PRODUCTOS

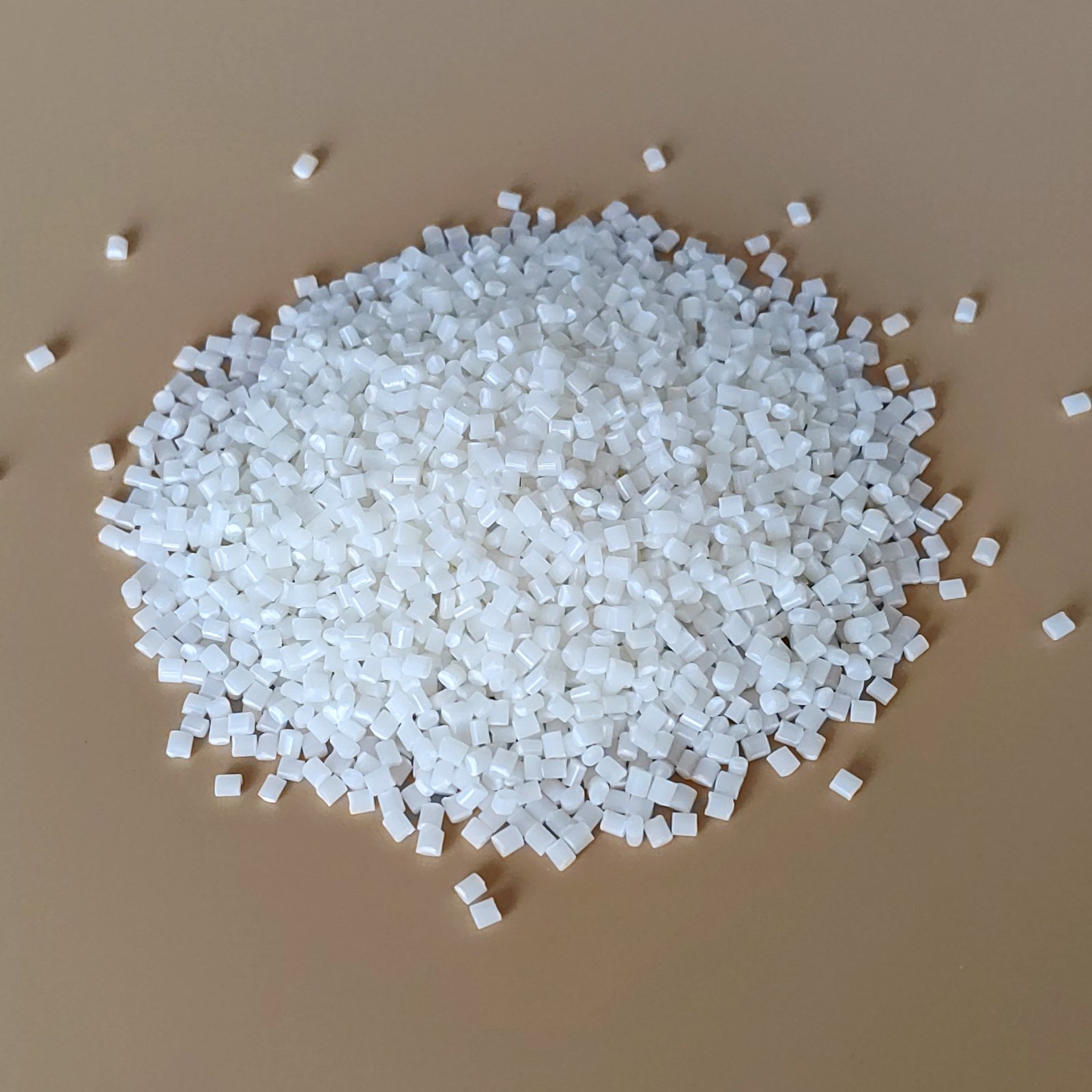

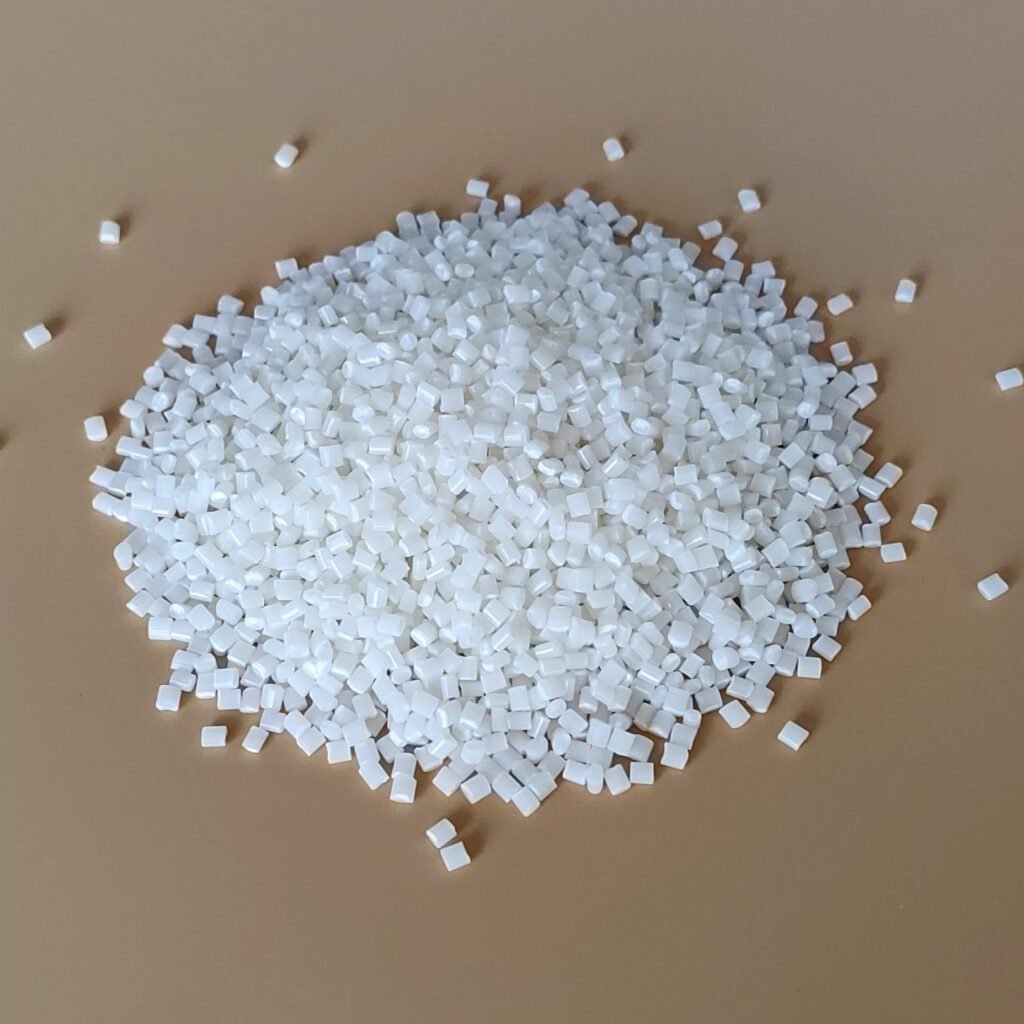

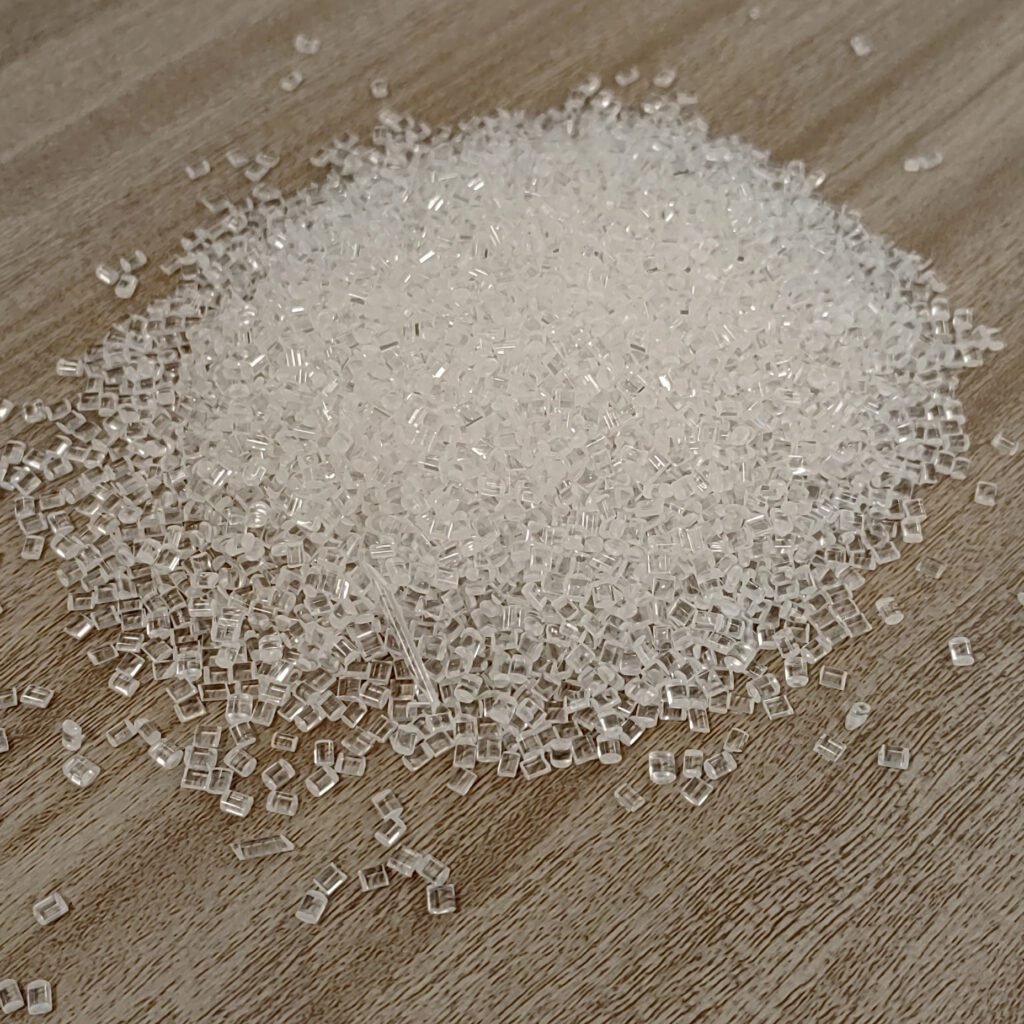

LG Chem ABS AF312A | High Impact Injection ABS Virgin Granules

Estructura del producto

What are ABS Virgin Granules?

ABS virgin granules refers to acrylonitrile butadiene-styrene copolymer pellets that have not been recycled.

Compared with recycled ABS, virgin particles have a more stable molecular structure and purity, and can provide better mechanical strength, color consistency and dimensional accuracy. This makes it an ideal choice for high-standard injection molded products such as TV casings, electrical components, and automotive interior parts.

1. Why choose flame-retardant grade ABS virgin granules?

In industries such as home appliances, office equipment, automotive electronics and electrical installations, flame retardancy is an important indicator for the selection of plastic materials.

The use of flame-retardant grade ABS virgin granules (such as LG Chem AF312A) can achieve:

・Complies with UL94 V-0, 5VB and 5VA fire protection standards

・It performs stably in high-temperature environments

・Good electrical insulation and impact toughness

・Suitable for the production of high-precision injection molded parts

2. Product highlights: LG Chem ABS AF312A

LG Chem ABS AF312A is a halogen-based flame-retardant injection-grade ABS virgin granule, specially developed for electrical and electronic components with complex structures.

Main performance parameters

・Melt index: 60 g/10min (High fluidity, suitable for thin-walled products)

・Notched impact strength: 25 kJ/m² (23°C, 3.2mm)

・Heat distortion temperature: 84°C (0.45MPa)

・Specific gravity: 1.19 g/cm³

・UL94 Flame retardant grade: V-0/5VA (2.5-3.0mm)

3. Typical application fields

・Television and monitor casings

・Components of electrical and electronic equipment

・Automotive interior parts and panels

・Office automation (OA) equipment casing

4. Performance comparison with ordinary ABS

| Propiedad | LG Chem AF312A | General ABS | Ventaja |

| Flame Resistance | V-0 / 5VA | media pensión | Stronger fire safety |

| Fluidez | Alto | Medio | Better thin-wall molding |

| Fuerza de impacto | 25 kJ/m² | ~18 kJ/m² | Enhanced durability |

| Surface Finish | Glossy | Estándar | Improved appearance |

5. Processing suggestions

・Processing method: Moldeo por inyección

・Barrel temperature: 220-260°C

・Mold temperature: 60-80°C

・Pre-drying conditions: Bake at 80°C for 3 hours

Reasonable drying and temperature control can ensure the surface finish and dimensional stability of the products.

6. LG ABS AF312A Data Sheet

| UL | Condición | Estándar | Valor | Unidad | |||

| CTI | IEC 60112 | 0 | SOCIEDAD ANÓNIMA | ||||

| Hola | Todos los colores 1,5 mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| Hola | Todos los colores 3,0 mm | UL 746A | 0 | SOCIEDAD ANÓNIMA | |||

| Alta Velocidad | UL 746A | 2 | SOCIEDAD ANÓNIMA | ||||

| HWI | Todos los colores 1,5 mm | UL 746A | 3 | SOCIEDAD ANÓNIMA | |||

| HWI | Todos los colores 2,0 mm | UL 746A | 3 | SOCIEDAD ANÓNIMA | |||

| RTI | Elec All Color 2.5mm | UL 746B | 85 | °C | |||

| RTI | Elec Todos los colores 3,0 mm | UL 746B | 85 | °C | |||

| RTI | Imp All Color 1.0mm | UL 746B | 60 | °C | |||

| RTI | Imp Todos los colores 1,5 mm | UL 746B | 75 | °C | |||

| RTI | Imp All Color 2.0mm | UL 746B | 75 | °C | |||

| RTI | Str All Color 1.0mm | UL 746B | 60 | °C | |||

| RTI | Str Todos los colores 1,5 mm | UL 746B | 75 | °C | |||

| RTI | Str All Color 2.0mm | UL 746B | 75 | °C | |||

| RTI | Cadena todo color 3,0 mm | UL 746B | 75 | °C | |||

| Resistividad volumétrica | Norma ASTM D257 | 1E14 | Ω.cm | ||||

| Estabilidad dimensional | UL746 | 0.0 | % | ||||

| Rigidez dieléctrica | Norma ASTM D149 | 30 | kilovoltios/mm | ||||

| Resistencia al arco | ASTM D495 | 7 | SOCIEDAD ANÓNIMA | ||||

| Clasificación de llama | Todos los colores 1,0 mm | UL94 | media pensión | ||||

| Clasificación de llama | Todos los colores 1,5 mm | UL94 | V-0 | ||||

| Clasificación de llama | Todos los colores 3,0 mm | UL94 | V-0 5VA | ||||

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Rendimiento 50 mm/min 3,2 mm | Norma ASTM D638 | 5 | % | |||

| Alargamiento | Fractura 50 mm/min 3,2 mm | Norma ASTM D638 | 20 | % | |||

| Resistencia a la flexión | 15mm/min 6.4mm | Norma ASTM D790 | 68.62 | MPa | |||

| Módulo de flexión | 15mm/min 6.4mm | Norma ASTM D790 | 2549.01 | MPa | |||

| Impacto de muesca Izod | 23 °C 3,2 mm | Norma ASTM D256 | 25 | kJ/m² | |||

| Impacto de muesca Izod | 23 °C 6,4 mm | Norma ASTM D256 | 21 | kJ/m² | |||

| Impacto de muesca Izod | -30°C 3.2mm | Norma ASTM D256 | 7 | kJ/m² | |||

| Impacto de muesca Izod | -30°C 6.4mm | Norma ASTM D256 | 7 | kJ/m² | |||

| Resistencia a la tracción | Rendimiento 50 mm/min 3,2 mm | Norma ASTM D638 | 44.11 | MPa | |||

| Módulo de tracción | 1.0mm/min 3.2mm | Norma ASTM D638 | 2254.90 | MPa | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| HDT | Sin recocer 0,45 MPa 6,4 mm | Norma ASTM D648 | 84 | °C | |||

| HDT | Sin recocer 1,8 MPa 6,4 mm | Norma ASTM D648 | 76 | °C | |||

| Temperatura de ablandamiento Vicat | 50 °C/h 50 N | Norma ASTM D1525 | 83 | °C | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Contracción | Flujo 3,2 mm | Norma ASTM D955 | 0.4~0.7 | % | |||

| Densidad | Norma ASTM D792 | 1.19 | gramos/cm³ | ||||

| Índice de fusión | 220°C 10 kg | Norma ASTM D1238 | 60 | g/10min | |||

| Dureza | Condición | Estándar | Valor | Unidad | |||

| Dureza Rockwell | R(Escala) | Norma ASTM D785 | 105 | ||||

| Inflamabilidad | Condición | Estándar | Valor | Unidad | |||

| Clasificación de llama | Todos los colores 1,0 mm | UL94 | media pensión | ||||

| Clasificación de llama | Todos los colores 1,5 mm | UL94 | V-0 | ||||

| Clasificación de llama | Todos los colores 2,0 mm | UL94 | V-0 5VB | ||||

| Clasificación de llama | Todos los colores 3,0 mm | UL94 | V-0 5VA | ||||

7. Purchase ABS virgin granules from Juyuan

Juyuan has 24 years of experience in international trade of plastic raw materials and has been supplying original ABS virgin particles to international brands such as LG Chem, SABIC and Toray for a long time.

Reasons for choosing Juyuan:

・All are genuine products supplied by the original factory and do not involve recycled materials or secondary granulation

・The global logistics system is well-developed, supporting bulk and sample shipments

・Provide technical selection and processing support

・Professional teams assist with export and customs declaration services

Whether you are an electrical manufacturer, an appliance assembly plant or a supplier of automotive plastic parts, Juyuan can match you with the right ABS virgin granules solution.

8. Frequently Asked Questions (FAQ)

Q1: What is the difference between ABS virgin granules and recycled granules?

ABS virgin granules have a complete molecular structure and stable physical properties. Their flame retardancy and mechanical properties are superior to recycled materials, making them suitable for high-requirement injection molded products.

Q2: Is AF312A suitable for thin-walled parts?

Yes. Its high melt index and flowability ensure smooth molding of thin-walled products without silver streaks.

Q3: Can AF312A be used in outdoor products?

This model is primarily used in indoor electronic devices. For outdoor use, a UV-resistant modified version can be selected according to requirements.

9. LG Chem's Recommended Similar Materials

| Modelo de producto | Densidad | Módulo de tracción | Resistencia a la tracción | Dureza Rockwell | Melt Flow Index | Alargamiento | Contracción | Módulo de flexión | Resistencia a la flexión | Temperatura de deflexión térmica | Flame Retardant Rating |

| AF366F | 1.19 g/cm³ | 2156.86 MPa | 39.21 MPa | 105 | 70 g/10min | 5% | 0.4~0.7% | 2352.94 MPa | 65.68 MPa | 89 °C | V-0 • 5VB • 5VA |

| AF366 | 1.19 g/cm³ | 2058.82 MPa | 39.21 MPa | 108 | 25 g/10min | 5% | 0.4~0.7% | 2450.98 MPa | 70.58 MPa | 90 °C | V-0 • 5VB • 5VA |

| AF365S | 1.19 g/cm³ | 2058.82 MPa | 44.11 MPa | 108 | 7.5 g/10min | 5% | 0.4~0.7% | 2450.98 MPa | 73.52 MPa | 95 °C | V-1 • V-0 • 5VB • 5VA |

| AF365F | 1.18 g/cm³ | 41.17 MPa | 105 | 75 g/10min | 5% | 0.4~0.7% | 2254.90 MPa | 66.66 MPa | 91 °C | V-1 • V-0 • 5VB • 5VA | |

| AF365 | 1.19 g/cm³ | 2058.82 MPa | 44.11 MPa | 108 | 30 g/10min | 5% | 0.4~0.7% | 2549.01 MPa | 73.52 MPa | 92 °C | V-1 • V-0 • 5VB • 5VA |

| AF360 | 1.19 g/cm³ | 2060 MPa | 36.3 MPa | 98 | 26 g/10min | 20% | 0.4% | 2260 MPa | 60.8 MPa | 92 °C | V-0 • 5VA |

| AF345 | 1.19 g/cm³ | 2160 MPa | 42.2 MPa | 103 | 37 g/10min | 20% | 0.4% | 2350 MPa | 68.6 MPa | 89 °C | V-0 • 5VB • 5VA |

| AF342 | 1.19 g/cm³ | 2160 MPa | 44.1 MPa | 103 | 37 g/10min | 20% | 0.4% | 2350 MPa | 68.6 MPa | 89 °C | V-0 • 5VB |

| AF312T | 1.18 g/cm³ | 2160 MPa | 42.2 MPa | 104 | 52 g/10min | 25% | 0.4% | 2600 MPa | 68.6 MPa | 84 °C | HB • V-0 • 5VB • 5VA |

| AF312F | 1.18 g/cm³ | 2058.82 MPa | 41.17 MPa | 103 | 90 g/10min | 5% | 0.4~0.7% | 2450.98 MPa | 66.66 MPa | 83 °C | V-0 • 5VB • 5VA |

| AF312C NP | 1.15 g/cm³ | 420 kg/cm² | 100 | 53 g/10min | 10% | 22000 kg/cm² | 590 kg/cm² | V-0 | |||

| AF312C C9057 | 400~490 kg/cm2 | 98 | 45.0~63.0 g/10min | 15.00% | 19500 kg/cm² | 560 kg/cm² | V-0 | ||||

| AF312A NP | 1.15 g/cm³ | 430 kg/cm² | 101 | 53 g/10min | 10% | 22300 kg/cm² | 600 kg/cm² | HB • V-0 • 5VB • 5VA | |||

| AF312A C9057 | 410~500 kg/cm² | 98 | 45.0~63.0 g/10min | 15.00% | 19500 kg/cm² | 560 kg/cm² | V-0 | ||||

| AF312 | 1.18 g/cm³ | 2160 MPa | 43.1 MPa | 104 | 52 g/10min | 20% | 0.4% | 2550 MPa | 70.6 MPa | 84 °C | HB • V-0 • 5VB • 5VA |

| AF303G | 1.19 g/cm³ | 40.3 MPa | 100 | 55 g/10min | 15% | 0.4% | 2400 MPa | 68.7 MPa | V-0 • 5VB |

【Recomendaciones relacionadas】

Taita ABS 5000 | High-Gloss ABS for 3C and Home Appliance Applications Más información>

CYCOLAC™ HMG47MD: Medical and Food-Contact ABS Plastic Raw Material Más información>

Is Plastic Harmful to the Environment? The Scientific Truth Behind a Misunderstood Material Más información>