PRODUCTS WE PROVIDE

POM C52021 Resin Overview | Properties Uses and Data Sheet

POM Plastic Material Overview | POM FM270 Properties and TDS

POM Material W2320 0035 Full Guide | Uses and Spec Sheet

Overview of High hardness Taisu Polyoxymethylene POM FM025E

BASF Polyoxymethylene Plastic H4320 AT Detailed Introduction

Introduction of High Impact Strength POM N2640 Z6 AT Granules

Characteristics and Applications of LUCEL Polyoxymethylene POM GC210

LUCEL POM GB-325 plastic raw material

LUCEL POM FW720F Low wear plastic raw material

LUCEL POM FW715CS Injection grade gear application raw material

LUCEL POM FW-715C Injection grade Switch application raw material

LUCEL POM FW-710F

Introduction to Film-Grade PP F280 Plastic Pellets with Data Sheet

Polypropylene PP B8101 Full Guide | Uses and Spec Sheet

Food Contact Grade PP M800E Granule Overview and Data Sheet

Versatile PP S1003 Resin Overview | Properties and Data Sheet

PP L-670M Raw Material Features Applications and Data Sheet

PP PPB-MP03-G(K8003) Polypropylene Granules Overview

Polypropylene PP 6331 Properties Applications and Data Sheet

SCG Chemicals PP PPB P838C Plastic Resin Full Guide

PP V30G

PP Z30G

Sinopec Polypropylene PPH Z30S

PP HP500P

Radel® R-5600 NT: Transparent Flame-Retardant PPSU Plastic

RADEL® R-5800 PPSU: Transparent Heat-Resistant Materials

DURADEX® D-3000 Series PPSU Material Grades Overview

Lehmann & Voss LUVOCOM® PPSU Series

EDGETEK™ RA-10GF-10CF/000 HI High Strength PPSU Resin

TECASON P MT Polyphenylsulfone for Medical & Industrial Use

RADEL® 5500 Black – Multi-Color Medical-Grade PPSU Material

RTP PPSU 1400 Series – Durable, Heat & Food Safe Resin

TECASON® P MT XRO® PPSU: Medical-Grade Multi-Color Plastic

RTP Lubricated PPSU: Strength, Heat Resistance & Precision

QUADRANT PPSU Series: Heat Resistance, Chemical Durability

LATI LAPEX Series | Dimensional Stability, Low Smoke PPSU

LG ABS TR558A Strong Impact Resistance ABS Virgin Plastic

Terluran® GP-35 ABS: Glossy Injection and Plating Material

Novodur® P2MC Plating-Grade ABS for Automotive & Appliance

Lustran ABS 348 Material for Medical and Food Grade Applications

LG Chem ABS AF312A | High Impact Injection ABS Virgin Granules

Taita ABS 5000 | High-Gloss ABS for 3C and Home Appliance

CYCOLAC™ HMG47MD | Food-Contact ABS Plastic Raw Material

Toyolac™ 700-314 ABS Resin Plastic for Automotive Interiors

Lotte ABS VH-0800 ABS Plastic Resin For Home Appliance

LG Chem ABS XR404: Heat-Resistant ABS Plastics for Automotive

ABS Material Overview | High-Flow ABS PA-737 for Automotive

ABS Pellets Introduction | Versatile Medium-Impact ABS 700 314 U

High-Clarity mLLDPE XP9100 Properties Uses and Technical Data

Introduction to High-Performance mLLDPE 1018MF and Datasheet

High-Performance mLLDPE SP0540 Properties Uses and TDS

Metallocene Linear Low Density Polyethylene SP1520 Overview

Versatile Metallocene LLDPE 3518CB Properties Uses and TDS

Introduce to Metallocene Linear Low Density Polyethylene 1327MD

Overview of High Strength mLLDPE 8784MK for Blow Molding Films

Introduction to High-Clarity mLLDPE D174 for Stretch Films

Overview of MLLDPE HP1018BM for Food Packaging

Introduction to mLLDPE PF1315AZ for Flexible Packaging

Overview of mLLDPE PF1320AZ Resin for Masterbatch and Coatings

Introduction to High Gloss mLLDPE D173 with Data Sheet

HDPE HTA 001HP5 | HDPE Resin for Bags and Film Blowing

HDPE HMA 016 | HDPE Pellet for Caps and Food Packaging

HDPE HD B1258 Pellet Features Applications and Data Sheet

Introduction to HDPE EGDA-6888 Granules with Data Sheet

HDPE 7200 Material Overview | Properties and Data Sheet

HDPE 5502HS Particle Uses, Characteristics, and Properties

HDPE 5200B Plastic Particle Full Guide | Uses and Spec Sheet

HDPE 550203LD Raw Material Full Guide and Datasheet

A Guide Into High Density Polyethylene (HDPE) P600 Resin

HDPE HD5301AA Virgin Material Overview | Properties and TDS

Introduction to HDPE HE3460 Resin Pellets with Datasheet

HDPE LH523 plastic pellet Overview | Properties and Datasheet

Automated Production & Strict Quality Control

JU YUAN News

-

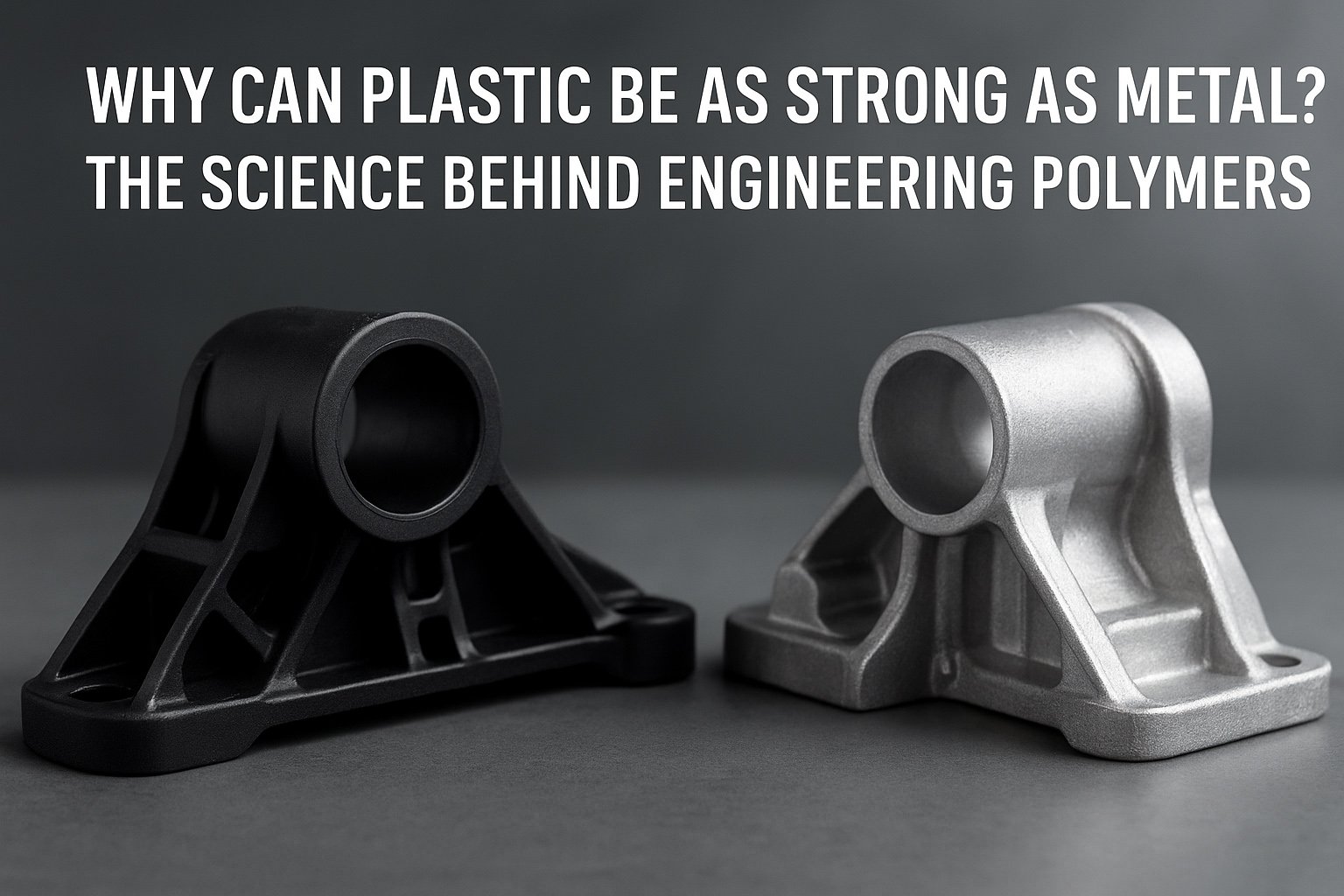

Why Can Plastic Be as Strong as Metal? The Science Behind Engineering Polymers

2025.11.03

I. From "Cheap Materials" to "High-performance Materials" : The Comeback of Plastic In the public's impression, "plastic" implies being thin, fragile and not durable.However, in modern manufacturing, this concept has long been outdated.Today's Engineering Plastics can rival or even surpass some metals in terms of strength, toughness and heat resistance, and are widely used in high-demand fields such as automobiles, aviation, electronics and medical care.The key behind t... -

Is Plastic Harmful to the Environment? The Scientific Truth Behind a Misunderstood Material

2025.10.31

I. The First Truth: Plastic is Indeed "Harmful," But Not the Whole Story From a scientific perspective, the harm caused by plastic is objectively real.Its behavior in the natural environment—especially its persistence after disposal—has become a global ecological challenge: ・Approximately 11 million tons of plastic enter the ocean annually; ・Over 90% of plastic waste is not fully recycled; ・Microplastics have been detected in marine life and even in the human ... -

Top 5 Most Watched Plastic Raw Material Trends in 2026

2025.10.30

With the recovery of global manufacturing, supply chain restructuring, and the accelerated expansion of the new energy industry, the plastic raw material market is ushering in structural opportunities.For international buyers, which materials will become market "hotspots" in 2026? Which categories are worth locking in inventory for in advance?Based on international data, customer purchasing feedback, and the dynamics of major raw material production capacity, Juyuan has compiled a lis... -

Refrigerator Plastics Guide: Performance, Cost & Supply

2025.10.28

In the home appliance industry chain, the manufacturing of plastic parts for refrigerators is an underestimated "systematic project".From the exterior panel to the internal sliding box, from the shelf support to the bottom structure, every plastic component directly affects the overall quality, energy consumption performance and service life of the entire machine.For injection molded parts manufacturers, how to strike a balance among performance, cost and supply stability has become t...