Nylon, PA and Polyamide

In the field of engineering plastics and polymer materials, Nylon (nylon), PA and Polyamide (polyamide) are frequently mentioned terms. Are they completely equivalent? In which scenarios are they respectively applicable? This article will guide you to systematically sort out the relationships and differences among the three, helping you to be more precise and efficient in material selection or technical communication.

01 | Basic Definitions of the Three Terms

| Term | Definition & Usage Context |

| Poliamida | The chemical name of a class of polymers containing amide bonds (–CONH–) in the main chain. Known for excellent mechanical strength and thermal resistance. |

| Pensilvania | Abbreviation of “Polyamide,” commonly used in product names, data sheets, and injection molding codes (e.g., PA6, PA66). |

| Nylon | The original trade name developed by DuPont, now a widely recognized term for polyamide materials, especially in fibers and consumer goods. |

✅ Summary: All three terms refer to the same family of materials, but their usage varies by industry and context.

02 | Usage Context Comparison

| Category | Poliamida | Pensilvania | Nylon |

|---|---|---|---|

| Terminology Type | Scientific/Chemical | Technical Abbreviation | Trade/Popular Name |

| Usage Scenario | Research papers, technical literature | Engineering drawings, material specs | Product packaging, consumer-facing content |

| Aplicaciones típicas | Material analysis, formulation | Injection molding, part design | Nylon cable ties, fibers, sheets |

📌 In practice, all three terms refer to the same material system, and the choice depends on the audience and context.

03 | Common Types of Polyamide Materials

Polyamide materials include a wide range of grades and structures, each with specific mechanical and thermal properties. Below are some of the most commonly used PA types and their characteristics:

| Type | Chemical Name | Características principales | Áreas de aplicación |

|---|---|---|---|

| PA6 | Polycaprolactam | Good toughness, low cost, easy processing | Electrical housings, gears, pulleys, handles |

| PA66 | Polyhexamethylene adipamide | High rigidity, excellent heat resistance | Structural components, engine parts |

| PA12 | Polylaurolactam | Low water absorption, excellent flexibility and cold resistance | Pneumatic tubing, cable sheaths, medical catheters, 3D printing |

| PA610 | Polyamide 610 | Partially bio-based, environmentally friendly | Pipes, brush filaments, industrial parts |

| PA46 | Polyamide 46 | High heat deflection, dimensional stability | Engine compartments, electrical connectors |

✅ Polyamides can be further enhanced through glass fiber reinforcement, flame retardancy, or heat stabilizers, allowing them to perform reliably in demanding environments.

04 | Preferred Terms by Industry

| Industry Sector | Common Terms | Typical Usage |

| Plásticos de ingeniería | PA, Polyamide | Precise material codes (e.g., PA66 GF30) |

| Automotive | Pensilvania | Used in engine parts, tubing, brackets |

| Electrical & Electronics | PA6, PA66 | Focus on insulation, flame resistance, and stability |

| Consumer Goods / Textiles | Nylon | Emphasizes light weight and flexibility (e.g., fibers, zippers, fasteners) |

| Medical & 3D Printing | PA12, Nylon | Emphasis on low moisture uptake, precision printing, chemical resistance |

📌 For professional engineering use, it’s best to refer to materials by their “PA + grade” for technical clarity and comparability.

Conclusion: Understand the essential unity behind the names

Although Nylon, PA and Polyamide have differences in their naming conventions, they all belong to the polyamide material system and have a broad application foundation and development potential. The use of different terms more reflects the differences in industry language and communication targets rather than the essential differences in materials.

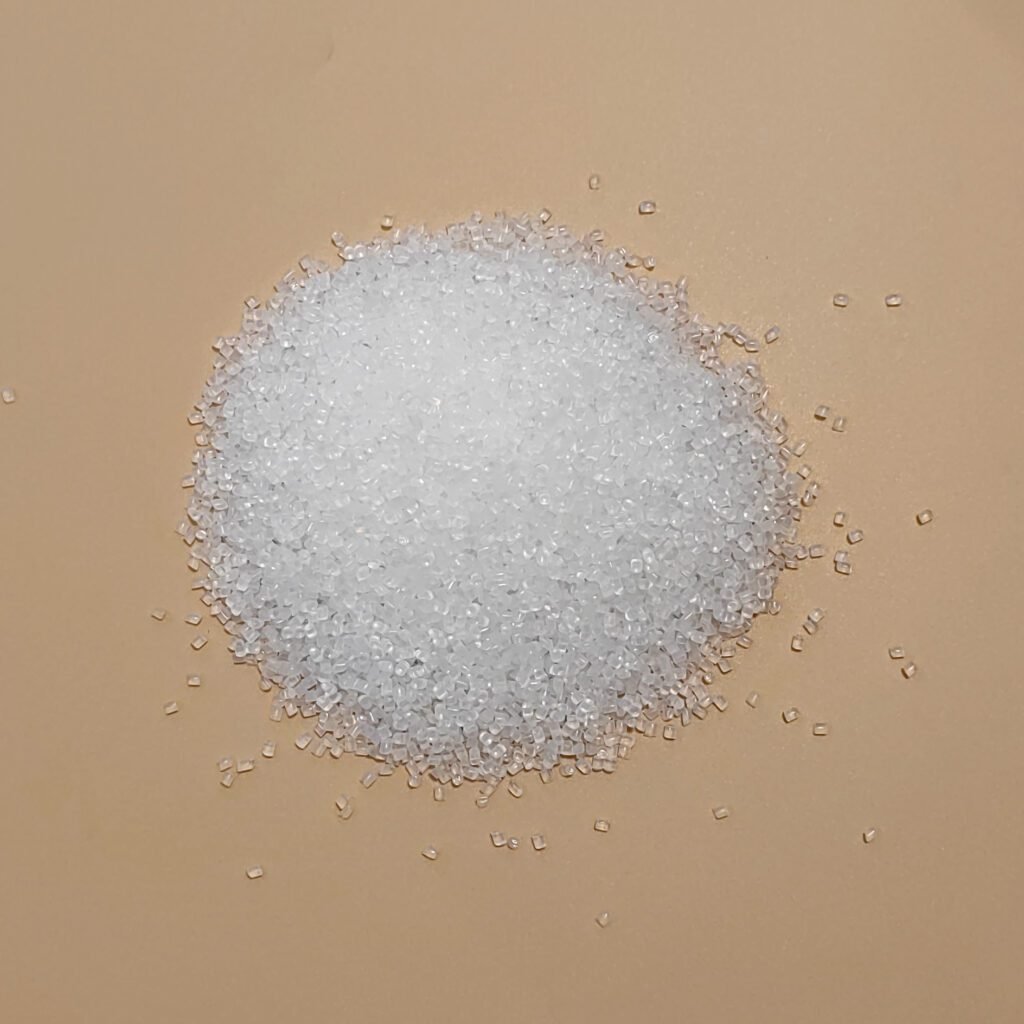

If you are looking for high-performance nylon raw materials suitable for injection molding, extrusion or 3D printing, we can offer multiple models such as PA6, PA66, PA12, etc. We support original factory stock, technical selection suggestions and customized modification services to meet the needs of various industrial scenarios.

Why Choose Us

📦 Suministro estable: long-term spot inventory of regular grades, controllable delivery time;

🔧 Technical support: selection guidance, processing suggestions, complete data sheet;

🏭 Direct supply from source: Cooperative brands cover international original manufacturers and high-quality modification factories;

🌍 Export services: Support FOB/CIF, and can assist in issuing compliance documents such as RoHS/REACH.

Explore More:

・ Guía completa de gránulos de plástico Changchun PA6 11G6-201

・ Descripción general de la materia prima plástica en pellets de poliamida B3WG6 de BASF PA6

・ Descripción general de la resina PA6 | Propiedades y ficha técnica de la 7301 NC010

Visit our PA6 Resource Center or Contáctenos for quotes, samples, or technical consultations.