PRODUCTOS

QUADRANT PPSU Series: Heat Resistance, Chemical Durability

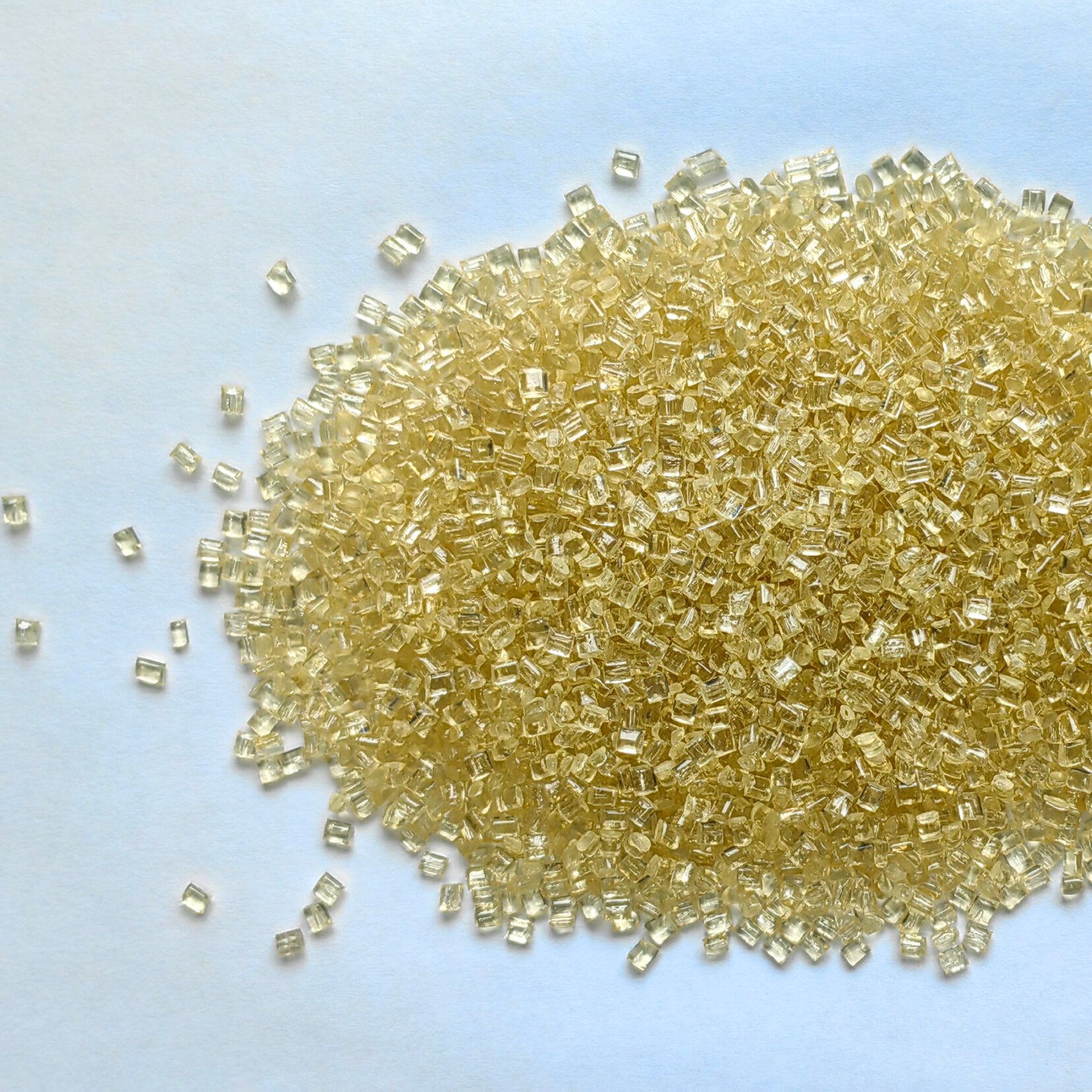

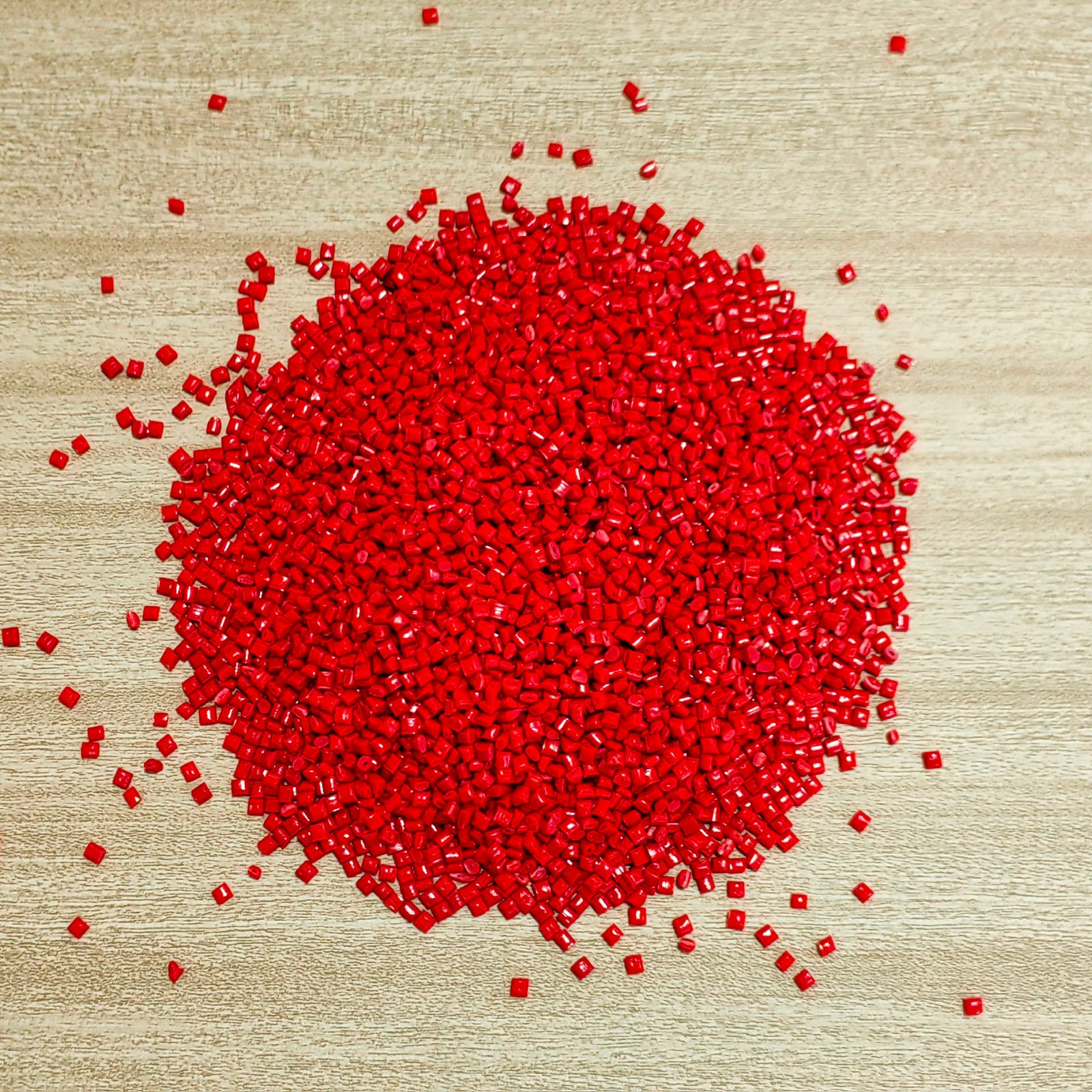

Estructura del producto

What is QUADRANT PPSU

In the medical, aerospace, electronic and electrical, and high-end industrial fields, PPSU (polyphenylsulfone) is widely adopted due to its outstanding high-temperature resistance, flame retardancy and mechanical properties. As a globally renowned manufacturer of engineering plastics, QUADRANT offers a variety of PPSU product models to meet the performance and application requirements of different customers. This article will not only compare three representative models - PPSU Unfilled Extruded, LSG PPSU, and PPSU LSG, but also make a horizontal comparison with other common high-performance plastics to help purchasers quickly find the most suitable material solution.

01 | A comprehensive comparison of Kuajun PPSU products

| Modelo de producto | Clasificación de llama | Mechanical Strength | Thermal Performance | Electrical Properties | Best-Suited Applications | Recommendation |

| PPSU Unfilled Extruded | V-0 ⭐⭐⭐⭐ | High tensile strength (83 MPa), flexural strength (108 MPa), excellent impact resistance (NB) | Tg 220℃, HDT 205℃ ⭐⭐⭐⭐ | Dielectric strength 26 KV/mm | Medical, electronics, impact-resistant parts | ★★★★★ |

| LSG PPSU | N/A | Limited data, stable friction coefficient (0.45) | — | — | Friction-related components, sliding parts | ★★☆☆☆ |

| PPSU LSG | V-2 ⭐⭐⭐ | Flexural strength (107 MPa), shear strength (62.1 MPa), high impact resistance (133 J/m) | Tg 220℃, Tm 260℃, HDT 207℃ | Dielectric strength 14.2 KV/mm | Medical devices, structural parts, lightweight applications | ★★★★☆ |

👉 At a glance:

✔ Pursuing the highest level of flame retardancy and strength → PPSU Unfilled Extruded

✔ Focus on friction performance and low parameter requirements → LSG PPSU

✔ It is necessary to balance strength and thermal performance, but the cost is more flexible → PPSU LSG

02 | Product Features Analysis

PPSU Unfilled Extruded

・Highlights: High flame retardancy (V-0), high temperature resistance (220°C), excellent electrical insulation (26 kV/mm)

・Mechanical Properties: Tensile strength 83 MPa, flexural strength 108 MPa, nearly indestructible unnotched impact strength

・Recommended Applications: High-end medical device housings, aerospace connectors, impact-resistant electrical components

LSG PPSU

・Highlight: Stable coefficient of friction (0.45)

・Recommended applications: Applications requiring friction resistance or surface motion, such as sliding mechanisms and lightly loaded structural parts

・Suitable customers: Industries with low requirements for flame retardancy or complete performance

PPSU LSG

・Highlight: High mechanical strength (tensile strength 75.8 MPa, flexural strength 107 MPa), excellent impact resistance (133 J/m)

・Thermal properties: Glass transition temperature 220°C, melting temperature 260°C, heat deflection temperature 207°C

・Recommended applications: Medical device components, structural parts requiring lightweighting while maintaining strength

03 | Comparison of PPSU with other high-performance plastics

| Material | Thermal Resistance | Clasificación de llama | Mechanical Properties | Chemical Resistance | Cost | Aplicaciones típicas |

| PPSU (QUADRANT series) | Tg 220℃, Tm 260℃ ⭐⭐⭐⭐ | V-0 / V-2 | High strength & toughness ⭐⭐⭐⭐ | Excellent (resists strong acids/alkalis, repeated sterilization) | ★★★ | Medical, aerospace, electrical insulation |

| Fuente de alimentación | ~190℃ Tg ⭐⭐ | HB–V-2 | Moderate strength | Promedio | ★★ | Electrical parts, food-contact items |

| PEI (Ultem) | 215℃ Tg ⭐⭐⭐ | V-0 | High strength, high rigidity | Good but slightly lower than PPSU | ★★★ | Aerospace, automotive, electronics |

| PEEK | Tg 143℃, Tm 343℃ ⭐⭐⭐⭐⭐ | V-0 | Exceptional strength & rigidity | Outstanding | ★★★★★ | Aerospace, oil & gas, medical implants |

Comparative conclusion

・Compared with PSU: Kuajun PPSU has stronger heat resistance and flame retardancy, and better impact strength.

・Compared with PEI: PPSU performs better in terms of chemical resistance and toughness, making it particularly suitable for medical disinfection environments.

・Compared with PEEK: PEEK has top-notch performance but is expensive. Kuajun PPSU offers comparable heat resistance and flame retardancy, making it a cost-effective alternative.

04 | Application industry scenarios

Medical industry: Surgical instrument handles, sterilized resistant components (recommended: PPSU Unfilled Extruded, PPSU LSG)

Aerospace: Lightweight connectors, flame-retardant and impact-resistant components (Recommended: PPSU Unfilled Extruded)

Electronic and electrical: Insulating parts, precision components for high-temperature environments (recommended: PPSU Unfilled Extruded, PPSU LSG)

Industrial equipment: Friction components, sliding mechanisms (Recommended: LSG PPSU)

05 | FAQ

Q1: What's the difference between PPSU Unfilled Extruded and PPSU LSG?

A1: Unfilled Extruded has a higher flame retardant grade (V-0), stronger electrical insulation strength, and is suitable for high-end fields. LSG, on the other hand, emphasizes mechanical strength and impact toughness, offering better value for money.

Q2: Why does LSG PPSU have fewer parameters?

A2: LSG PPSU is a special application model, mainly used in scenarios with friction performance requirements, so the complete set of mechanical and thermal data is not provided.

Q3: If I want to make a medical device shell, which model should I choose?

A3: PPSU Unfilled Extruded (high flame retardancy and high strength) or PPSU LSG (balancing mechanical performance and cost-effectiveness) is recommended.

Q4: Compared with PEI and PEEK, what are the advantages of PPSU?

A4: PPSU has more advantages in chemical resistance, impact performance and cost control, and is an upgraded choice for PEI and a cost-effective alternative to PEEK.

Q5: Are these models easy to procure in the supply chain?

A5: As a professional trader, our company can supply the QUADRANT Cross-Jun PPSU series for a long time and provide customers with flexible purchasing and customization services.

06 | Conclusión

QUADRANT Cross-Jun PPSU series covers a wide range of materials, from top-grade flame-retardant high-strength to friction performance applications and even more cost-effective comprehensive materials. By comparing it with other plastics, it can be seen that PPSU has unique value in industries such as medical care, aviation, and electrical engineering. As a long-term cooperative trader, our company can provide one-stop PPSU material solutions for purchasers, helping you quickly find the most suitable products.

【Recomendaciones relacionadas】

ColorRx® PPSU-1000RX & 2000RX | Medical-grade PPSU Más información>

LATI LAPEX Series | Dimensional Stability, Low Smoke PPSU Más información>

High-Performance Plastic Pellets Empower Dental Devices Más información>