As global attention to the safety of infant products continues to escalate, the EU will implement stricter BPA limit regulations (EU 2024/3190) from 2025, making the seemingly traditional topic of "what materials to choose for baby bottles" once again the focus of industry attention. We can't help but ask: Is the traditional PC material really "unsafe"? Are the high-priced PPSU baby bottles "worth the money"? This article will combine the new regulation trends, mainstream material characteristics and actual application differences to clarify a more scientific material selection path for baby bottle brands and manufacturers.

01|2025 regulations are added: food contact plastics are being redefined

According to the latest EU 2024/3190 regulations issued by the EU, from 2025, more stringent restrictions will be imposed on the migration of **bisphenol A (BPA)** in food contact materials.

✅ Important clarification: The new regulations do not completely ban PC materials, but require that their migration amount is lower than a specific limit and provide a compliance statement.

❗For brands, whether they have the latest test report and compliance declaration document (DoC) will become a key threshold for whether the product can enter the market.

This means that the safety of materials is no longer a binary issue of "whether it contains BPA", but has turned to "verifiable migration control capabilities" and "full process traceability capabilities".

02|PC, PPSU, PP: Comparative analysis of the three major mainstream materials for baby bottles

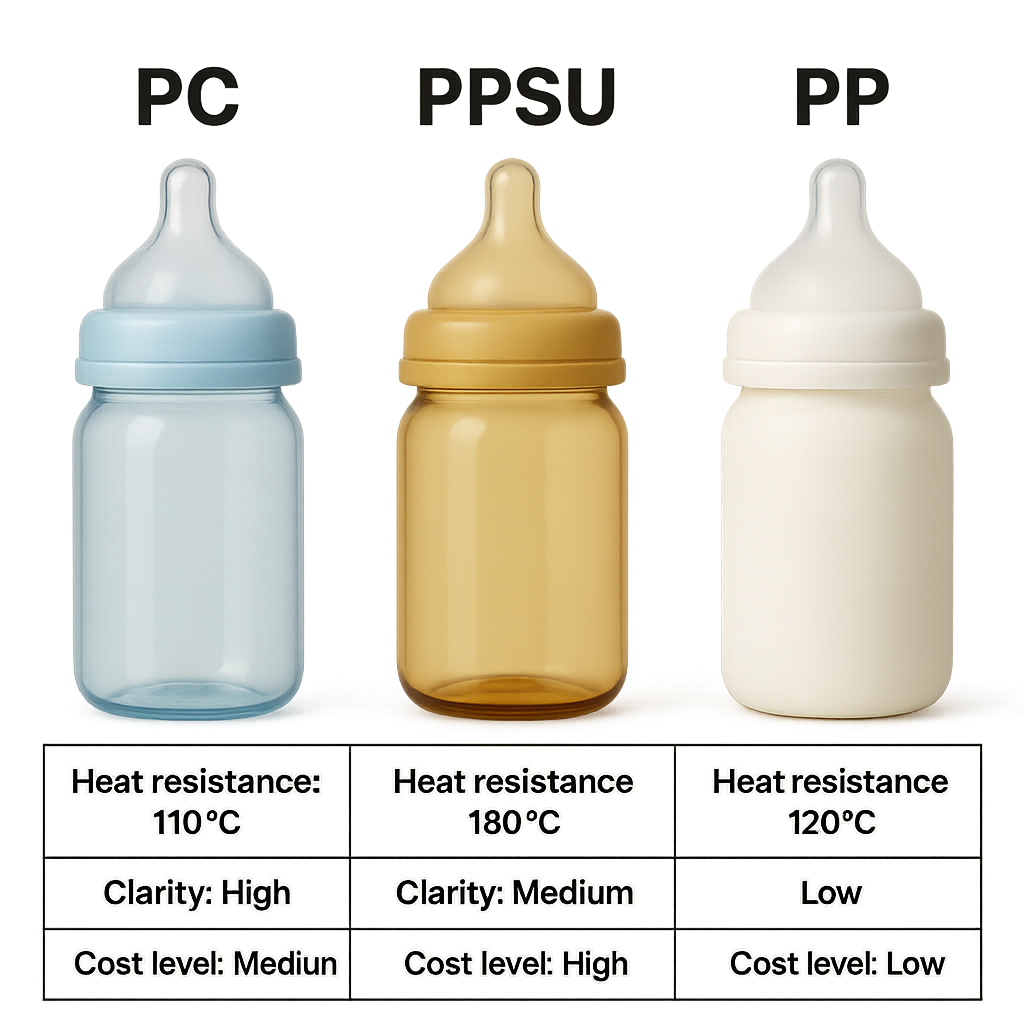

Currently, the three most common baby bottle materials on the market are: PC, PPSU, and PP. The core differences between them are as follows:

| Material | Contains BPA? | Heat Resistance | Transparencia | Cost | Typical Positioning |

| PC (Polycarbonate) | Compliant formula with controlled migration | Medium (130°C) | Alto | Medio | Used by most major brands |

| PPSU (Polyphenylsulfone) | BPA-free | High (above 180°C) | Alto | Alto | High-end / mainly for European and American exports |

| PP (Polypropylene) | BPA-free | Ordinary (110°C) | Pobre | Bajo | Main choice for economical e-commerce products |

A few realistic reminders:

✅ If PC materials meet the migration limit, they are fully compliant and usable.

✅ Although PPSU has excellent performance, it is often over-promoted, especially when high temperature and high pressure are not required for actual use.

✅ Although PÁGINAS is cheap, there may be a slight risk of additive release, and it is easy to age, has poor transparency, and has a limited service life.

03|Realistic testing ≠ extreme experiments: Don’t go astray in material selection

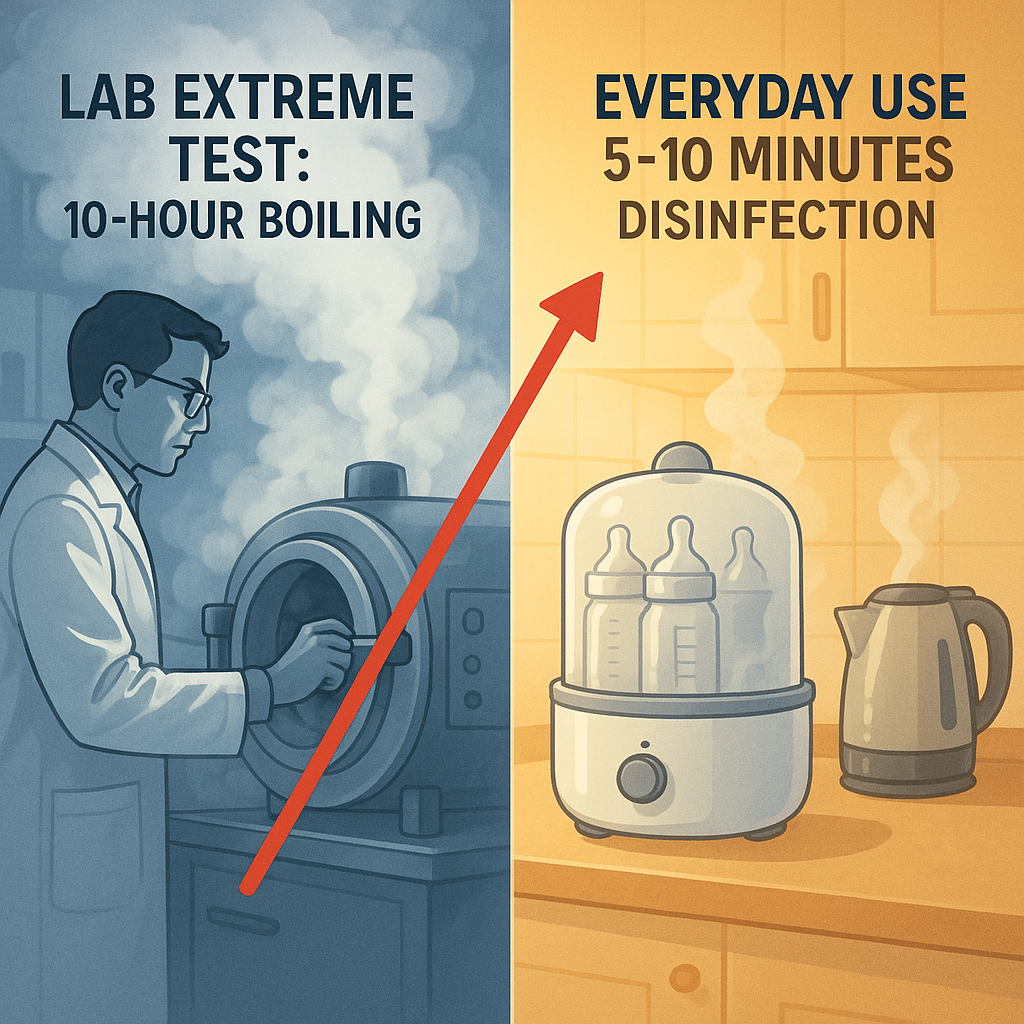

In recent years, there is a phenomenon in the industry that deserves attention:

❗ Low-profit materials are easily used in “extreme testing” to amplify defects, such as: continuously boiling PC bottles for 10 hours and then testing their release levels.

・However, this type of extreme experiment is very different from consumers’ daily disinfection (about 5-10 minutes);

・Some PPSU manufacturers use this “extreme test manufacturing comparison” method to shape material advantages, thereby promoting sales of high-priced products;

・In fact, regulators pay more attention to “material performance and compliance under standard scenarios” rather than the absolute destruction point under extreme conditions.

04|Industry recommendations: Build a sustainable, safe and transparent material selection system

For brands and manufacturers:

📌 Is the material compliant? Please make sure to update RoHS, REACH, and DoC reports;

📌 Is it over-designed? Do not blindly upgrade materials, but rationally evaluate the actual usage scenarios;

📌 Is it sustainable? Pay more attention to dimensions such as material source, stability and recyclability.

For raw material suppliers (such as juyuans.com):

🔍 We can recommend a variety of food-grade plastic materials, including: transparent PC, medical-grade PPSU, high-purity PP;

📦 Provide small batch samples, process support and regulatory consultation;

🤝 Help customers shorten the material selection-trial production-certification cycle.

05|Material selection recommendation: In addition to PPSU, what other food contact materials are worth paying attention to?

Based on different brand positioning and process requirements, you can also consider the following models:

| Material Grade | Características | Recommended Applications |

| PC Tritan TX2001 | BPA-free, high transparency | Infant water cups, mid-section structure of baby bottles |

| PPSU 3020 SW | High heat resistance, injection molding grade | High-end baby bottle bodies |

| PP-H Food Grade | Easy to process, economical | Baby bottle caps, handles, auxiliary structures |

Conclusion|"Expensive materials = safer" is a misunderstanding, scientific material selection is the right way

In the context of new regulations, material selection should no longer rely on the traditional concept of "expensive = safe", but return to practical application, compliance verification and user needs.

As a one-stop supplier of plastic raw materials, we suggest that companies and consumers jointly promote the healthy development of the industry, so that "safe milk bottles" are not just a marketing slogan, but a full-link transparency and responsibility from raw materials to finished products.

If you want to know more about the technical specifications, certification services and alternative solutions of plastic raw materials for baby bottles, please visit our website: juyuans.com.