PRODUCTOS

Radel® R-5600 NT: Transparent Flame-Retardant PPSU Plastic

Estructura del producto

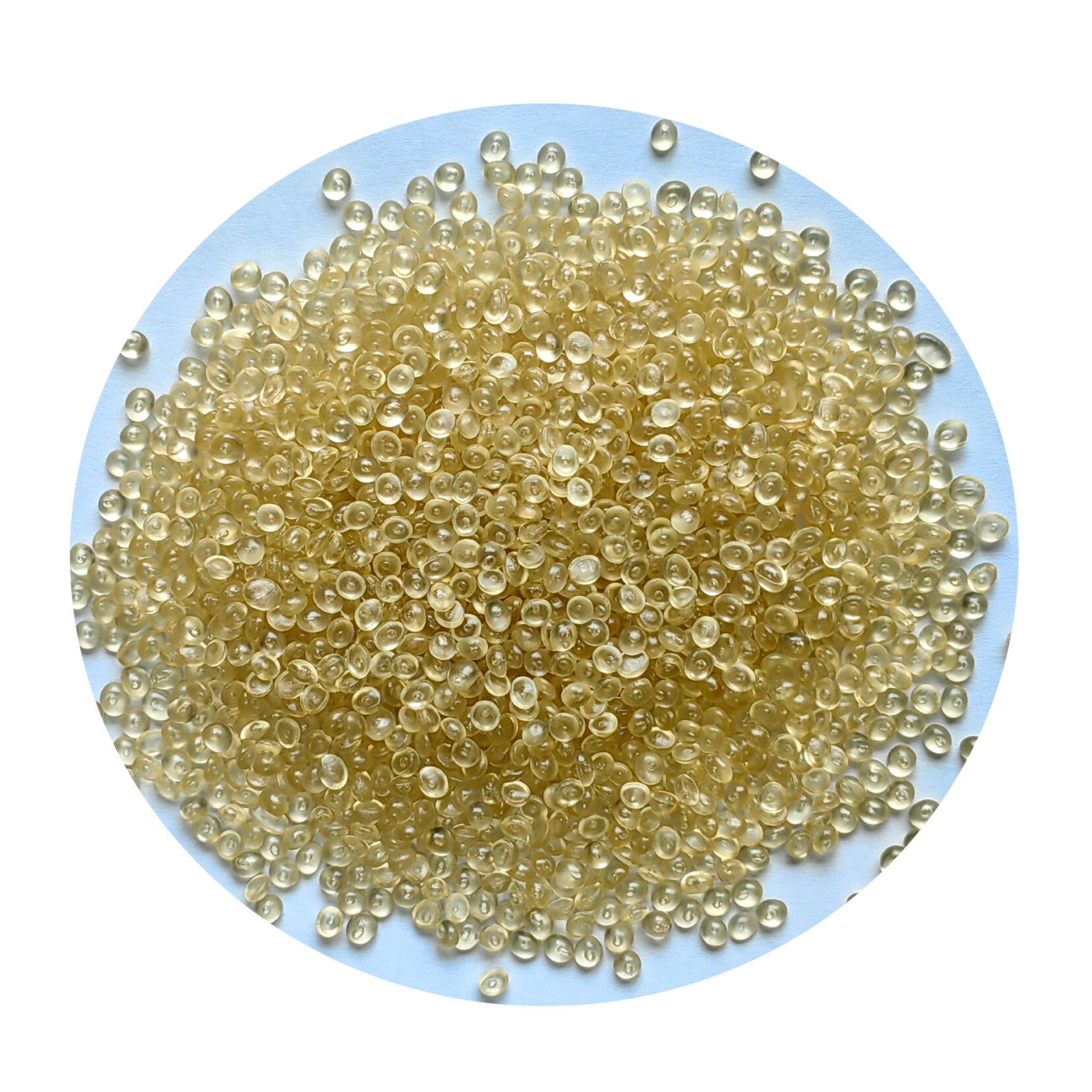

What is Radel® R-5600 NT

In high-standard industries such as aerospace, food service and medical applications, the reliability, safety and performance of materials often determine whether a product can win market recognition. As a high-performance polysulfone (PPSU) material developed by Solvay, Radel® R-5600 NT, with its outstanding transparency, thermal stability and chemical resistance, has become an ideal solution for many harsh environments.

01 | Material Highlights and Core Characteristics

Excelente resistencia al fuego: The material itself meets the UL94 V-0 flame retardant grade, ensuring safety without the need for additional additives.

High-temperature resistance and steam sterilization: Even in an environment of repeated high-temperature steam sterilization, it can still maintain its strength and transparency.

Outstanding chemical and alkali resistance: Compared with traditional transparent plastics such as PC and PEI, Radel® R-5600 NT has more advantages in acidic, alkaline and chemical contact environments.

Stress crack resistance: It can maintain long-term structural stability even under continuous stress or complex mechanical loads.

Optical transparency: Available in clear transparent or amber color options, it not only meets functional requirements but also takes into account design aesthetics.

02 | Campos de aplicación típicos

Food service industry: Suitable for high-end catering utensils and drinking water system components that can be repeatedly disinfected.

Aerospace Industry: Due to its lightweight, high heat resistance, and flame retardant properties, it is widely used in aircraft interior components.

Medical and laboratory: It performs outstandingly in situations that require repeated high-temperature sterilization, such as medical containers, transparent casings, and laboratory equipment.

Electronic and electrical: Thanks to its excellent electrical insulation and long-term heat resistance index (RTI), it also has application value in the protection of some electronic components.

03 | Advantages in Process and Technology Processing

The Radel® R-5600 NT is made by injection molding and has the following advantages:

・High fluidity, supporting complex structure design and thin-wall forming;

・It can be processed on standard injection molding equipment without any additional modification.

・It has excellent transparency after processing and can be directly used for appearance parts.

・Compatible with various dyeing processes, colors can be customized according to customer requirements.

04 | Radel® R-5600 NT Data Sheet

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |||

| Dieléctrico | Fuerza 0,025 mm | Norma ASTM D149 | 200 | kilovoltios/mm | |||

| Dieléctrico | Fuerza 3,2 mm | Norma ASTM D149 | 15 | kilovoltios/mm | |||

| Dieléctrico | Constante 60 Hz 3,2 mm | Norma ASTM D150 | 3.44 | ||||

| Volumen | Resistividad 3,2 mm | Norma ASTM D257 | 9E+15 | Ω.cm | |||

| Moldeo por extrusión | Condición | Estándar | Valor | Unidad | |||

| Seco | Temperatura | 171 | °C | ||||

| Seco | Tiempo | 4.0 | hora | ||||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Fuego | Clasificación NC BK 0,25 mm | UL94 | V-0 | ||||

| Fuego | Clasificación NC BK 0,40 mm | UL94 | V-0 | ||||

| Fuego | Clasificación de todos los colores 0,75 mm | UL94 | V-0 | ||||

| Fuego | Clasificación Todos los colores 1,5 mm | UL94 | V-0 | ||||

| Fuego | Clasificación Todos los colores 3,0 mm | UL94 | V-0 | ||||

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Rendimiento 3,2 mm | Norma ASTM D638 | 7.2 | % | |||

| Alargamiento | Romper 3,2 mm | Norma ASTM D638 | 60~120 | % | |||

| Flexión | Fuerza 5.0%Stren 3.2mm | Norma ASTM D790 | 91.0 | MPa | |||

| Flexión | Módulo 3,2 mm | Norma ASTM D790 | 2340 | MPa | |||

| Izod | Impacto de muesca 3,2 mm | Norma ASTM D256 | 690 | j/m | |||

| De tensión | Módulo 3,2 mm | Norma ASTM D638 | 2340 | MPa | |||

| De tensión | Fuerza 3,2 mm | Norma ASTM D638 | 70.3 | MPa | |||

| De tensión | Resistencia al impacto 3,2 mm | Norma ASTM D1822 | 399 | kJ/m² | |||

| Rendimiento óptico | Condición | Estándar | Valor | Unidad | |||

| Refractivo | Índice | Norma ASTM D542 | 1.672 | ||||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Densidad | Norma ASTM D792 | 1.29 | gramos/cm³ | ||||

| Derretir | Índice 365°C 5kg | Norma ASTM D1238 | 34~40 | g/10min | |||

| Contracción | Flujo 3,2 mm | Norma ASTM D955 | 0.70 | % | |||

| Agua | Absorción 24h | Norma ASTM D570 | 0.37 | % | |||

| Agua | Equilibrio de absorción | Norma ASTM D570 | 1.1 | % | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| CLE | Flujo 3,2 mm | Norma ASTM D696 | 5.6E-5 | cm/cm/°C | |||

| Vaso | Temperatura de transición DSC 20°C/min | MÉTODO INTERNO | 220 | °C | |||

| HDT | Sin recocer 1.8MPa 3.2mm | Norma ASTM D648 | 207 | °C | |||

| UL | Condición | Estándar | Valor | Unidad | |||

| Arco | Resistencia | ASTM D495 | 5 | SOCIEDAD ANÓNIMA | |||

| Pelota | Presión | IEC 60695-10-2 | 125 | °C | |||

| Comparativo | Índice de seguimiento | IEC 60112 | 5 | SOCIEDAD ANÓNIMA | |||

| Dieléctrico | Fortaleza | Norma ASTM D149 | 36 | kilovoltios/mm | |||

| GWFI | 1,5 mm | IEC 60695-2-12 | 960 | °C | |||

| Hola | TODOS 3,0 mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| Alta Velocidad | UL 746A | 0 | SOCIEDAD ANÓNIMA | ||||

| HWI | NC-BK 0,25 mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| RTI | Tira TODOS 3,0 mm | UL 746B | 180 | °C | |||

| UL | Clasificación de llama NC BK 0,25 mm | UL94 | V-0 | ||||

| UL | Clasificación de llama NC BK 0,40 mm | UL94 | V-0 | ||||

| Volumen | Resistividad | Norma ASTM D257 | 1E+19 | Ω.cm | |||

Technical Data Overview of Radel® R-5600 NT

05 | Innovation and Industry Competitive Advantage

Replace traditional materials: Compared with PC and PEI, it has higher chemical resistance and long-term stability, and a longer service life.

Environmental protection and compliance: Certified as food contact grade, meeting the strict requirements of the international market for safety and sustainability.

High-end application endorsement: Solvay, as a globally leading supplier of high-performance materials, has achieved extensive success in its PPSU series in fields such as aviation, medical care, and food.

06 | Customer Feedback

Summary of feedback from some customers

・"In the application of aviation seat components, Radel® R-5600 NT significantly reduces maintenance frequency."

・" The catering equipment supply chain has significantly reduced replacement costs due to its advantage of being able to withstand repeated high-temperature cleaning."

・" The balance between transparency and flame retardancy is outstanding, providing a dual guarantee for design and safety."

07 | Frequently Asked Questions (FAQ)

Q1: What common transparent plastics can Radel® R-5600 NT replace?

A1: Common PC and PEI are inferior to PPSU in terms of chemical resistance and steam sterilization stability. Therefore, in situations where long-term durability is required, R-5600NT is a better choice.

Q2: Is it suitable for direct contact with food?

A2: Yes, the material meets the food contact grade standards and can be used in drinking water systems, catering containers, etc.

Q3: How can advantages be demonstrated in aviation applications?

A3: It is lightweight, has excellent flame retardant performance and strong durability, fully meeting the dual requirements of safety and lightweight in the aviation industry.

08 | Recommendations for Similar Products

In addition to Radel® R-5600 NT, the following PPSU materials are also worth paying attention to:

・ACUDEL® 79000: Modified PPSU, featuring excellent resistance to cleaning agents and chemicals, suitable for aviation and food contact parts.

・TegraCore™ R-1050 PPSU: Radel® PPSU foamed structural material, lightweight and flame-retardant, widely used in aircraft interiors and structural components.

・PPSU HTS-2400: High-temperature grade PPSU, with outstanding heat resistance and hydrolytic stability, is suitable for long-term application in harsh environments.

・RADEL® RMR7: Solvay's high-end PPSU series, which combines flame retardancy, steam sterilization resistance and mechanical strength, is suitable for medical and aerospace fields.

09 | Our Advantages as an Export Supplier

Channel advantages: Cooperating with leading global brands, stable supply of goods, and guaranteed supply of genuine products.

Technical support: We can provide material selection, processing technology suggestions and application solutions.

Customized service: We can recommend the most suitable PPSU or alternative materials based on the industry requirements of the customers.

International Experience: Rich experience in export operations and customs clearance helps customers quickly enter the target market.

【Recomendaciones relacionadas】

Injection Molding Defects & Solutions | Plastic Material Supply Más información>

DURADEX® D-3000 Series PPSU Material Grades Overview Más información>

RADEL® R-5800 PPSU: Transparent Heat-Resistant Materials Más información>