PRODUCTOS

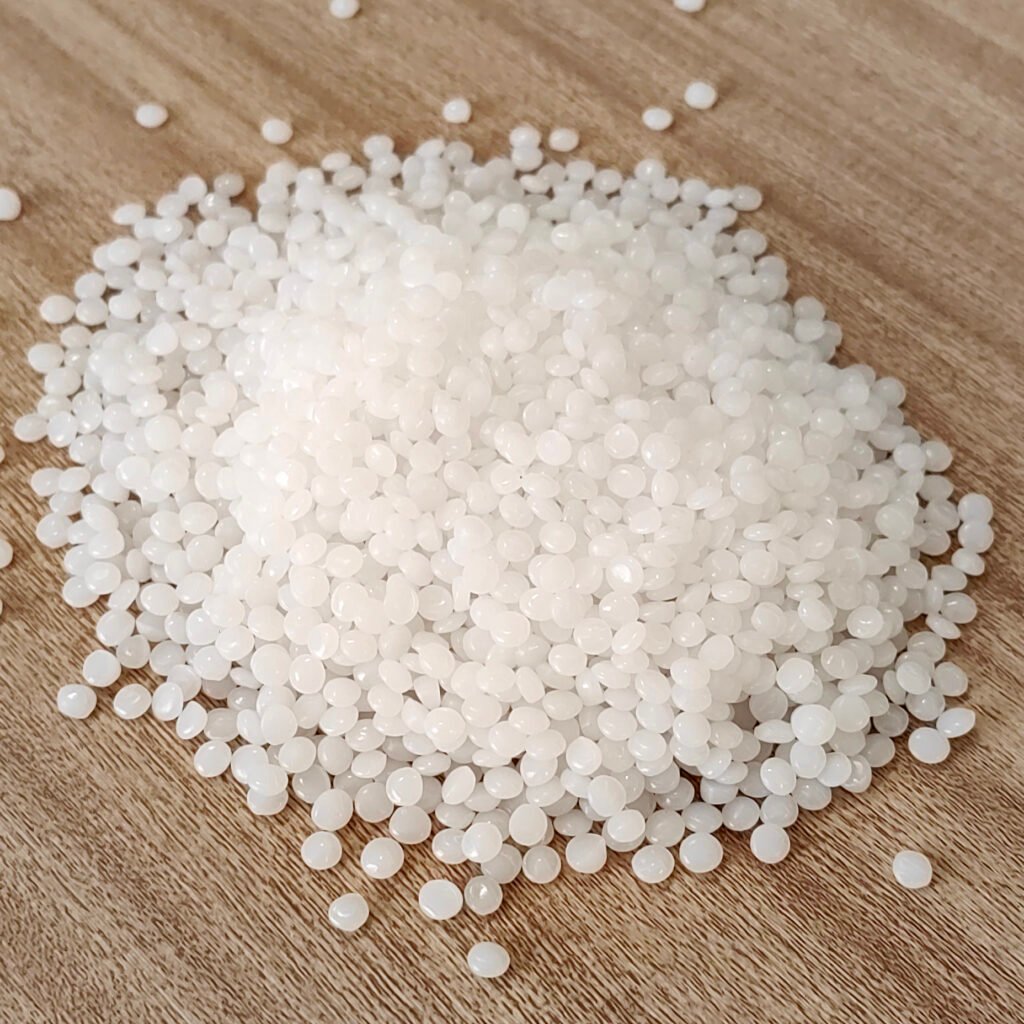

Descripción general del pellet de plástico HDPE LH523 | Propiedades y ficha técnica

Estructura del producto

El HDPE LH523 es un granulado plástico de polietileno de alta densidad (HDPE) de alto rendimiento en color natural, apto para procesos de moldeo por inyección y recubrimiento. Este material de HDPE posee excelentes propiedades, como alto brillo, alta gravedad específica, alta dureza, alta resistencia al impacto, alta rigidez, baja deformación, resistencia al agrietamiento por tensión y facilidad de procesamiento, lo que lo hace ideal para productos exigentes como cartuchos de sellado, carrocerías de vehículos todo terreno y aplicaciones de recubrimiento.

VENTAJAS DEL PRODUCTO

Superficie de alto brillo para una apariencia mejorada.

HDPE LH523 tiene una excelente superficie brillante, lo que hace que la superficie del producto final sea suave y delicada, y mejora el efecto visual y la textura del producto.

Alta rigidez y resistencia al impacto para una mayor durabilidad

La combinación de alta rigidez y alta resistencia al impacto permite que los productos mantengan una excelente estabilidad estructural en entornos hostiles, reduciendo el riesgo de daños.

Resistencia al agrietamiento por tensión para una vida útil más larga

El pellet de plástico HDPE tiene excelentes propiedades de agrietamiento por tensión ambiental (ESCR), que pueden resistir el estrés mecánico a largo plazo y el ataque químico, lo que garantiza que los productos no se agrieten fácilmente en el uso a largo plazo.

Baja deformación y buena estabilidad dimensional.

La estructura molecular optimizada reduce eficazmente la deformación y la distorsión durante el enfriamiento y el almacenamiento, lo que garantiza una forma estable del producto para aplicaciones de alta precisión.

Excelente rendimiento de procesamiento, mejora la eficiencia de producción.

Las características de fácil moldeo hacen que fluya bien en el proceso de inyección y recubrimiento y llene el molde de manera uniforme, lo que ayuda a mejorar la eficiencia de la producción y reducir los costos de fabricación.

APLICACIÓN DE PRODUCTOS

Cartuchos de sellador

El pellet de HDPE LH523 es adecuado para la fabricación de cartuchos selladores de alta resistencia y gran durabilidad que son resistentes al agrietamiento o la deformación en entornos de alta presión, mejorando la seguridad de la construcción.

Carrocería de vehículo de playa (ATV)

Su alta resistencia al impacto y a la intemperie lo convierten en un material ideal para carrocerías y componentes de vehículos todo terreno, lo que garantiza una alta resistencia y estabilidad en entornos exteriores difíciles.

Aplicaciones de recubrimiento

El plástico material Los pellets son adecuados para recubrimientos protectores de alto brillo y alta abrasión, que pueden mejorar significativamente la durabilidad y la estética de la superficie de los productos, así como mejorar su resistencia a la corrosión, para satisfacer las necesidades de tratamiento de superficies de una variedad de sectores industriales y de consumo.

PARÁMETROS DE LOS PRODUCTOS

| Dureza | Condición | Estándar | Valor | Unidad | |||

| Costa | Dureza D | ASTM D2240 | 68 | ||||

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Alargamiento | Romper | Norma ASTM D638 | 300 | % | |||

| Flexión | Módulo | Norma ASTM D747 | 8200 | kg/cm² | |||

| Izod | Impacto de muesca | Norma ASTM D256 | 3.5 | kg-cm/cm | |||

| Secante | Módulo 1% moldeado | Norma ASTM D638 | 7600 | kg/cm² | |||

| De tensión | Rendimiento de fuerza | Norma ASTM D638 | 230 | kg/cm² | |||

| Torsión | Módulo | ASTM D1043 | 9200 | kg/cm² | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Densidad | Norma ASTM D792 | 0.956 | gramos/cm³ | ||||

| Derretir | Índice | Norma ASTM D1238 | 23 | g/10min | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| Bajo | Fragilidad por temperatura F50 | ASTM D746 | -76.0 | °C | |||

| Derritiendo | Temperatura | Norma ASTM D3418 | 132 | °C | |||

| vicat | Temperatura de ablandamiento | Norma ASTM D1525 | 125 | °C | |||

EXHIBICIÓN DEL PRODUCTO

Haga clic aquí para descargar TDS para HDPE LH523

CONTÁCTENOS

¡Contáctanos para más información del producto! Si está buscando pellets de plástico HDPE de alto rendimiento, bienvenido a contactarnos para obtener más detalles del producto y cotizaciones, ¡trabajemos juntos para crear soluciones plásticas de alta calidad!

【Recomendaciones relacionadas】

HDPE DMDA8008: Moldeo por inyección de HDPE de alto impacto bolita para contenedores duraderos Más información>

HDPE Q TR-131: HDPE de grado alimenticio de alta resistencia bolita para película duradera Más información>

HDPE 7000F: HDPE de moldeo por soplado de alta resistencia material Para películas y embalajes duraderos Más información>