PRODUCTOS

BASF PSU 2010 | High Flowability PSU Polysulfone for Household

Estructura del producto

What is PSU Polysulfone

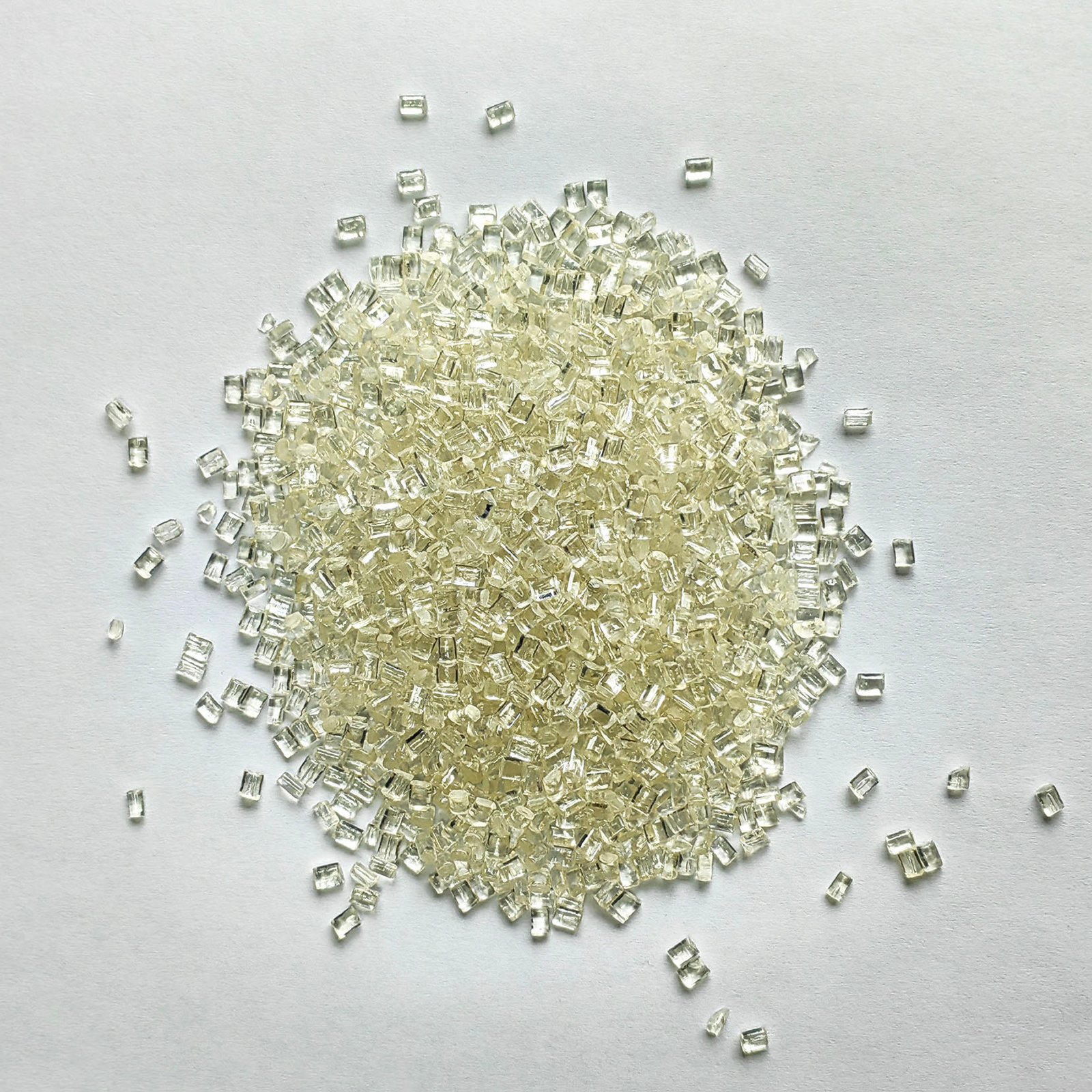

Basf PSU 2010 is a flame-retardant grade PSU Polysulfone material, marked as PSU-FR, in granular form, suitable for injection molding process. This material features medium viscosity, flame retardancy, high-temperature resistance, dimensional stability and other characteristics. It has good fluidity. The unreinforced formula ensures stable processing performance even in complex mold designs. Its typical applications cover household items, automotive electronic connectors, electrical components and other fields with strict requirements for heat resistance and safety.

01 | Material Highlights and Characteristics

Flame retardant performance: Flame retardant grade HB - V2, which can meet the safety standards of various electrical and automotive applications.

Heat resistance performance: High heat resistance grade design, maintaining stable mechanical strength in long-term working environments.

Dimensional stability: Small deformation under high temperature and load conditions, ensuring the long-term reliability of components.

Processing adaptability: Medium-viscosity granules with excellent fluidity, suitable for injection molding of complex structural parts.

Non-reinforced formula: Maintains good toughness and molding flexibility, suitable for the requirements of lightweight and precision parts.

02 | PSU Polysulfone Basf Ultrason®S 2010 Data Sheet

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |||

| CTI | IEC 60112 | 125 | V | ||||

| Dieléctrico | Fortaleza | CEI 60243 | 40 | kilovoltios/mm | |||

| Dieléctrico | Constante 100 Hz | IEC 60250 | 3.1 | ||||

| Dieléctrico | Constante | IEC 60250 | 3.1 | ||||

| Disipación | Factor de 100 Hz | IEC 60250 | 8 | ||||

| Disipación | Factor 1 MHz | IEC 60250 | 64 | ||||

| Superficie | Resistividad | CEI 60093 | 1E+15 | Ω | |||

| Volumen | Resistividad | CEI 60093 | 1E+13 | Ω.cm | |||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Fuego | Clasificación de todos los colores 0,75 mm | UL94 | media pensión | ||||

| Fuego | Clasificación Todos los colores 1,5 mm | UL94 | media pensión | ||||

| Fuego | Clasificación Todos los colores 3,0 mm | UL94 | V-2 | ||||

| Dureza | Condición | Estándar | Valor | Unidad | |||

| Pelota | Indentation Hardness | ISO 2039 | 135 | MPa | |||

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Charpy | Impacto de muesca -30°C | ISO 179 | 6 | kJ/m² | |||

| Charpy | Impacto de muesca 23°C | ISO 179 | 5.5 | kJ/m² | |||

| Charpy | Impacto sin muesca -30°C | ISO 179 | NÓTESE BIEN | kJ/m² | |||

| Charpy | Impacto sin muesca 23°C | ISO 179 | NÓTESE BIEN | kJ/m² | |||

| Alargamiento | Rendimiento 23°C | ISO 527 | 6 | % | |||

| Izod | Muesca de impacto -30°C | ISO 180 | 6 | kJ/m² | |||

| Izod | Impacto de muesca 23°C | ISO 180 | 5.5 | kJ/m² | |||

| De tensión | Módulo 23°C | ISO 527 | 2550 | MPa | |||

| De tensión | Resistencia Rendimiento 23°C | ISO 527 | 75 | MPa | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Densidad | ISO 1183 | 1.23 | gramos/cm³ | ||||

| Derretir | Índice 360°C 10kg | ISO 1133 | 90 | cm³/10min | |||

| Contracción | Fluir | ISO 294 | 0.68 | % | |||

| Contracción | xFlujo | ISO 294 | 0.72 | % | |||

| Agua | Absorción 50RH | ISO 62 | 0.3 | % | |||

| Agua | Absorption Saturation | ISO 62 | 0.8 | % | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| CLE | Fluir | MÉTODO INTERNO | 5.3E-5 | cm/cm/°C | |||

| HDT | 1,8MPa | ISO 75 | 176 | °C | |||

| UL | Condición | Estándar | Valor | Unidad | |||

| Arco | Resistencia | ASTM D495 | 6 | SOCIEDAD ANÓNIMA | |||

| Comparativo | Índice de seguimiento | IEC 60112 | 3 | SOCIEDAD ANÓNIMA | |||

| Dieléctrico | Fortaleza | Norma ASTM D149 | 50 | kilovoltios/mm | |||

| Dimensional | Estabilidad | UL746 | 0.0 | % | |||

| Hola | TODOS 0,75 mm | UL 746A | 1 | SOCIEDAD ANÓNIMA | |||

| Hola | TODOS 1,5 mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| Hola | TODOS 3,0 mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| Alta Velocidad | UL 746A | 2 | SOCIEDAD ANÓNIMA | ||||

| HWI | TODOS 0,75 mm | UL 746A | 3 | SOCIEDAD ANÓNIMA | |||

| HWI | TODOS 1,5 mm | UL 746A | 3 | SOCIEDAD ANÓNIMA | |||

| HWI | TODOS 3,0 mm | UL 746A | 2 | SOCIEDAD ANÓNIMA | |||

| RTI | Eléctrico TODO 0,75 mm | UL 746B | 155 | °C | |||

| RTI | Imp TODO 0,75 mm | UL 746B | 130 | °C | |||

| RTI | Eléctrico TODOS 1,5 mm | UL 746B | 155 | °C | |||

| RTI | Diablillo TODO 1,5 mm | UL 746B | 130 | °C | |||

| RTI | Str TODOS 1,5 mm | UL 746B | 155 | °C | |||

| RTI | Eléctrico TODO 3.0mm | UL 746B | 155 | °C | |||

| RTI | Diablillo TODOS 3,0 mm | UL 746B | 130 | °C | |||

| RTI | Tira TODOS 3,0 mm | UL 746B | 155 | °C | |||

| UL | Clasificación de llama TODOS 0,75 mm | UL94 | media pensión | ||||

| UL | Clasificación de llama TODOS 1,5 mm | UL94 | media pensión | ||||

| UL | Clasificación de llama TODOS 3,0 mm | UL94 | V-2 | ||||

| Volumen | Resistividad | Norma ASTM D257 | 1.0E15 | Ω.cm | |||

03 | Technical Process Analysis

Basf PSU 2010 adopts injection molding process and is particularly suitable for high-precision and complex-structured products.

・Medium-viscosity particles: They have excellent melt fluidity during injection molding and can reduce the filling pressure.

・Mold compatibility: Good thermal stability can reduce dimensional shrinkage during the cooling process and enhance product consistency.

・Surface quality: The formed parts have a high degree of smoothness and are suitable for terminal applications with high requirements for appearance.

This makes Ultrason®S 2010 PSU Polysulfone perform well in small and complex structures such as automotive electronic connectors.

04 | Industry Application Scenarios

Household items: Excellent heat resistance and chemical resistance, suitable for kitchen and electrical components that need to be used for a long time.

Automotive electronics: Ensure the stability of electronic connectors and electrical components in the high-temperature engine compartment environment.

Electrical components: Flame retardancy and dimensional stability make it an ideal choice for insulators, housings and connectors.

05 | Market Trends and Customer Feedback

Recently, the demand for PSU Polysulfone in the fields of new energy vehicle electronics and smart home has been continuously increasing. Purchaser feedback: The triple advantages of "high heat resistance + flame retardancy + processing stability" of PSU 2010 have effectively solved:

・The pain point of plastic parts being prone to deformation in high-temperature environments

・The risk of electrical components not meeting the flame retardant grade standards

・The defect rate problem caused by insufficient fluidity in the injection molding process

06 | Procurement Process and FAQ

Q1: Is PSU 2010 suitable for high-temperature electrical environments?

A1: Yes, this material features high heat resistance and flame retardancy, making it suitable for long-term high-temperature working conditions.

Q2: Does this PSU Polysulfone material need additional reinforcement to be applied in automotive electronics?

A2: No need. The dimensional stability and fluidity of PSU 2010 have met the requirements of such applications.

Q3: How to ensure the stability of the supply chain?

A3: Through Juyuan's global channels, stable supply and rapid delivery support can be obtained.

Q4: What are the suitable processing methods?

A4: Injection molding is the main process, suitable for large-scale production of precision parts.

07 | Similar recommendation materials

| Fabricante | Product Grade | Densidad | Melt Flow Index | Resistencia a la tracción | Alargamiento | Contracción | Temperatura de fusión | Módulo de tracción | Temperatura de deflexión térmica | Notched Izod Impact | Linear Expansion Coefficient |

| BASF | 2010 G4 | 1.38 g/cm³ | 40 cm³/10min | 115 MPa | 2.90% | 0.31% | — | 6600 MPa | 184 °C | 8.0 kJ/m² | 2.6E-5 cm/cm/°C |

| BASF | 2010 G6 | 1.46 g/cm³ | 30 cm³/10min | 125 MPa | 2.20% | 0.29% | — | 8900 MPa | 185 °C | 8,5 kJ/m² | 2E-5 cm/cm/°C |

| BASF | 2010 NAT | 1.23 g/cm³ | 90 cm³/10min | 75 MPa | 6% | 0.68% | 330~390 °C | 2550 MPa | 176 °C | 5,5 kJ/m² | 5.3E-5 cm/cm/°C |

| BASF | 2010 G4 UN | 1.38 g/cm³ | 45 cm³/10min | 115 MPa | 2.90% | 0.31% | 350~390 °C | 6600 MPa | 184 °C | 8,5 kJ/m² | 2.6E-5 cm/cm/°C |

| BASF | 2010 G4 SW 15038 | 1.38 g/cm³ | 45 cm³/10min | 115 MPa | 2.50% | 0.31% | 350~390 °C | 6400 MPa | 184 °C | 8 kJ/m² | 2.6E-5 cm/cm/°C |

| BASF | 2010 G6 UN | 1.46 g/cm³ | 30 cm³/10min | 125 MPa | 2.20% | 0.29% | 350~390 °C | 8900 MPa | 185 °C | 8,5 kJ/m² | 2E-5 cm/cm/°C |

08 | The supply advantage of Juyuan

As a supplier with 24 years of international experience in plastic raw material trade, Juyuan is committed to providing customers with:

・Global direct procurement channels: Established stable cooperation with multiple international producers to ensure the authenticity of the goods and the continuity of supply.

・Customized services: Based on the customer's industry and application scenarios, provide selection suggestions and alternative solutions;

・Fast delivery: Relying on the international logistics network, shorten the procurement cycle and reduce the inventory pressure on customers;

・Technical support: Provide customers with process parameter references and application guidance to help enhance production stability.

【Recomendaciones relacionadas】

A Complete Guide to China’s Major Plastic Raw Material Procurement Hubs & Markets Más información>

RTP PSU EMI 961 Polysulfone Plastic for EMI & ESD Protection Más información>

Americhem PSU-GF30HF High-flow PSU Resin for Injection Molding Más información>