I. Process Overview

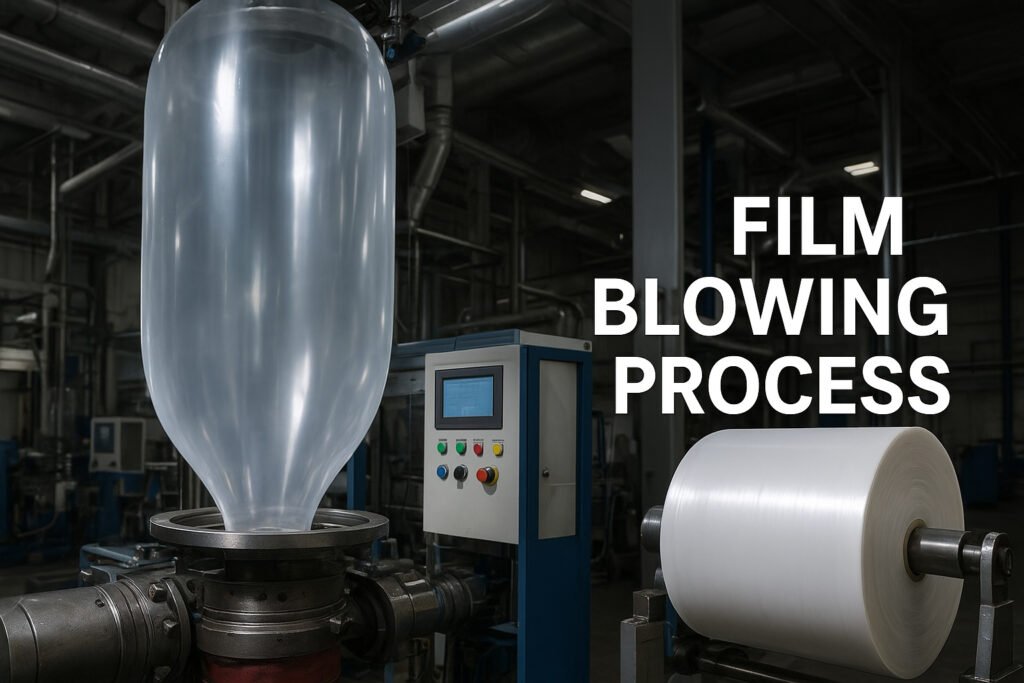

Blown Film forming (film Blowing) is one of the most core processes in the plastic packaging industry and is widely used in food packaging films, agricultural mulching films, shrink films and functional barrier films. This process involves heating and melting plastic particles, extruding them into cylindrical films through the die head of an extruder, then inflating them into shape by air pressure, cooling and setting them, and winding them up. The blown film forming process features high production efficiency and strong product applicability, and it is the mainstream method for global film manufacturing.

Ii. Process Flow

Raw material preparation: Plastic raw material particles (such as PE, PÁGINAS, EVA) need to be dried and screened to ensure stability during the melting process.

Extrusion melting: The particles are heated and plasticized in the screw and then stably discharged by the melt pump.

Moldeo por soplado: The die head extrudes to form a tubular melt, and air is blown in to create bubbles.

Cooling and setting: Air ring cooling is used to solidify the film surface, enhancing transparency and strength.

Traction winding: The film is stretched by traction to adjust the molecular orientation and the finished product is wound up.

Iii. Common Defects and Improvement Measures

Uneven Thickness

・Phenomenon: There are thickness differences in the film either horizontally or vertically, which affects its strength and printing effect.

・Reasons: Die head clearance deviation, unstable bubbles, uneven cooling air ring.

・Improvement measures: Introduce automatic thickness control (AGC/IBC system); Optimize the structure of the cooling air ring; Select raw materials with uniform molecular weight distribution (MWD).

・Our advantages: We supply PE/PP resins with stable fluidity and molecular weight distribution, ensuring consistent film thickness, helping customers reduce scrap rates and lower costs.

Bubble Breakage

・Phenomenon: Frequent bubble rupture leads to machine shutdown and waste of raw materials.

・Reasons: Insufficient melt strength of the resin, high moisture content, and contamination by impurities.

・Improvement measures: Select resins with high molecular weight and excellent resistance to stress cracking; Dry the raw materials to less than 200 ppm; Ensure the purity of raw materials.

・Our advantages: We offer vacuum packaging raw materials with high cleanliness and low moisture content, and can recommend PE resin models suitable for high-strength blown film, helping customers enhance production stability.

Haze & Poor Clarity

・Phenomenon: The film has high haze and poor transparency, making it unsuitable for high-end packaging.

・Reasons: High crystallinity, uneven cooling or poor optical properties of the resin.

・Improvement measures: Use high-transparency PEBD, mPE or copolymers; Add optical masterbatch; Increase the cooling air velocity.

・Our advantages: We can supply high-transparency PE resins and optically modified masterbatches, suitable for food and pharmaceutical packaging, helping customers differentiate themselves in the high-end market.

Creases and Streaks (Wrinkles & Streaks)

・Phenomenon: Streaks or wrinkles appear on the film surface, affecting printing and lamination.

・Reasons: Unstable traction speed, die head contamination, and uneven melt temperature distribution.

・Improvement measures: Use a constant tension traction system; Clean the die head regularly; Optimize the control of melt temperature.

・Our advantages: We offer high-quality blown film grade raw materials with low gel content, reducing the risk of streaks and black spots, ensuring a smooth and consistent film surface, and enhancing the efficiency of subsequent printing and lamination.

Bright spots or pockmarks on the film surface (Fish Eyes/Gels)

・Phenomenon: Bright spots, black dots or pockmarks appear on the film, affecting its appearance and mechanical properties.

・Reason: There are unmelted particles or gels in the raw materials. There are burnt substances at the die mouth. The raw materials are unevenly mixed.

・Improvement measures: Replace the filter screen with a finer one; Regularly clean the screw and die head; Optimize the proportion of raw materials.

・Our advantages: We offer high-purity raw materials that are strictly screened and filtered to ensure the cleanliness of the film surface and help customers meet food and medical grade film standards.

Iv. Application Fields

Película de embalaje: Food, daily chemical, industrial packaging;

Películas agrícolas: greenhouse films, mulching films;

Functional films: barrier films, shrink films, multi-layer composite films.

V. Our Supply Advantages

As a professional supplier of plastic raw material pellets, we not only provide high-quality raw materials but also help our customers solve practical production problems

Batch stability: Strictly control the melt index and molecular weight distribution to ensure consistency.

Low moisture content guarantee: Factory inspection and vacuum packaging to reduce bubble and hole defects.

Multi-category supply: One-stop solutions for PE, PÁGINAS, EVA, and functional masterbatches.

International service experience: Covering multiple markets and providing comprehensive logistics and after-sales support.

Technical support: Based on the customer's process, recommend the most suitable resin model to enhance production efficiency.

Vi. Summary

Film Blowing blown film process is an indispensable link in the plastic packaging industry, but process defects often lead to cost increase and quality fluctuation. Only by choosing stable blown film grade raw materials and optimizing process parameters can the transparency, strength and consistency of the product be ensured. As a professional supplier of plastic raw materials, we not only deliver high-quality resins but also help international purchasers enhance their competitiveness through technical support and one-stop services.