PRODUCTOS

LG ABS TR558A Strong Impact Resistance ABS Virgin Plastic

Estructura del producto

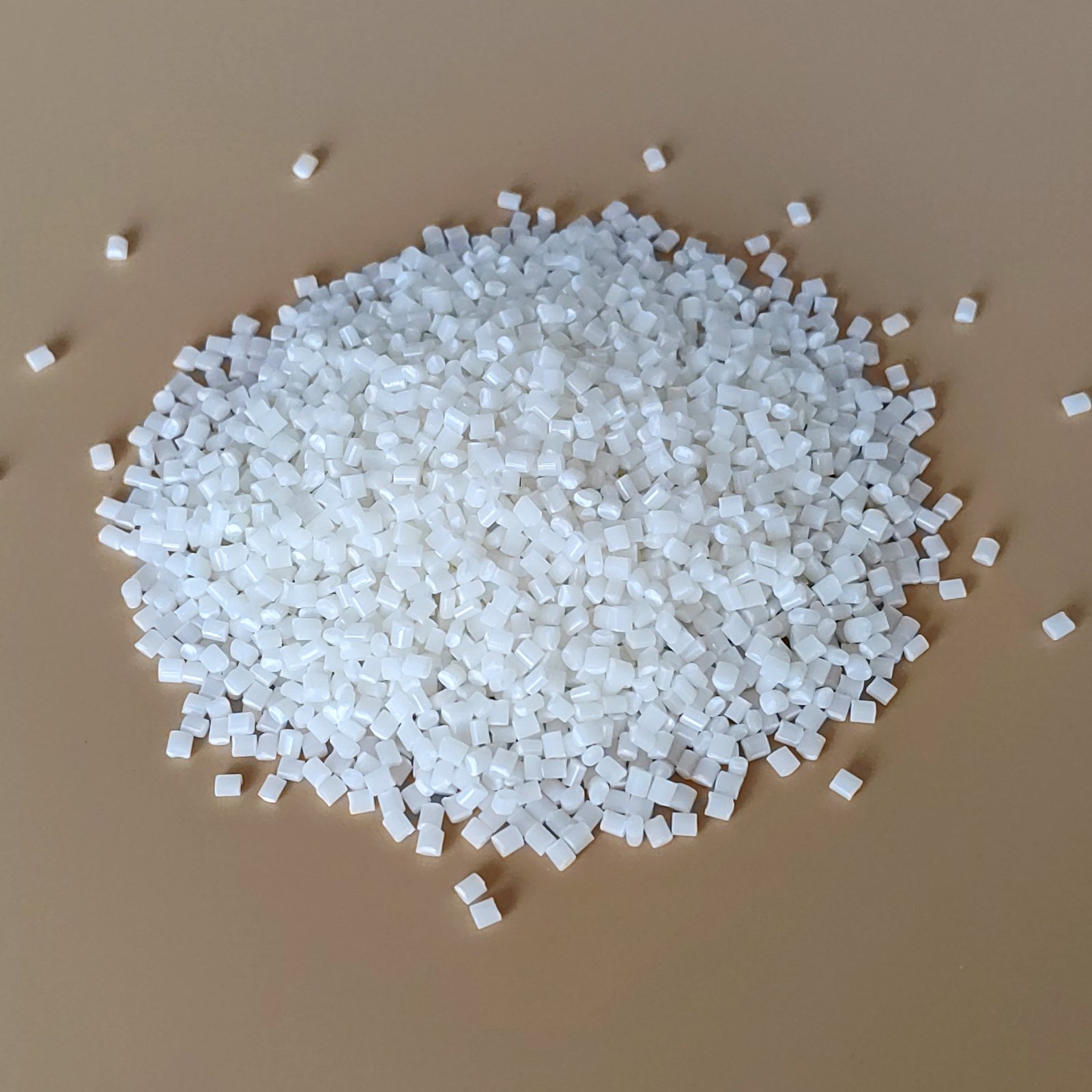

What is ABS Virgin Plastic?

LG Chem ABS TR558A is a transparent injection-grade material based on MABS (methyl acrylonitrile butadiene-styrene copolymer), integrating rigidity, toughness and optical properties. As abs virgin plastic, it contains no recycled material impurities, has stable optical purity and batch consistency, and is very suitable for the manufacturing of products with high requirements for transparency and appearance.

1. Material Highlights and Characteristics

Clear and bright, with excellent visual performance: High light transmittance and low haze, making the product present a clean and transparent texture in the lighting or display environment.

It combines impact toughness and flexibility: It can maintain good impact strength in both normal and low-temperature environments, reducing the risk of product breakage.

Outstanding structural stability: Low shrinkage rate, precise forming dimensions, suitable for components that require high assembly accuracy.

Reliable electrical insulation performance: It meets the safety requirements for electronic and electrical materials and is suitable for a variety of electrical structural components.

Flexible molding processing: Excellent injection molding fluidity, capable of maintaining a smooth appearance and high transparency under complex molds.

2. Typical Application Directions

TR558A is widely used in various transparent and semi-transparent products

・Enclosures of household appliances and electronic devices: air purifiers, speakers, and display device frames.

・Lighting system components: LED lampshades, light guide plates, diffusion components.

・Home and consumer goods: Transparent panels, display boxes, digital accessory shells.

・Decorative parts and mechanical Windows: Transparent components used to balance aesthetics and structural strength.

These fields fully demonstrate the advantages of abs virgin plastic in terms of appearance and performance compatibility.

3. Processing and Technological Characteristics

TR558A is compatible with mainstream injection molding equipment, has a wide processing temperature range and stable flow performance.

To achieve the best transparency, it is recommended to keep the mold surface highly polished and thoroughly dry. Materials are relatively sensitive to the cooling rate. Controlling the cooling rhythm can reduce internal stress and improve optical performance.

4. ABS TR558A Data Sheet

| Rendimiento óptico | Condición | Estándar | Valor | Unidad | |||

| Transmitancia | 3200μm | Norma ASTM D1003 | 90 | % | |||

| Bruma | Norma ASTM D1003 | 1.8 | % | ||||

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Yield 23℃ 50mm/min 3.20mm | Norma ASTM D638 | 5 | % | |||

| Alargamiento | Break 23℃ 50mm/min 3.20mm | Norma ASTM D638 | 15 | % | |||

| Resistencia a la flexión | 23℃ 15mm/min 3.20mm | Norma ASTM D790 | 79 | MPa | |||

| Módulo de flexión | 23℃ 15mm/min 3.20mm | Norma ASTM D790 | 2550 | MPa | |||

| Impacto de muesca Izod | 23 ℃ 3,20 mm | Norma ASTM D256 | 125 | j/m | |||

| Impacto de muesca Izod | -30℃ 3.20mm | Norma ASTM D256 | 35 | j/m | |||

| Impacto de muesca Izod | 23 ℃ 6,40 mm | Norma ASTM D256 | 115 | j/m | |||

| Impacto de muesca Izod | -30℃ 6.40mm | Norma ASTM D256 | 35 | j/m | |||

| Resistencia a la tracción | Break 23℃ 50mm/min 3.20mm | Norma ASTM D638 | 52 | MPa | |||

| Módulo de tracción | 23℃ 50mm/min 3.20mm | Norma ASTM D638 | 2350 | MPa | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| HDT | Unannealed 1.8MPa 6.40mm | Norma ASTM D648 | 83 | ℃ | |||

| Temperatura de ablandamiento Vicat | 50 ℃/h 50 N | Norma ASTM D1525 | 91 | ℃ | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Contracción | 2.00mm 23℃ | Norma ASTM D955 | 0.4~0.7 | % | |||

| Densidad | 23℃ | Norma ASTM D792 | 1.11 | gramos/cm³ | |||

| Índice de fusión | 220℃ 10kg | Norma ASTM D1238 | 25 | g/10min | |||

| Dureza | Condición | Estándar | Valor | Unidad | |||

| Dureza Rockwell | R(Escala) | Norma ASTM D785 | 113 | ||||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Clasificación de llama | Todos los colores 1,5 mm | UL94 | media pensión | ||||

| Clasificación de llama | Todos los colores 3,0 mm | UL94 | media pensión | ||||

5. Innovation and Industry Advantages

TR558A adopts an improved MABS structure, achieving a balance between optical transparency and mechanical properties

・Compared with traditional transparent ABS, its low-temperature impact resistance is better.

・Compared with PC transparent materials, it has lower energy consumption for molding and less processing difficulty.

・As abs virgin plastic, it has stable batches and uniform flow, which is convenient for long-term mass production and international project certification.

In the market of transparent materials for electronic and electrical appliances, TR558A has become a representative model with high cost performance.

6. Customer Feedback

Customers from Asia and Europe generally evaluate that TR558A has a short molding cycle and stable product appearance.

Some manufacturers claim that this material has better gloss retention than similar MABS in mass production and is particularly suitable for injection molding applications of high-transparency lampshades and electronic display components.

7. Frequently Asked Questions (FAQ)

Q1: Can TR558A be blended with standard ABS?

It is recommended to use it alone to maintain the stability of transparency and mechanical properties.

Q2: Can it be used in food contact products?

This model is a general-purpose transparent ABS and does not fall under the food contact grade.

Q3: How to avoid the appearance of silver streaks or bubbles?

Maintaining adequate dryness, good mold exhaust, and controlling injection speed can effectively improve the appearance.

8. Recommendation of Similar Materials

| Fabricante | Modelo de producto | Densidad | Módulo de tracción | Resistencia a la tracción | Dureza Rockwell | Melt Flow Index (MFI) | Alargamiento a la rotura | Contracción | Módulo de flexión | Resistencia a la flexión |

| LG Chem | TR-558AI | 1.08 g/cm³ | 2191 MPa | 51.3 MPa | 112 | 15 g/10min | 6% | — | 79 MPa | 2368.8 MPa |

| LG Chem | TR558A | 1.11 g/cm³ | 2350 MPa | 52 MPa | 113 | 25 g/10min | 5% | — | 2550 MPa | 79 MPa |

| LG Chem | TR-557I | 1.07 g/cm³ | — | 41 MPa | 105 | 20 g/10min | 40% | — | 1990 MPa | 64 MPa |

| LG Chem | TR557 | 1.09 g/cm³ | 2050 MPa | 48 MPa | 107 | 21 g/10min | 5% | — | 2250 MPa | 71 MPa |

| LG Chem | TR-556 | 1.09 g/cm³ | 2100 MPa | 49 MPa | 109 | 5 g/10min | 15% | — | 2300 MPa | 79 MPa |

| LG Chem | TR-530F | 1.06 g/cm³ | 196000 psi | 4790 psi | 88 | 10 g/10min | 15% | — | 218000 psi | 7110 psi |

| Mitsubishi Rayon | TR-2 | 1.05 g/cm³ | — | 47.1 MPa | 110 | 1.4 g/10min | 2350% | 0.50% | 2450 MPa | 72.6 MPa |

| Denka | TP-801 | 1.1 g/cm³ | — | 42 MPa | 34 | — | — | 0.30% | 2180 MPa | 69 MPa |

9. Supply and Service Advantages of Juyuan

As a supplier specializing in international trade of plastic raw materials, Juyuan has long provided abs virgin plastic series materials, featuring:

・Stable supply capacity: Direct procurement of resources from brands such as LG, SABIC, and INEOS;

・Flexible procurement mode: Supports bulk and sample supply to meet the needs of different projects;

・Technical guidance and selection support: Assist customers in matching suitable materials and process parameters;

・Efficient logistics system: Ensuring stable delivery times and smooth customs clearance, facilitating rapid production for global customers.

Conclusión

LG Chem's ABS TR558A integrates a transparent appearance, toughness and ease of processing, making it a reliable transparent ABS solution for the modern electronics, electrical appliances and lighting industries. Juyuan will continue to assist global manufacturers in creating plastic products that are both aesthetically pleasing and high-performance with its professional supply chain and high-quality abs virgin plastic products.

【Recomendaciones relacionadas】

Terluran® GP-35 ABS: Glossy Injection and Plating Material Más información>

Novodur® P2MC Plating-Grade ABS for Automotive & Appliance Más información>

Why Can Plastic Be as Strong as Metal? The Science Behind Engineering Polymers Más información>