PRODUCTOS

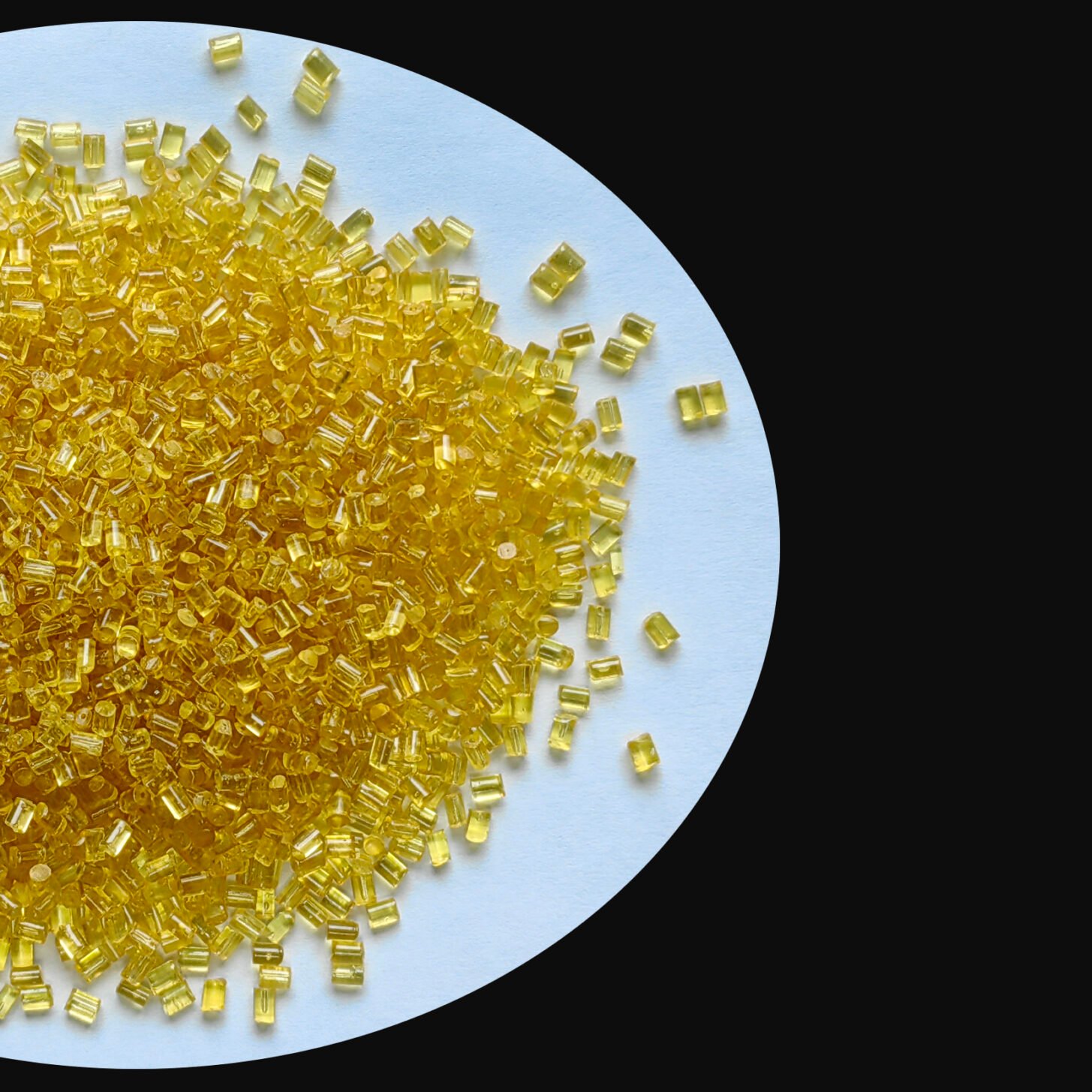

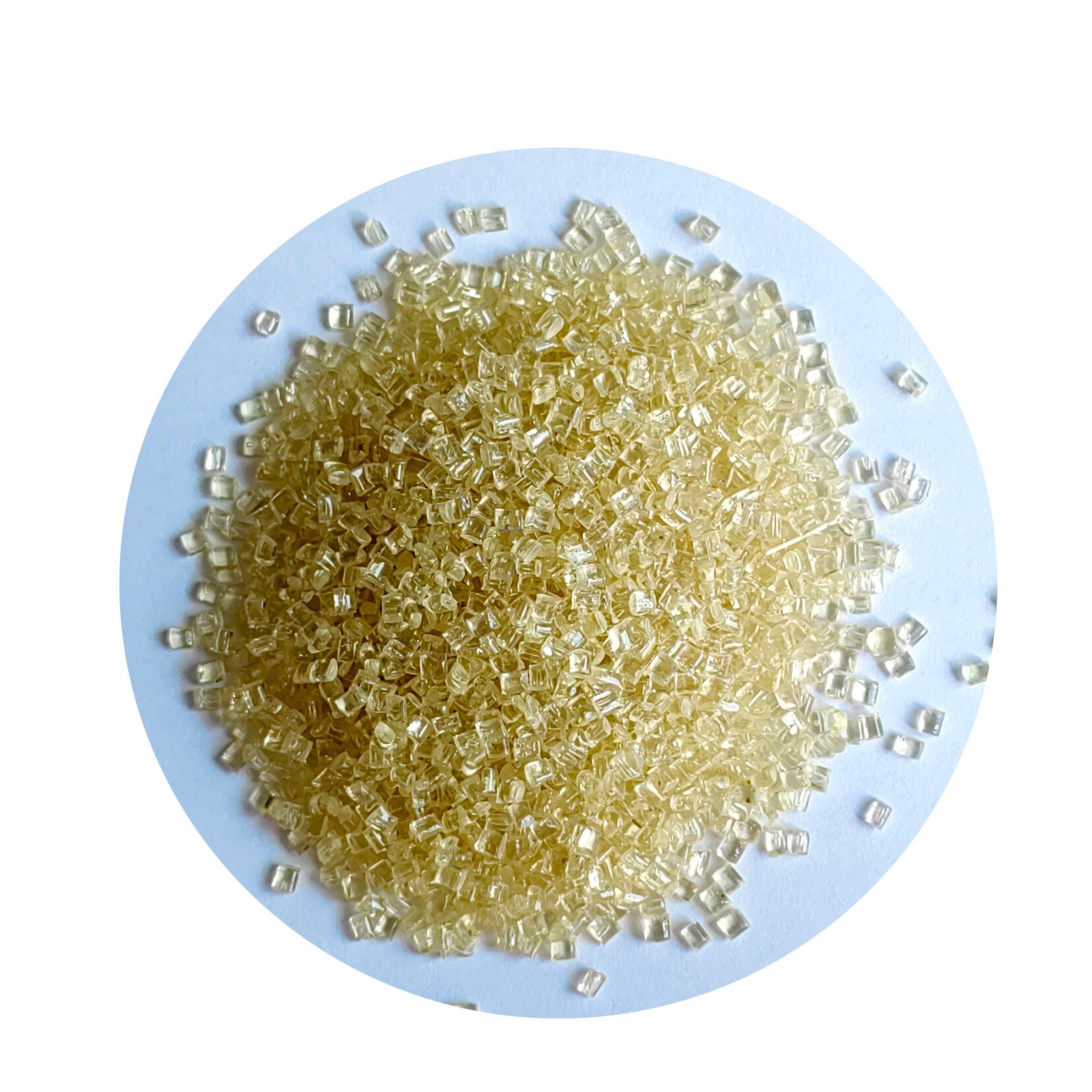

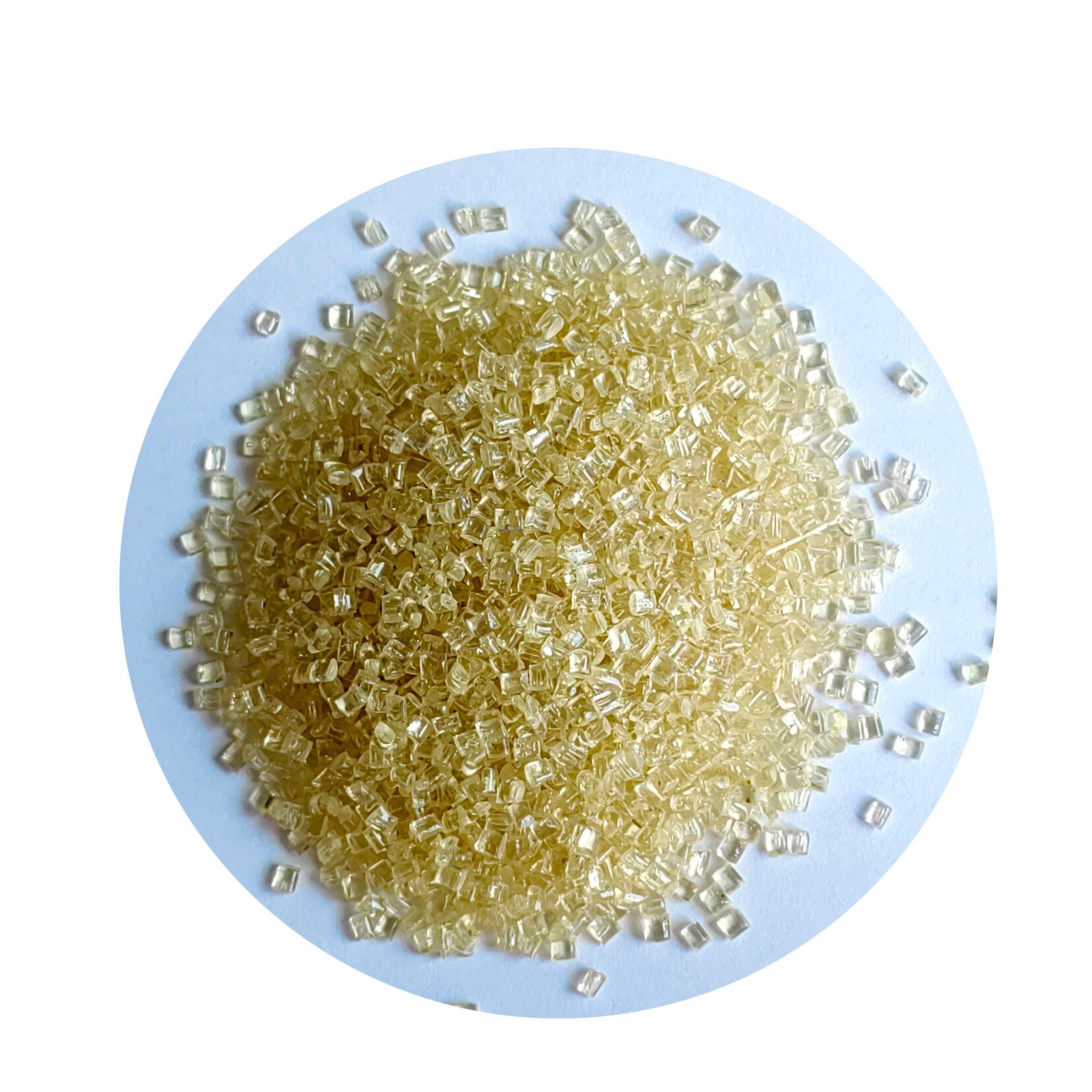

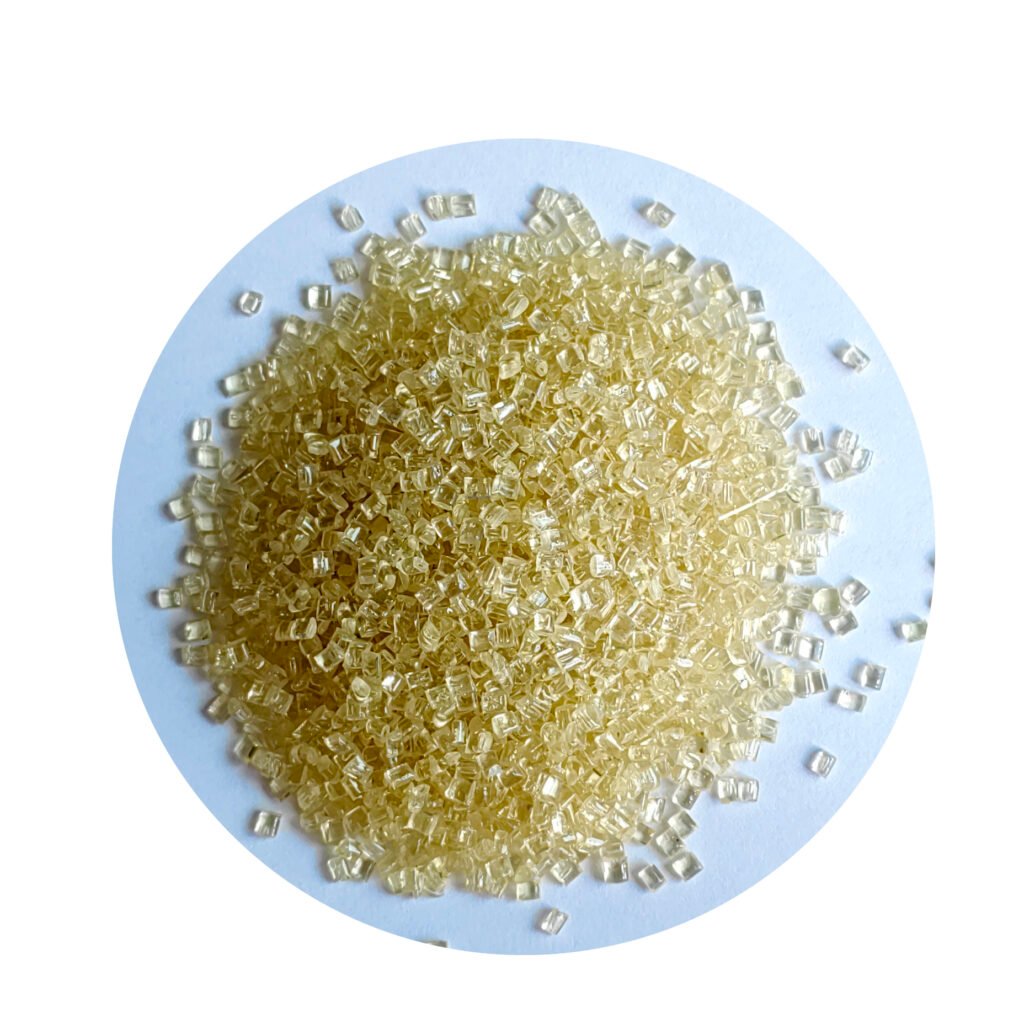

EPISPIRE PSU EP-340 | Heat-Resistant Polysulfone for Medical

Estructura del producto

What is EPISPIRE

Solvay’s EPISPIRE PSU EP-340 is an unfilled polysulfone material that delivers a rare balance of transparency, strength, and thermal stability. With its resistance to heat, low distortion under stress, and reliable optical clarity, it has become a trusted choice across electronics, automotive, medical, and optical industries.

01 | Key Material Features

Optical Reliability

EP-340 provides stable light transmission with controlled haze, enabling its use in transparent housings, viewing windows, and optical components.

Heat Resistance

The material withstands continuous service at temperatures above 250 ℃ while maintaining rigidity and strength.

Mechanical Integrity

Its tensile and flexural strength, combined with solid impact resistance, outperform many standard engineering plastics.

Dimensional Precision

Low shrinkage and minimal water absorption allow molded parts to retain tight tolerances even in demanding environments.

Processing Adaptability

A balanced melt index supports both injection and extrusion molding, making the grade well suited for automated, large-scale production.

02 | Typical Applications

Electronics & Electrical: Insulation parts, transparent covers, high-heat component housings.

Medical Devices: Transparent casings and sterilizable parts that withstand repeated autoclaving.

Automotive: Heat- and UV-resistant lampshades, sensor housings, and protective shells.

Optical Systems: Filters, detection modules, and light-transmitting protective panels.

03 | Processing Notes

EP-340 offers smooth melt flow and consistent filling, which minimizes stress-related defects in transparent parts. For medical or optical applications, precise temperature management ensures clarity and surface quality. When components are exposed to long-term heat, staged annealing is recommended to improve dimensional stability. The material’s low moisture uptake further reduces risks of warpage during post-processing.

04 | EPISPIRE PSU EP-340 Data Sheet

| Rendimiento óptico | Condición | Estándar | Valor | Unidad | |||

| Transmitancia | 2.5μm | Norma ASTM D1003 | 45 | % | |||

| Bruma | 2.5μm | Norma ASTM D1003 | 15 | % | |||

| Yellowness Index | ASTM D1925 | 80 | YI | ||||

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Norma ASTM D638 | 50 | % | ||||

| Alargamiento | 23℃ | Norma ASTM D638 | 15 | % | |||

| Alargamiento | Rendimiento 23°C | Norma ASTM D638 | 7.7 | % | |||

| Resistencia a la flexión | 23℃ | Norma ASTM D790 | 116 | MPa | |||

| Módulo de flexión | 23℃ | Norma ASTM D790 | 2600 | MPa | |||

| Impacto de muesca Izod | 23℃ | Norma ASTM D256 | 91 | j/m | |||

| Resistencia a la tracción | Rendimiento 23°C | Norma ASTM D638 | 94 | MPa | |||

| Módulo de tracción | 23℃ | Norma ASTM D638 | 2500 | MPa | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| HDT | Recocido 1,8 MPa | Norma ASTM D648 | 255 | ℃ | |||

| Temperatura de fusión | 400 | ℃ | |||||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Absorción de agua | 23℃ 24 horas | ISO 62 | 0.8 | % | |||

| Contracción | Fluir | ASTM D995 | 0.009 | % | |||

| Densidad | Norma ASTM D792 | 1.35 | gramos/cm³ | ||||

| Índice de fusión | 400℃ 5kg | Norma ASTM D1238 | 10 | g/10min | |||

05 | Advantages Over Alternatives

・Combines optical clarity with mechanical and thermal stability, a rare property set among engineering plastics.

・Can substitute higher-cost polymers such as PEI or PPSU when cost-performance balance is critical.

・Proven record in both medical and electrical industries, backed by extensive testing and user validation.

06 | Industry Feedback

Medical sector: Transparent housings remain clear and stable even after repeated sterilization.

Automotive users: Good transparency retention under heat and UV exposure, lowering replacement frequency.

07 | FAQs

Q1: How does EP-340 differ from PPSU?

PPSU offers higher impact toughness, while EP-340 stands out for its cost advantage, processability, and optical clarity.

Q2: Can it replace PC (polycarbonate)?

Yes, especially in high-temperature or sterilization environments where PC tends to fall short, though cost is higher than PC.

Q3: Is EP-340 suitable for food contact?

Certain certified grades are available for use in water-handling and food-contact parts. Compliance must be confirmed against specific local regulations.

08 | Recommended Alternatives

Customers may also consider other polysulfone and polyarylsulfone grades for different balances of toughness, optical clarity, or cost.

| Modelo de producto | Value Summary | Densidad | MFI | Resistencia a la tracción | Alargamiento | Contracción | Temperatura de fusión | Módulo de tracción | Heat Distortion Temperature | Dureza Rockwell | Izod Notched Impact | Módulo de flexión | Izod Impact Strength | CLTE | Resistencia a la flexión |

| R-7120 | 1.42 g/cm³ | 12 g/10min | 117 MPa | 2.2 % | 363 ℃ | 7300 MPa | 180 ℃ | 75 J/m | 6500 MPa | 1.1E-3 cm/cm/℃ | 155 MPa | ||||

| 1200 | Flame Retardant: V-0 | 1.21 g/cm³ | 207 MPa | 3 % | 8270 MPa | 160 ℃ | 64 | 42.7 J/m | 8270 MPa | 1070 J/m | 3.06E-3 cm/cm/℃ | 310 MPa | |||

| S-1000 | Flame Retardant: V-0 | 1.23 g/cm³ | 66 MPa | 100 % | 2410 MPa | 149 ℃ | 90 J/m | 2630 MPa | 1.03E-2 cm/cm/℃ | 97 MPa | |||||

| B-322 | Flame Retardant: V-0 | 1.47 g/cm³ | 6.5 g/10min | 0.3 % | 293.5 °C | 80 | 8.16 kJ/m² | 74.48 kJ/m² | 2.7E-3 cm/cm/°C | ||||||

| P-1720 NT 13 | Flame Retardant: V-0 | 1.24 g/cm³ | 7 g/10min | 70.3 MPa | 75 % | 0.7 % | 357 ℃ | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 5.6E-3 cm/cm/℃ | 106 MPa | ||

| M-2300 MR | 1.24 g/cm³ | 7.5 g/10min | 75.8 MPa | 70 % | 0.7 % | 357 ℃ | 2480 MPa | 178 ℃ | 53 J/m | 2760 MPa | 5.6E-3 cm/cm/℃ | 107 MPa | |||

| B-430 | Flame Retardant: V-0 | 1.52 g/cm³ | 7 g/10min | 121 MPa | 2.5 % | 0.25 % | 279.5 ℃ | 166 ℃ | 96.1 J/m | 9380 MPa | 2.7E-3 cm/cm/℃ | 185 MPa |

09 | Why Source from Juyuan?

With 24 years of experience in global plastics trade, Juyuan ensures:

・Fast Fulfillment – Ready stock shortens delivery lead times.

・Model Selection Expertise – Guidance across multiple PSU and related grades.

・Global Supply Network – Reliable sourcing from established manufacturers worldwide.

・Technical Support – Help with processing challenges, certification, and design optimization.

By choosing Juyuan, customers secure not only EPISPIRE PSU EP-340 supply but also a dependable partner for long-term success.

【Recomendaciones relacionadas】

RTP Engineering Plastics Series Comparison | Juyuan Más información>

Plastic Material Data Sheet Explained: Key Properties, Test Methods & Value Guide Más información>

Udel® PSU Series Comparison | High-Strength, Heat-Resistant Plastics Más información>