PRODUCTOS

RADEL® PPSU | High Tough Plastics for Medical & Aerospace

Estructura del producto

What is RADEL® PPSU

RADEL® PPSU (polysulfone), as Solvay's flagship high-performance plastic, has long been used in industries with high safety standards such as aviation, medical care, rail transit, and electronics and electrical engineering.

Its comprehensive features make it the first choice for purchasers in terms of "safety, durability and compliance".

As an international supplier of plastic raw materials, Juyuan now presents to you a comprehensive guide for selecting the RADEL® PPSU series.

01 | Common advantages of the RADEL® PPSU series

High flame retardant grade: Complies with aviation standards, low smoke and low toxicity.

Excelente resistencia química: Resistant to cleaning agents and various chemical media.

Stable mechanical properties: high toughness and not prone to cracking.

Flexible processing: Supports multiple methods such as injection molding, extrusion, and thermoforming.

High thermal stability: The maximum heat distortion temperature can reach up to 202℃.

02 | Typical application fields of RADEL® PPSU

Aerospace: Aircraft seats, interior parts, panels, guide rail assemblies.

Medical devices: Surgical instruments, sterilized reusable parts (thanks to PPSU's ability to withstand repeated high-temperature steam sterilization).

Rail transit: Interior components and insulating parts of carriages, taking into account both safety and durability.

Electronic and electrical: Insulating components, structural parts that withstand high temperatures.

03 | Performance of each model and applicable scenarios

PPSU R-7700 / R-7700 GY734

・Features: Sheet material grade, excellent toughness, low smoke, and outstanding impact resistance.

・Mechanical properties: Tensile strength 58.6 MPa, flexural strength 100 MPa.

・Thermal performance: HDT up to 202℃, suitable for high-temperature environment applications.

・Applicable scenarios: Aircraft interiors, aerospace structural components, and applications with extremely high requirements for strength and heat resistance.

PPSU R-7400 / R-7400 GY714

・Features: High fluidity, specifically designed for injection molding, with both toughness and easy processability.

・Mechanical properties: Tensile strength 75.8 MPa, elongation up to 40%.

・Thermal performance: HDT 182℃, melt index 16 g/10min.

・Applicable scenarios: Complex-shaped aviation components, aircraft seat assemblies, and occasions that require high processing efficiency.

PPSU R-7300 / R-7300 BG870 / R-7300 WH7363

・Features: Color options available, low smoke emissions, and strong chemical resistance.

・Mechanical properties: Flexural strength 110 MPa, tensile strength 75.8 MPa.

・Thermal performance: HDT 182℃, melt index 16 g/10min.

・Applicable scenarios: Aircraft interior parts, aviation engineering applications, especially suitable for components that require both aesthetics and safety.

PPSU R-7535 / R-7558

・Features: High toughness, with notched impact strength as high as 160 J/m.

・Mechanical properties: Tensile strength 72.4 MPa, flexural modulus 2410 MPa.

・Thermal performance: HDT -196 ℃.

・Applicable scenarios: Components that require impact resistance and toughness, such as aviation safety components and parts subjected to impact.

PPSU R-7625

・Features: It combines high strength and rigidity, with a low shrinkage rate.

・Mechanical properties: Tensile strength 86.2 MPa, flexural strength 121 MPa.

・Thermal performance: HDT 193℃, melt index 17 g/10min.

・Applicable scenarios: High-strength structural components, suitable for aviation and industrial applications with requirements for mechanical load-bearing capacity.

04 | A quick comparison of models

| Grade | Ventajas clave | HDT (℃) | Tensile Strength (MPa) | Notched Impact (J/m) | Aplicaciones típicas |

|---|---|---|---|---|---|

| R-7700 | High toughness, heat-resistant, sheet grade | 202 | 58.6 | 130 | High-temperature structural parts |

| R-7400 | High flowability, injection molding friendly | 182 | 75.8 | 80 | Complex aircraft components |

| R-7300 Series | Low smoke, color options available | 182 | 75.8 | 80 | Aerospace interior parts |

| R-7535/7558 | High impact strength, outstanding toughness | 196 | 72.4 | 160 | Safety components |

| R-7625 | High strength, low shrinkage | 193 | 86.2 | 69 | Load-bearing parts |

05 | Common comparison dimensions for purchasers

If strength and rigidity are of concern → R-7625 is recommended

If you are concerned about toughness and impact resistance → R-7535 / R-7558 are recommended

If you are concerned about heat resistance → the R-7700 series is recommended

If you are concerned about processing efficiency → the R-7400 series is recommended

If you are concerned about aesthetics and interior safety → the R-7300 series is recommended

06 | FAQ (Frequently Asked Questions)

Q1: What is the difference between RADEL® PPSU and ULTEM (PEI)?

・PPSU offers greater toughness and impact resistance, making it suitable for applications requiring repeated impact or high strength.

・ULTEM offers greater stiffness and dimensional stability, making it more suitable for precision parts.

Q2: Why is RADEL® PPSU particularly suitable for aviation and medical fields?

・Aviation: Flame retardant, low smoke, meeting aviation safety regulations;

・Medical: Resistant to steam sterilization, can be repeatedly disinfected at high temperatures without degradation.

Q3: How to strike a balance between cost and performance?

・The unit price of PPSU is higher than that of conventional engineering plastics, but its total life cycle cost is lower: it reduces maintenance and replacement frequency, especially in high-safety industries.

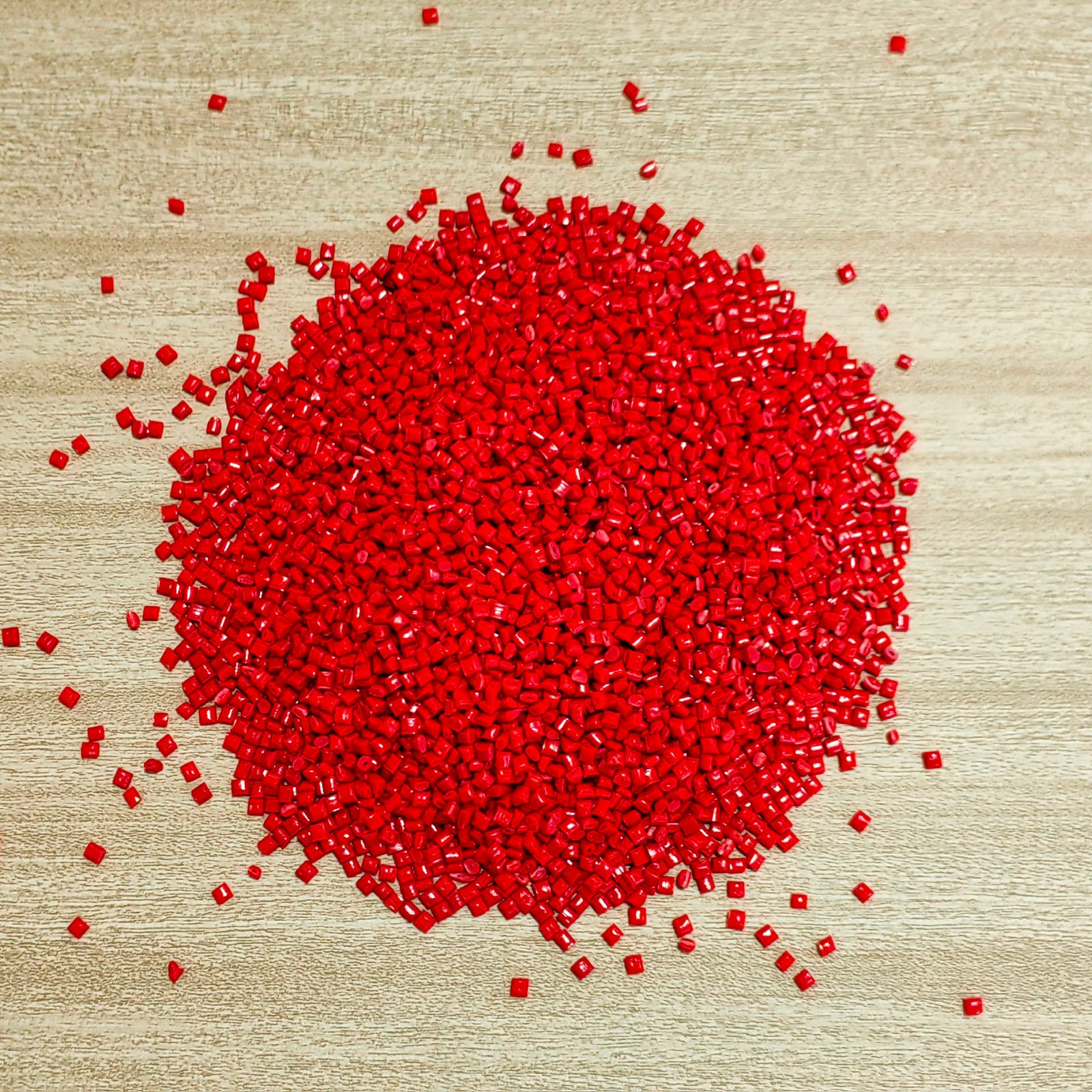

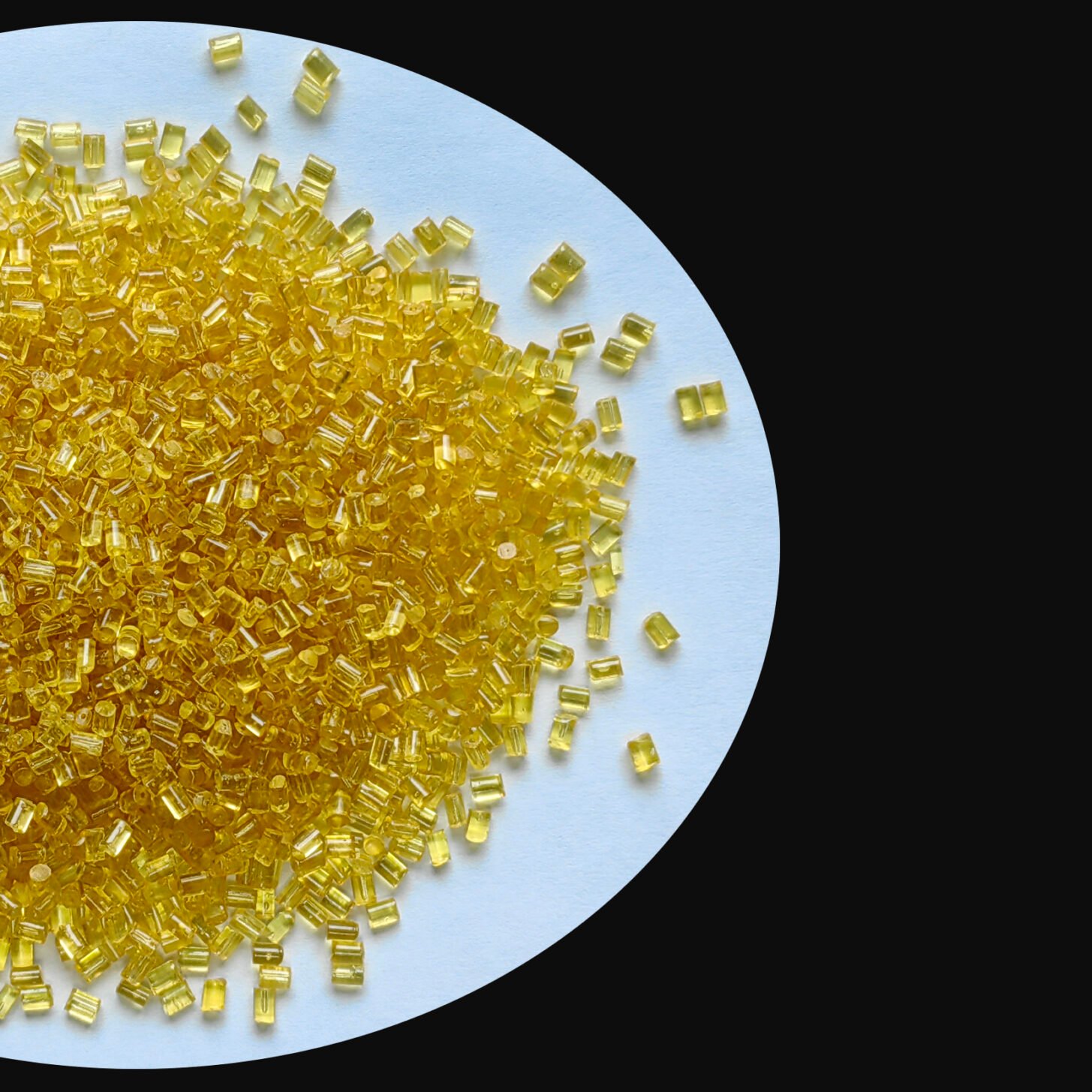

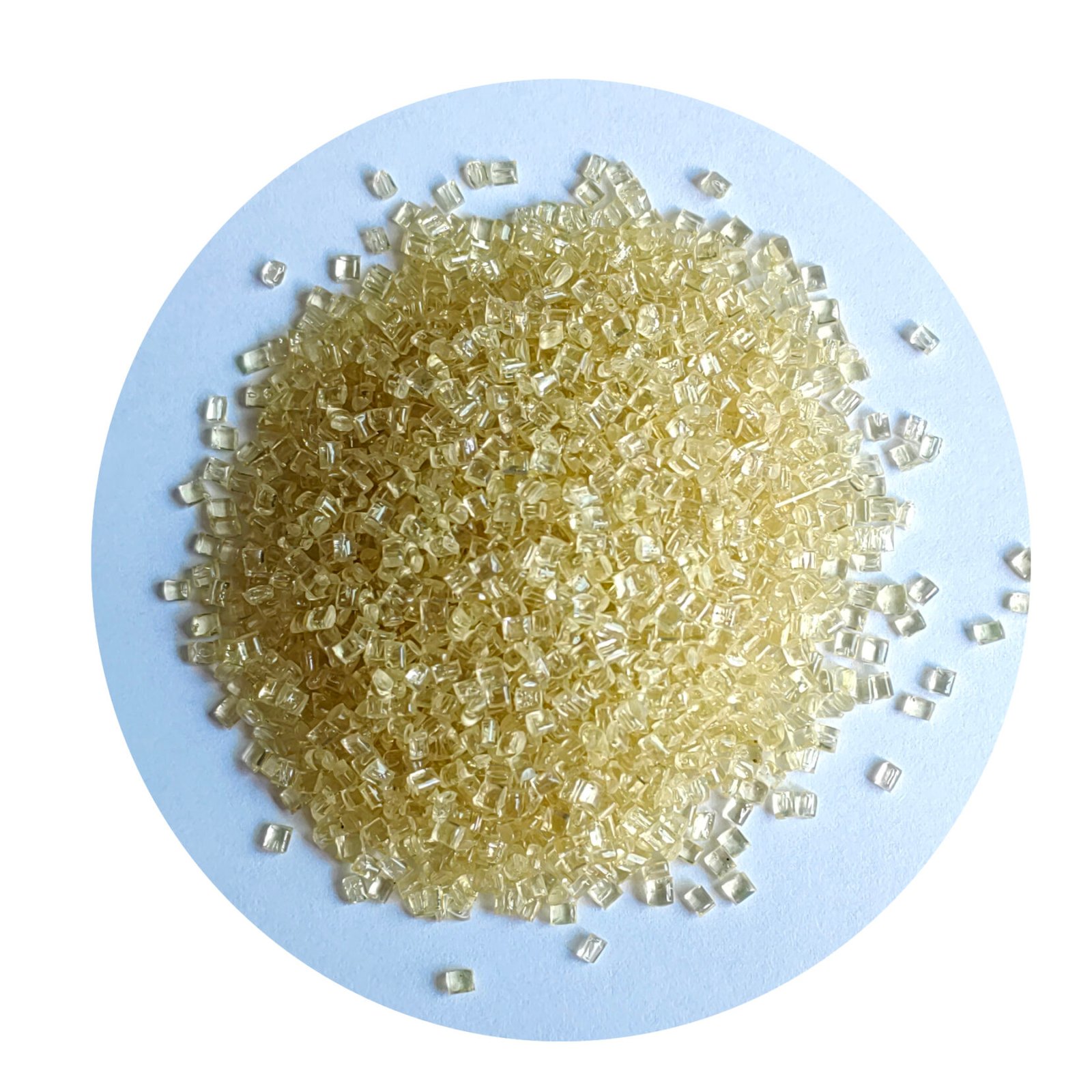

Q4: Are there any color and shape options?

・Yes. In addition to the regular transparent/black granules, some models support gray, white and custom colors. In terms of form, particles, plates and profiles can be selected.

Q5: What value-added services can Juyuan provide?

・Spot supply/International shipping

・Model selection suggestions

・Technical data support

・Multi-channel procurement ensures the stability of supply

07 | Conclusion

The RADEL® PPSU series covers a wide range of requirements from high-flow injection molding grade to high-heat-resistant sheet grade. Purchasers can quickly select based on strength, toughness and processing methods.

As an international supplier of plastic raw materials, Juyuan offers a full range of RADEL® PPSU products and can match the most suitable solutions for you based on industry needs.

👉 If you are looking for aerospace-grade PPSU high-performance plastic, please contact Juyuan immediately for professional support and first-hand supply.

【Recomendaciones relacionadas】

From Plastic Pellets to Films: A Complete Guide from Material Selection to Applications Más información>

Solvay Radel® R-5100 PPSU Flame-Retardant Guide | Juyuan Más información>

RADEL® R-7159 Series | PPSU Aerospace-Grade Material Guide Más información>