PRODUCTOS

Introducción al polietileno lineal de baja densidad de metaloceno 1327MD

Estructura del producto

Introducción a MLLDPE 1327MD

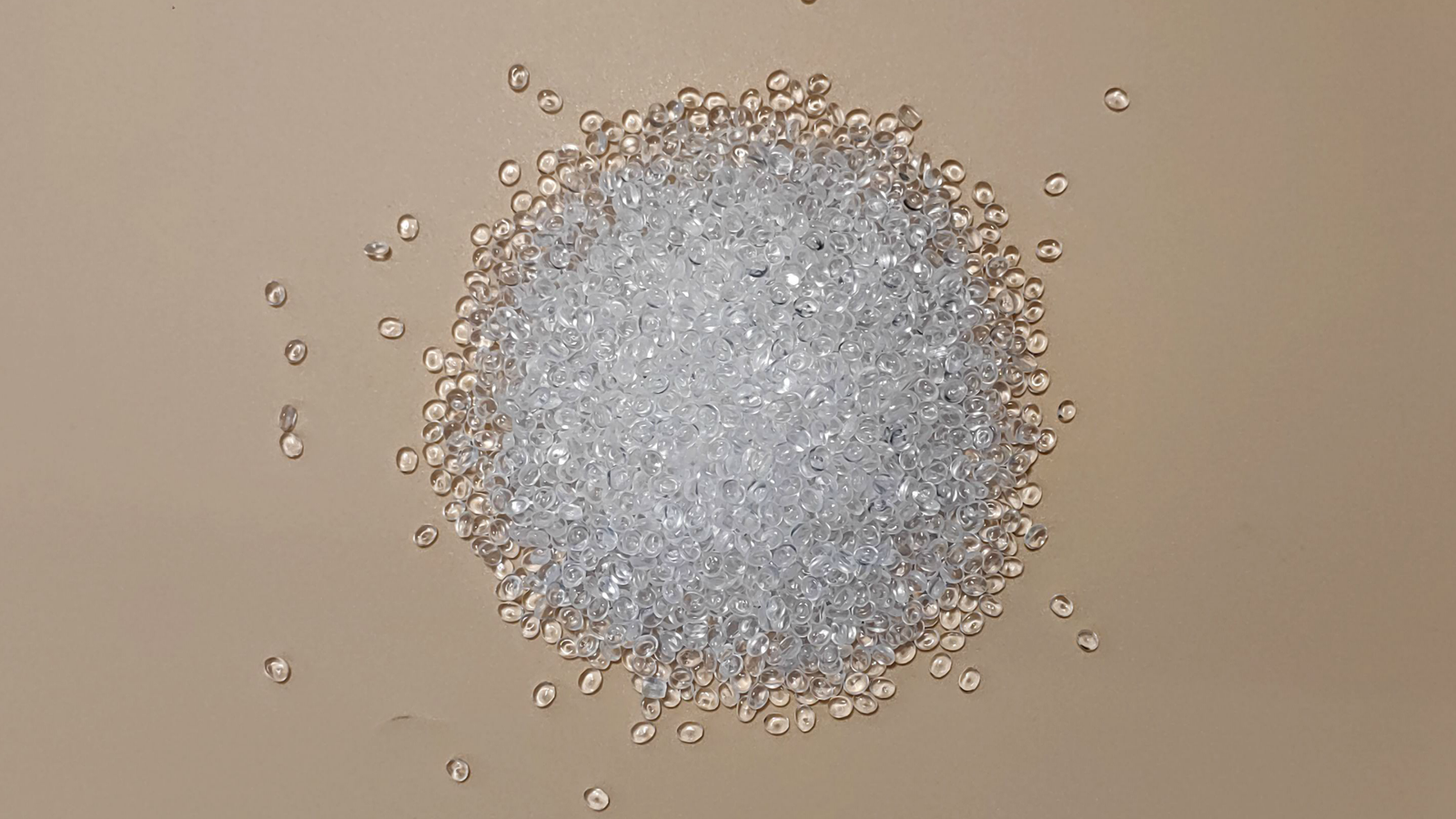

Los gránulos de plástico mLLDPE 1327MD son un copolímero de polietileno lineal de baja densidad (mLLDPE) de metaloceno de alto rendimiento y aspecto natural, diseñado para procesos de moldeo por soplado. Sus propiedades incluyen grado de película y grado de moldeo por soplado, y cumplen con las normas de contacto con alimentos. La adición de agentes de apertura y un copolímero de seis carbonos mejora sus propiedades de procesamiento y resistencia mecánica.

1. Propiedades del MLLDPE 1327MD

El material LLDPE de metaloceno se caracteriza por su alto módulo y alta tenacidad, lo que lo hace excelente para aplicaciones en películas. Ofrece buena flexibilidad, resistencia al desgarro y a la perforación. Sus excelentes propiedades de barrera lo hacen ampliamente utilizado en envases alimentarios e industriales, incluyendo bolsas para revestimiento de cajas, envases de barrera para alimentos, bolsas para pan, envases sellados, bolsas verticales, bolsas de basura, bolsas con cierre hermético y películas retráctiles.

2. Aplicaciones del polietileno lineal de baja densidad de metaloceno

Además, el gránulo mLLDPE1327MD agrega agentes de apertura, estabilizadores térmicos, aditivos de formación y potenciadores de deslizamiento para optimizar el rendimiento del procesamiento, mejorar la suavidad de la superficie de la película y mejorar la facilidad de uso de la película, lo que lo convierte en una opción ideal para materiales de embalaje de alta calidad.

3、Metaloceno Parámetros de LLDPE 1327MD

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Elmendorf | Flujo de resistencia al desgarro | ASTM D1922 | 190 | gramo | |||

| Elmendorf | Resistencia al desgarro xFlow | ASTM D1922 | 450 | gramo | |||

| Alargamiento | Interrupción del flujo | Norma ASTM D882 | 560 | % | |||

| Alargamiento | xRuptura de flujo | Norma ASTM D882 | 620 | % | |||

| Descendente | Resistencia al impacto del peso | ASTM D1709 | 140 | gramo | |||

| Punción | Resistencia | MÉTODO INTERNO | 38 | norte | |||

| Punción | Resistencia | MÉTODO INTERNO | 1.7 | Yo | |||

| Secante | Módulo de flujo 1% | Norma ASTM D882 | 310 | MPa | |||

| Secante | Módulo 1% xFlow | Norma ASTM D882 | 330 | MPa | |||

| De tensión | Resistencia Flujo Rendimiento | Norma ASTM D882 | 13 | MPa | |||

| De tensión | Resistencia x Caudal Rendimiento | Norma ASTM D882 | 14 | MPa | |||

| De tensión | Rotura de flujo de fuerza | Norma ASTM D882 | 47 | MPa | |||

| De tensión | Fuerza xFlow Break | Norma ASTM D882 | 39 | MPa | |||

| Rendimiento óptico | Condición | Estándar | Valor | Unidad | |||

| Brillo | 45° | Norma ASTM D2457 | 25 | ||||

| Bruma | Norma ASTM D1003 | 26 | % | ||||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Densidad | Norma ASTM D1505 | 0.927 | gramos/cm³ | ||||

| Derretir | Índice 190°C 2,16kg | Norma ASTM D1238 | 1.3 | g/10min | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| Derritiendo | Pico de temperatura | MÉTODO INTERNO | 123 | °C | |||

| vicat | Temperatura de ablandamiento | Norma ASTM D1525 | 116 | °C | |||

Haga clic aquí para descargar la ficha técnica de mLLDPE 1327MD

4. Exhibidor de pellets MLLDPE 1327MD

Buscando altoalta calidad polietileno lineal de baja densidad de metaloceno¿Alcance o¡Contáctenos ahora para discutir sus necesidades con nuestros expertos!

【Recomendaciones relacionadas】

MLLDPE XP9100: mLLDPE de alto rendimiento para moldeo por soplado y envasado Más información>

mLLDPE 1018MF: Resina de polietileno de baja densidad (MLLDPE) de alto rendimiento para envases agrícolas Más información>

mLLDPE D174: Copolímero de película de alta tenacidad para aplicaciones de extrusión Más información>