PRODUCTOS

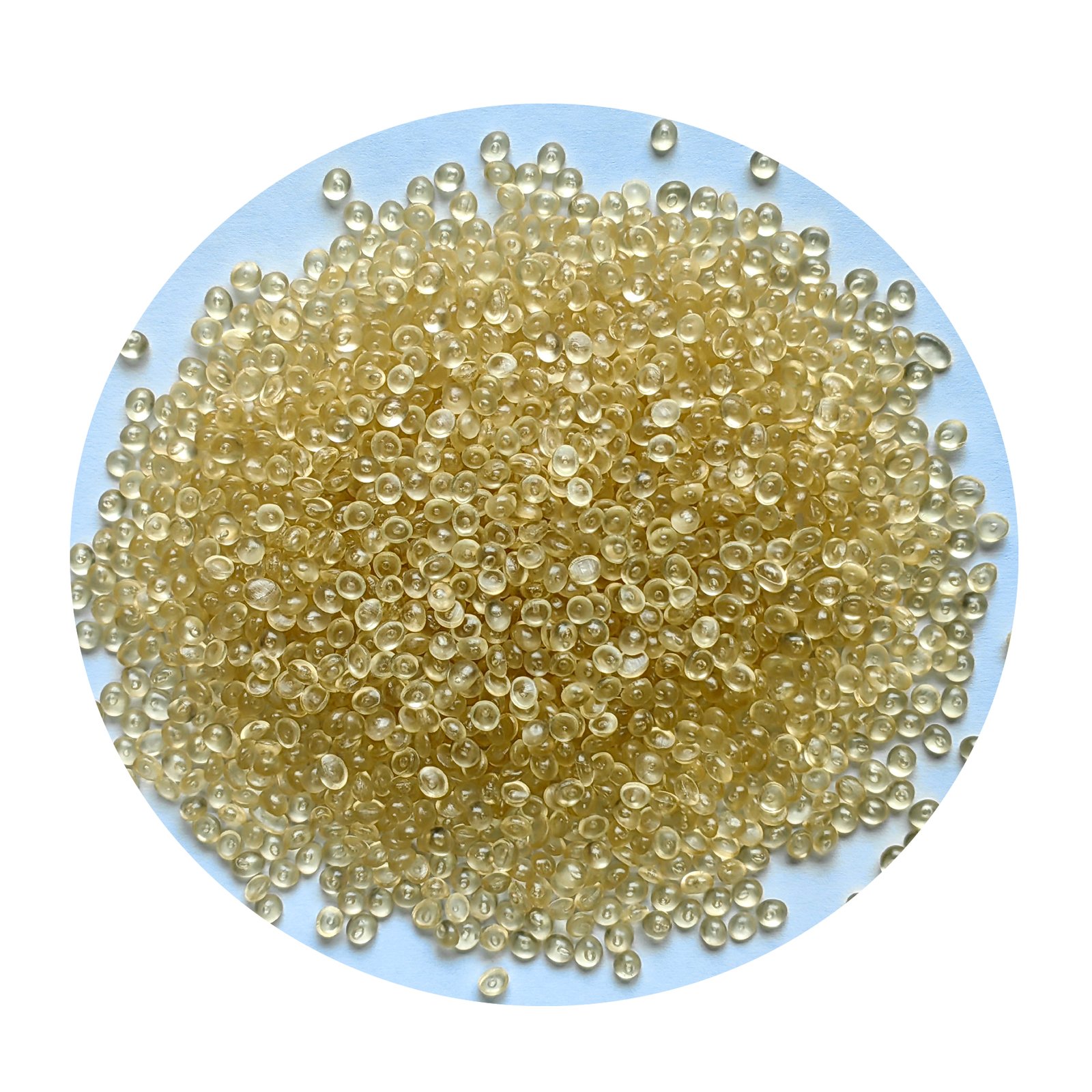

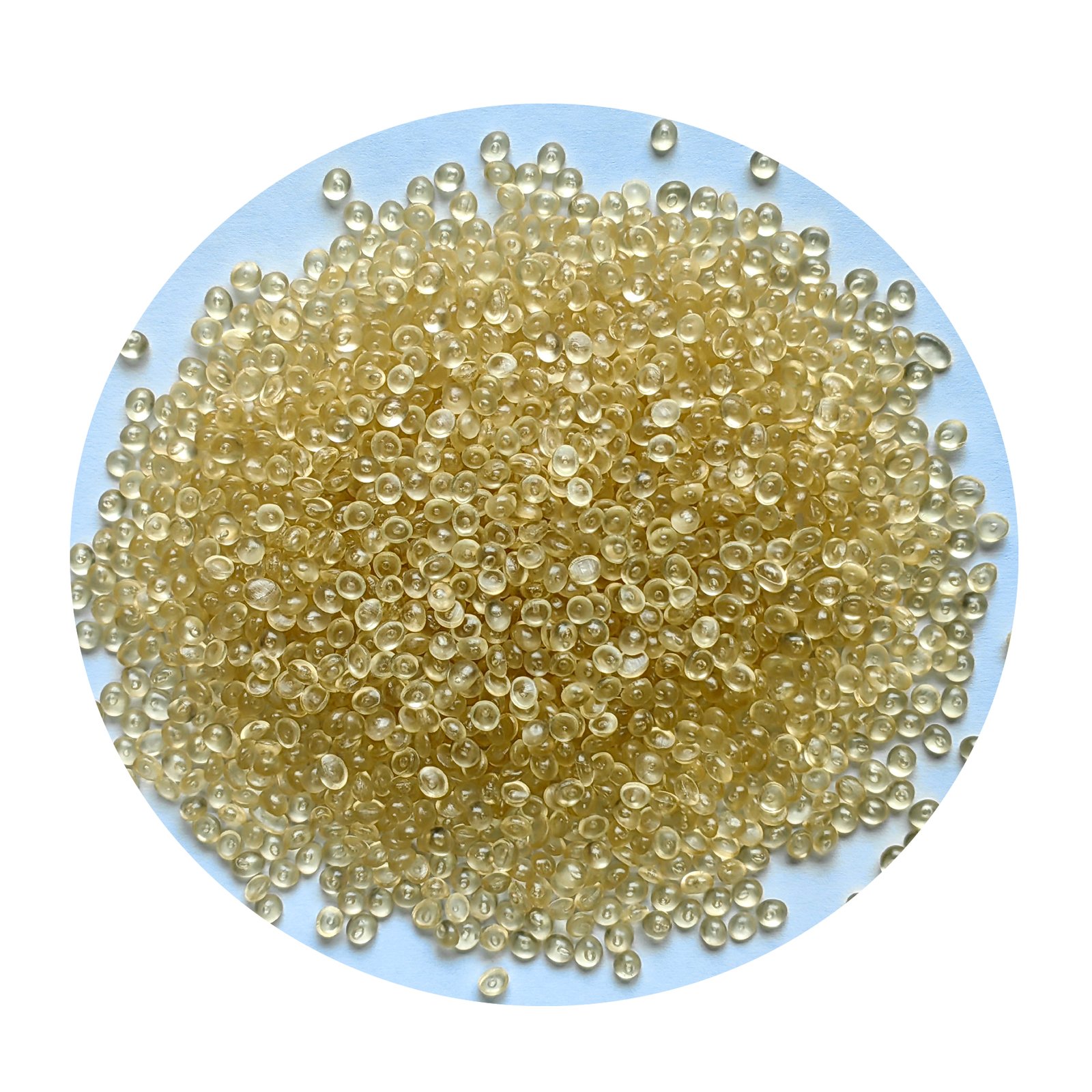

PESU 2010 MR | High Flow & Flame-Retardant PESU polymer

Estructura del producto

What is PESU Polymer

PESU 2010 MR is a polyethersulfone (PESU polymer) material for injection molding launched by BASF. It is favored by customers in the electronics, industrial equipment and structural parts industries for its strong dimensional stability, excellent fluidity and outstanding high temperature resistance.

As a supplier of plastic raw materials, we can provide original particles, sample testing, parameter information and related selection suggestions for customers with processing, modification and terminal injection molding needs.

01 | Core characteristics: not just high heat resistance

Starting from the material properties and combining actual test data, we analyze the outstanding performance of PESU 2010 MR in multiple key dimensions:

✅ Excelente estabilidad dimensional

・The linear expansion coefficient is only 5.2E-5 cm/cm/°C, which is much lower than most engineering plastics, ensuring the precise shape of parts in high temperature environments;

・The shrinkage rate is small (0.82% in the flow direction and 0.86% in the vertical direction), which is particularly friendly to precision parts and insert structures with high tolerance requirements;

・Even in multiple thermal cycle environments, it can maintain structural stability and reduce deformation.

✅ Good fluidity and friendly processing

・The melt index is 70 cm³/10min, which is a medium to high flow level, which is conducive to the injection molding of complex structures and thin-walled parts;

・High molding efficiency, suitable for mass production scenarios that are sensitive to beats (such as plugs, precision modules, snap-on structures, etc.);

・No special mold structure is required, conventional injection molding equipment can be used for stable production.

✅ Strong thermal performance, adaptable to high temperature conditions

・The heat deformation temperature is as high as 205°C (ISO 75), and it can withstand continuous heat source or current heating;

・Pesu polymer can be used in high temperature load areas such as engine compartment interior, control module, electrical connection box, etc.;

・It still has good thermal deformation control ability without annealing conditions.

✅ Excellent electrical performance, suitable for high insulation applications

・Volume/surface resistance up to 10¹⁵ Ω, insulation strength 37 kV/mm;

・Stable dielectric constant (3.8 @1MHz) + low dissipation factor, suitable for RF/high frequency environment;

・Can be used for micro-electric devices, control modules, relay bases and other parts that are sensitive to leakage and creepage.

02 | Typical application direction of pesu polymer: serving high temperature and high precision requirements

As a trader, we recommend PESU 2010 MR for the following structural scenarios, and customers can compare and select according to the purpose:

| Application Segment | Key Requirements | Advantages of PESU 2010 MR |

| Electrical Structural Parts | Flame retardancy, insulation, snap-fit design | UL94 V-0 rated + excellent insulation + high flowability |

| Automotive Electronic Modules | Heat resistance, electrical performance, dimensional accuracy | Thermal stability + dimensional precision + injection molding suitability |

| Industrial Connectors | Aging resistance, thermal shock durability | Thermal deformation resistance + high impact toughness |

| Base Resin for Compounding | Flame retardant or high-flow formulations | Medium viscosity + high formulation versatility |

| Medical Device Housings | Non-metal contact parts, good toughness | Non-reinforced + ductile + easy to mold |

If you have a customized application direction, you can contact us to obtain material recommendations and analog model options.

03 | PESU Polymer Technical Highlights

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Rendimiento 23°C | ISO 527 | 6.9 | % | |||

| Impacto de muesca Izod | 23ºC | ISO 180 | 6.5 | kJ/m² | |||

| Impacto de muesca Izod | -30°C | ISO 180 | 7.0 | kJ/m² | |||

| Resistencia a la tracción | Rendimiento 23°C | ISO 527 | 85.0 | MPa | |||

| Módulo de tracción | 23ºC | ISO 527 | 2650 | MPa | |||

| Impacto Charpy sin muesca | 23ºC | ISO 179 | NÓTESE BIEN | ||||

| Impacto Charpy sin muesca | -30°C | ISO 179 | NÓTESE BIEN | ||||

| Impacto con entalla Charpy | 23ºC | ISO 179 | 6.5 | kJ/m² | |||

| Impacto con entalla Charpy | -30°C | ISO 179 | 7.0 | kJ/m² | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| HDT | 1.8MPa sin recocer | ISO 75 | 205 | °C | |||

| CLE | Fluir | 5.2E-5 | cm/cm/°C | ||||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Absorción de agua | Saturación de 23 °C | ISO 62 | 2.2 | % | |||

| Absorción de agua | 23°C 50RH Balance | ISO 62 | 0.80 | % | |||

| Contracción | Fluir | ISO 294 | 0.82 | % | |||

| Contracción | xFlujo | ISO 294 | 0.86 | % | |||

| Densidad | ISO 1183 | 1.37 | gramos/cm³ | ||||

| Índice de fusión | 360°C 10kg | ISO 1133 | 70 | cm³/10min | |||

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |||

| CTI | IEC 60112 | 100 | V | ||||

| Constante dieléctrica | 1 MHz | IEC 60250 | 3.80 | ||||

| Constante dieléctrica | 100 Hz | IEC 60250 | 3.90 | ||||

| Resistividad volumétrica | CEI 60093 | 1E15 | Ω.cm | ||||

| Rigidez dieléctrica | CEI 60243 | 37 | kilovoltios/mm | ||||

| Factor de disipación | 1 MHz | IEC 60250 | 0.014 | ||||

| Factor de disipación | 100 Hz | IEC 60250 | 0.0017 | ||||

| Resistividad superficial | CEI 60093 | 1E15 | Ω | ||||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Clasificación de llama | 1,5 mm | UL94 | V-0 | ||||

| Clasificación de llama | 3 mm | UL94 | V-0 | ||||

04 | Regulatory and testing compliance: flame retardant and safety standards for global markets

・UL94 V-0 (1.5mm & 3.0mm) certification meets the mandatory fire protection standards for electronic and electrical components;

・Water absorption data is divided into saturation (2.2%) and equilibrium (0.80%). It is recommended to fully dry before molding to ensure stable electrical performance;

・CTI value is 100V, which can meet the basic anti-tracking requirements of industrial control cabinets and transformer structural components.

05 | Frequently Asked Questions (FAQ)

Q1: Is this model suitable for high-temperature and complex electronic components?

A: Absolutely suitable. It has high heat deformation temperature and good fluidity, and performs well in dimensional control and assembly.

Q2: Can it be used for modification processing?

A: Yes. PESU 2010 MR is a non-reinforced material, suitable as a flame retardant substrate, viscosity adjustment resin, compounding additive and other material solutions.

Q3: Does the mold need special treatment?

A: No. It is recommended to use high temperature resistant mold steel (such as S136, H13), and keep the mold temperature above 130°C to obtain better surface quality and dimensional control.

Q4: Is the material available in stock? Can I request a sample?

A: Yes, as a 24-year professional plastic raw material supplier, Juyuan has a stable supply channel and can provide sample testing, small batch delivery, parameter data package and other supporting services.

06 | Welcome to contact us for technical information and samples

As a supplier of high temperature engineering plastics such as PESU, PPSU, PEEK, we can provide you with:

✅ Original genuine channels, long-term spot;

✅ Sample provision and injection molding suggestions;

✅ Comparison of the same type of materials (such as PESU G6 / G4, etc.);

✅ Engineering plastic selection consultation and process guidance;

📩 Need sample testing or product application suggestions? Welcome to leave a message through the form on the right side of the page, and we will reply within 24 hours.

🔍 To browse more high-temperature materials, please go to the "PESU Materials" column of this site to obtain model comparisons and application solution recommendations.

Keywords: PESU 2010 MR,pesu polymer,pes polymer, flame-retardant polyethersulfone,BASF, plastic resin supplier,dimensional stability,high flowability

【Recomendaciones relacionadas】

PESU 7020 P: Flake-Form pes plastic material for High-Performance Coating Applications Más información>

PESU 2010 G4: 20% Glass Fiber Reinforced Polyethersulfone for Printing Components Más información>

Material Selection for Baby Bottles Under New Regulations: Is Moving from PC to PPSU Really Justified by Higher Cost? Más información>