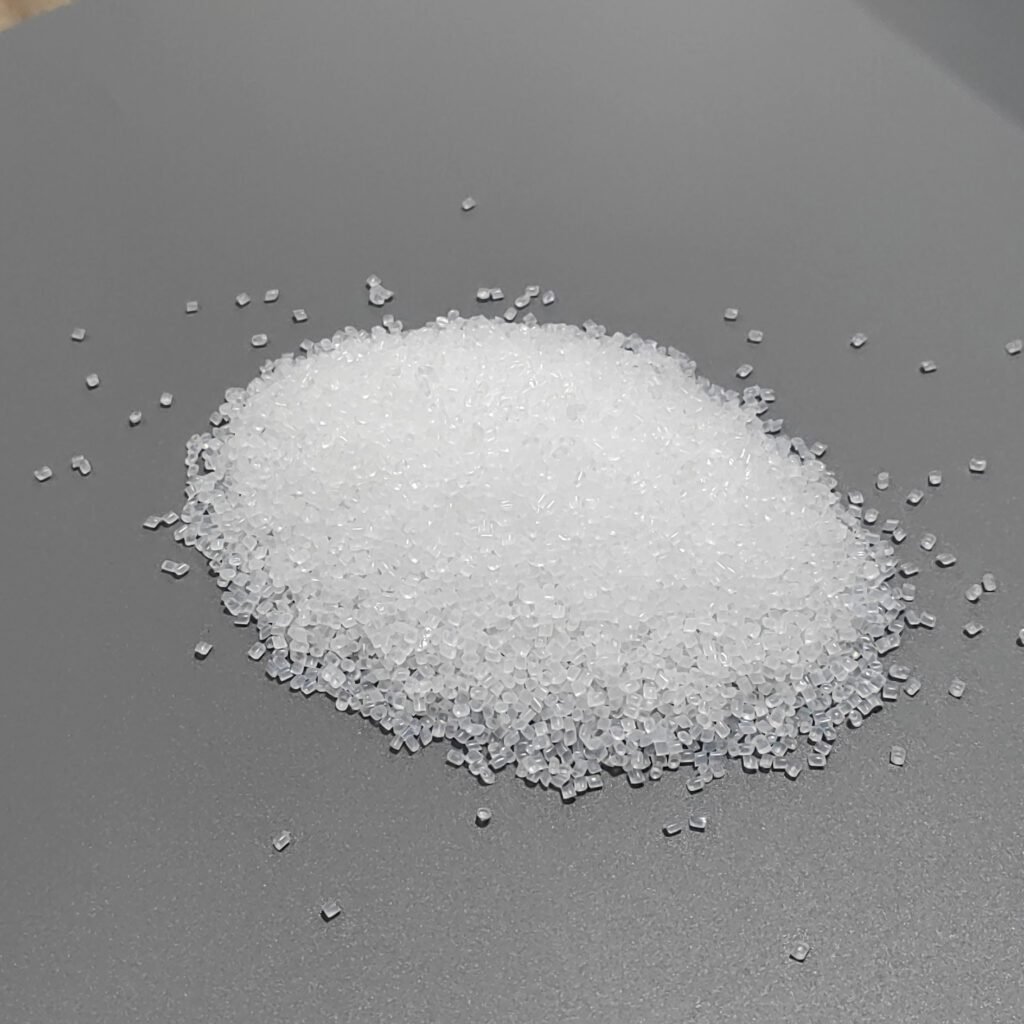

At a time when engineering plastics are developing rapidly and performance requirements are becoming increasingly diversified, nylon materials (Polyamide, PA for short) are still the backbone of structural and functional parts manufacturing. In particular, PA66 (nylon 66) and PA6 (nylon 6) are often confused because of their similar names and properties. However, for product designers, material engineers and even raw material purchasers, clarifying the key differences between the two is the basis for accurate material selection, cost control and quality assurance.

This article will focus on the core theme of "PA66 vs PA6", combined with the trends of the plastics industry and new material dynamics in 2025, to provide you with a comprehensive and practical reference for material selection and procurement.

01 | Basic Property Comparison Between PA66 and PA6

| Propiedad | PA66 | PA6 |

|---|---|---|

| Monomer Composition | Hexamethylene diamine + Adipic acid | ε-Caprolactam |

| Molecular Structure | More compact, higher crystallinity | Looser chains, lower crystallinity |

| Melting Point | Approx. 260 °C | Approx. 220 °C |

| Absorción de agua | Relatively lower | Slightly higher |

| Mechanical Strength | Higher (more rigid and stronger) | Slightly lower (better toughness, ductility) |

| Wear Resistance | Excelente | Excelente |

| Procesabilidad | Requires higher molding temperature, easier demolding | Lower processing temperature, more mold-friendly |

| Cost | Relatively higher | More cost-effective |

02 | Differences in applicable scenarios and industry decisions

| Application Area | Recommended Material | Reason |

|---|---|---|

| High-temperature components | PA66 | Higher melting point and superior thermal stability |

| Automotive structural parts | PA66 | High strength and heat resistance, ideal for under-the-hood parts |

| Electrical & electronic housings | PA6 | Significant cost advantage with acceptable dimensional stability |

| Industrial gears & pulleys | PA6 (or modified PA6) | Excellent wear resistance and processability, ideal for volume production |

| Household appliance structures | PA6 | Good flowability, high injection efficiency, and cost savings |

Summary: If the application scenario you are facing has extremely high requirements for rigidity, heat resistance, and mechanical strength, PA66 is a better choice; if you focus on cost control and processing efficiency, PA6 is more attractive for purchasing.

03 | Performance comparison of glass fiber reinforced PA66 vs PA6 (taking 30% GF as an example)

| Propiedad | PA66-GF30 (e.g. Ultramid A3EG6) | PA6-GF30 (e.g. Ultramid B3EG6) |

|---|---|---|

| Densidad | 1.35 g/cm³ | 1.36 g/cm³ |

| Resistencia a la tracción | 190 MPa | 175 MPa |

| Módulo de flexión | 8500 MPa | 7500 MPa |

| Notched Impact Strength (23℃) | 8 kJ/m² | 9 kJ/m² |

| Heat Deflection Temp (1.8MPa) | 250 ℃ | 220 ℃ |

| Water Absorption (Saturation) | 2.0% | 2.5% |

| Recommended Processing Temp | Mold: 90–110℃ / Barrel: 270–300℃ | Mold: 60–80℃ / Barrel: 230–260℃ |

📌 Data source: BASF Ultramid technical manual (A3EG6 and B3EG6), for reference only, please evaluate the specific data in combination with the actual batch and mold conditions.

Interpretation suggestions:

・If the project has extremely high requirements for high temperature deformation and structural rigidity, it is recommended to use PA66-GF30;

・If you pursue cost efficiency and allow slightly lower thermal performance, you can consider PA6-GF30 as a substitute;

・The difference in water absorption and processing conditions also needs to be considered in combination with the tolerance of the product and the post-processing method.

04 | Nylon industry trends in 2025: carbon neutrality, lightweight, and functional composites become the main theme

Recycled PA6/PA66 is favored

With the continuous update of the EU Green Agreement, REACH and RoHS regulations, more and more brands have begun to specify PCR (Post-Consumer Recycled) PA materials, especially in the fields of home appliance housings and automotive interiors.

PA66 demand growth bottleneck + substitution trend

Due to the frequent price fluctuations of adipic acid and hexamethylenediamine and the tight global production capacity, some PA66 applications are being replaced by high-performance modified PA6 (such as glass fiber reinforced PA6), especially in light-load automotive parts, tool housings and other scenarios.

High-performance blended materials are developing rapidly

By blending with resins such as PPE and PBT or adding carbon fiber and lubricants, PA6 and PA66 are evolving in the direction of "customization and functional composite". The material performance is no longer "hard-hitting", but "precisely matching the use needs".

05 | Procurement suggestions and Juyuan advantages

As an international plastic raw material trader with 24 years of industry experience, Juyuan has been deeply involved in the field of nylon materials for many years and can provide customers with:

・Full brand coverage: covering international mainstream PA6/PA66 brands such as BASF, DuPont, Ocean, teijín, Asahi Kasei, etc.;

・Customized modification services: providing flame retardant, reinforced, hydrolysis resistant, UV resistant and other formulation support;

・Fast delivery system: always have spot inventory, support bulk bags, tons of bags, containers and other delivery modes;

・Traceable compliance guarantee: All materials are attached with COA, support UL yellow card, RoHS, REACH certification query.

06 | FAQ

Q1: How much more expensive is PA66 than PA6? Is it worth it?

In general, the price of PA66 is 15%-30% higher than that of PA6, but if the application does have higher requirements for temperature resistance and strength, this part of the cost is worth investing.

Q2: Is PA6 suitable for automotive structural parts?

Suitable for low-load, non-hot zone structural parts. If it is modified with glass fiber reinforcement (GF30), it can replace some PA66 applications.

Q3: How to choose PA6 or PA66?

It is recommended to consider the use temperature, load requirements, water absorption control requirements and cost control strategies. If you are not sure, please contact our engineers for samples and technical suggestions.

Conclusión

PA66 and PA6 are not a question of "who is better", but the art of decision-making of "which is more suitable". In today's increasingly segmented materials and customized applications, understanding the differences between the two and making flexible choices based on actual needs is the core logic of efficient procurement.

Juyuan will continue to escort your raw material decisions with professional, transparent and highly responsive services. If you need more technical information or samples, please feel free to contact us.