PRODUCTS

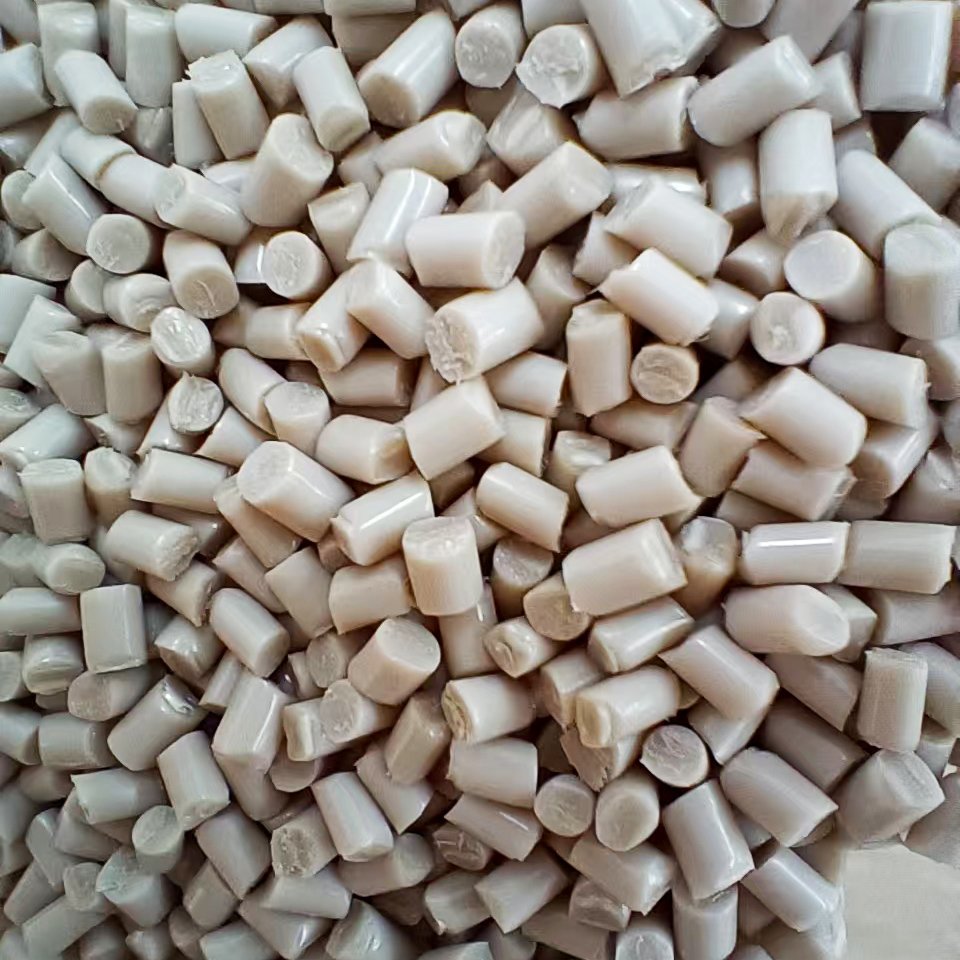

Wear-Resistant TECACOMP® PEEK TRM PVX black 1046944

Product Struction

1. Introduction: From Single Performance to System Balancing—The New Direction of PEEK Plastics

In the global manufacturing industry, material buyers are facing a common trend: material selection is no longer based solely on "parameters," but rather on "stability, cost-effectiveness, and system compatibility."

TECACOMP® PEEK TRM PVX black 1046944, developed by Ensinger, was born in this context. It's not just ordinary peek plastic; it's a composite solution specifically optimized for high-load, wear-resistant, and flame-retardant applications.

This material combines carbon fiber, graphite, and PTFE fillers, resulting in:

・High rigidity and pressure resistance

・Extremely low coefficient of friction

・Excellent thermal stability and flame retardancy

For companies seeking a "multi-functional" material in the automotive, mechanical, energy, or electrical sectors, TECACOMP® PEEK TRM PVX offers significant design freedom and process compatibility.

2. The Three Most Important Issues for Buyers: Lifespan, Processability, and Cost-Effectiveness

1. Service Life: Reducing Replacement Frequency through the Material

When choosing peek plastic, buyers often ask, "How long can I go without having to replace this part?"

TRM PVX Black 1046944's enhanced wear resistance and load-bearing properties directly extend component life. Its self-lubricating structure enables operation in oil-free or low-oil conditions, eliminating premature wear caused by lack of lubrication.

This means extended maintenance intervals and reduced downtime costs in:

・Production lines with long equipment runs

・Mechanical components subject to continuous friction at high temperatures

・Enclosed environments where frequent maintenance is infrequent

2. Processing Compatibility: An Industry-Friendly Material for Injection Molding

Unlike some highly filled plastics, TECACOMP® PEEK TRM PVX maintains excellent flow and mold-filling properties during injection molding. For buyers, this means:

・No significant adjustments to mold investments are required

・Highly smooth product surfaces reduce secondary processing

・Suitable for the production of complex-shaped parts

At the same time, its low shrinkage and controlled linear expansion ensure dimensional accuracy, making it ideal for mass production of high-precision mechanical components and multi-assembly structures.

3. Cost-Return: Not Just Unit Price, but Lifecycle Benefits

Although the unit price of Peek Plastic is higher than that of conventional engineering plastics, this composite PEEK material demonstrates significant economic benefits over long-term use.

By reducing maintenance frequency, extending part life, and reducing lubrication consumption, it delivers a higher return on investment (ROI) for manufacturers.

Buyers' actual calculations have shown that under continuous use, its lifespan can be extended by approximately 30%-50% compared to standard PEEK, while reducing overall costs.

3. Application Scenario Analysis: Key Component Solutions for Multiple Industries

1. Automotive Industry

In automotive powertrain systems, TECACOMP® PEEK TRM PVX black 1046944 can be used in:

・Pump and valve bushings and seals

・Transmission gears

・Sliding bearings in low-lubrication environments

Its low friction and high heat resistance significantly reduce energy consumption, increase component life, and maintain structural stability even at high temperatures.

2. Mechanical Engineering

In equipment engineering, this peek plastic is used in:

・Bearing seats, slide guides, roller bushings

・Hot-end mechanical parts

・Guides in precision motion modules

It can replace some metal parts, offering lightweight and corrosion-resistant advantages while avoiding structural failure due to metal fatigue.

3. Electrical and Electronics Industry

Ensinger's PEEK has excellent anti-static properties, with both surface and volume resistivity within stable ranges, preventing static electricity accumulation. It is commonly used in:

・Motor insulation components

・High-temperature connectors and supports

・Safety components in explosion-proof areas

4. Special Environments: High Temperature, High Pressure, and Chemically Corrosive Environments

TRM PVX demonstrates outstanding high-temperature resistance (up to 300°C for short periods) and chemical resistance, resisting a wide range of acids, bases, and high-pressure steam. Therefore, it is widely used in:

・Oil and gas equipment seals

・Semiconductor cleaning fixtures

・High-temperature parts of food machinery

4. TECACOMP® PEEK TRM PVX black 1046944 Data Sheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Break 50mm/min | ISO 527 | 1.8 | % | |||

| Compressive Strength | 5mm/min | ISO 604 | 180 | MPa | |||

| Compressive Modulus | 1mm/min | ISO 604 | 4100 | MPa | |||

| Flexural Strain | 2.0mm/min | ISO 178 | 2.0 | % | |||

| Flexural Strength | 2.0mm/min | ISO 178 | 195 | MPa | |||

| Flexural Modulus | 2.0mm/min | ISO 178 | 11200 | MPa | |||

| Tensile Strength | 50mm/min | ISO 527 | 155 | MPa | |||

| Tensile Modulus | 50mm/min | ISO 527 | 12500 | MPa | |||

| Charpy Un-notch Impact | ISO 179 | 30 | kJ/m² | ||||

| Thermal | Condition | Standard | Value | Unit | |||

| Operating Temperature | Short Time | INTERNAL METHOD | 300 | °C | |||

| Operating Temperature | Long-Term | INTERNAL METHOD | 260 | °C | |||

| Heat Conductivity Coefficient | Perpendicular to Surface | DIN 821 | 0.5 | W/(m·K) | |||

| Heat Conductivity Coefficient | On Surface | DIN 821 | 0.9 | W/(m·K) | |||

| HDT | ISO 75 | 340 | °C | ||||

| Melting Temperature | DIN 53765 | 343 | °C | ||||

| Glass Transition Temperature | DIN 53765 | 143 | °C | ||||

| CLE | Flow 23~55°C | ISO 11359 | 1.3E-5 | cm/cm/°C | |||

| CLE | Flow 200~300°C | ISO 11359 | 2.2E-5 | cm/cm/°C | |||

| CLE | xFlow 23~55°C | ISO 11359 | 4.5E-5 | cm/cm/°C | |||

| CLE | xFlow 200~300°C | ISO 11359 | 1.47E-4 | cm/cm/°C | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 23°C 50RH | ISO 62 | 0.1 | % | |||

| Bulk Density | ISO 60 | 0.63 | g/cm³ | ||||

| Shrinkage | Flow | ISO 294 | 0.27 | % | |||

| Shrinkage | xFlow | ISO 294 | 0.85 | % | |||

| Density | INTERNAL METHOD | 1.5 | g/cm³ | ||||

| Melt Index | 380°C 5kg | ISO 1133 | 20 | g/10min | |||

| Melt Index | 380°C 5kg | ISO 1133 | 16 | cm³/10min | |||

| Electrical properties | Condition | Standard | Value | Unit | |||

| Volume Resistivity | IEC 61340-2-3 | 1.2E+6 | Ω.cm | ||||

| Surface Resistivity | IEC 61340-2-3 | 1.4E+4 | Ω | ||||

| Flammability | Condition | Standard | Value | Unit | |||

| Flame Rating | UL94 | V-0 | |||||

5. Technical In-Depth Analysis: The Triple Function of the Composite System

・Carbon Fiber (CF) Reinforcement: Provides high modulus and deformation resistance, enabling the material to maintain structural integrity under high loads.

・Graphite Filling: Optimizes the friction interface, ensuring surface stability during sliding and preventing dry wear.

・PTFE Lubricating Phase: Forms a microscopic lubricating layer, reducing wear and energy consumption, and extending component life.

This ternary structure makes TECACOMP® PEEK TRM PVX more than just a "reinforced" plastic, but rather a comprehensive system with balanced mechanical, thermal, and chemical stability.

6. Procurement Value Assessment: Comparative Advantages Compared to Conventional PEEK or Metal

| Comparison Dimension | Conventional PEEK | TECACOMP® PEEK TRM PVX | Metal Components |

| Wear Resistance | Moderate | Excellent (self-lubricating) | Requires external lubrication |

| Weight | Light | Light | Heavy |

| Heat Resistance | High | Very high (continuous up to 260 °C) | High |

| Processability | Average | Excellent | Requires machining |

| Maintenance Cost | Medium | Low | High |

| Antistatic Property | Weak | Stable | Good |

For purchasers, this performance comparison means:

・Lighter, more maintenance-efficient system architecture with the same functionality

・Product upgrades through material substitution

・Increasing added value in the export or precision equipment sectors

7. FAQ: Most Common Technical Inquiries Before Purchasing

Q1: What flame retardancy rating does this peek plastic meet?

It has passed the UL94 test and received a V-0 rating, making it suitable for use in equipment and electronic components requiring strict flame retardancy.

Q2: Can the material be used in food contact applications?

TRM PVX is primarily designed for industrial use. For food-grade applications, Ensinger's TECAPEEK natural series is recommended.

Q3: Does the injection molding process require special screws or molds?

No special equipment is required; high-temperature molds (above 180°C) are sufficient to achieve good surface quality.

Q4: Does it maintain lubricity under high-speed friction?

Yes, PTFE and graphite work synergistically to maintain a low coefficient of friction even under dry conditions.

Q5: Can it be used as a direct metal replacement?

It can directly replace aluminum or brass in most light- and medium-duty structures and offers improved corrosion resistance.

8. Juyuan: Professional PEEK Supply and Application Support

As an international plastic raw material trader, Juyuan specializes in providing high-end engineering plastic raw materials and technical services to industrial customers.

With years of experience in the PEEK plastics field, we can provide you with:

・Material Alternative Comparison

・Injection Molding and Processing Recommendations

・Export and Logistics Support

・Sample Evaluation and Technical Data

If you are looking for PEEK raw materials for high-temperature, high-load, wear-resistant, or flame-retardant applications, Juyuan can provide you with the most suitable material selection advice and one-stop procurement support.

9. Recommended Materials in the Same Category

| Product Model | Specific Gravity | Tensile Strength | Elongation | Shrinkage | Tensile Modulus | Heat Deflection Temperature | Flexural Modulus | Flexural Strength |

| PEEK TRM X black 1046849 | 1.61 g/cm³ | 155 MPa | 1.8 % | 0.26 % | 12500 MPa | 335 °C | 10300 MPa | 190 MPa |

| PEEK GR15 TF15 black 1061060 | 1.47 g/cm³ | 65 MPa | 2.8 % | 1.5 % | 4000 MPa | 165 °C | ||

| PEEK TRM XS mod. black 1017677 | 1.39 g/cm³ | 215 MPa | 1.7 % | 16000 MPa | ||||

| PEEK TRM XS black 1046942 | 1.4 g/cm³ | 185 MPa | 1.3 % | 0.37 % | 18500 MPa | 340 °C | 18400 MPa | 245 MPa |

10. Conclusion: Choosing "Long-Term Value" in Material Procurement

Ensinger TECACOMP® PEEK TRM PVX black 1046944 represents more than just a composite material; it also embodies the evolution of peek plastic into a "durable, all-around material" in modern industry.

It addresses the most practical pain points for buyers: wear resistance, heat resistance, flame retardancy, long lifespan, and wide compatibility.

With the future manufacturing trend toward higher efficiency and lower energy consumption, this material will undoubtedly become a key step in the "material upgrade" journey for many companies.

Choose Juyuan, and choose a long-term, reliable materials partner.

【Related Recommendations】

Fluorseals FLUTECK™ K300: Food-Grade PEEK Resin Learn more>

VESTAKEEP® 2000 FC30: Self-Lubricating Polyether Ether Ketone Learn more>

PA6 vs POM: A classic comparison and selection guide for engineering plastics Learn more>