PRODUCTOS

PES Plastic Material BASF 7020 P for Coating Applications

Estructura del producto

What is PES Plastic Material

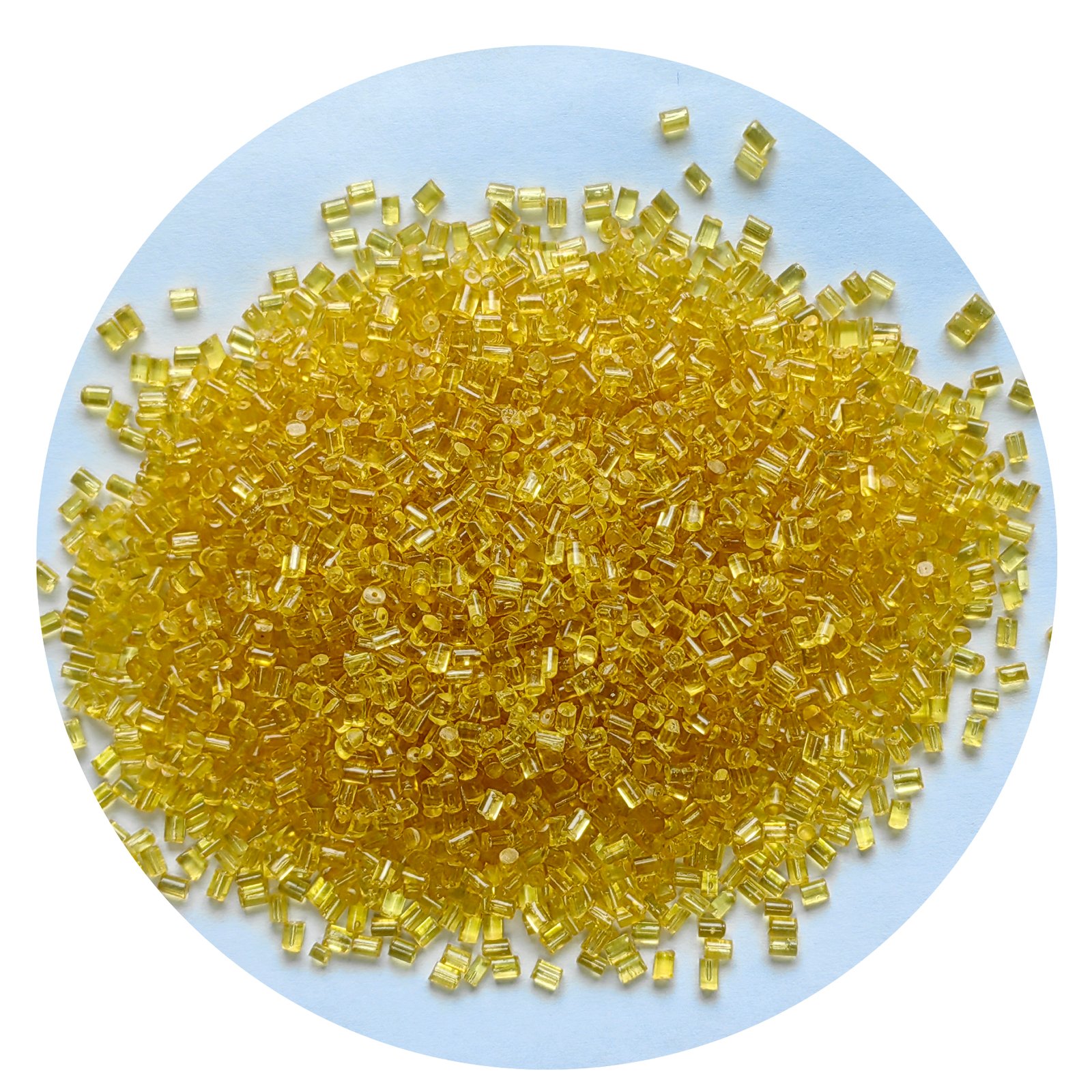

Against the backdrop of the continuous evolution of new energy batteries, electrochemical separation membranes and high-end filtration technologies, the demand for functional high-performance coating materials is becoming increasingly refined and specialized. As a sheet-like structure material specifically designed for coating processes, BASF PESU 7020P is becoming a key carrier for the functional upgrade of diaphragms. This pes plastic material with high molecular weight and ultra-high viscosity not only demonstrates excellence in thermal stability, chemical inertness and film uniformity, but also promotes the realization of the next-generation battery film and filtration coating technology.

I. Material Analysis: Comprehensive Adaptation from Structure to Performance

PESU (polyethersulfone) materials have gained a foothold in numerous high-end applications due to their outstanding thermal properties and chemical resistance. PESU 7020P is further optimized on this basis and customized specifically for high-performance coating application scenarios:

| Propiedad | Data / Characteristics |

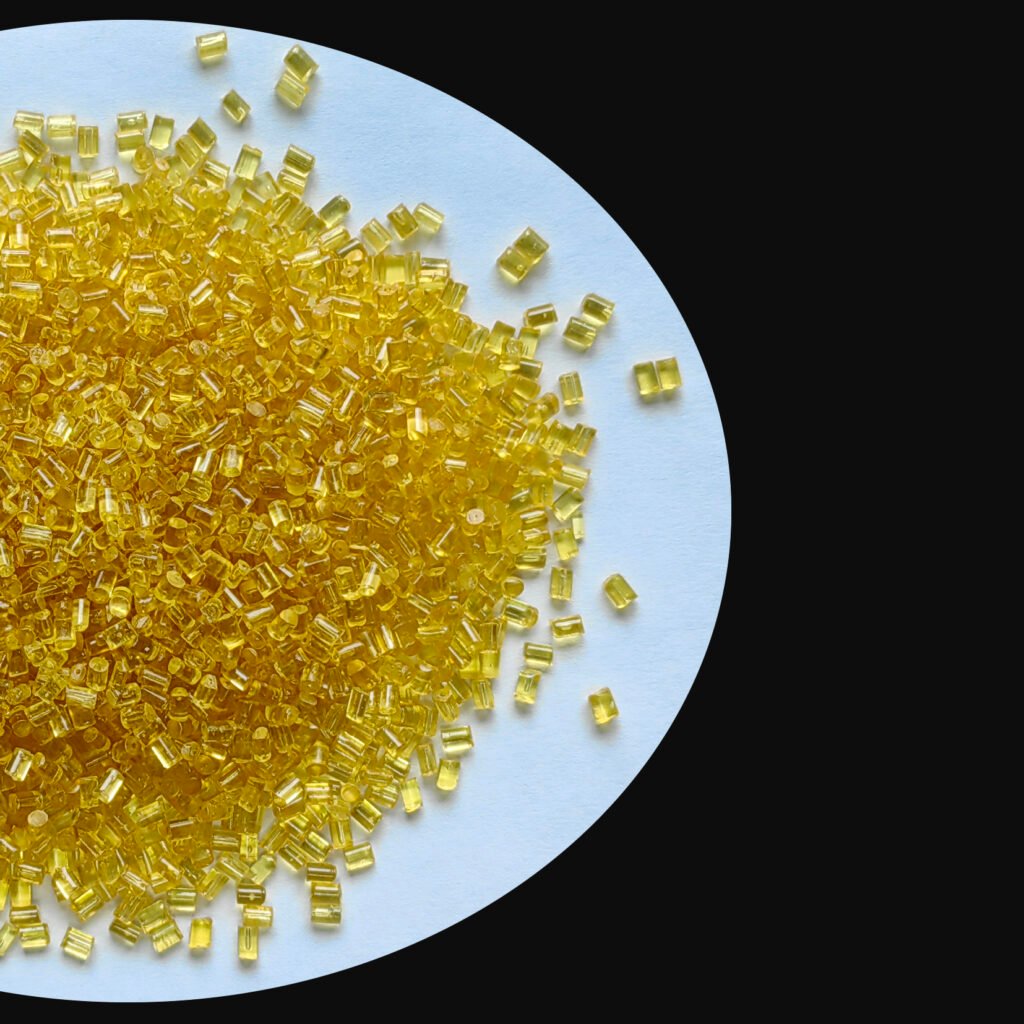

| Material Form | Flake (optimized for solvent-based formulations) |

| Método de procesamiento | Designed for coating and cast-film applications |

| Glass Transition Temp. | 230°C – ensures thermal stability of coated films under high temperatures |

| Equilibrium Water Abs. | 1.00% – minimizes dimensional changes due to moisture uptake |

| Molecular Weight (Mw) | 92,000 – high polymer chain length enhances mechanical integrity |

| Viscosidad relativa | 105 cm³/g – ensures consistent flowability in coating formulations |

| Densidad aparente | 0.25 g/cm³ – facilitates processability and precise mixing control |

Ii. Analysis of Coating Advantages: Why PESU 7020P?

In the field of coating film materials, the key lies not only in "heat resistance", but also in "stability during the film-forming process, uniformity of the film structure after coating and chemical compatibility". The PESU 7020P precisely hits the following key advantages:

✅ High-viscosity film formation, enhancing surface consistency

Its ultra-high relative viscosity ensures that the coating liquid spreads evenly on the substrate surface, forming a continuous and poreless film structure, which is suitable for high-precision battery separators.

✅Soluble in a variety of solvents, suitable for a variety of processes

It can be made into a uniform coating liquid through polar solvents such as DMSO and NMP, and is compatible with existing coating production lines, facilitating seamless upgrades.

✅ Strong thermal stability, enhancing the thermal shrinkage resistance of the diaphragm

With a glass transition temperature of 230°C, it maintains dimensional stability and is less prone to warping at high temperatures, making it particularly suitable for functional layers in high-temperature charging and discharging scenarios.

✅Good chemical inertness and compatible with multiple electrolytic systems

It demonstrates excellent solvent resistance when exposed to lithium-ion electrolytes, alkaline media, alcohols and ether solutions, providing long-term reliable protection for coated components.

Iii. Typical Applications: A New Foundation for High-end Separation and Energy Storage Systems

Functional layer of new energy battery diaphragm

・PESU 7020P, as the material of the functional layer on the diaphragm surface, can enhance the heat resistance stability and electrolyte wettability of the diaphragm.

・It is widely applied in new technologies of lithium batteries, sodium batteries and solid-state batteries, promoting the dual improvement of battery safety and performance.

Precision filtration and reverse osmosis membranes

・High-molecular-weight polyethersulfone is the basis for constructing structures such as ultrafiltration membranes and hollow fiber membranes.

・Its film is non-toxic, transparent and has high mechanical properties, and can be used in fields such as biopharmaceuticals and the preparation of pure water for electronics.

Functional electronic thin film coating

・It is applied to surface protective films of electronic components, transparent anti-static layers, etc.

・The coating film combines transparency, insulation and thermal stability.

Iv. Industry Trends: A New Era of "fluorine-free + high-temperature" diaphragm Functional layers

With "fluorine-free" and "high-temperature" becoming the main themes of new energy material research and development, PESU 7020P has followed the trend

| Trend Direction | PESU 7020 P Advantage Description |

| Development of fluorine-free membranes | Inherently halogen- and fluorine-free, PESU offers an environmentally friendly and degradable solution. |

| High-temperature adaptability | High glass transition temperature (Tg 230°C) combined with high molecular weight ensures thermal durability. |

| Optimized control of high-viscosity systems | Exceptional viscosity allows balanced flow and spreadability, supporting high-speed coating processes. |

| Innovation in multilayer membrane structures | Compatible with PVDF, PI, and other substrates to create advanced multi-layer membrane systems. |

V. Frequently Asked Questions (FAQ)

Q1: What are the differences between PESU 7020P and traditional PVDF coating materials?

A: PESU 7020P is fluorine-free and environmentally compliant. Meanwhile, its higher glass transition temperature can enhance the stability of the coating under high-temperature conditions, making it one of the powerful alternatives to PVDF.

Q2: Our company has a wide range of product lines. Can we provide coating matching solutions based on different membrane structures?

A: Of course. Juyuan Plasticization is a professional service provider with over 24 years of experience in the field of plastic raw materials. We not only offer PES material particles but also support modification customization, model comparison and application selection, helping you precisely meet your project requirements.

Q3: Could you provide guidance on dissolving and coating suggestions for high-viscosity PES plastic material?

A: Yes. We can provide complete process parameters such as solvent ratios, coating thickness control, and drying condition suggestions to assist the R&D team in efficiently completing sample making.

Q4: Is PESU 7020P suitable for membrane lamination?

A: Yes. It has a high heat distortion point, excellent mechanical strength and moderate surface tension, making it suitable for multi-layer lamination with substrates such as PI, PET and non-woven fabrics.

Conclusión

PESU 7020P is not merely a polyethersulfone flake particle; it represents a directional transformation in high-performance coating materials. Today, in the pursuit of high-temperature adaptability, environmental protection safety and process compatibility, this pes plastic material will continue to inject technological depth into the functional film, separation film and electronic film industries.

If you are looking for a PES coating material that combines high thermal stability, chemical inertness and process controllability, please feel free to contact Juyuan Plasticization. We will provide you with professional material selection advice and application solutions to help your products break through technical boundaries.

【Recomendaciones relacionadas】

PES and PESU Explained: Choosing the Right Polysulfone for Your Application Más información>

PESU 3010 MR UN: High-Viscosity PES Plastic for Medical & Rail Applications Más información>

PESU 2010 HC: Flame-Retardant PES Material for Medical and Electronic Applications Más información>