PRODUCTOS

Fluorseals FLUTECK™ K300: Food-Grade PEEK Resin

Estructura del producto

What is FLUTECK™ K300?

Among many specialty engineering plastics, polyetheretherketone (PEEK) has become a core material for demanding applications due to its exceptional thermal stability and chemical inertness. Fluorseals' FLUTECK™ K300 is a flame-retardant, food-contact-grade PEEK-based material specifically developed to balance high-temperature performance with long-term reliability.

The formulation focuses on three key factors: safety, durability, and molding stability. As a flame-retardant PEEK-FR material with FDA food contact approval, it meets regulatory requirements while ensuring the precision and longevity of structural components in food machinery, medical equipment, and high-end industrial applications.

I. Material Highlights: The Design Philosophy Behind Its Stable Structure

1. Dual Flame Retardancy and Food Safety Certification

Unlike ordinary engineering plastics, FLUTECK™ K300 holds a UL94 V-0 flame retardancy rating, effectively suppressing combustion in high-temperature or electrical environments. It also meets FDA food contact standards and can be directly used in food packaging and processing equipment components, meeting global compliance requirements.

2. Dimensional Stability and Creep Resistance

Ordinary plastics are prone to deformation or fatigue cracking under prolonged loads or thermal cycling. However, FLUTECK™ K300's molecular chain exhibits excellent creep resistance, enabling it to maintain dimensional stability and structural strength in precision components, making it particularly suitable for parts with tight assembly tolerances.

3. Excellent Mechanical Balance

This peek plastic material maintains stiffness and strength while also possessing a certain degree of toughness and fatigue resistance. This balanced performance allows design engineers to achieve an ideal compromise between lightweighting and durability.

4. Compatibility with Electrical and Radiation Environments

With its high volume resistivity and excellent dielectric properties, FLUTECK™ K300 is suitable for use in electronic and electrical components. Furthermore, it is radiation-resistant and compatible with radiation sterilization, making it widely used in medical and nuclear technology equipment.

II. Process Compatibility: Designed for Precision Injection Molding

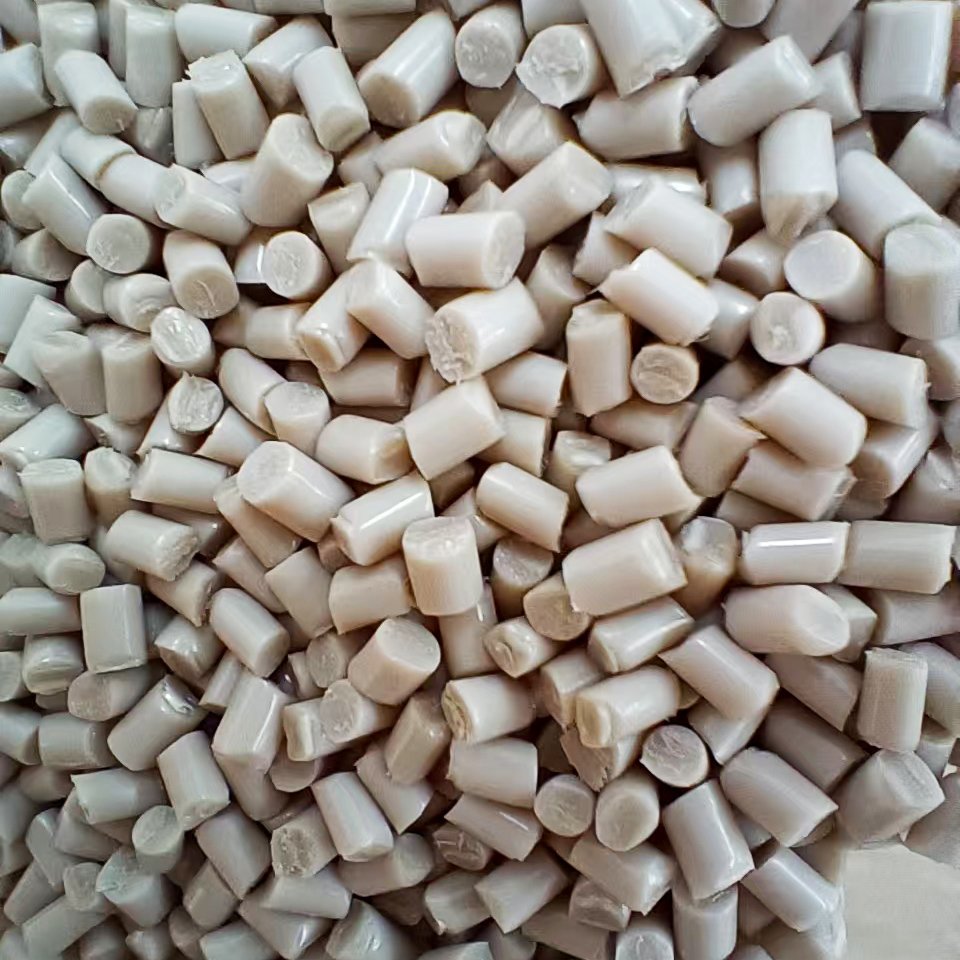

FLUTECK™ K300, supplied as a pelletized injection molding compound, exhibits excellent flowability and thermal stability, making it suitable for high-precision injection molding. Its stable melt properties at around 340°C make it suitable for molding complex molds and thicker parts.

Compared to traditional non-flame-retardant PEEK grades, K300 offers more controlled shrinkage and superior surface finish, reducing processing errors and post-processing complexity while maintaining high performance. This makes it ideal for automated and highly repeatable production lines.

III. Industry Applications: From Food Machinery to Medical Technology

1. Food Processing and Packaging Equipment

Its FDA certification and flame-retardant properties make it suitable for food conveying systems, heating trays, valve bodies, and thermal insulation supports. It is resistant to grease, steam, and chemical cleaning agents without releasing harmful substances.

2. Medical and Pharmaceutical Equipment

Maintaining stable performance in sterile environments is a top priority for medical device engineers. FLUTECK™ K300 can be used in surgical instrument holders, testing instrument supports, pump and valve components, and other applications. It can withstand multiple irradiation sterilization cycles without degradation.

3. Electrical and Electronics Industry

In high-temperature electrical environments, its insulation properties and low dielectric constant provide excellent insulation. It can be used in relay holders, sensor housings, and precision connectors to prevent arcing, leakage, and thermal aging.

4. Chemical and Energy Industry

Its resistance to chemical corrosion and permeation makes it suitable for manufacturing media-resistant pump bodies, compressor seals, and reactor linings. It also offers long-term stability against strong acids, alkalis, and solvents.

IV. FLUTECK™ K300 Data Sheet

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Romper | Norma ASTM D638 | 10 | % | |||

| Impacto de muesca Izod | Norma ASTM D256 | 85 | j/m | ||||

| Resistencia a la tracción | Rendimiento 23°C | Norma ASTM D638 | 95 | MPa | |||

| Módulo de tracción | Norma ASTM D638 | 3.3~4 | GPA (médico general) | ||||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| Coeficiente de conductividad térmica | 23℃ | ASTM E1530 | 0.25 | W/(m·K) | |||

| Calor específico | 23℃ | 2.2 | kJ/(kg·℃) | ||||

| HDT | Sin recocer 1,80 MPa | Norma ASTM D648 | 157 | ℃ | |||

| Temperatura de fusión | Norma ASTM D3418 | 340~343 | ℃ | ||||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Absorción de agua | 24 horas | Norma ASTM D570 | 0.10 | % | |||

| Contracción | Fluir | Norma ASTM D955 | 1~1.3 | % | |||

| Densidad | Norma ASTM D792 | 1.300~1.32 | gramos/cm³ | ||||

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |||

| Resistividad volumétrica | Norma ASTM D257 | 1E17 | Ω.cm | ||||

| Resistividad superficial | Norma ASTM D257 | 1E17 | Ω | ||||

| Dureza | Condición | Estándar | Valor | Unidad | |||

| Dureza Rockwell | M(Escala) | Norma ASTM D785 | 90 | ||||

| Dureza Shore D | ASTM D2240 | 80 | |||||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Clasificación de llama | UL94 | V-0 | |||||

V. Regulations and Sustainable Manufacturing

As global manufacturing continues to trend toward sustainability, the recyclability and long lifespan of peek plastic materials make them a key alternative to metal and multi-layer composites.

FLUTECK™ K300 is FDA-compliant and contains no banned ingredients under EU RoHS and REACH environmental regulations, meeting the green compliance requirements of international production lines.

Its long service life reduces equipment replacement frequency, lowering overall energy consumption and maintenance costs throughout its lifecycle, making it an ESG-compliant engineering material choice.

VI. Similar Recommendations

| Fabricante | Modelo de producto | Peso específico | Resistencia a la tracción | Alargamiento | Contracción | Temperatura de fusión | Módulo de tracción | Dureza Shore D | Temperatura de deflexión térmica | Dureza Rockwell | Notched Izod Impact Strength | Linear Expansion Coefficient |

| BARLOG | XF1730 | 1.51 g/cm³ | 0.3 % | 343 ℃ | 11800 MPa | 328 ℃ | ||||||

| BARLOG | XS1700 | 1.3 g/cm³ | 1 % | 343 ℃ | 3100 MPa | 150 ℃ | ||||||

| BARLOG | XC1730 | 1.4 g/cm³ | 0.2 % | 343 ℃ | 23500 MPa | 310 ℃ | ||||||

| Centroplast | Polyetheretherketone | 1.31 g/cm³ | 110 MPa | 20 % | 340 °C | 4400 MPa | 160 °C | 105 | 5E-5 cm/cm/°C | |||

| Fluorseals | K304 | 1.40 g/cm³ | 75 MPa | 5 % | 342 ℃ | 3 GPa | 84 | 150 ℃ | 90 | 50 J/m | 5.5E-5 cm/cm/℃ |

VII. Frequently Asked Questions (FAQs)

Q1: What is the difference between FLUTECK™ K300 and standard PEEK?

A: It is a flame-retardant PEEK-FR grade, UL94 V-0 certified, and safe for use in food, medical, and electronics applications. Compared to standard PEEK, it prioritizes safety and stability.

Q2: What brands and models can it replace?

A: It can replace flame-retardant PEEK grades such as Victrex and Solvay. Juyuan can assist with performance comparisons and alternative selection.

Q3: Are there any process requirements for injection molding or extrusion?

A: No special equipment is required; a standard high-temperature injection molding machine is sufficient. Juyuan can provide recommended temperatures, mold design, and processing advice.

Q4: What are the advantages of purchasing from Juyuan?

A: Juyuan provides stock availability, process consulting, international logistics, and sample testing services, enabling customers to quickly evaluate and scale production.

VIII. Why Choose Fluorseals and Juyuan

Fluorseals specializes in fluoropolymers and high-end engineering plastics. Its FLUTECK™ series is widely used in the pharmaceutical, energy, and semiconductor industries for its high purity and batch stability.

As an international plastic raw material trader, Juyuan provides global customers with a stable supply of Fluorseals PEEK series, professional selection advice, and small-batch customization support.

For engineers and buyers seeking a reliable source, Juyuan offers a full-process solution, from material consulting and sample testing to long-term supply.

【Recomendaciones relacionadas】

Solvay GATONE™ 5600: Flame-Retardant PEEK Natural Material Más información>

Hippe PEEK BG: Balancing Rigidity & Heat Resistance PEEK Engineering Plastic Más información>

Plastic Bottle Bottom Labels: The True Meaning Behind the Triangle Arrow Numbers Más información>