PRODUCTOS

EDGETEK™ RA-10GF-10CF/000 HI High Strength PPSU Resin

Estructura del producto

EDGETEK™ RA-10GF-10CF/000 HI

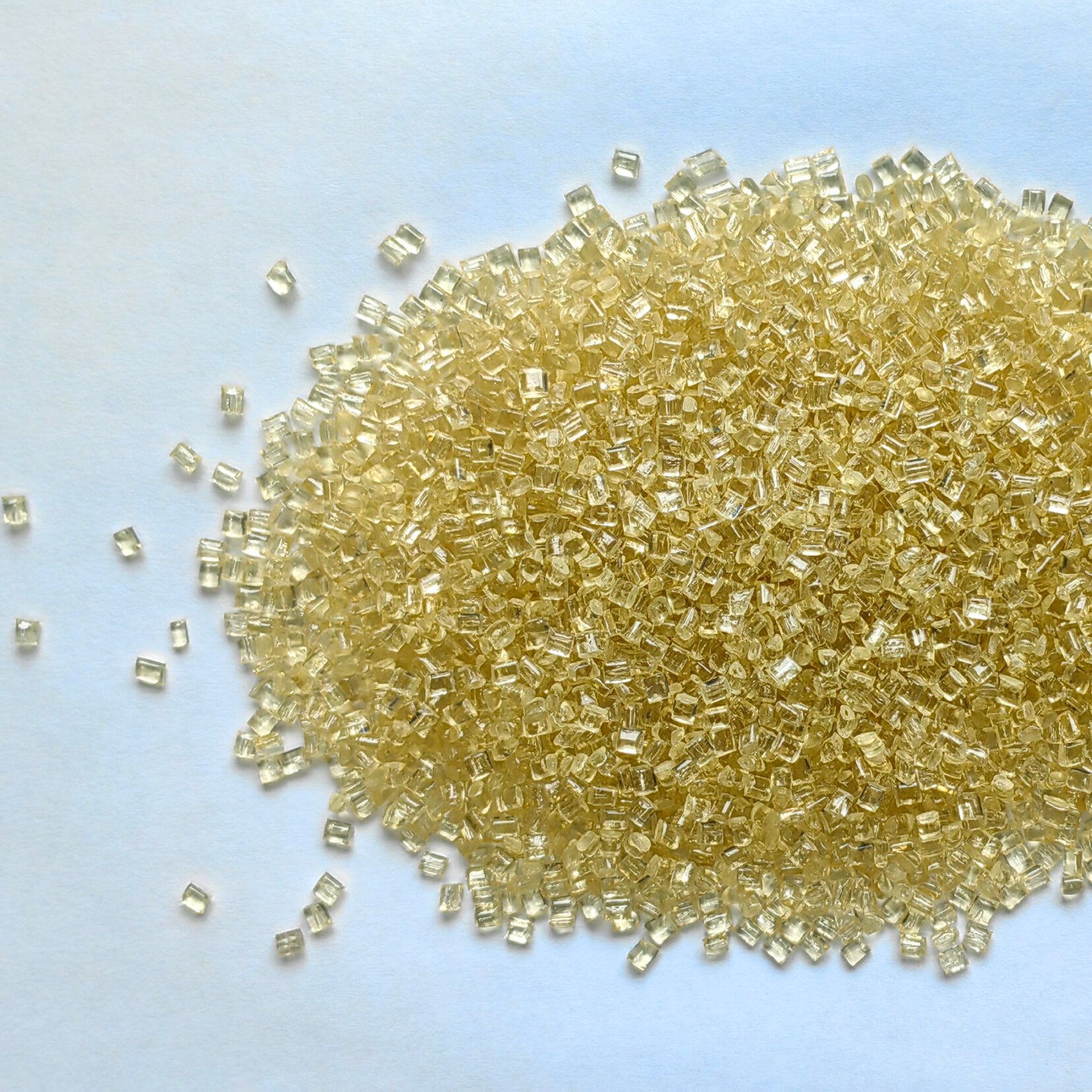

Avient's EDGETEK™ PPSU RA-10GF-10CF/000 HI is a glass fiber + carbon fiber reinforced polysulfone (PPSU) composite material. This material combines the inherent advantages of PPSU such as high-temperature resistance, flame retardancy, and hydrolysis resistance. At the same time, it introduces dual reinforcement of glass fiber and carbon fiber, significantly enhancing mechanical properties and structural stability. It is widely applicable to high-demand applications in electronics and electrical, automotive, medical, and industrial fields.

1. Material Highlights and Characteristics

High-strength reinforcement: Bending strength 190 MPa, tensile strength 121 MPa, meeting the requirements of high-load structural components.

Excellent rigidity and dimensional stability: The flexural modulus is as high as 6890 MPa, the shrinkage rate is as low as 0.10 to 0.15%, and the formed parts have almost no deformation.

Outstanding flame retardant performance: UL94 V-0 grade, meeting strict safety standards.

Outstanding heat resistance: The heat distortion temperature (HDT) is as high as 213℃, allowing it to withstand high-temperature environments for a long time.

Good impact resistance: The notched impact value of the cantilever beam is 110 J/m, balancing rigidity and toughness.

Stable electrical performance: Surface resistance 1E6 Ω, suitable for application scenarios with requirements for electrical insulation.

2. In-depth Performance Interpretation

Mechanical properties

・Through the synergistic reinforcement of 10% glass fiber and 10% carbon fiber, the material significantly increases modulus and strength while maintaining toughness, making it particularly suitable for structural components in high-stress environments.

Thermal performance

・PPSU itself has outstanding heat resistance, and after annealing treatment, its heat distortion temperature can reach as high as 213℃, ensuring that the material remains stable in high-temperature environments.

Flame Retardancy and Safety

・It meets the UL94 V-0 flame retardant grade, ensuring safe application in electronic and electrical equipment as well as automotive components.

Processing performance

・The injection molding process is friendly, and the low shrinkage rate ensures high precision of the products, making it suitable for mass production of complex structural parts.

3.Typical Application Fields

Industria automotriz: High-temperature zone components, structural parts, and electronic module housings.

Electronic and electrical: Heat-resistant and flame-retardant components, connectors, insulating housings.

Medical devices: High-strength surgical tool components, reusable sterilizable equipment casings.

Industrial equipment: Mechanical components that are resistant to chemicals and impacts.

4. EDGETEK™ PPSU RA-10GF-10CF/000 HI Data Sheet

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Break 5.1mm/min | Norma ASTM D638 | 4.0 | % | |||

| Resistencia a la flexión | Norma ASTM D790 | 190 | MPa | ||||

| Módulo de flexión | Norma ASTM D790 | 6890 | MPa | ||||

| Impacto de muesca Izod | 23 ℃ 6,40 mm | Norma ASTM D256 | 110 | j/m | |||

| Resistencia a la tracción | Break 5.1mm/min | Norma ASTM D638 | 121 | MPa | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| HDT | Annealing 1.80MPa 3.20mm | Norma ASTM D648 | 213 | ℃ | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Contracción | xFlujo | Norma ASTM D955 | 0.10~0.15 | % | |||

| Densidad | Norma ASTM D792 | 1.40 | gramos/cm³ | ||||

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |||

| Resistividad superficial | Norma ASTM D257 | 1E6 | Ω | ||||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Clasificación de llama | UL94 | V-0 | |||||

5. Process and Processing Advantages

Compatible with injection molding: Suitable for mass production of complex structural parts.

High Dimensional Precision: Extremely low shrinkage ensures consistent molded parts.

Excellent Surface Quality: Carbon fiber reinforcement improves both the material's appearance and structural stability.

6. Innovation and Industry Competitiveness

Compared to traditional unreinforced PPSU or single glass fiber reinforced PPSU, the dual-reinforcement system (GF+CF) offers superior strength, modulus, and heat resistance, making it particularly suitable for high-end applications with demanding performance requirements. As a globally renowned supplier of high-performance materials, Avant guarantees stable quality and supply chain.

7. Customer Feedback

Feedback from selected customers:

・"Compared to standard PPSU, RA-10GF-10CF/000 HI offers superior dimensional stability and thermal shock resistance."

・"During mass injection molding, product consistency and flame retardancy safety fully meet international customer standards."

8. FAQ Frequently Asked Questions

Q1: Can this material be used in long-term high-temperature environments?

A1: Yes, the heat distortion temperature is 213℃, and it can be stably used for a long time at high temperatures.

Q2: How does the enhancement effect compare with pure PPSU?

A2: The mechanical strength and rigidity have been significantly enhanced, while maintaining toughness and flame retardancy.

Q3: Does it comply with international safety certifications?

A3: The material meets the UL94 V-0 flame retardant grade and is suitable for global market applications.

9. Recommendations for Similar Materials

| Grade / Model | Density (g/cm³) | Tensile Strength (MPa) | Tensile Modulus (MPa) | Flexural Strength (MPa) | Notched Impact Strength | Heat Deflection Temp (℃, 1.8MPa) | Clasificación de llama |

| Centroplast Polyphenylensulfone | — | 105 | 3400 | — | 3.5 kJ/m² (ISO 179) | 190 | V-0 (3mm/6mm) |

| Stratasys Polyphenylsulfone | 1.28 | 55 | 2068 | 110 | 58.73 J/m (ASTM D256) | 189 | V-0 (3.2mm) |

10. Our Advantages as an Export Supplier

First-hand supply source: Direct connection with the original factory to ensure genuine products and stable supply.

Global export experience: Familiar with market standards in Europe, America and Asia, and supports customized solutions.

Technical support: Provide performance comparison, application recommendation, and processing technology guidance.

Efficient logistics: Quick delivery to meet customers' urgent needs.

【Recomendaciones relacionadas】

RADEL® 5500 Black – Multi-Color Medical-Grade PPSU Material Más información>

TECASON P MT Polyphenylsulfone for Medical & Industrial Use Más información>

FDA Food Grade Plastics: A Must-Read for Purchasing Food-Grade Plastics Más información>