use.

Excellent mechanical and structural properties

・Tensile strength of 69 MPa and flexural modulus of 2620 MPa ensure the durability of housings and structural components.

・Impact strength (534 J/m without notches) meets structural stability requirements during transportation, assembly, and long-term use.

Processing and dimensional stability

・Suitable for injection moulding with a shrinkage rate of only 0.50–0.70%.

・Suitable for mass production of high-precision components, reducing moulding defects and rework costs.

Balanced functional and structural performance

・Combining the heat and chemical resistance of a PSU with the conductive and shielding properties of metal fibers.

・A single material meets both electrical functional and structural requirements, reducing the need for multiple materials.

02 | PSU EMI 961 polysulfone plastic Data Sheet

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Norma ASTM D638 | 10.0 | % | ||||

| Resistencia a la flexión | Norma ASTM D790 | 97 | MPa | ||||

| Módulo de flexión | Norma ASTM D790 | 2620 | MPa | ||||

| Impacto sin muescas Izod | 3.20mm | ASTM D4812 | 534 | j/m | |||

| Impacto de muesca Izod | 3.20mm | Norma ASTM D256 | 53 | j/m | |||

| Resistencia a la tracción | Norma ASTM D638 | 69 | MPa | ||||

| Módulo de tracción | Norma ASTM D638 | 2758 | MPa | ||||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Contracción | 3.20mm | Norma ASTM D955 | 0.50~0.70 | % | |||

| Densidad | Norma ASTM D792 | 1.35 | gramos/cm³ | ||||

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |||

| Resistividad volumétrica | Norma ASTM D257 | 1E2 | Ω.cm | ||||

| Resistividad superficial | Norma ASTM D257 | 1E5 | Ω | ||||

| Resistividad superficial | ESD STM11.11 | 1E4 | Ω | ||||

03 | Recommended Applicable Industries and Applications

・Electronic and Electronics: Electromagnetic shielding enclosures, module housings, connectors

・Communications: 5G base station components, RF module housings

・Medical instruments: Protective housings for electrostatically sensitive devices

・Industrial equipment: Electrical control boxes, sensor packaging

Buyers in these applications often face issues such as signal interference, electrostatic damage, and insufficient structural strength. PSU EMI 961 was designed to address these pain points.

04 | Technical Process and Application Analysis

・Fiber Dispersion Process: Uniformly dispersing stainless steel fibers within the PSU matrix creates a stable conductive path, ensuring shielding performance persists over time.

・Injection Moulding Key Points: Moulding temperature and pressure must be controlled to ensure proper fibre orientation, maximising electromagnetic shielding effectiveness.

・Secondary Processing Adaptability: Machining, plating, or bonding can be performed to meet diverse product aesthetic and functional requirements.

The material's process advantages make it suitable not only for traditional electronic enclosures but also for complex geometries, lightweight modules, and precision components.

05 | Industry Trends and Application News

5G and Communications Equipment: With the increasing demand for electromagnetic shielding in 5G base stations and antenna systems, conductive plastics such as PSU EMI 961 and other polysulfone plastics are gradually replacing some metal housings to reduce weight and lower processing costs.

Medical Devices: European and American markets have stricter requirements for electromagnetic interference safety in high-end equipment such as MRI and CT scans, making PSU EMI 961 a potential material choice for housings and module packaging.

Semiconductor Manufacturing: ESD/EMI-grade polysulfone plastics are being adopted for safe workbenches and component carriers, reducing electrostatic breakdown and yield loss.

06 | Customer Applications and Feedback

Electronic component manufacturers: After adopting PSU EMI 961 as the RF module housing, the product passed electromagnetic compatibility testing on the first attempt, reducing the cost of additional shielding layers.

Medical device suppliers: Feedback indicates that the material maintains stable conductivity during long-term operation, avoiding signal drift and static electricity failures, thereby enhancing device reliability.

Industrial control system manufacturers: By selecting PSU EMI 961 as an alternative to metal materials, weight was reduced by 20%, and assembly efficiency was improved.

07 | FAQ - Common Questions from Purchasers

Q1: Does the conductivity of PSU EMI 961 decrease over time?

A: Stainless steel fibres are uniformly dispersed and tightly bonded to the matrix, ensuring stable performance over the long term.

Q2: What are its advantages over metal housings?

A: Lighter weight, more flexible processing, and higher molding precision, while maintaining electromagnetic shielding performance.

Q3: Can it replace other ESD/EMI materials?

A: Comparisons can be made based on resistance range and mechanical requirements, such as ESD C 980, EMI 962, ESD A 901, and ESD C 901. We can provide specific parameter comparisons and alternative solutions.

Q4: What are the procurement cycles and supply stability?

A: Juyuan maintains long-term partnerships with international channels and can arrange spot or bulk orders based on customer needs. We also provide logistics and customs clearance support.

08 | Recommended Materials for the Same Application

| Fabricante | Modelo de producto | Descripción | Densidad | Resistencia a la tracción | Alargamiento | Contracción | Módulo de tracción | Notched Izod Impact | Módulo de flexión | Unnotched Izod Impact | Resistencia a la flexión |

| Americhem | ESD C 901 | Material Feature: Electrostatic Protection | 1.37 g/cm³ | 76 MPa | 1.5~3.0 % | 0.40~0.50 % | 5171 MPa | 43 J/m | 4826 MPa | 267 J/m | 121 MPa |

| Americhem | ESD A 901 | Material Feature: Electrostatic Protection • Static Dissipation | 1.34 g/cm³ | 69 MPa | 2.0~4.0 % | 0.40~0.50 % | 4826 MPa | 27 J/m | 4137 MPa | 374 J/m | 110 MPa |

| Americhem | EMI 962 | Material Feature: Electrostatic Protection • Electromagnetic Shielding • RF Shielding | 1.38 g/cm³ | 69 MPa | 10.00% | 0.50~0.70 % | 2758 MPa | 53 J/m | 2620 MPa | 427 J/m | 97 MPa |

| Americhem | ESD C 980 | Material Feature: Electrostatic Protection | 1.28 g/cm³ | 121 MPa | 2.50% | 0.05~0.15 % | 7584 MPa | 64 J/m | 7584 MPa | 481 J/m | 197 MPa |

| Americhem | EMI 960.5 | Material Feature: Electrostatic Protection • Electromagnetic Shielding • RF Shielding | 1.29 g/cm³ | 69 MPa | 10.00% | 0.50~0.70 % | 2758 MPa | 53 J/m | 2620 MPa | 534 J/m | 97 MPa |

09 | Why choose Juyuan as your supplier?

・With 24 years of international trade experience, we are familiar with the certification and customs clearance requirements of various countries.

・Multi-channel supply guarantees reduce procurement risks and ensure stable delivery.

・Professional technical support provides material performance analysis, alternative material recommendations, and processing guidance.

・Long-term partnerships assist buyers with cost optimization and market trend analysis.

【Recomendaciones relacionadas】

Sultron™ PSU: High-Temperature Polysulfone Material for Engineering Applications Más información>

Enviroplas ENV48-NC570 | Oil Resistance PSU Plastic for Medical Más información>

PSU G1000 Unfilled Flame-Retardant Injection Molding PSU Material Más información>