PRODUCTOS

BASF PPSU 3010 NAT Overview | Heat-Resistant PPSU Material

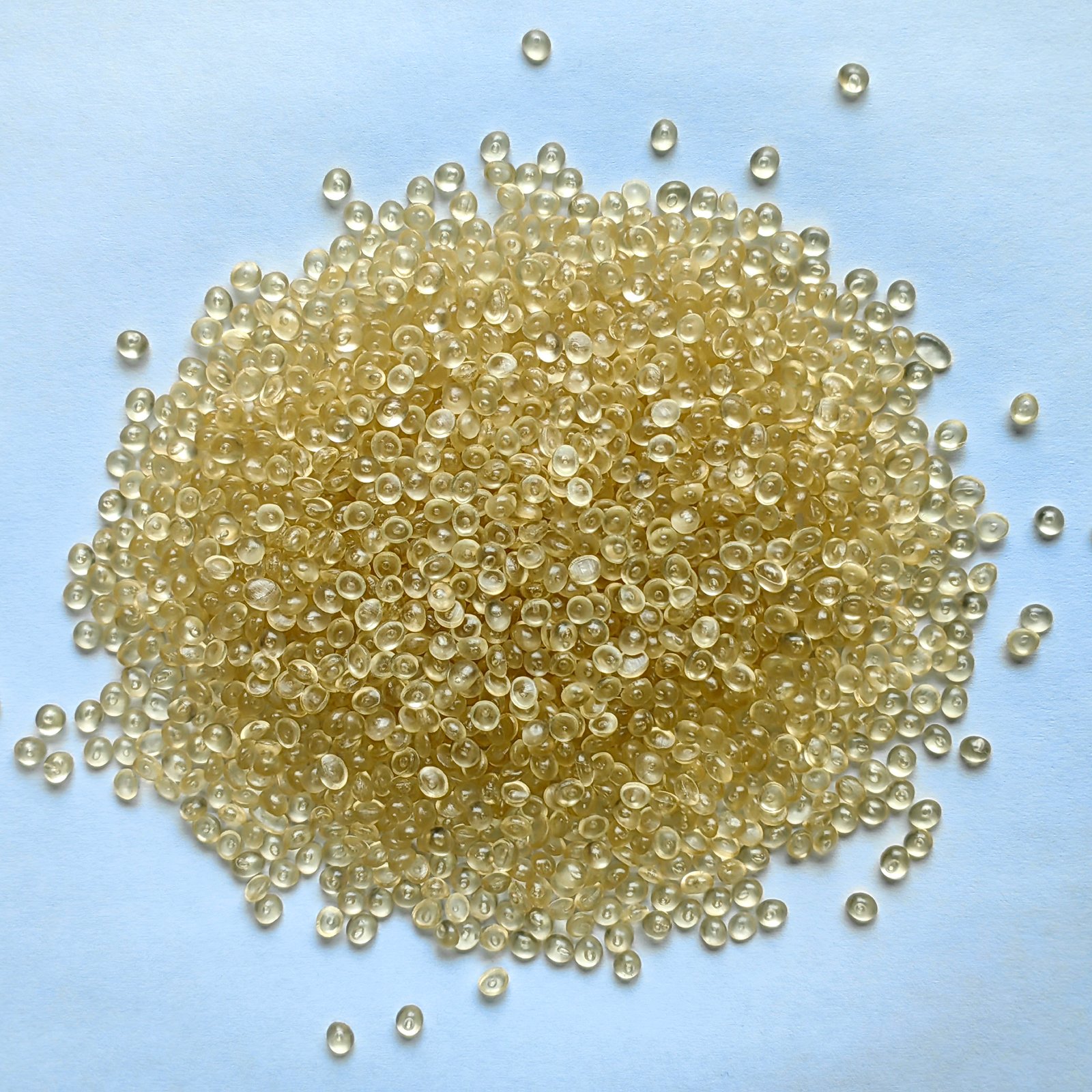

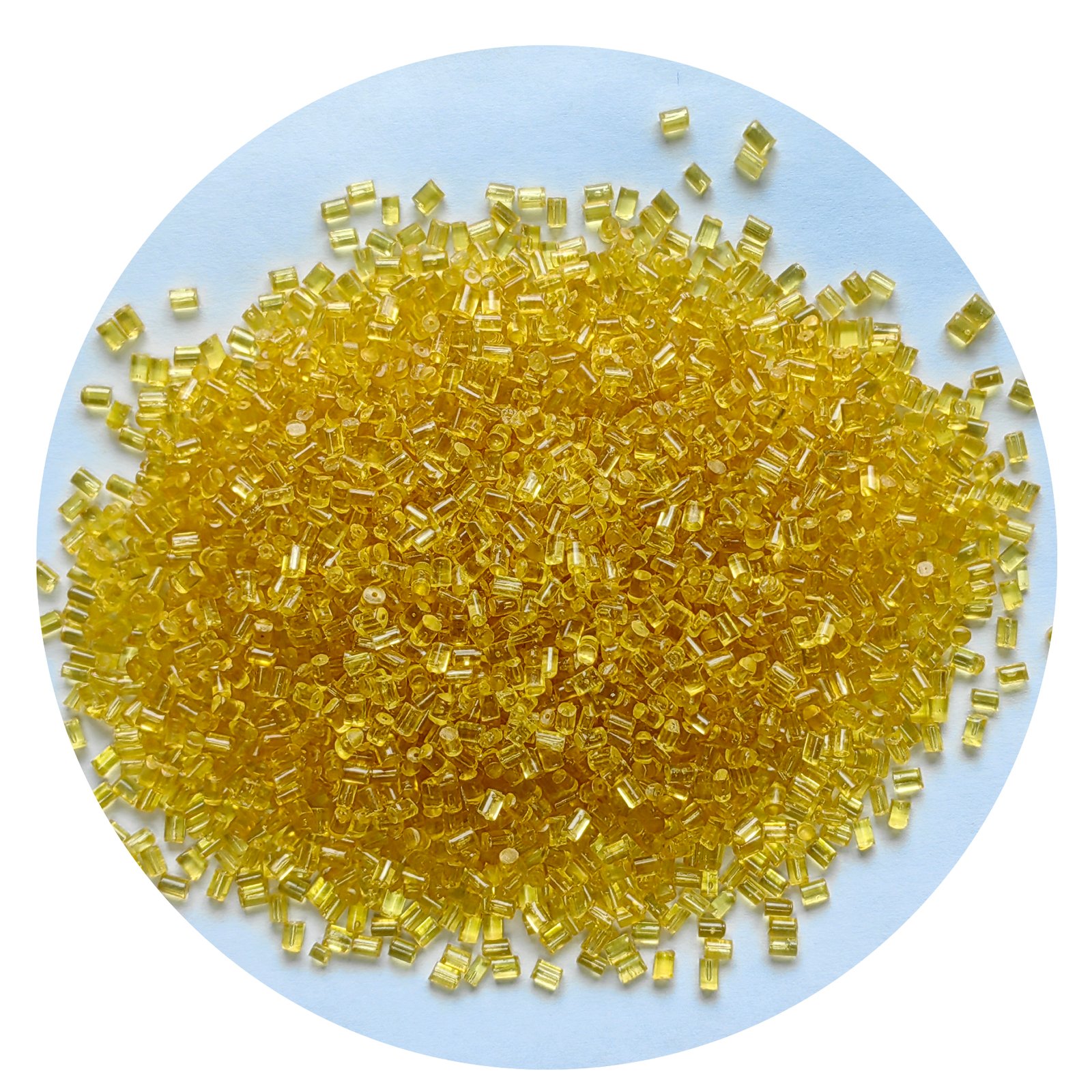

Estructura del producto

What is PPSU Material

In fields with extremely high material requirements such as high-end medical equipment, electronic and electrical components, and aviation applications, PPSU (polyphenylsulfone) materials have gradually become the main players in high-performance engineering plastics due to their excellent thermal stability, flame retardancy, and dimensional stability. This article will take BASF PPSU 3010 NAT as the core sample, from performance interpretation to application trends, to provide a full range of reference for material selectors.

01 | PPSU Material Technology Core Analysis: High Temperature, High Impact, High Stability

PPSU 3010 NAT is a non-reinforced high-viscosity injection molding grade PPSU material, which exhibits the following outstanding performance characteristics:

・Extremely high thermal stability: The glass transition temperature is as high as 220°C, and the heat deformation temperature (HDT) is 198°C. It can work for a long time in high temperature and high pressure environments, meeting the stringent requirements of steam sterilization.

・Excellent impact toughness: Even at low temperatures (-30°C), its simply supported beam notched impact strength still reaches 25 kJ/m², ensuring structural integrity.

・Flame retardant and halogen-free: UL94 V-0 flame retardant performance, and no halogen flame retardants are added, which is more in line with the current environmental protection and regulatory trends in the electrical and electronic industry.

・Outstanding chemical stability: Excellent resistance to cleaning agents, disinfectants, aliphatic solvents, etc., especially suitable for repeated cleaning scenarios such as medical and laboratories.

02 | Processing performance and process recommendations

As a high-viscosity injection molding grade PPSU, the processing of 3010 NAT has certain technical barriers, but it also brings excellent structural strength and surface quality. The following are processing recommendations:

| Processing Stage | Recommended Parameters |

| Melt Temperature | 350–390°C |

| Mold Temperature | ≥150°C, to prevent material cold spots and internal stress |

| Screw Shear Rate | Low shear, to avoid thermal degradation |

| Drying Conditions | 120°C for 4–6 hours (Moisture absorption rate: 1.2%) |

In addition, the melt index is 35 cm³/10min (360°C/10kg), and the fluidity performance is in the middle among similar PPSU materials. It is suitable for injection molding of medium and large structural parts and is recommended for multi-cavity molds or thick-walled products.

03 | Application Frontier: Medical, Aviation, and Electrical Scenarios Go Hand in Hand

Medical Equipment:

・Can be repeatedly sterilized with high-temperature steam (>1000 times)

・No deformation, discoloration, or brittle cracking

・Applicable to surgical instrument housings, blood filtration components, dental instruments, maternal and infant products, etc.

Aerospace:

・Can replace some metal parts, reduce weight while maintaining mechanical strength

・Low thermal expansion coefficient, suitable for precision connectors

Electrical and Electronics:

・UL V-0 flame retardant rating + high insulation (volume resistivity 1E+15 Ω·cm, insulation strength 44 kV/mm)

・CTI reaches 150V, suitable for applications that require arc resistance, such as wiring terminals, battery shells, and power converter shells

04 | PPSU material Technical Highlights

| UL | Condición | Estándar | Valor | Unidad | |||

| Clasificación de llama | NC BK 1,5 mm | UL94 | V-0 | ||||

| Clasificación de llama | NC BK 3,0 mm | UL94 | V-0 | ||||

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Rendimiento 50 mm/min | ISO 527 | 7.8 | % | |||

| Impacto de muesca Izod | 23ºC | ISO 180 | 55 | kJ/m² | |||

| Impacto de muesca Izod | -30°C | ISO 180 | 25 | kJ/m² | |||

| Resistencia a la tracción | Rendimiento 50 mm/min | ISO 527 | 74 | MPa | |||

| Módulo de tracción | ISO 527 | 2250 | MPa | ||||

| Impacto Charpy sin muesca | 23ºC | ISO 179 | NÓTESE BIEN | kJ/m² | |||

| Impacto Charpy sin muesca | -30°C | ISO 179 | NÓTESE BIEN | kJ/m² | |||

| Impacto con entalla Charpy | 23ºC | ISO 179 | 75 | kJ/m² | |||

| Impacto con entalla Charpy | -30°C | ISO 179 | 25 | kJ/m² | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| HDT | 1,8MPa | ISO 75 | 198 | °C | |||

| Temperatura de fusión | 350~390 | °C | |||||

| Temperatura de transición vítrea | 10 °C/min | ISO 11357 | 220 | °C | |||

| CLE | Flow 23~80°C | ISO 11359 | 5.5E-5 | cm/cm/°C | |||

| CLE | Flow 180°C | DIN 53752 | 6.3E-5 | cm/cm/°C | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Absorción de agua | 23ºC | ISO 62 | 1.2 | % | |||

| Absorción de agua | 23°C 50RH Balance | ISO 62 | 0.60 | % | |||

| Contracción | Fluir | ISO 294 | 0.9 | % | |||

| Contracción | xFlujo | ISO 294 | 1 | % | |||

| Densidad | ISO 1183 | 1.29 | gramos/cm³ | ||||

| Índice de fusión | 360°C 10kg | ISO 1133 | 35 | cm³/10min | |||

| Viscosidad relativa | ISO 307 | 71 | cm³/g | ||||

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |||

| CTI | Solución A | IEC 60112 | 150 | V | |||

| Constante dieléctrica | 1 MHz | IEC 62631-2-1 | 3.7 | ||||

| Constante dieléctrica | 100 Hz | IEC 62631-2-1 | 3.8 | ||||

| Resistividad volumétrica | IEC 62631 | 1E+15 | Ω.cm | ||||

| Rigidez dieléctrica | K20/K20 | CEI 60243 | 44 | kilovoltios/mm | |||

| Factor de disipación | 1 MHz | IEC 62631-2-1 | 0.0089 | ||||

| Factor de disipación | 100 Hz | IEC 62631-2-1 | 0.0017 | ||||

| Resistividad superficial | IEC 62631-3-2 | 1E15 | Ω | ||||

| Dureza | Condición | Estándar | Valor | Unidad | |||

| Dureza de indentación de bola | H358/30 | ISO 2039 | 124 | MPa | |||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Clasificación de llama | NC BK 1,5 mm | UL94 | V-0 | ||||

| Clasificación de llama | NC BK 3,0 mm | UL94 | V-0 | ||||

05 | Performance Testing and Standard Adaptation

All key performances of BASF PPSU 3010 NAT have been certified by international authoritative standards, including:

・UL94 flame retardant rating: V-0 (1.5mm and 3.0mm)

・ISO 527/179/180 Mechanical strength test series

・ISO 75/11357 thermal performance certification

・IEC 62631 series electrical performance measurement

・ISO 2039 ball pressure hardness (124 MPa)

Complete material certification information and data sheets can be provided to support the regulatory compliance process of the medical and electronics industries.

06 | Customer FAQ

Q1: Can natural color PPSU be colored? Will the performance decrease after coloring?

Answer: It can be colored through special masterbatch, and high-temperature stable pigments are recommended. Additives must undergo biocompatibility testing to avoid affecting medical use.

Q2: Can PPSU be sterilized by high-pressure steam?

Answer: It is completely feasible. 3010 NAT can withstand multiple 134°C steam sterilization without deformation, and is suitable for repeatedly used medical device shells and structural parts.

Q3: Is it suitable for replacing metal parts or PC/ABS?

Answer: In high temperature, high load and chemical environment, PPSU is a high-quality alternative to traditional materials such as PC/ABS. Especially in flame-retardant, electrical, and structural integrated products, the advantages are obvious.

07 | Trend insights of PPSU Material: Dual drive of regulations + performance

As the EU REACH, RoHS, US FDA, UL and other regulations become stricter, environmentally friendly high-performance engineering plastics represented by PPSU will gradually replace traditional halogen-containing flame-retardant plastics or general materials with unstable structures. At the same time, the growth of reusable medical devices, portable electronic devices and high-precision connection components will continue to drive the demand for PPSU.

From the perspective of material structure, non-reinforced PPSU is more suitable for appearance parts that need to maintain dimensional accuracy and surface texture, while high-viscosity versions such as BASF 3010 NAT take into account impact toughness and processing adaptability, and are ideal materials for the new generation of high-reliability products.

08 | Alternative PPSU Materials to Consider

For engineers and purchasers seeking PPSU materials with similar or complementary performance to BASF PPSU 3010 NAT, the following models offer reliable alternatives for diverse high-performance applications:

| Fabricante | Product Family | Grade | Densidad | Melt Flow Index | Resistencia a la tracción | Alargamiento a la rotura | Contracción | Módulo de tracción | Temperatura de deflexión térmica. | Notched Izod Impact | Módulo de flexión | Unnotched Izod Impact | CLTE (Flow) | Resistencia a la flexión |

| Solvay | PPSU | D-3000 | 1.29 g/cm³ | 30 g/10min | 70 MPa | 90% | 0.70% | 2300 MPa | 204°C | 640 J/m | 2300 MPa | — | — | 100 MPa |

| Solvay | PPSU | R-5800BK937 | 1.29 g/cm³ | 24 g/10min | 69.6 MPa | 7.20% | 0.70% | 2340 MPa | 207°C | — | 2410 MPa | 70.40 kJ/m² | 5.6E-5 cm/cm/°C | 91 MPa |

| Solvay | PPSU | R-5800 TR BK561 | 1.29 g/cm³ | 24 g/10min | 69.6 MPa | 7.20% | 0.70% | 2340 MPa | 207°C | — | 2410 MPa | 70.40 kJ/m² | 5.6E-5 cm/cm/°C | 91 MPa |

| Haoran (Shandong) | PPSU | P300 | 1.31 g/cm³ | — | 59 MPa | 8.20% | 0.9–1.1% | 2120 MPa | 195°C | 37.04 kJ/m² | 2460 MPa | 261.53 kJ/m² | 5.4E-5 cm/cm/°C | 96 MPa |

09 | Obtaining samples and technical support

As a professional supplier of plastic raw materials, we can provide:

・BASF original package granule samples

・Complete technical data sheets and processing instructions

・Origin and certification information that complies with medical/electrical regulations

・Customized material matching services

Welcome to contact us on the right side of the page to obtain sample applications or technical solution suggestions.

【Recomendaciones relacionadas】

PESU 2010 MR:High Flow & Flame-Retardant PESU Polymer Más información>

PESU 2010 G4: 20% Glass Fiber Reinforced Polyethersulfone for Printing Components Más información>

Material Selection for Baby Bottles Under New Regulations: Is Moving from PC to PPSU Really Justified by Higher Cost? Más información>