PRODUCTOS

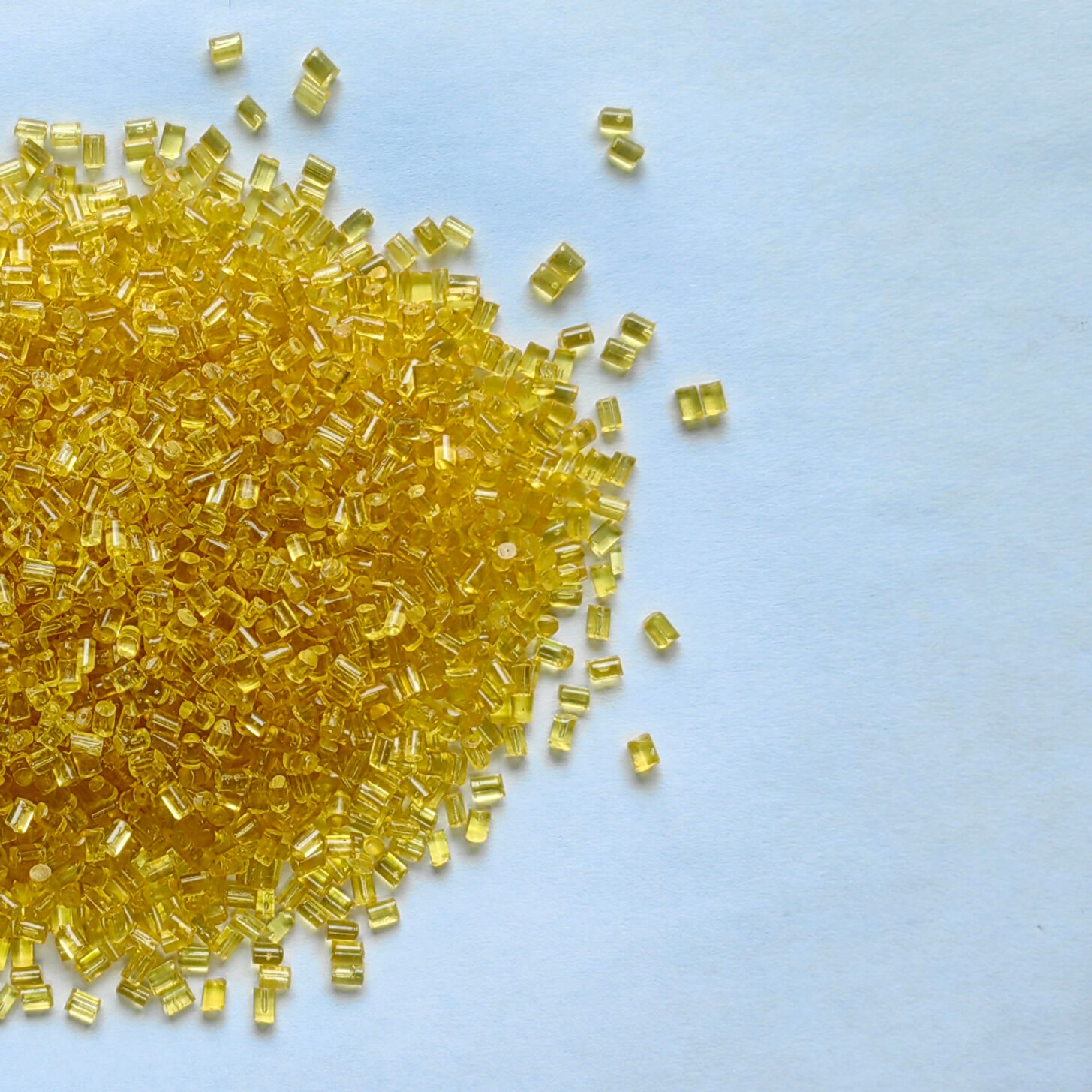

QUADRANT® PSU unfilled | Heat Resistant PSU Polysulfone

Estructura del producto

What is Udel® GF-120 NT

QUADRANT® PSU unfilled is an unfilled polysulfone (psu) material, renowned for its excellent mechanical, electrical and thermal properties. As an amorphous engineering plastic, it offers excellent dimensional accuracy and service life while maintaining transparency and stability, making it an ideal alternative to PC.

01 | Material Highlights and Characteristics

Stable mechanical properties: Tensile strength reaches 88 MPa, bending strength is 120 MPa, and it combines rigidity and toughness.

Outstanding thermal performance: The heat distortion temperature can reach up to 170℃, and the glass transition temperature is 190℃, allowing for long-term use in high-temperature environments.

Chemical resistance and dimensional stability: Linear expansion coefficient 5.5E-5 cm/cm/℃, with a relatively low water absorption rate (0.3%), ensuring a stable structure.

Electrical insulation performance: Dielectric constant of 3, insulation strength of 30 KV/mm, volume resistance up to 1E14 Ω·cm, suitable for electrical and electronic component applications.

Flame retardancy and safety: Oxygen index 30%, meeting UL94 HB fire resistance rating, reliable safety in general electronic and industrial environments.

Autoclaving compatibility: Capable of withstanding steam and autoclaving, maintaining stable performance.

02 | QUADRANT® PSU unfilled Data Sheet

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Rendimiento 23°C | ISO 527 | 5 | % | |||

| Alargamiento | 23℃ | ISO 527 | 10 | % | |||

| Resistencia a la compresión | ISO 604 | 25 | MPa | ||||

| Resistencia a la compresión | ISO 604 | 49 | MPa | ||||

| Resistencia a la compresión | ISO 604 | 101 | MPa | ||||

| Resistencia a la flexión | 23℃ | Norma ASTM D790 | 120 | MPa | |||

| Resistencia a la tracción | Rendimiento 23°C | ISO 527 | 88 | MPa | |||

| Módulo de tracción | 23℃ | ISO 527 | 2850 | MPa | |||

| Coeficiente de fricción | Dinámica | 0.55 | |||||

| Impacto Charpy sin muesca | 23℃ | ISO 179 | NÓTESE BIEN | kJ/m² | |||

| Impacto con entalla Charpy | ISO 179 | 3.5 | kJ/m² | ||||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| Coeficiente de conductividad térmica | DIN 52612 | 0.26 | W/(m·K) | ||||

| HDT | Sin recocer 1,80 MPa | Norma ASTM D648 | 170 | ℃ | |||

| Temperatura de transición vítrea | ISO 11357 | 190 | ℃ | ||||

| CLE | Fluir | ISO 11359 | 5.5E-5 | cm/cm/℃ | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Absorción de agua | 23℃ 50RH | 0.3 | % | ||||

| Absorción de agua | Saturación | 0.8 | % | ||||

| Densidad | ISO 1183 | 1.24 | gramos/cm³ | ||||

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |||

| CTI | IEC 60112 | 150 | V | ||||

| Constante dieléctrica | IEC 60250 | 3 | |||||

| Resistividad volumétrica | CEI 60093 | 1E14 | Ω.cm | ||||

| Rigidez dieléctrica | CEI 60243 | 30 | kilovoltios/mm | ||||

| Factor de disipación | IEC 60250 | 0.001 | |||||

| Resistividad superficial | CEI 60093 | 1E13 | Ω | ||||

| Dureza | Condición | Estándar | Valor | Unidad | |||

| Dureza Rockwell | M(Escala) | ISO 2039 | 89 | ||||

| Dureza de indentación de bola | ISO 2039 | 115 | MPa | ||||

| Dureza Shore D | 80 | ||||||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Índice limitante de oxígeno | ISO 4589 | 30 | % | ||||

| Clasificación de llama | UL94 | media pensión | |||||

03 | Typical Application Fields

Medical Care and Laboratory

・Applications that can replace PCS, such as medical care devices, surgical auxiliary components, and laboratory containers.

・Supports autoclaving to meet the hygiene and durability requirements of medical scenarios.

Electronics and Electrical Engineering

・It is applied to insulating parts, coil bobbins, electrical enclosures, etc.

・It has excellent electrical performance, with a low dielectric constant and high insulation strength.

Componentes industriales

・Used in valves, pump components and fluid conveying systems.

・It still maintains mechanical strength and stability in high-temperature and corrosive environments.

The field of contact between household appliances and food

・Due to its high-temperature resistance and excellent mechanical properties, it can be applied to kitchen appliance components and food containers.

04 | Flexibility in processing and design

QUADRANT® PSU unfilled is suitable for injection molding processes and can produce complex and precise components. Its non-filled structure ensures good transparency and uniformity, and is widely used in structural components, appearance components and functional parts.

05 | Industry Trends and Values

Replacing traditional materials: Compared with PC and metal, psu polysulfone is more heat-resistant and lighter, meeting the modern lightweight design requirements.

Compliance and environmental protection: With the tightening of standards in the medical, food contact and electrical industries, materials that comply with RoHS and flame retardant regulations are increasingly favored.

Long service life and sustainability: It features creep resistance and low water absorption, which can extend the product's service life and reduce replacement and maintenance costs.

06 | Similar recommendations

| Fabricante | Modelo de producto | Peso específico | Resistencia a la tracción | Alargamiento | Módulo de tracción | Heat Distortion Temp | Dureza Rockwell | Izod Impact (Notched) | Módulo de flexión | CTE (cm/cm/℃) | Resistencia a la flexión |

| QUADRANT | LSG PSU | 1.24 g/cm³ | 88 MPa | 10% | 2850 MPa | 170 ℃ | 89 | — | — | 5.5E-5 cm/cm/℃ | 120 MPa |

| QUADRANT | LSG | — | — | — | — | — | — | — | — | — | — |

| Westlake | Unfilled (THERMALUX) | 1.24 g/cm³ | 70.3 MPa | 5.50% | 2480 MPa | 181 ℃ | 69 | 69 J/m | 2690 MPa | 5.6E-5 cm/cm/℃ | 106 MPa |

| Westlake | Film (THERMALUX) | 1.24 g/cm³ | 73.1 MPa | 110% | 2480 MPa | 174 ℃ | — | — | 2690 MPa | — | — |

| SHINIL | PSU-CNT | 1.38 g/cm³ | 96.1 MPa | — | — | 185 ℃ | — | 58.8 J/m | 11201 MPa | — | 156.96 MPa |

07 | FAQ Frequently Asked Questions

Q1: Is QUADRANT® PSU unfilled suitable for long-term high-temperature use?

Yes, its heat distortion temperature can reach 170℃, maintaining good performance in high-temperature environments.

Q2: What are the advantages compared with PC?

A2: psu polysulfone is more resistant to high temperatures and hydrolysis, and performs better in terms of electrical properties and chemical stability.

Q3: Can it be applied to electrical insulation components?

A3: Perfectly suitable. It has a low dielectric constant and a high volume resistance, meeting the insulation requirements.

08 | Why Choose Juyuan?

As an international plastic raw material supplier with 24 years of experience, Juyuan offers customers:

Multi-channel supply guarantee: Long-term stable supply of QUADRANT® PSU unfilled and other engineering plastic pellets.

Professional material selection support: Recommend suitable grades based on application requirements to reduce procurement trial-and-error costs.

Global delivery capability: Flexible response, covering multiple markets.

Value-added services: Provide industry cases and market trend references to assist customers in optimizing material selection and application design.

Choosing Juyuan is not only about purchasing psu polysulfone raw materials, but also about obtaining a reliable partner.

【Recomendaciones relacionadas】

ColorRx® PSU-1000RX | Medical-Grade PSU Material for Biocompatibility Más información>

Udel® GF-120 NT Glass-Fiber Reinforced Polysulfone for Medical Más información>

5G Telecommunication Plastics Selection and Procurement Guide | Juyuan Más información>