PRODUCTOS

Medical-Grade PSU P-1700 LCD | Medical-Grade Udel® PSU

Estructura del producto

What is Udel® PSU

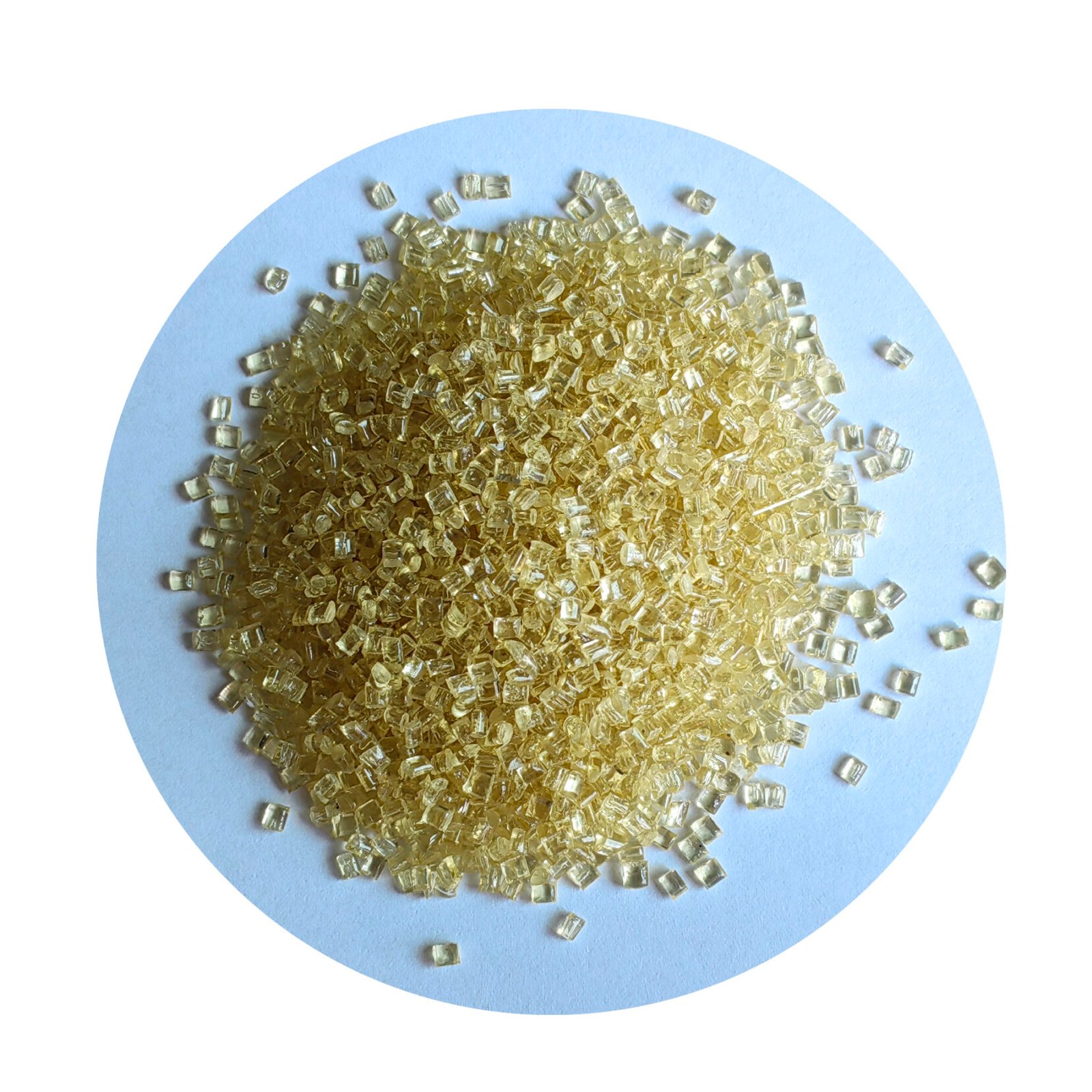

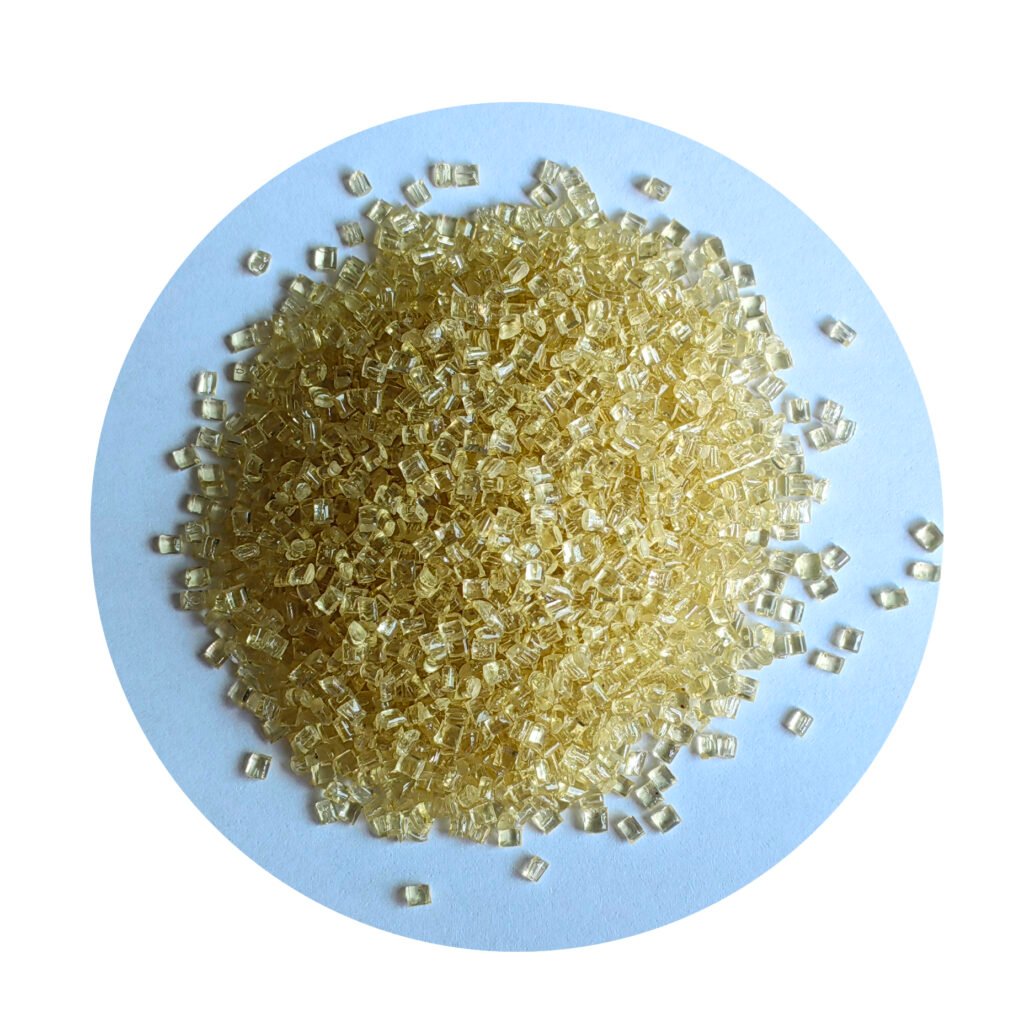

Udel® P-1700 LCD is a polysulfone (PSU) particle launched by Solvay, which is transparent to light yellow in color and is specifically designed for high-demand medical, food contact and electronic applications. It possesses multiple material properties such as high heat resistance, hydrolysis resistance, food contact grade and medical grade, and also has the properties of acid resistance, alkali resistance, alcohol resistance, chemical corrosion resistance, high toughness and hydrocarbon resistance. As a reliable supply channel for Udel® PSU, Juyuan offers stable raw materials and professional material selection guidance to help purchasers achieve safe and efficient production.

01 | Product highlights

Multiple material properties: high heat resistance grade, hydrolysis resistance grade, food contact grade, medical grade, ensuring the safety and reliability of the product in high-temperature sterilization, damp heat environments, and scenarios where it comes into contact with food or the human body.

Comprehensive chemical resistance: Resistant to erosion by acids, alkalis, alcohols and various chemical solvents, and also resistant to hydrocarbons, suitable for harsh working conditions.

High toughness and mechanical balance: Tensile strength 70.3 MPa, flexural strength 106 MPa, tensile modulus 2480 MPa, flexural modulus 2690 MPa, balancing strength and toughness.

High-temperature resistance: Heat distortion temperature 174℃, suitable for high-temperature sterilization and long-term usage environments.

Dimensional and water absorption stability: Shrinkage rate 0.70%, water absorption rate as low as 0.30%, ensuring the accuracy of injection molding or film forming.

Outstanding electrical performance: Dielectric constant ~3.03, volume resistance 5E16 Ω·cm, insulation strength 17 KV/mm, suitable for scenarios with high insulation requirements.

02 | Udel® PSU P-1700 LCD Data Sheet

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Romper | Norma ASTM D638 | 50~100 | % | |||

| Resistencia a la flexión | Norma ASTM D790 | 106 | MPa | ||||

| Módulo de flexión | Norma ASTM D790 | 2690 | MPa | ||||

| Impacto de muesca Izod | Norma ASTM D256 | 69 | j/m | ||||

| Tensile impact strength | Norma ASTM D1822 | 420 | kJ/m² | ||||

| Resistencia a la tracción | Norma ASTM D638 | 70.3 | MPa | ||||

| Módulo de tracción | Norma ASTM D638 | 2480 | MPa | ||||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| HDT | Sin recocer 1,80 MPa | Norma ASTM D648 | 174 | ℃ | |||

| CLE | Fluir | Norma ASTM D696 | 5.6E-5 | cm/cm/℃ | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Absorción de agua | 24 horas | Norma ASTM D570 | 0.30 | % | |||

| Contracción | Fluir | Norma ASTM D955 | 0.70 | % | |||

| Densidad | Norma ASTM D792 | 1.24 | gramos/cm³ | ||||

| Índice de fusión | 343℃ 2,16 kg | Norma ASTM D1238 | 6.5 | g/10min | |||

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |||

| Constante dieléctrica | 60 Hz | Norma ASTM D150 | 3.03 | ||||

| Constante dieléctrica | 1 kHz | Norma ASTM D150 | 3.04 | ||||

| Constante dieléctrica | 1 MHz | Norma ASTM D150 | 3.02 | ||||

| Resistividad volumétrica | Norma ASTM D257 | 5E16 | Ω.cm | ||||

| Rigidez dieléctrica | Norma ASTM D149 | 17 | kilovoltios/mm | ||||

| Factor de disipación | 60 Hz | Norma ASTM D150 | 0.0011 | ||||

| Factor de disipación | 1 kHz | Norma ASTM D150 | 0.0013 | ||||

| Factor de disipación | 1 MHz | Norma ASTM D150 | 0.005 | ||||

03 | Typical applications

・High-precision diaphragms and films

・Medical equipment and food contact utensils

・Laboratory equipment resistant to chemical solvents

・Key components of coating and solution deposition processes

04 | Process adaptation

Processing methods: Injection molding, extrusion molding, coating, solution deposition

Processing features: Moderate fluidity, easy to control thickness and precision, suitable for complex molds and high-precision film processing

Processing suggestion: Under high-temperature processing conditions, the advantages of hydrolysis resistance and chemical resistance can be further exerted

05 | Industry trends

The demand for high-performance polymers in medical devices, food processing equipment and high-end electronic products is constantly increasing. Udel® P-1700 LCD, with its high heat resistance, high toughness, chemical corrosion resistance and multiple safety properties, is becoming the preferred material for diaphragms, films and high-insulation components. Purchasers are increasingly concerned about reliable Udel® PSU suppliers and technical support capabilities.

06 | Similar recommendations

| Fabricante | Modelo de producto | Peso específico | Melt Flow Index | Resistencia a la tracción | Alargamiento | Contracción | Módulo de tracción | Heat Deflection Temp | Izod Notched Impact | Módulo de flexión | Resistencia a la flexión |

| Solvay | P-1700 BK 935 | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 106 MPa |

| Solvay | P-1700 NT 11 MR | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 106 MPa |

| Solvay | P-1700 RD 7505 | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 106 MPa |

| Solvay | P-1700 BU 1457 | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 106 MPa |

| Solvay | P-1700 WH 6417 MG | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 106 MPa |

| Solvay | P-1700 GN 535 | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 106 MPa |

| Solvay | P-1700 NT 11 LCD | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 106 MPa |

| Solvay | P-1700 TR BU 701 | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 106 MPa |

| Solvay | P-1700 BK 1615 | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 106 MPa |

| Solvay | P-1700 BU 775 MR | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 106 MPa |

07 | Common Purchasing Questions (FAQ)

Q1: Is Udel® P-1700 LCD suitable for high-temperature sterilization?

A: Yes, its heat distortion temperature can reach 174℃, and it can withstand high-temperature sterilization and long-term high-temperature use.

Q2: How resistant is the material in a chemical environment?

A: It has the properties of acid resistance, alkali resistance, alcohol resistance and hydrocarbon resistance, and can cope with various chemical environments.

Q3: Is it applicable to food contact or medical applications?

A: The material possesses both food contact grade and medical grade properties and complies with relevant safety standards.

Q4: What issues should be noted during the processing?

A: Suitable for injection, extrusion, coating and solution deposition processes. It is recommended to maintain the precision of the mold to ensure the dimensions and surface quality.

Q5: Are there any restrictions on the purchase volume?

As an international Udel® PSU supplier, Juyuan supports both small-batch trial orders and large-batch orders, flexibly meeting the diverse needs of different customers.

08 | Procurement advantage

Suministro estable: Juyuan offers reliable Udel® PSU raw material supply to ensure uninterrupted long-term production

Professional material selection guidance: Assist in model selection, optimization of processing parameters and material matching

Global distribution capacity: Supports small-batch trial orders and large-batch supply

Multi-industry applicability: It can be efficiently applied in medical care, food, electronics, etc

【Recomendaciones relacionadas】

SABIC PSU GZ004-GY4E009 PSU Materials for Car Hood Más información>

PSU GX07409H for Medical Care Products | PSU Supplier Guide Más información>

Guide to Plastics in Electronics: 2025 Selection & Compliance of Electronic Plastic Resins Más información>