PRODUCTOS

PPSU R-5500 NT Overview | Medical & Aerospace PPSU Resin

Estructura del producto

What is PPSU Resin

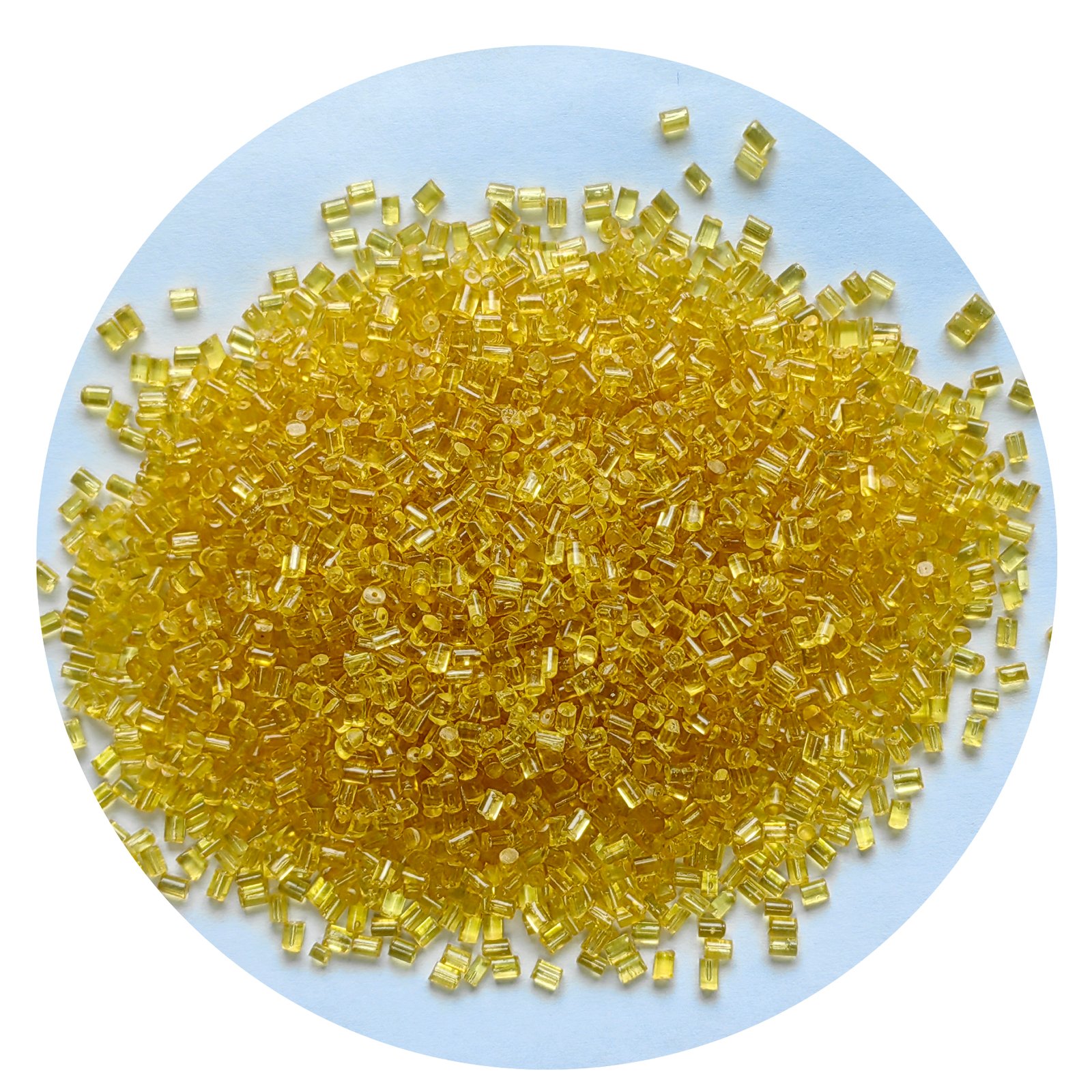

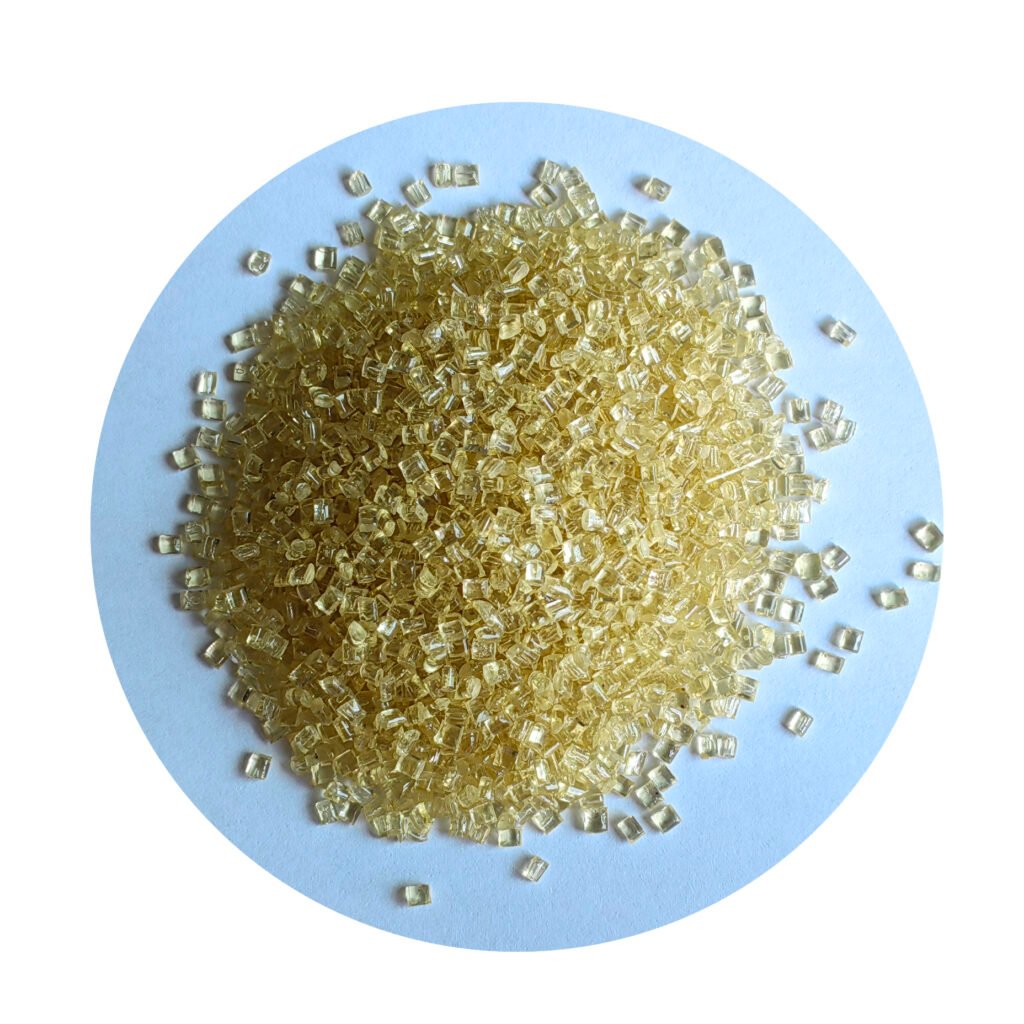

PPSU R-5500 NT is a high-performance PPSU resin (polyphenylsulfone resin) launched by Solvay. It has excellent chemical resistance, biocompatibility and multiple sterilization compatibility, and is particularly suitable for demanding medical devices, aerospace and food contact applications. As a non-reinforced, translucent amorphous thermoplastic material, it can still maintain the stability of structure and performance under long-term high temperature, strong oxidation and repeated sterilization environments, and is widely used in high-value parts that require long-term use.

01 | Key Performance Highlights of PPSU resin

・Multiple sterilization compatibility: supports steam, high pressure, ethylene oxide, electron beam, gamma irradiation and other sterilization methods to meet the sterilization needs of multiple scenarios in the medical industry;

・Excellent stress crack resistance: long-term contact with medical cleaning agents such as alcohol and iodine can still maintain structural integrity;

・Excellent biocompatibility and food contact safety: in line with USP Class VI and ISO 10993, suitable for medical contact surfaces and food containers;

・Strong thermal stability: can withstand heat deformation temperatures up to 207°C, suitable for high-temperature operations or repeated thermal disinfection scenarios;

・Impact and bending resistance: has an unnotched impact strength of nearly 700 J/m, ensuring that the components are not easy to break during high-pressure and high-frequency operations.

02 | Solvay PPSU R-5500 NT Typical application areas

・Medical equipment: disposable or reusable surgical instrument housings, connectors, dental tools, inhaler structural parts;

・Aerospace: used for aircraft internal components, such as aviation-grade electrical housings, interior fixtures;

・Food and drinking water: baby bottle components, internal parts of commercial drinking water equipment, hot drink containers;

・Laboratory consumables: autoclave-grade centrifuge tubes, microfluidic chip housings, high-precision medical analysis module housings.

03 | Process and processing recommendations

・Injection molding is the main process, and the recommended mold temperature is controlled between 130–150°C;

・Suitable for thin-wall precision structure molding, it is recommended that the melt temperature be controlled at around 360°C;

・This material has good dimensional stability and is suitable for secondary assembly, welding or bonding processing;

・It is recommended to use a hot runner system to reduce material waste.

04 | Technical Data Overview of

| Rendimiento óptico | Condición | Estándar | Valor | Unidad | |||

| Índice de refracción | Norma ASTM D542 | 1.67 | |||||

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | 23℃ | Norma ASTM D638 | 7.2 | % | |||

| Resistencia a la flexión | 23℃ | Norma ASTM D790 | 91 | MPa | |||

| Módulo de flexión | 23℃ | Norma ASTM D790 | 2410 | MPa | |||

| Impacto sin muescas Izod | Norma ASTM D256 | 690 | j/m | ||||

| Resistencia a la tracción | 23℃ | Norma ASTM D638 | 69.6 | MPa | |||

| Módulo de tracción | 23℃ | Norma ASTM D638 | 2340 | MPa | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| HDT | Sin recocer 1,80 MPa | Norma ASTM D648 | 207 | ℃ | |||

| Temperatura de transición vítrea | 220 | ℃ | |||||

| CLE | Fluir | Norma ASTM D696 | 5.6E-5 | cm/cm/℃ | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Absorción de agua | 23℃ 24 horas | Norma ASTM D570 | 0.37 | % | |||

| Contracción | Fluir | ASTM D995 | 0.7 | % | |||

| Densidad | Norma ASTM D792 | 1.29 | gramos/cm³ | ||||

| Índice de fusión | 360℃ 10kg | Norma ASTM D1238 | 15 | g/10min | |||

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |||

| Resistividad volumétrica | Norma ASTM D257 | 9E15 | Ω.cm | ||||

| Rigidez dieléctrica | Norma ASTM D149 | 15 | kilovoltios/mm | ||||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Índice limitante de oxígeno | ISO 4589 | 38 | % | ||||

| Clasificación de llama | All color 0.79mm | UL94 | V-0 | ||||

05 | PPSU resin comparison analysis

| Material Grade | Heat Resistance | Sterilization Compatibility | Biocompatibility | Recommended Applications |

| PPSU R-5500 NT | ★★★★★ | Full-spectrum | ISO/USP certified | High-end medical, aerospace |

| PPSU R-5000 NT-15 | ★★★★☆ | Primarily steam | ISO certified | Medical, food contact |

| ordenador personal | ★★★☆☆ | Steam-sensitive | BPA concerns | Disposable devices |

| PÁGINAS | ★★☆☆☆ | Thermally unstable | Non-toxic | General containers, thin-walled parts |

06 | User reviews (excerpts)

・"We have been using R-5500 NT for a long time in surgical instrument shells. After dozens of autoclaves, it still does not change color or crack. It is completely trustworthy."

- Equipment Engineering Supervisor of a Class III Hospital

・"After replacing PC with PPSU, the bottle's drop resistance and cleanability have been greatly improved, and customer satisfaction has been significantly improved."

- Project Manager of a Baby Brand

07 | Recommended Variants: R-5500 BK937 & R-5500 GN1007

In addition to the transparent PPSU R-5500 NT, Solvay also offers two color-compounded variants based on the same high-performance resin platform. These options meet the same stringent sterilization and biocompatibility standards, while providing enhanced visual differentiation:

| Fabricante | Material Name | Grade | Densidad | Melt Flow Index | Resistencia a la tracción | Alargamiento a la rotura | Contracción | Módulo de tracción | Temperatura de deflexión térmica | Módulo de flexión | Notched Izod Impact | Coefficient of Linear Thermal Expansion | Resistencia a la flexión |

| Solvay | PPSU | R-5500 BK937 | 1.29 g/cm³ | 15 g/10min | 69.6 MPa | 7.20% | 0.70% | 2340 MPa | 207 °C | 2410 MPa | 690 J/m | 5.6E-5 cm/cm/°C | 91 MPa |

| Solvay | PPSU | R-5500 GN1007 | 1.29 g/cm³ | 15 g/10min | 69.6 MPa | 7.20% | 0.70% | 2340 MPa | 207 °C | 2410 MPa | 690 J/m | 5.6E-5 cm/cm/°C | 91 MPa |

08 | FAQ

Q1: What is the difference between PPSU R-5500 NT and PPSU R-5000 NT?

A: R-5500 NT has more comprehensive sterilization compatibility (including electron beam and gamma ray), and is more suitable for high-frequency sterilization of medical devices; R-5000 NT is a general-purpose type.

Q2: Can it be used for baby bottles? Will it release harmful substances?

A: Yes, R-5500 NT is a BPA-Free material that complies with FDA and EU food contact regulations and is suitable for repeated boiling and high-temperature rinsing.

Q3: Is this material suitable for 3D printing?

A: Currently this model is mainly used for injection molding. If 3D printing is required, it is recommended to use special PPSU printing materials.

Q4: Will high-pressure steam sterilization cause material discoloration?

A: No under normal conditions. R-5500 NT has excellent antioxidant and thermal stability, and can adapt to more than 300 sterilization cycles.

09 | Our supply advantages

As a raw material supplier focusing on the field of engineering plastics since 2014, we provide the following value-added services to help customers efficiently implement projects:

・Support small batch orders to flexibly meet R&D and trial production needs;

・Free sample application, suitable for performance testing or evaluation;

・Material modification service: color, flame retardant, and enhanced grade can be customized on demand;

・One-to-one technical support to help solve mold, process or application problems;

・Stable delivery, long-term cooperation with global mainstream brands to ensure direct supply of original materials.

If you are looking for PPSU resin that can withstand extreme sterilization conditions and is suitable for high-end medical and industrial uses, PPSU R-5500 NT is undoubtedly your ideal choice. Welcome to contact us to apply for samples or technical consultation to start higher standard material selection.

【Recomendaciones relacionadas】

Solvay R-5100 NT15 PPSU Resin for Medical & Food-Grade Más información>

PPSU P 3010: Food-Safe Resin for Baby Bottles & Sterilization Más información>

K 2025 Insights: Green Plastics and Smart Manufacturing Más información>