PRODUCTOS

Descripción general de MLLDPE HP1018BM para envases de alimentos

Estructura del producto

Presentamos el MLLDPE HP1018BM

Polietileno de baja densidad (mLbd) HP1018BM Es un copolímero de polietileno lineal de baja densidad (mLLDPE) de metaloceno de alto rendimiento, que utiliza un proceso de moldeo por soplado y presenta excelentes propiedades mecánicas y de procesamiento. El material utiliza copolímero de hexeno y tecnología de catálisis de metaloceno para mejorar la resistencia, la tenacidad y la resistencia al impacto de la película, además de ofrecer un buen rendimiento de termosellado y resistencia a la perforación, lo que lo hace excelente para aplicaciones de envasado.

1. Propiedades del MLLDPE HP1018BM

El mLLDPE HP1018BM presenta una excelente resistencia al impacto de dardos y una excelente durabilidad en productos de película delgada. Su formulación contiene agentes de apertura, antioxidantes, aditivos de conformado y potenciadores de deslizamiento, que no solo mejoran la estabilidad del material, sino que también optimizan el flujo de procesamiento y las propiedades superficiales, lo que contribuye a aumentar la eficiencia de la producción y a mejorar la apertura y la suavidad de la película.

2. Aplicaciones del polietileno lineal de baja densidad de metaloceno

El LLDPE metaloceno HP1018BM se utiliza ampliamente en películas industriales, películas compuestas, envases de alimentos, películas laminadas, películas agrícolas y otros campos, siendo especialmente adecuado para envases de alta resistencia y tenacidad. Sus excelentes propiedades mecánicas y adaptabilidad al procesamiento lo convierten en la opción ideal para soluciones de envasado que requieren alta resistencia al impacto, alta transparencia y un excelente rendimiento de termosellado.

3、Metaloceno Parámetros del LLDPE HP1018BM

| Moldeo por soplado | Condición | Estándar | Valor | Unidad | |||

| Explotar | relación ascendente | 1.5~3.0 | |||||

| Derretir | Temperatura | 150~180 | °C | ||||

| Comportamiento mecánico | Condición | Estándar | Valor | Unidad | |||

| Elmendorf | Resistencia al desgarro Flujo de película de 25 μm 500 mm/min | ASTM D1922 | 280 | g/µm | |||

| Elmendorf | Resistencia al desgarro xFlow 25μm Película 500 mm/min | ASTM D1922 | 370 | g/µm | |||

| Alargamiento | Película de 25 μm de 500 mm/min de rotura de flujo | Norma ASTM D882 | 550 | % | |||

| Alargamiento | Película de 25 μm de xFlow Break 500 mm/min | Norma ASTM D882 | 640 | % | |||

| Descendente | Método de resistencia al impacto de peso de una película de 25 μm | ASTM D1709 | 700 | gramo | |||

| Secante | Módulo 1% Flujo Película de 25 μm 500 mm/min | Norma ASTM D882 | 2800 | kg/cm² | |||

| Secante | Módulo 1% xFlow Película de 25 μm 500 mm/min | Norma ASTM D882 | 3100 | kg/cm² | |||

| De tensión | Resistencia a la rotura del flujo 500 mm/min 25 μm Película | Norma ASTM D882 | 520 | kg/cm² | |||

| De tensión | Resistencia xFlow Break 500 mm/min Película de 25 μm | Norma ASTM D882 | 450 | kg/cm² | |||

| Rendimiento óptico | Condición | Estándar | Valor | Unidad | |||

| Bruma | Película de 25 μm | Norma ASTM D1003 | 18 | % | |||

| Propiedad fisica | Condición | Estándar | Valor | Unidad | |||

| Densidad | Norma ASTM D1505 | 0.918 | gramos/cm³ | ||||

| Derretir | Índice 190°C 2,16kg | Norma ASTM D1238 | 1 | g/10min | |||

| Térmico | Condición | Estándar | Valor | Unidad | |||

| Derritiendo | DSC de temperatura | MÉTODO INTERNO | 118 | °C | |||

Haga clic aquí para descargar la ficha técnica del mLLDPE HP1018BM

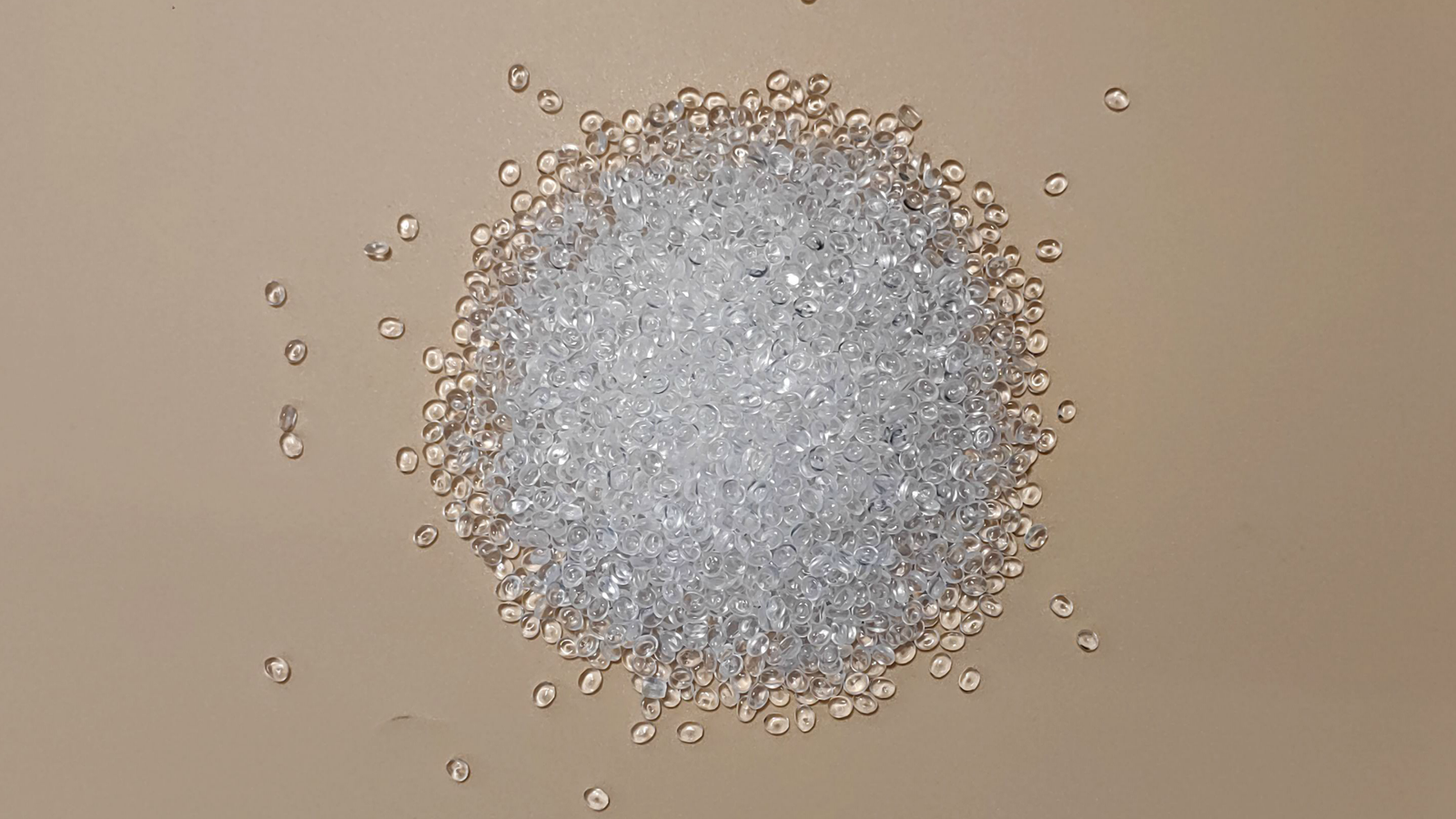

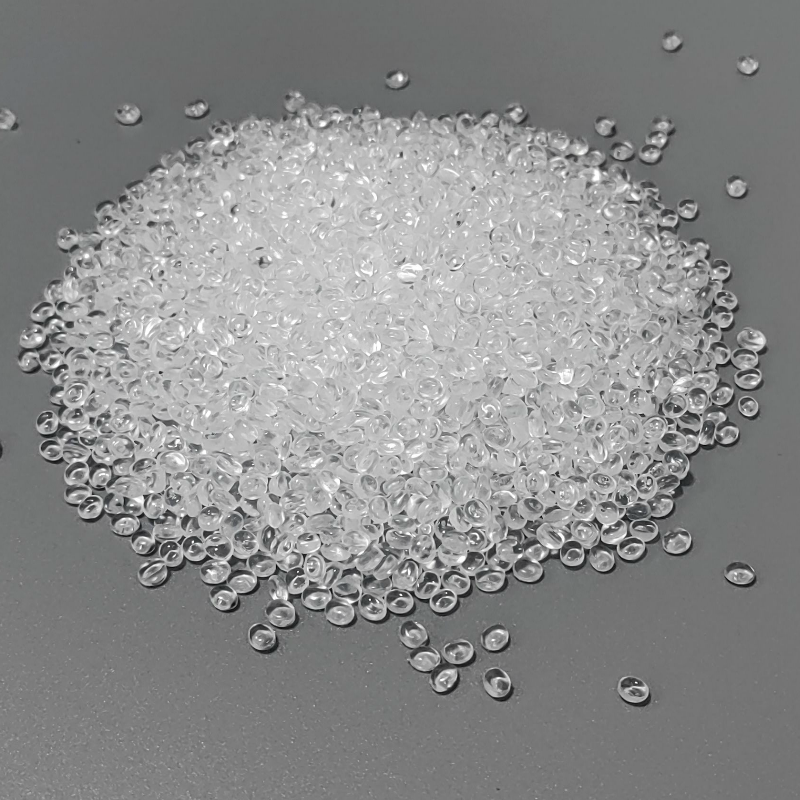

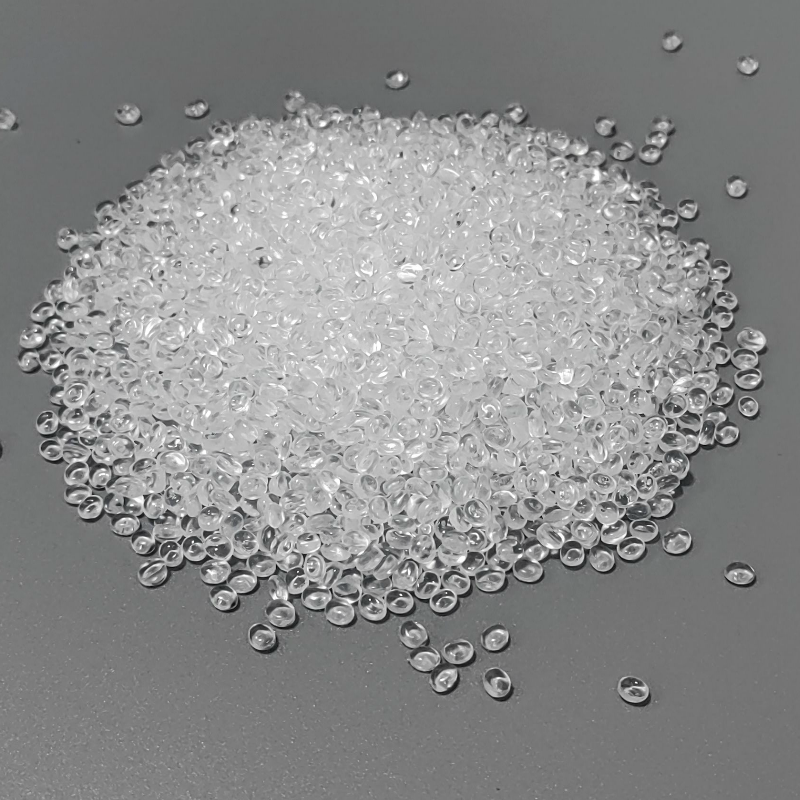

4、Exhibidor de gránulos MLLDPE HP1018BM

¿Tienes preguntas o necesitas soluciones personalizadas? ¡Ponte en contacto con nosotros para recibir asesoramiento personalizado!

【Recomendaciones relacionadas】

mLLDPE D173: Resina MLLDPE de grado de película resistente y de alta claridad para embalaje Más información>

mLLDPE PF1315AZ: Resina base de alto rendimiento para envases flexibles y revestimientos Más información>

mLLDPE D174: Copolímero de película de alta tenacidad para aplicaciones de extrusión Más información>