1. Introduction

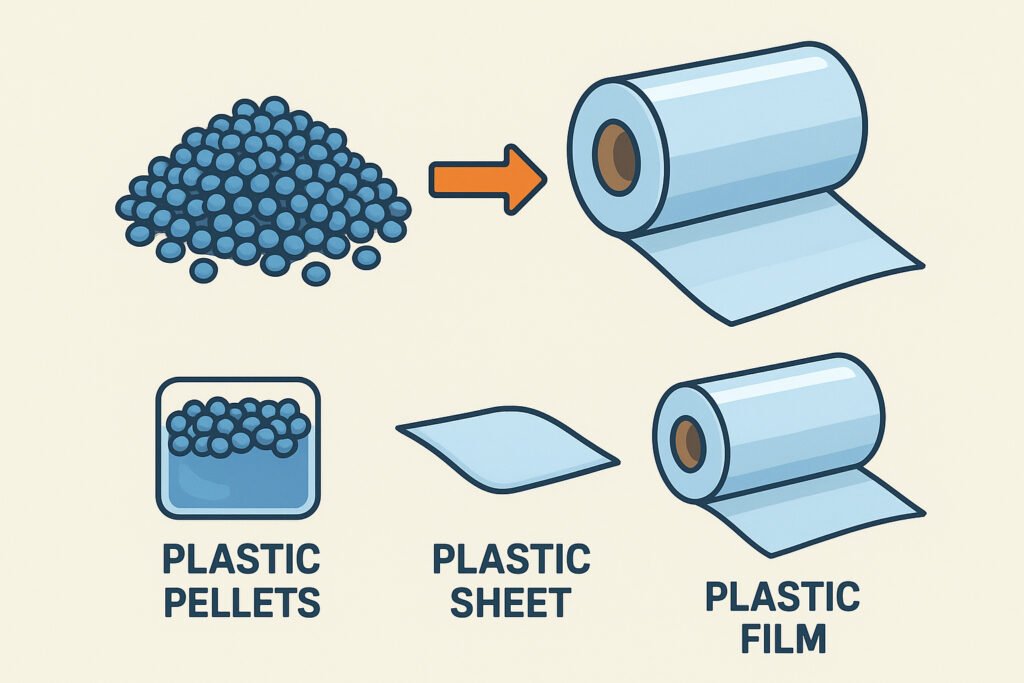

Plastic films are widely used in fields such as food packaging, industrial protective films, agricultural mulching films and functional films. The performance, transparency, toughness and barrier properties of the film largely depend on the type and performance of the raw material particles. Understanding the relationship between raw material particles and film processing is the key to producing high-quality films.

2. Plastic raw materials for film production

2.1 Polyethylene (PE) particles

・Features and Applications

LDPE/LLDPE: It has good melt fluidity and high flexibility, making it suitable for packaging films such as food bags, cling film, and express delivery bags

HDPE: It features high rigidity and good puncture resistance, and is widely used in industrial films and greenhouse films

・Key points for material selection: Density, molecular weight and MFI directly affect the tensile property, transparency and processing performance of the film

・Juyuan's advantages: Long-term stable supply of high-purity PE particles, high consistency of particle batches, helping film manufacturers maintain stable product quality

2.2 Polypropylene (PP) particles

・Type: Homogeneous polypropylene, copolymer

・Features and Applications

It is used for BOPP film and CPP film, suitable for high transparency and high stretch packaging

The molecular structure and melt index affect the biaxial stretching performance and optical effect of the film

・Juyuan's advantages: It can provide PP particles with different melt fluidity and molecular weight according to customer requirements, and supports customized film production

2.3 Functional particles such as MASCOTA, PVC, Pensilvania, EVA, y ordenador personal

・Applications: Transparent film, barrier film, heat-resistant film, optical film

・MASCOTA: It has good transparency and high mechanical strength, and is used for food packaging and optical films

・PA (Nylon) : Puncture-resistant, high strength, suitable for industrial packaging and composite films

・EVA: It has good flexibility and is mostly used in agricultural films and functional composite films

・PC (Polycarbonate) : High-temperature resistant and with excellent optical properties, it is used in safety films and protective films

・Juyuan's advantages: It offers a wide range of high-performance functional particles to meet the demands of high-end films, functional films and composite films, helping customers quickly adapt to market changes

2.4 Key Points for Raw Material Selection

・Melt fluidity (MFI)

・Tensile strength and elongation

・Thermal stability and temperature resistance

・Transparency and haze

・Cost and processing compatibility

3. From particles to film: The impact of processing technology on raw materials

3.1 Blown film process Extrusion

・PE and PP pellets are most commonly used.

・Features: Suitable for producing bags and agricultural films.

・Raw material requirements: Moderate melt flowability, good toughness, and balanced tensile properties.

3.2 Cast Film Extrusion

・Used for high-transparency or functional films.

・Raw material pellets require a uniform melt and a stable molecular weight distribution.

3.3 Biaxially oriented film (BOPP/BOPET)

・Polypropylene (BOPP), polyester (BOPET)

・The raw material molecular structure directly affects the stretch ratio, transparency, and mechanical properties.

3.4 Material-Process Interaction

・Different pellet properties determine film quality: Transparent films require high-purity pellets, while puncture-resistant films require high-molecular-weight pellets.

・Raw material density, MFI, and molecular weight distribution directly affect processing stability and film thickness uniformity.

3.5 Juyuan's Advantages

・With extensive industry experience, we can provide customers with advice on matching pellets with processing technology, reducing the risk of production defects.

4. The type of film corresponds to the application of raw materials

4.1 Flexible packaging film

・Mainly PE and PP particles, food bags, express delivery bags, and cling film

・PET can be used for transparent packaging and high-barrier films

4.2 Industrial Membrane

・PC, PA and PE are used for protective films, electrical insulating films and industrial tapes

・High tensile film requires raw materials with high toughness and good heat resistance

4.3 Agricultural Film

・HDPE and EVA particles are used to produce greenhouse films and ground films

・The toughness and aging resistance of raw materials determine their service life

4.4 Functional Film

・Barrier film, photovoltaic backsheet film, safety film

・The raw materials need to have the characteristics of high-temperature resistance, UV resistance or high strength

4.5 Juyuan Advantages

・The raw materials cover a wide range of application scenarios, quickly meeting the different film requirements of customers

5. Raw Material Testing and Film Quality Control

MFI (Melt Flow Index): Impacts film extrusion stability

Density: Impacts film toughness and transparency

Tensile strength and elongation: Determine film tear resistance

Transparency and haze: Directly impact the visual quality of packaging films

Heat shrinkage and temperature resistance: Impact shrink film and films for high-temperature applications

Juyuan's Advantages: Providing detailed raw material testing data and technical support to help customers optimize film quality

6. Industry Trends and Challenges

Sustainable materials: Bio-based and degradable particles are used for films to meet environmental protection requirements

High-performance films: The demand for transparency, barrier properties and mechanical strength is increasing

Cost and performance balance: Reasonably select raw material particles to achieve the best cost performance

Juyuan's advantages: Keeping up with global material trends, it offers degradable particles and high-performance functional particles to help customers upgrade their products

7. Summary

The performance and application of plastic films are highly dependent on the characteristics of raw material particles. From PE, PP to functional plastics, the selection of raw materials determines the transparency, toughness, heat resistance and barrier properties of the film. Reasonable matching of raw materials and processing techniques in procurement and production is the core point for manufacturing high-quality films.

8. FAQ

Q1: Which plastic pellets are suitable for high-transparency packaging film?

A1: Low-density PE, LLDPE, or high-purity PET pellets are more suitable for high-transparency film.

Q2: What are the differences in pellet selection between blown film and cast film processes?

A2: Blown film has high requirements for toughness and tensile properties; Casting has high requirements for the uniformity and transparency of the melt.

Q3: What raw material characteristics are required for high-barrier films?

A3: Particles requiring high molecular weight and low gas permeability, such as PET, PA or multi-layer composite materials.