PRODUCTOS

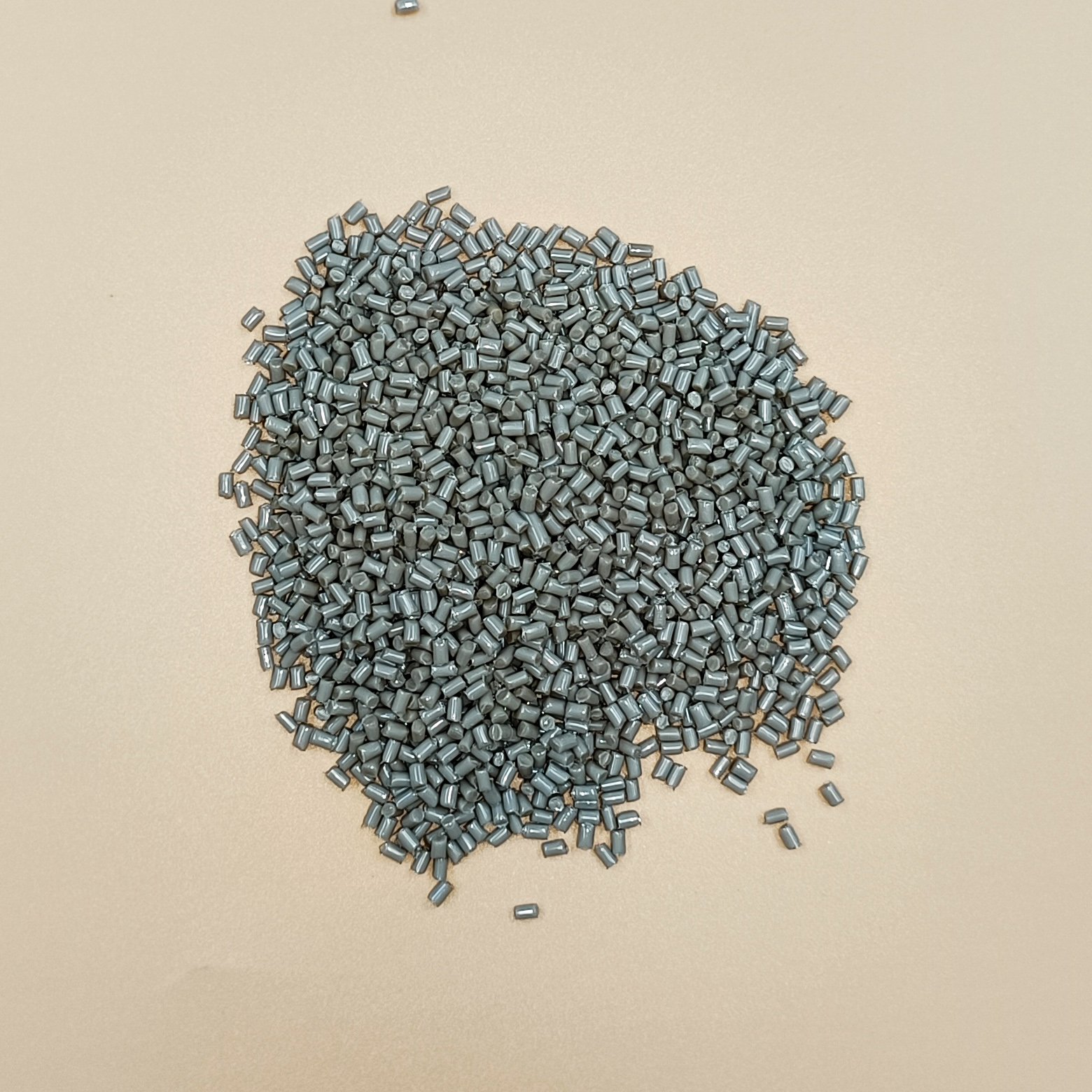

HiFill® 450 A | Medium Flowability PEEK Engineering Plastic

Estructura del producto

What is PEEK Engineering Plastic

HiFill® 450 A is a PEEK engineering plastic launched by Techmer PM. It belongs to the PEEK-FR series and is specially developed for high-temperature, flame-retardant and chemically resistant working conditions.

As a pipe-grade material, it combines UL94 V-0 flame retardancy grade with stable structural strength, and performs exceptionally well in electrical equipment, industrial pipelines and automotive components.

PEEK (Polyether Ether Ketone) is a high-performance engineering plastic, which is widely used in aviation, energy and medical fields due to its excellent thermal stability, mechanical strength and dimensional stability. PEEK 450 A, while maintaining the core performance of PEEK, optimizes flame retardancy and processing fluidity, making it more suitable for the molding of complex structural parts.

01 | Performance Analysis: Key Data and Engineering Significance

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Producir | Norma ASTM D638 | 5.0 | % | |||

| Resistencia a la flexión | Norma ASTM D790 | 172 | MPa | ||||

| Módulo de flexión | Norma ASTM D790 | 4100 | MPa | ||||

| Impacto de muesca Izod | 23 ℃ 3,20 mm | Norma ASTM D256 | 80 | j/m | |||

| Resistencia a la tracción | Producir | Norma ASTM D638 | 96.5 | MPa | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| HDT | Sin recocer 1,80 MPa | Norma ASTM D648 | 160 | ℃ | |||

| CLE | Fluir | Norma ASTM D696 | 4.7E-5 | cm/cm/℃ | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Absorción de agua | 24 horas | Norma ASTM D570 | 0.12 | % | |||

| Contracción | Flow 3.20mm | Norma ASTM D955 | 0.16 | % | |||

| Densidad | Norma ASTM D792 | 1.30 | gramos/cm³ | ||||

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |||

| Resistividad volumétrica | Norma ASTM D257 | 1E15 | Ω.cm | ||||

| Rigidez dieléctrica | Short Time | Norma ASTM D149 | 12 | kilovoltios/mm | |||

| Dureza | Condición | Estándar | Valor | Unidad | |||

| Dureza Rockwell | R(Escala) | Norma ASTM D785 | 105 | ||||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Clasificación de llama | 4.0mm | UL94 | V-0 | ||||

Feature summary:

・It belongs to moderately fluid peek engineering plastic, taking into account both processing stability and structural density.

・The heat distortion temperature reaches 160℃, supporting continuous high-temperature use.

・The UL94 V-0 flame retardant performance meets the electrical and automotive safety standards.

・Excellent insulation and low water absorption ensure long-term dimensional stability.

02 | Processing compatibility: Compatible with injection molding and extrusion processes

HiFill® 450 A features excellent fluidity and thermal stability, making it suitable for a variety of processing techniques.

・Injection molding: Suitable for medium-wall thickness products such as connectors, valve bodies, and insulating shells.

・Extrusion molding: It is highly suitable for applications such as cable protection pipes, chemical conveying pipes, and fuel pipes.

・Secondary processing: Supports CNC cutting and surface electroplating treatment, making it easy to achieve customized design.

This type of peek engineering plastic can maintain melt stability in a high-temperature molding environment, reducing the risks of decomposition and vaporization.

03 | Application field: The combination of safety and durability

HiFill® 450 A performs outstandingly in situations where high structural safety and thermal stability are required

・Industrial pipelines and fluid conveying systems: Possessing both chemical resistance and flame retardancy.

・Electrical equipment and connecting parts: Excellent insulation performance, suitable for high-voltage environments.

・Automobile and transportation components: Suitable for engine compartment accessories and hydraulic system pipelines.

・Analytical instruments and medical devices: Support high-temperature disinfection and long-term operation.

04 | Industry Trends: The Growth Potential of Flame-retardant PEEK Engineering Plastics

・With the expansion of the new energy and intelligent manufacturing industries, the market demand for flame-retardant grade peek engineering plastic has risen rapidly.

・Compared with materials such as PPS and PA, the PEEK-FR series has higher engineering reliability in terms of long-term heat resistance and low smoke zero halogen flame retardant systems.

・In the future, its application in new energy electrical connection systems, chemical fluid control and aviation components will continue to expand.

05 | Similar Recommendations (Medium Fluidity PEEK Series)

The following materials, like HiFill® 450 A, belong to the medium-flowable PEEK engineering plastic system and are suitable for injection molding and extrusion products:

| Fabricante | Modelo de producto | Descripción | Densidad | Índice de fusión | Resistencia a la tracción | Alargamiento | Contracción | Temperatura de fusión | Módulo de tracción | Temperatura de deflexión térmica | Izod Notched Impact | Módulo de flexión | Resistencia a la flexión | Property Summary |

| 4Plas | 9R22130 | Material Feature: Medium Flowability | 1.52 g/cm³ | — | 175 MPa | 2.50% | — | 344 ℃ | 11,000 MPa | 300 ℃ | 8 kJ/m² | — | — | Flame Rating: V-0Notched Impact: 8 kJ/m²Melting Temperature: 344 ℃ |

| 4Plas | 9R22740 | Material Feature: Medium Flowability | 1.43 g/cm³ | — | 275 MPa | 1.50% | — | 344 ℃ | 32,500 MPa | 300 ℃ | 6 kJ/m² | — | — | Flame Rating: V-0Notched Impact: 6 kJ/m²Melting Temperature: 344 ℃ |

| Avient | PK-30GF/000 NC | Material Feature: Medium FlowabilityMaterial Application: Injection Molding | 1.48 g/cm³ | 3.0 g/10min | 180 MPa | 4.00% | 0.20–0.50% | — | — | 320 ℃ | 120 J/m | 11,000 MPa | 270 MPa | Flame Rating: V-0Notched Impact: 12.24 kJ/m² |

06 | Frequently Asked Questions (FAQ)

Q1: To which category of peek engineering plastic does PEEK 450 A belong?

A: It belongs to the flame-retardant grade pipe type PEEK-FR system, featuring medium fluidity and good electrical insulation.

Q2: Can it be mixed with other PEEK models?

A: It is recommended to use it independently to maintain melting stability and performance consistency.

Q3: In which processes is this material suitable?

A: It can be used in both injection molding and extrusion processes and is suitable for preparing precision structural components and tubes.

07 | Reasons to Choose Juyuan

As an international supplier with 24 years of experience in plastic raw material trading, Juyuan offers a reliable PEEK raw material supply chain and professional technical support

・Stock supply of flame-retardant and reinforced PEEK from multiple brands;

・Provide modified formulas and blending support;

・Provide suggestions on forming parameters and processing consultation;

・Support flexible delivery for small-batch and long-term orders.

Juyuan is committed to providing customers with high cost-performance peek engineering plastic solutions.

【Recomendaciones relacionadas】

SABIC LGL33 | Plastic PEEK Material for Automotive Engine Hood Más información>

Lubrizol Carbo-Rite™ A-1441: Corrosion-Resistant PEEK Granules Más información>

High Impact Plastic | Engineering Material Guide for Buyers Más información>