What Is Thermoplastic Polyurethane?

Against the backdrop of the continuous evolution of material technology, thermoplastic polyurethane (TPU) has gradually become an important material connecting rigid plastics and flexible elastomers. It not only has excellent processing performance and physical strength, but also demonstrates broad application potential in multiple industries. So, what material is tpu? What are its performance advantages and market trends worth paying attention to?

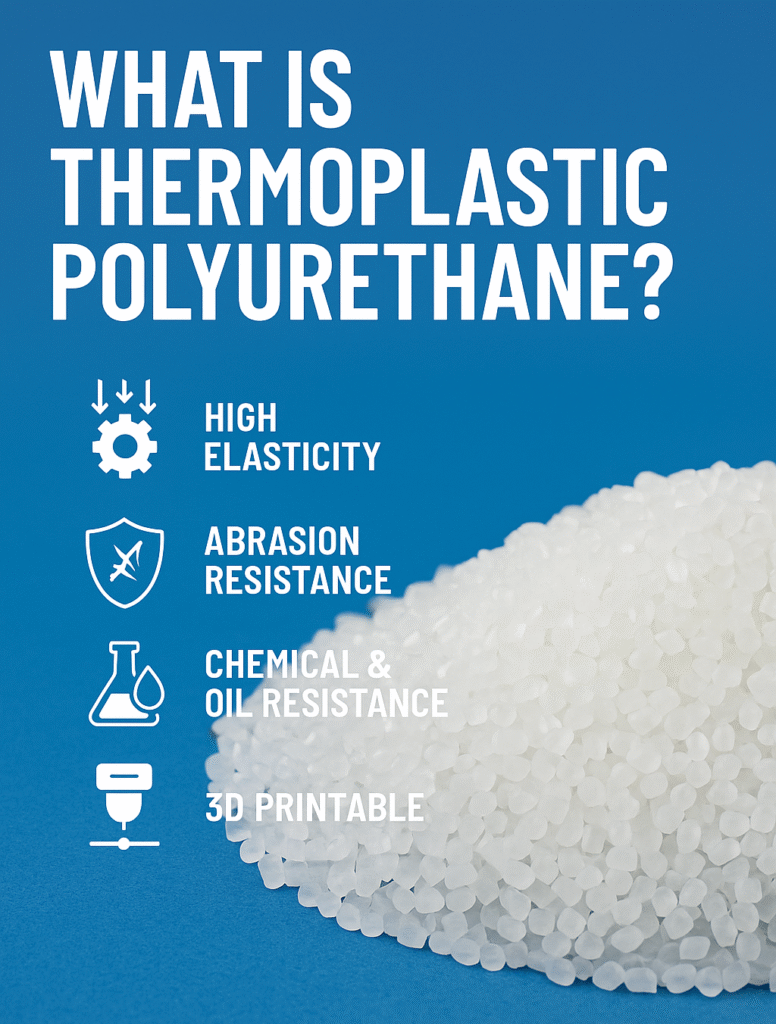

What Is Thermoplastic Polyurethane

1. Material definition: Engineering plastics that are both flexible and processable

TPU is a thermoplastic elastomer and belongs to the polyurethane family. Unlike traditional thermosetting polyurethane, TPU can be melted multiple times after heating and then cooled to form, making it suitable for various processing techniques such as injection molding, extrusion, blow molding and 3D printing. This reversible thermoplasticity enables it to be highly flexible in industrial production.

Main performance features:

・High elasticity and tear resistance, suitable for complex force scenarios

・Excellent wear resistance and oil resistance, meeting the requirements of industrial use

・Good transparency and easy colorability support designs that combine appearance and functionality

・It has strong biocompatibility and is suitable for use in medical and wearable products

TPU can be classified into polyester type, polyether type and caprolactone type according to its structure, and each type has different advantages in hydrolysis resistance, flexibility and high-temperature stability.

2. Market status Quo and Application Trends

At present, TPU particles are maintaining rapid growth worldwide. According to industry data, the market size is expected to approach 5 billion US dollars in 2025 and maintain an average annual growth rate of over 7% until 2033.

Main application fields

・Automobile manufacturing: used for wiring harness sheaths, interior covering parts, and sealing systems

・Consumer electronics: phone cases, cable covers, components for smart wearable devices

・Medical industry: catheters, flexible connectors, biomedical tubes

・Sports shoes and functional clothing: midsoles, outsoles, air cushions, anti-slip components

・Flexible 3D printing: used for prototype manufacturing and customizing small-batch components

The Asia-Pacific region is the main consumer area of TPU particles, and the downstream processing capacity in China and Southeast Asia continues to expand. The European and American markets, on the other hand, pay more attention to the development of TPU in high-performance and green applications.

3. Environmental protection and technological innovation drive product upgrading

Under the background of "dual carbon", the sustainable development potential of TPU is being further explored. Many international enterprises have initiated environmental protection upgrades for TPU materials

・Huntsman Avalon Gecko TPU offers excellent dry and wet anti-slip performance and is suitable for safety products and green consumer goods

・Basf has launched a biomass balanced TPU based on renewable raw materials, which can significantly reduce carbon emissions and has been certified by LCA

・Some TPU brands are attempting a fully recycled closed-loop system design to enhance the material recycling rate and improve the environmental friendliness of their products

Driven by these factors, TPU is transforming from a traditional engineering plastic to a material option that better meets the demands of future sustainable manufacturing.

4. The processing method is flexible and adaptable to various manufacturing scenarios

TPU is compatible with a variety of thermoplastic processing techniques and has high controllability in the manufacturing process

・Injection molding: Suitable for high-precision products such as structural components and electronic casings

・Extrusion molding: Widely used in pipes, cable sheaths, films and profiles

・Blow molding process: such as lightweight products like shoe sole air cushions and inflatable structures

・3D printing: Applied in customized medical care, prototype design, and flexible components

The hardness of TPU has a wide adjustable range (Shore 60A to 75D), which can not only meet the soft touch but also the higher rigidity requirements.

5. Strategic value of materials for the future

With the manufacturing industry moving towards intelligence, lightweighting and green low-carbon development, TPU has long-term strategic value in multiple emerging fields:

・In the field of new energy vehicles: lightweight cable sheaths, interior covering, and sensor protection structures

・Wearable and health devices: Medical accessories that are comfortable to the skin, have antibacterial and flexible requirements

・Circular economy system: Some recyclable TPU helps brands shape an environmental value label

・Intelligent shoe material system: It combines shock absorption and structural load-bearing capacity in intelligent sports equipment

6. Ensure stable supply and choose professional and reliable partners

The downstream applications of TPU have high requirements for material consistency and supply stability. As a plastic raw material supplier with years of international trade experience, Juyuan can provide customers with TPU particles covering application fields such as injection molding, extrusion, shoe materials, and medical care. It supports technical selection, sample testing, and bulk purchasing, and offers full-process services including customs declaration and transportation.

Conclusion

Thermoplastic polyurethane (TPU) is no longer merely a functional material for a specific industry; it is gradually becoming an important choice for various industries seeking flexibility, sustainability and processing efficiency. In the manufacturing trend that emphasizes both functionality and environmental protection, TPU has a steadily growing market potential and high adaptability.

If you are looking for injection molding grade, extrusion grade or high-performance environmentally friendly TPU particles, please feel free to contact Juyuan for technical data and sample solutions.

What Is Thermoplastic Polyurethane