PRODUCTOS

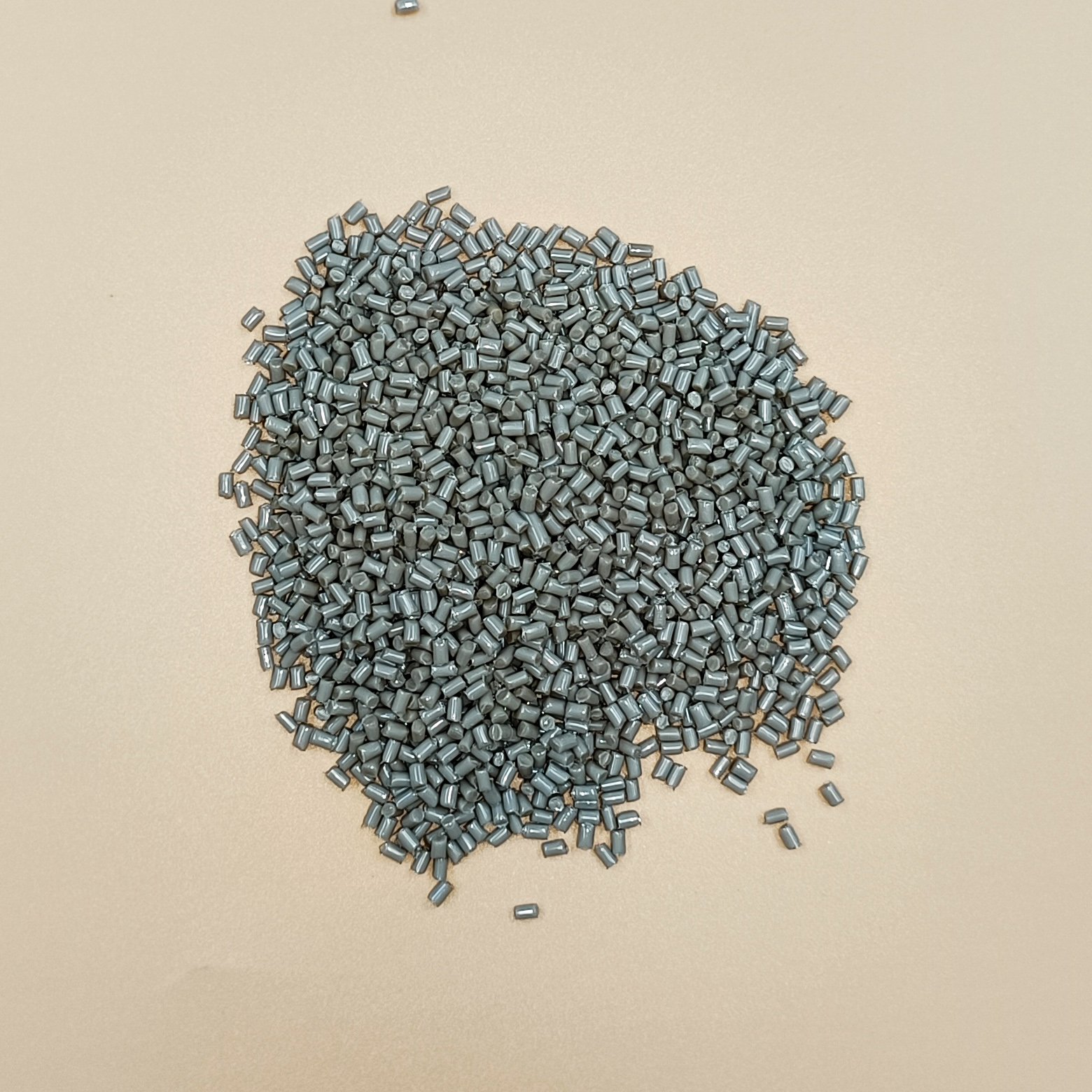

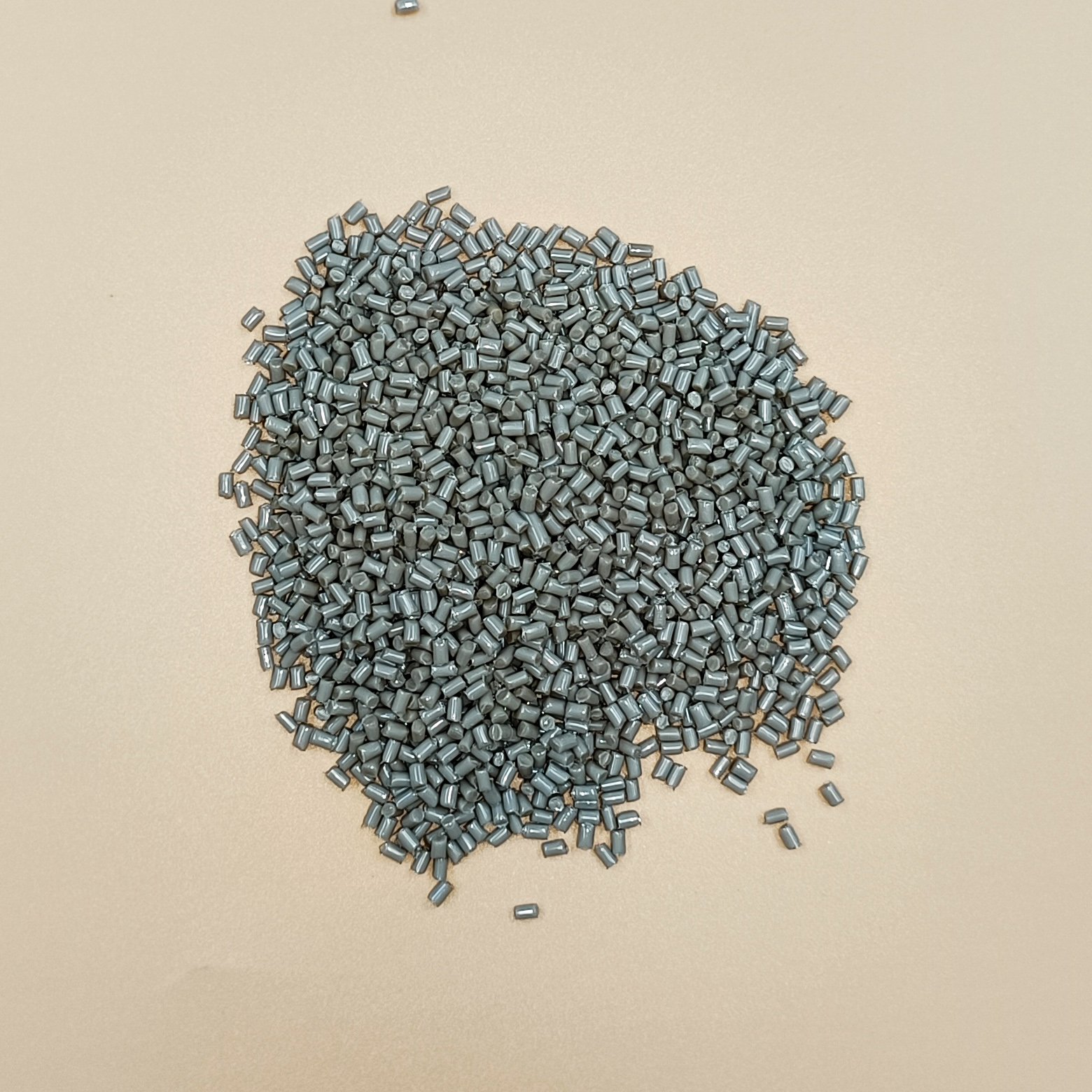

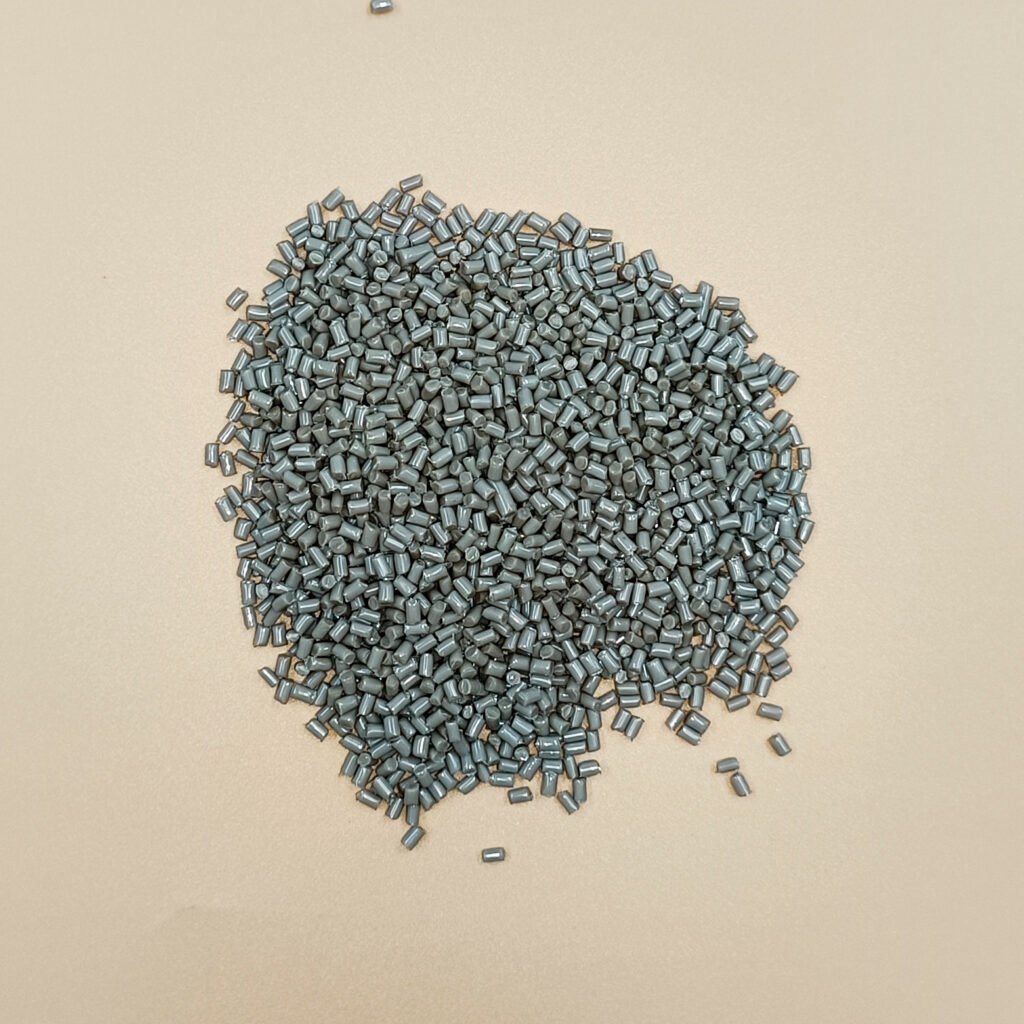

ColorRx® PEEK-3000RX: Medical-Grade PEEK Raw Material

Estructura del producto

What is PEEK Raw Material

ColorRx® PEEK-3000RX is a peek raw material for the medical industry under AURUMICHEM. This material demonstrates stable and reliable performance in the field of high-standard medical devices due to its excellent biocompatibility, chemical corrosion resistance and radiation resistance. With its balanced mechanical strength and thermal stability, it has become an ideal material choice for the manufacturing of disposable medical supplies, implant-grade components and surgical auxiliary instruments.

1. Overview of material properties

ColorRx® PEEK-3000RX is a high-purity system of unfilled grade PEEK, produced through a precisely controlled polymerization process to ensure batch-to-batch consistency and low precipitation characteristics. Its main features include:

・Excellent biocompatibility: Complies with multiple biological testing standards and can be in long-term contact with human tissues or body fluids.

・Excellent chemical stability: Resistant to acids, alkalis, alcohol and various disinfectants;

・Gamma-ray and ethylene oxide sterilization resistance: It can maintain mechanical and appearance properties during multiple sterilization cycles.

・Medium to high flow characteristics: Melt index (MI) 36 g/10min (400°C/2.16kg), facilitating micro-injection molding of complex medical devices;

・High thermal stability: The heat distortion temperature reaches 320°F (approximately 160°C), making it suitable for high-temperature operations and sterilization environments.

2. Performance analysis

ColorRx® PEEK-3000RX maintains material purity while still featuring excellent mechanical balance:

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Rendimiento 50 mm/min | Norma ASTM D638 | 5.2 | % | |||

| Alargamiento | Rotura 50 mm/min | Norma ASTM D638 | 10~20 | % | |||

| Resistencia a la flexión | 50 mm/min | Norma ASTM D790 | 22000 | psi | |||

| Módulo de flexión | 50 mm/min | Norma ASTM D790 | 550000 | psi | |||

| Impacto de muesca Izod | 23℃ | Norma ASTM D256 | 0.95 | ft-lb/pulgada | |||

| Resistencia a la tracción | Rendimiento 50 mm/min | Norma ASTM D638 | 14400 | psi | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| HDT | Recocido 1,8 MPa | Norma ASTM D648 | 320 | ℉ | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Absorción de agua | 24 horas | Norma ASTM D570 | 0.10 | % | |||

| Contracción | Flow 3.20mm | Norma ASTM D955 | 0.014~0.016 | in/in | |||

| Densidad | Norma ASTM D792 | 1.30 | gramos/cm³ | ||||

| Índice de fusión | 400℃ 2.16kg | Norma ASTM D1238 | 36 | g/10min | |||

| Dureza | Condición | Estándar | Valor | Unidad | |||

| Dureza Rockwell | R(Escala) | Norma ASTM D785 | 102 | ||||

These performance data indicate that the peek raw material achieves a good balance between flexibility and rigidity, and is highly suitable for medical device structural components that require impact resistance and anti-deformation.

3. Processing suggestions

ColorRx® PEEK-3000RX is mainly produced by injection molding. Its high melt fluidity makes it suitable for multi-cavity molds and precision injection molding production. Recommended processing conditions

・Barrel temperature: 370-400°C

・Mold temperature: 160-200°C

・Drying conditions: 3 to 4 hours at 150°C

・Recommended Screw Speed: Medium to prevent shear degradation

in mold design, the low shrinkage rate of the material (0.014-0.016 in/in) should be taken into account to ensure dimensional accuracy and surface flatness.

4. Application performance in the medical field

Thanks to its chemical inertness and stability, ColorRx® PEEK-3000RX has been widely used in:

・Disposable medical devices (such as catheter connectors, fixtures, and connecting parts);

・Reusable sterilizable medical care supplies;

・Surgical support instruments, joint components of medical robots;

・Temporary implants or non-long-term contact medical components.

Its gamma-ray resistance performance enables this peek raw material to adapt to the diverse sterilization process requirements in the modern medical industry, including irradiation, steam and ethylene oxide.

5. Market Trends and Material advantages

As global medical devices move towards "lightweight, precision and repeatable sterilization", PEEK materials are gradually replacing traditional metals and engineering plastics such as PPSU and PEI.

ColorRx® PEEK-3000RX, with its stable physical properties and excellent flow processability, offers medical device manufacturers more flexible design space and a higher safety factor.

For the medical-grade plastic supply chain, choosing compliant, stable and traceable peek raw material has become the core standard for international procurement.

6. Similar recommendations

If your application requires PEEK materials of different grades, Juyuan can also provide

| Product Series | Modelo de producto | Densidad | Resistencia a la tracción | Alargamiento | Contracción | Módulo de tracción | HDT | Notched Izod Impact Strength | Módulo de flexión | Unnotched Izod Impact Strength | Resistencia a la flexión | Notched Impact Strength |

| InStruc™ | PEEKGF30 | 1.53 g/cm³ | 23000 psi | 2.0~3.0 % | 0.002~0.004 in/in | 1500000 psi | 600 ℉ | 2.0 ft-lb/in | 1500000 psi | 18 ft-lb/in | 40000 psi | 10.89 kJ/m² |

| InElec™ | PEEKCNT5 | 1.32 g/cm³ | 15000 psi | 5.0~6.0 % | 650000 psi | 1.0 ft-lb/in | 700000 psi | 30000 psi | 5.44 kJ/m² | |||

| InStruc™ | PEEKBS6 | 1.33 g/cm³ | 13000 psi | 9.0 % | 0.010~0.013 in/in | 600000 psi | 340 ℉ | 1.2 ft-lb/in | 500000 psi | 15 ft-lb/in | 17500 psi | 6.53 kJ/m² |

| InStruc™ | PEEKGF30HFMD | 1.53 g/cm³ | 23000 psi | 2.0~3.0 % | 0.002~0.004 in/in | 1500000 psi | 600 ℉ | 2.0 ft-lb/in | 1500000 psi | 18 ft-lb/in | 40000 psi | 10.89 kJ/m² |

7. Conclusion: Juyuan's professional supply advantages

As a supplier with 24 years of international trade experience in plastic raw materials, Juyuan is committed to providing high-quality and traceable peek raw material for customers in the medical industry. We not only focus on product performance, but also provide global technical support and rapid response delivery services to help customers achieve reliable production and continuous innovation in high-demand application fields.

【Recomendaciones relacionadas】

VESTAKEEP® 2000FC30: Composite Lubrication Natural PEEK Material Más información>

VESTAKEEP® PEEK 2000GF30: Natural PEEK for High-Rigidity Structural Applications Más información>

The Role of Plastic Raw Materials in Fishing Nets: A Deep Dive into PA6 Más información>