PRODUCTOS

BASF P 3010 Food-Safe PPSU Plastic Material for Baby Bottles

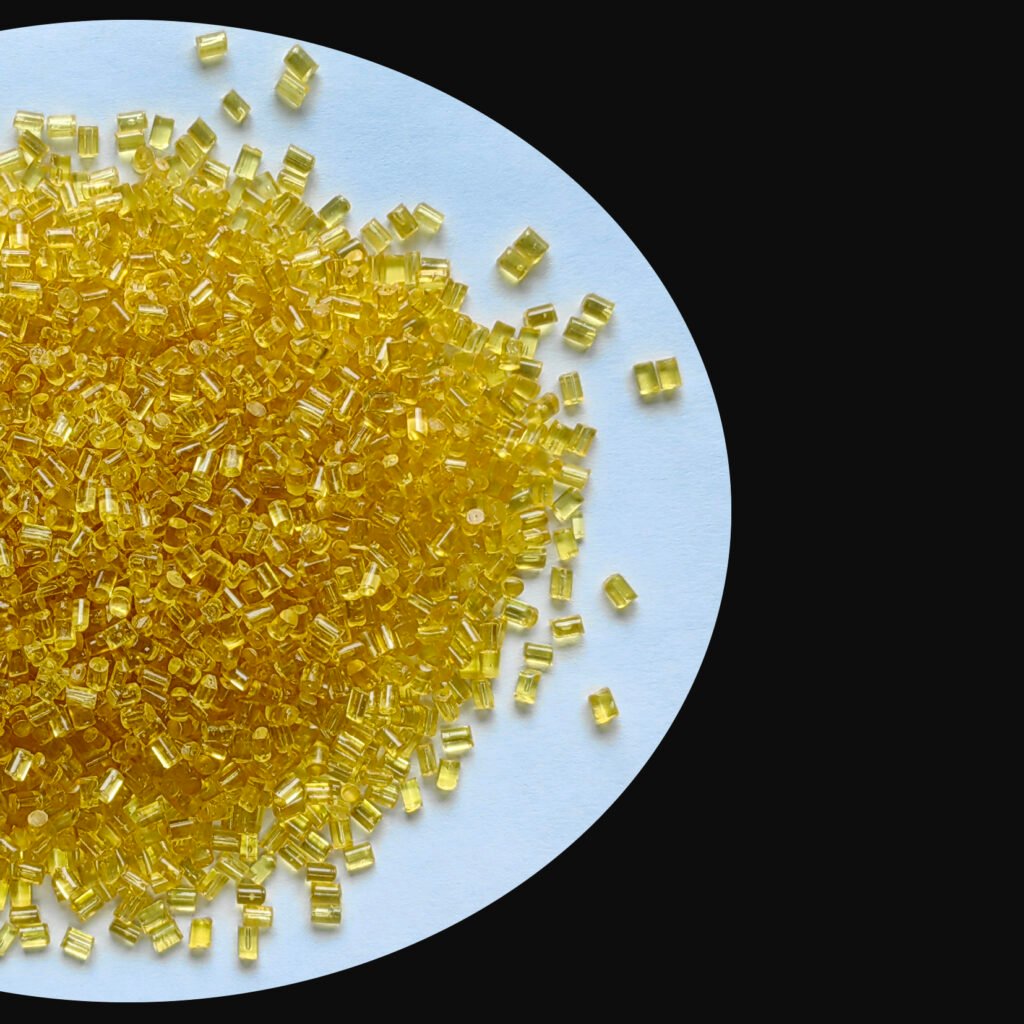

Estructura del producto

What is PPSU Plastic Material

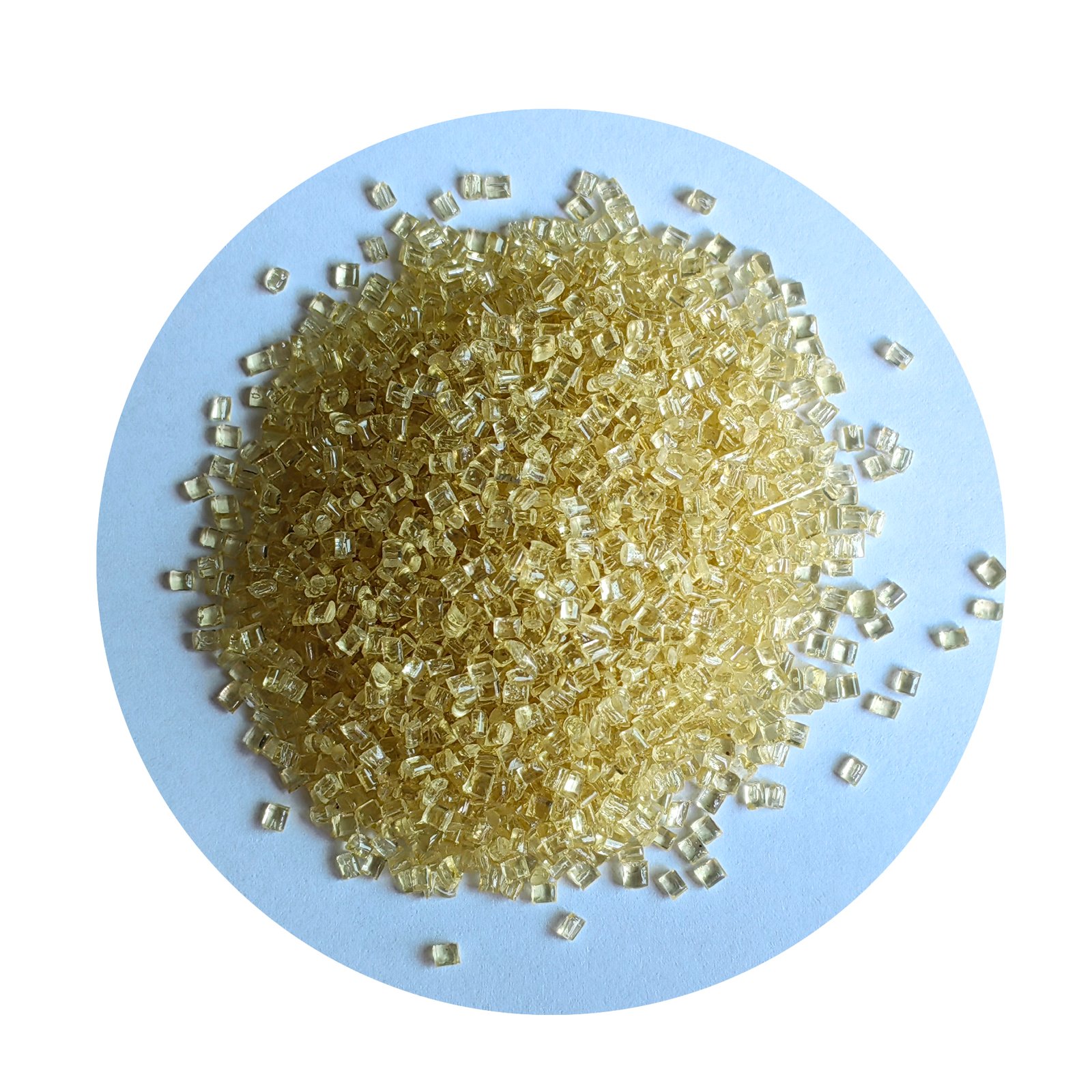

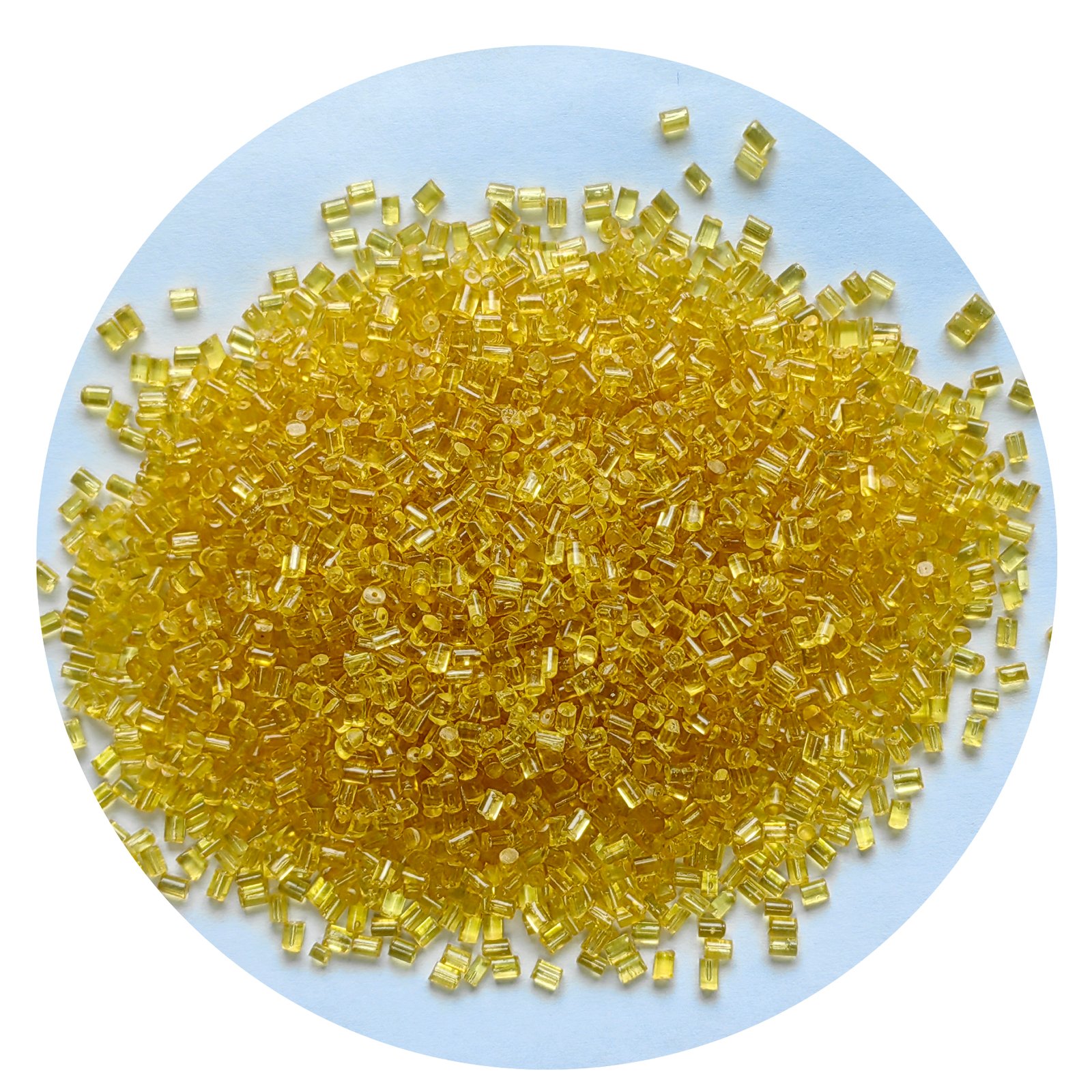

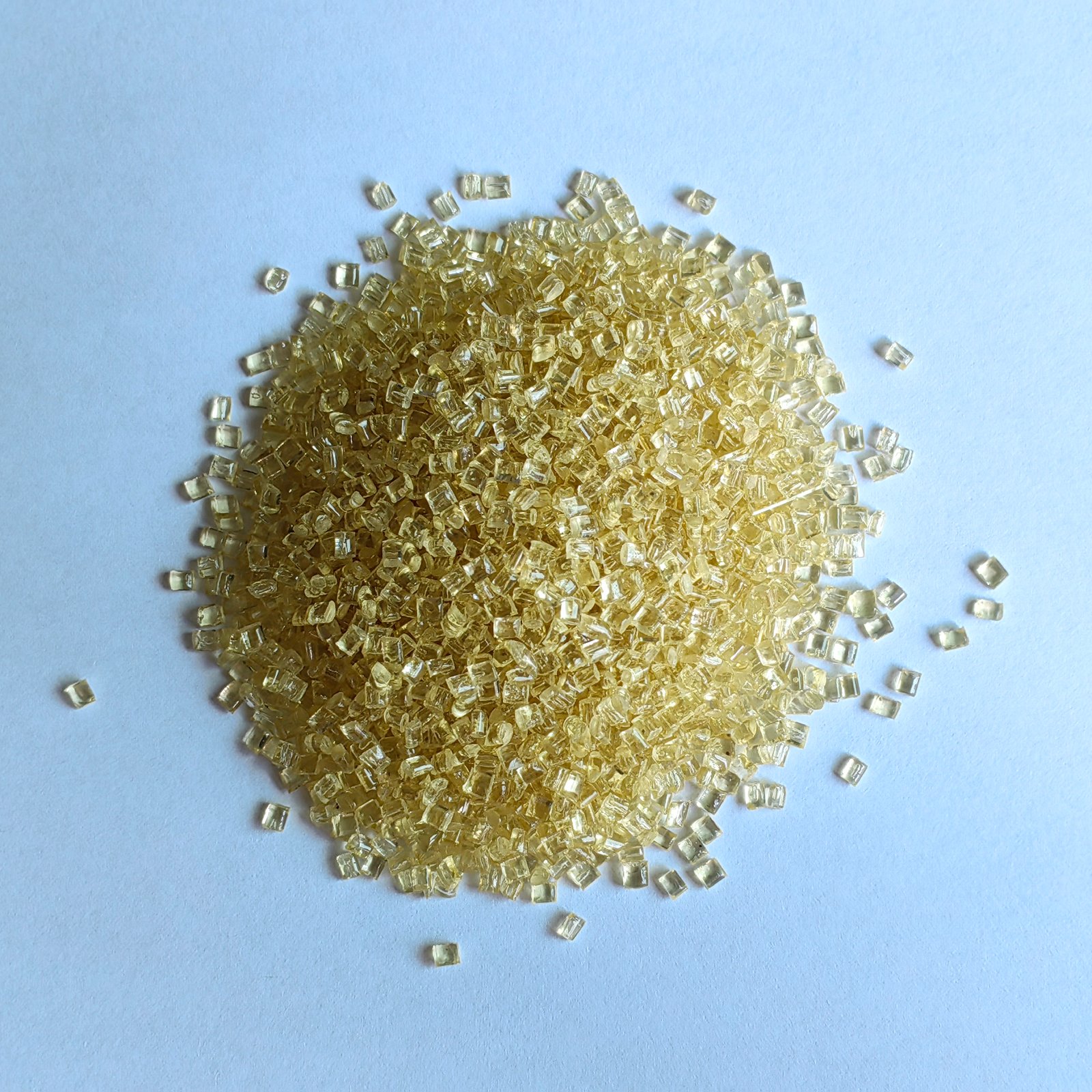

Basf PPSU P 3010 is an unreinforced polyphenylsulfone (PPSU) plastic material, specifically developed to meet the high safety standards in the field of food contact for infants and children. With excellent toughness, chemical resistance and thermal stability, this material is widely used in products such as baby bottles and medical devices that need to be in long-term contact with high temperatures and disinfectants, representing the leading level of current high-end ppsu plastic materials.

01 | Core Properties of PPSU Plastic Materials

Non-enhanced design, better toughness

Unlike common glass fiber reinforced plastics, PPSU P 3010 adopts a pure non-reinforced formula without adding glass fibers or mineral fillers. This design ensures a higher elongation at break and stronger impact resistance, making it particularly suitable for scenarios where infants and toddlers are prone to falling.

Resistant to chemical corrosion and long-lasting stability

This ppsu plastic material can resist the erosion of various disinfectants, alkaline cleaners and food residues. Even under the condition of repeated high-temperature steam disinfection, it can maintain the stability of structure and performance, and is not prone to brittleness or cracking.

High-temperature resistant and flame-retardant, with dual safety guarantees

The heat distortion temperature of PPSU P 3010 is as high as nearly 200℃, which can easily handle the high-pressure disinfection treatment of baby bottles. In addition, the material has a UL94 V-0 flame retardant rating, which can effectively suppress the risk of combustion spread and ensure safety during use.

Low moisture absorption rate and high dimensional accuracy

The material has a low water absorption rate, and the shrinkage rate after processing is controlled within a small range. The formed products hardly deform, making it suitable for high-precision molds and complex structural designs.

02 | Application Direction: Not limited to baby bottles

PPSU P 3010 has demonstrated advantages in various fields that require "high security + frequent use" :

・Baby bottles, straws, pacifier connectors, etc

・Medical device components that can be repeatedly sterilized at high temperatures

・Inner linings of thermos cups and high-end tableware that need to come into contact with hot food

・Structural components that require heat resistance and flame retardancy in small household appliances or electronic products

Among food contact products such as baby bottles, PPSU P 3010 is BPA-free, safe and environmentally friendly, and meets the regulatory requirements of multiple markets including Europe, America and China.

03 | Processing Guide of PPSU Plastic Material

Injection molding recommended parameters

・Injection molding temperature: 320-360℃

・Mold temperature: 120-150℃

・Drying conditions: 160℃ for more than 4 hours (to prevent moisture absorption and defects such as silver streaks)

Compatible with high-speed forming equipment

・This ppsu plastic material has good melt stability and is suitable for high-speed injection molding and multi-cavity mold applications, which can ensure the consistency and appearance quality of the products.

04 | Overview of PPSU Plastic Material Properties

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |

| Alargamiento | Rendimiento 23°C | ISO 527 | 7.8 | % | |

| Impacto de muesca Izod | -30℃ | ISO 180 | 25 | kJ/m² | |

| Impacto de muesca Izod | 23℃ | ISO 180 | 55 | kJ/m² | |

| Resistencia a la tracción | Rendimiento 23°C | ISO 527 | 74.0 | MPa | |

| Módulo de tracción | 23℃ | ISO 527 | 2270 | MPa | |

| Impacto Charpy sin muesca | -30℃ | ISO 179 | NÓTESE BIEN | kJ/m² | |

| Impacto Charpy sin muesca | 23℃ | ISO 179 | NÓTESE BIEN | kJ/m² | |

| Impacto con entalla Charpy | -30℃ | ISO 179 | 25 | kJ/m² | |

| Impacto con entalla Charpy | 23℃ | ISO 179 | 75 | kJ/m² | |

| Térmico | Condición | Estándar | Valor | Unidad | |

| HDT | Sin recocer 1,80 MPa | ISO 75 | 198 | ℃ | |

| CLE | Fluir | 5.5E-5 | cm/cm/℃ | ||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |

| Absorción de agua | 23℃ Saturation | ISO 62 | 1.2 | % | |

| Absorción de agua | 23℃ 50RH Balance | ISO 62 | 0.60 | % | |

| Contracción | xFlujo | ISO 294 | 1.0 | % | |

| Contracción | Fluir | ISO 294 | 0.90 | % | |

| Densidad | ISO 1183 | 1.29 | gramos/cm³ | ||

| Índice de fusión | 360℃ 10kg | ISO 1133 | 35 | cm³/10min | |

| Propiedades electricas | Condición | Estándar | Valor | Unidad | |

| CTI | IEC 60112 | 150 | V | ||

| Constante dieléctrica | 100 Hz | IEC 60250 | 3.80 | ||

| Constante dieléctrica | 1 MHz | IEC 60250 | 3.70 | ||

| Resistividad volumétrica | CEI 60093 | 1E15 | Ω.cm | ||

| Rigidez dieléctrica | CEI 60243 | 44 | kilovoltios/mm | ||

| Factor de disipación | 100 Hz | IEC 60250 | 0.0017 | ||

| Factor de disipación | 1 MHz | IEC 60250 | 0.0089 | ||

| Resistividad superficial | CEI 60093 | 1E15 | Ω | ||

| Dureza | Condición | Estándar | Valor | Unidad | |

| Dureza de indentación de bola | ISO 2039 | 124 | MPa | ||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |

| Clasificación de llama | Todos los colores 1,5 mm | UL94 | V-0 | ||

| Clasificación de llama | Todos los colores 3,0 mm | UL94 | V-0 | ||

Click here to download TDS for PPSU P 3010

Note: The above are typical values. For actual application, please refer to the processing conditions and batch inspection data.

05 | Original factory craftsmanship and quality control

PPSU P 3010 is polymerized by BASF's German factory using high-purity raw materials. The production process includes:

・Temperature-controlled polymerization reaction to ensure stable molecular weight

・Twin-screw extrusion granulation ensures uniform particle size

・Moisture-proof and dry, vacuum-sealed packaging

・Each batch undergoes tests for thermal performance, mechanical strength, food contact safety and other items to ensure product consistency and compliance

06 | Horizontal comparison of PPSU Plastic Material

| Material | Heat Resistance | Toughness | Food Safety | BPA-Free |

| PÁGINAS | Moderado | Moderado | Compliant | Sí |

| ordenador personal | Alto | Medio | Controversial | No |

| PPSU P 3010 | Excelente | Alto | Highly Stable | Sí |

Under multiple steam disinfection or hot water cleaning conditions, PPSU plastic material can still maintain its strength and luster, making it the preferred solution to replace traditional PC.

07 | Collection of Customer Feedback

After upgrading from PC to PPSU P 3010, the drop resistance and service life of the baby bottles have been significantly improved, and the user feedback has also become more stable.

-- Project Manager of a well-known domestic maternal and infant brand

After switching to PPSU P 3010, our medical components are not afraid of repeated disinfection and save after-sales maintenance costs.

-- Technical Director of a medical consumables manufacturer

08 | Frequently Asked Questions (FAQ)

Q1: What food safety certifications has PPSU P 3010 obtained?

A: Complies with EU 10/2011 of the European Union, FDA 21 CFR 177.1655 of the United States, and GB 4806 series standards of China, and is suitable for long-term contact with food.

Q2: Is this PPSU plastic material suitable for repeated high-temperature steam disinfection?

A: Yes, the heat distortion temperature of PPSU P 3010 is close to 200℃. It can repeatedly withstand high-pressure steam environments and still maintain its shape and mechanical properties.

Q3: Why choose the non-enhanced type over the non-enhanced type?

A: Non-reinforcing materials are superior in terms of fracture ductility and toughness, and are particularly suitable for applications that require cracking prevention, such as baby bottles, medical devices, pressure connectors, etc.

Q4: If you want the color of the material to match the brand, can it be customized?

A: Customized colors, dye addition or masterbatch services are available to meet the brand's color matching and differentiation needs.

09 | Our supply advantages

Focusing on the supply of plastic materials for 24 years

Deeply engaged in the field of high-performance plastic raw materials such as PPSU, PESU, and PEEK, we understand the materials and also the language of your industry.

Flexibly support small-batch and sample-making requirements

No MOQ minimum order requirement, facilitating the rapid advancement of trial production, small-scale testing, and market validation for start-up projects.

Modification and customization services are available

Adjust the melt index, rigidity, flame retardancy grade, color formula, etc. according to application requirements, and support one-stop solutions from standard materials to high-end customization.

The materials technology engineer provides full-process assistance

From material selection consultation, process suggestions to analysis of difficult problems, we are not merely "sellers of materials", but providers of plastic solutions.

Original factory genuine product, quality traceable

All PPSU materials are from the original authorized channels of BASF, providing batch test reports and third-party certifications to ensure that each batch of materials is compliant and reassuring.

【Recomendaciones relacionadas】

Solvay R-5100 NT15 PPSU Resin for Medical & Food-Grade Más información>

PPSU R-5000 NT High-Heat PPSU Resin for Medical and Food-Grade Injection Molding Más información>

K 2025 Insights: Green Plastics and Smart Manufacturing Más información>