PRODUCTS

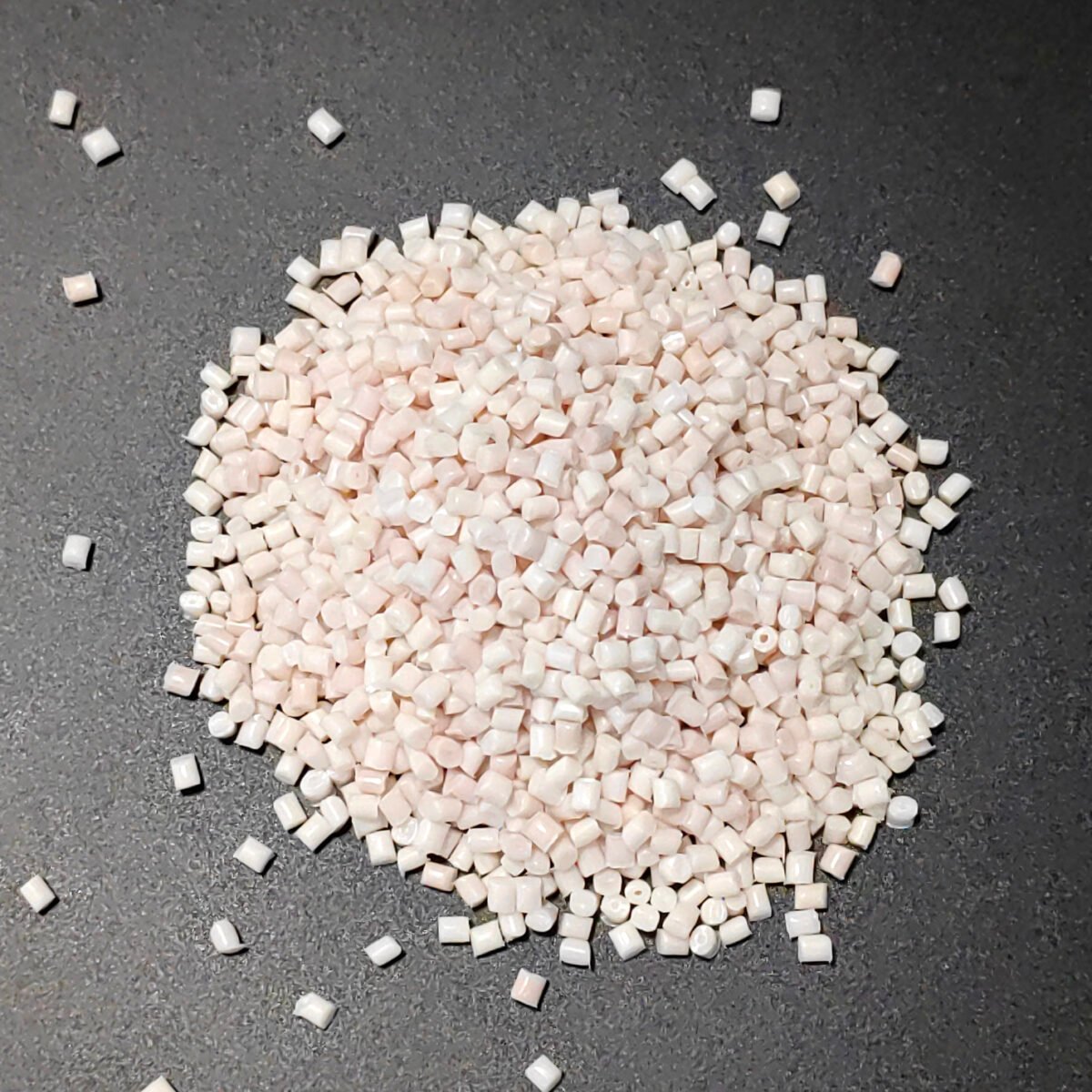

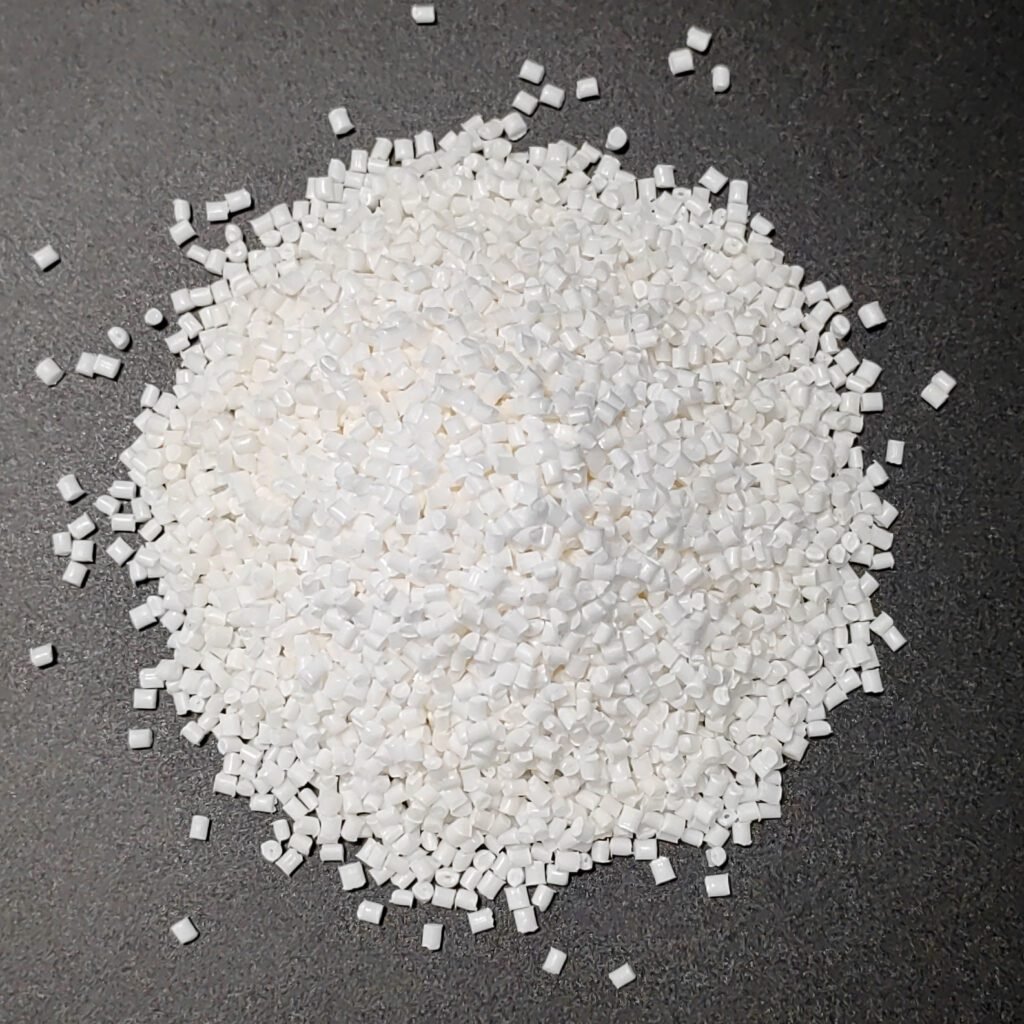

LANXESS PA6 BKV30H2.0 901510 | Nylon Polyamide 6 Overview

Product Struction

What is Nylon Polyamide 6

LANXESS PA6 BKV30H2.0 901510 is a high-performance glass-fibre reinforced nylon polyamide 6 (PA6) material with excellent mechanical strength, thermal stability and dimensional accuracy. It is formulated with 30% glass fibre and modified with heat stabilizers, making it particularly suitable for injection-moulded parts that operate for long periods of time in high-temperature environments, such as automotive structural parts, electrical components, and industrial equipment housings.

01 | Product performance advantages

1. It has high structural strength and meets the usage requirements of load-bearing components

The bending modulus can reach 9500 MPa, and the bending strength is 270 MPa. It can effectively support high-load working conditions and enhance the overall rigidity.

The tensile strength reaches 175 MPa, and the elongation at break is 3.5%. It is not prone to brittle fracture when subjected to tensile force.

The notched impact strength of Charpy reaches 9 kJ/m², and it also has a certain impact toughness, making it suitable for dynamic load scenarios.

2. Excellent thermal stability, suitable for high-temperature working environment

The heat distortion temperature (1.8MPa) reaches 215°C, and the Vicat softening temperature is 200°C, which can maintain good dimensions and mechanical properties in a hot environment.

The material has been added with a heat-stabilizing formula, which can significantly reduce the risk of performance deterioration caused by long-term high temperatures and extend the service life.

3. It has reliable electrical insulation performance and can be used in the field of electronics and electrical engineering

The CTI tracking index reaches 425V, which helps prevent surface arc corrosion.

Volume resistivity up to 1 × 10¹⁵ Ω-cm, surface resistivity of 1 × 10¹⁴ Ω, with good electrical insulation.

Insulation strength of 35 kV/mm, to meet the reliability requirements of high-voltage electrical components.

4. Strong dimensional stability, high processing accuracy

Low moulding shrinkage (0.06% in the flow direction and 0.13% in the vertical direction), which contributes to high-precision moulding and consistency control of products.

Excellent fluidity and balanced processing window, suitable for complex structure of the injection mould processing.

5. Compliance with flame retardant standards

Passed UL 94 HB flame retardant test at different thicknesses, suitable for industrial and consumer products with general flame retardant requirements.

02 | Polyamide BKV30H2.0 901510 Typical application areas

LANXESS PA6 BKV30H2.0 901510 is widely used in the following industries and products:

Automotive industry:

Cooling fan blades

Engine mounts

Lamp bracket, electronic control module shell

Electrical/Electronic:

Cable junction boxes

Relay and switch bases

Insulated guide rails, motor housings

Industrial Equipment:

Small gears, brackets

Pump and valve housings, mechanical interface components

Appliance housings:

Heater housings, power tool components

The material is particularly suitable for structural components at high temperatures, high mechanical stress, requirements for dimensional tolerances, and has good electrical safety properties.

03 | LANXESS Nylon 6 BKV30H2.0 901510 Processing recommendations

Processing method: injection moulding

Cylinder temperature: recommended range 260°C - 280°C

Mould temperature: 80°C recommended

Keeping the material dry can improve the surface quality and mechanical properties and avoid moulding defects such as bubbles and silver lines.

04 | Nylon Polyamide 6 BKV30H2.0 901510 Datasheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Flexural Strength | 2.0mm/min | ISO 178 | 270/160 | MPa | |||

| Flexural Modulus | 2.0mm/min | ISO 178 | 8500/5000 | MPa | |||

| Izod Un-notch Impact | 23°C | ISO 180 | 65/80 | kJ/m² | |||

| Izod Un-notch Impact | -30°C | ISO 180 | 60/55 | kJ/m² | |||

| Izod Notch Impact | 23°C | ISO 180 | 10/20 | kJ/m² | |||

| Izod Notch Impact | -30°C | ISO 180 | 10/10 | kJ/m² | |||

| Tensile Modulus | 1.0mm/min | ISO 527 | 9500/5800 | MPa | |||

| Tensile Creep Modulus | 1hr | ISO 899 | /5100 | MPa | |||

| Tensile Creep Modulus | 1000hr | ISO 899 | /4100 | MPa | |||

| Charpy Un-notch Impact | 23°C | ISO 179 | 75/90 | kJ/m² | |||

| Charpy Un-notch Impact | -30°C | ISO 179 | 65/60 | kJ/m² | |||

| Charpy Notch Impact | 23°C | ISO 179 | 10/20 | kJ/m² | |||

| Charpy Notch Impact | -30°C | ISO 179 | 10/10 | kJ/m² | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | 0.45MPa | ISO 75 | 215 | °C | |||

| HDT | 1.8MPa | ISO 75 | 200 | °C | |||

| Melting Temperature | 10°C/min | ISO 11357 | 222 | °C | |||

| Vicat Softening Temperature | 50°C/hr 50N | ISO 306 | 200 | °C | |||

| Vicat Softening Temperature | 120°C/hr 50N | ISO 306 | 200 | °C | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 23°C | ISO 62 | 7.0 | % | |||

| Density | ISO 1183 | 1.36 | g/cm³ | ||||

| Electrical properties | Condition | Standard | Value | Unit | |||

| Dielectric Constant | 1MHz | IEC 60250 | 3.8/4.4 | ||||

| Dielectric Constant | 100Hz | IEC 60250 | 4.2/12 | ||||

| Volume Resistivity | IEC 60093 | 1E+15/1E+12 | Ω.cm | ||||

| Dielectric Strength | 1.0mm | IEC 60243 | 35/30 | KV/mm | |||

| Dissipation Factor | 1MHz | IEC 60250 | 0.017/0.078 | ||||

| Dissipation Factor | 100Hz | IEC 60250 | 0.01/0.255 | ||||

| Surface Resistivity | IEC 60093 | 1E14/1E13 | Ω | ||||

Click here to download TDS for PA6 BKV30H2.0 901510

05 | Material innovation and technical background

LANXESS PA6 BKV30H2.0 901510 is based on LANXESS's many years of accumulated experience in polyamide 6 technology, and adopts directional glass fibre reinforcement technology and second-generation heat stabilizer system. Compared with traditional PA6 reinforcement, this product has technical innovations in the following aspects:

Thermal stability enhancer system H2.0: This proprietary formulation can effectively prevent polyamide molecular chain breakage under high-temperature aging environments (e.g., continuous operation at 140-150°C), thus prolonging the life of the product.

Low-warp reinforcement: Optimisation of the length distribution and orientation of the glass fibres significantly improves the dimensional stability of the product and reduces the risk of internal stresses and deformations in large injection-moulded parts.

Balanced mould flow design: Improved flowability enables better performance in the moulding of thin-walled complex structures, shortening cycle times and reducing scrap rates.

The material has been widely adopted by German local automotive and industrial equipment manufacturers, and is a typical representative of the combination of ‘thermal stability + high rigidity’ in the LANXESS Durethan® series.

06 | Manufacturing process and quality control

LANXESS BKV30H2.0 901510 is manufactured using an automated continuous co-extrusion process with a full quality tracking and data visualisation system, which ensures excellent consistency from batch to batch.

Manufacturing process overview:

Raw material pre-treatment: Selection of high-purity polyamide resins and surface-treated glass fibres to control moisture and impurities.

High-temperature blending: the glass fibre and PA6 resin are evenly dispersed through the twin-screw extruder to control the glass fibre breakage rate.

Addition of heat stabilising and lubricating modifiers: to improve oxidation resistance and moulding smoothness under long-term thermal load.

Cooling and Pelletising: Ensure consistent pellet size for easy handling by customer's automatic feeding system.

Multi-batch quality control: including melt index, specific gravity, glass fibre content, mechanical strength, electrical properties and other comprehensive tests.

LANXESS factories are certified to ISO 9001 / IATF 16949 / ISO 14001 to ensure that each batch of material meets the stringent requirements of high-end manufacturing.

07 | Sustainability and Environmental Advantages

Although it is an engineering plastic, PA6 BKV30H2.0 901510 also shows certain advantages on the sustainable level:

High recyclability: Polyamide 6 itself can be recycled under certain conditions and supports closed-loop recycling programmes.

EU REACH & RoHS compliant: the raw material is lead-free, halogen-free, free of neighbouring benzene and does not contain SVHC substances.

Low volatility: Suitable for application scenarios that require odour and VOC, such as in-car spaces.

LANXESS has also introduced renewable energy power supply mechanisms in several factories around the world, creating a ‘low carbon footprint’ raw material sourcing option for its customers.

08 | Get in touch with us

For more technical parameters, TDS information or sample quotation, please feel free to contact us!

【Related Recommendations】

BASF PA6 B27 E: High-Insulation Nylon 6 for Electrical & Structural Applications Learn more>

UBE PA6 1013B: Nylon 6 for Electrical and Structural Components Learn more>

PET 8050:Halogen-Free Flame Retardant PET Resin for Structural and Electrical Parts Learn more>