CÁC SẢN PHẨM

PEEK 450G | Medical & Food Contact Applications PEEK Plastic

Cấu trúc sản phẩm

What is PEEK 450G

PEEK 450G is a non-reinforced polyetheretherketone (PEEK) plastic produced by Victrex, featuring a semi-crystalline structure, high fluidity, good toughness and thermal stability.

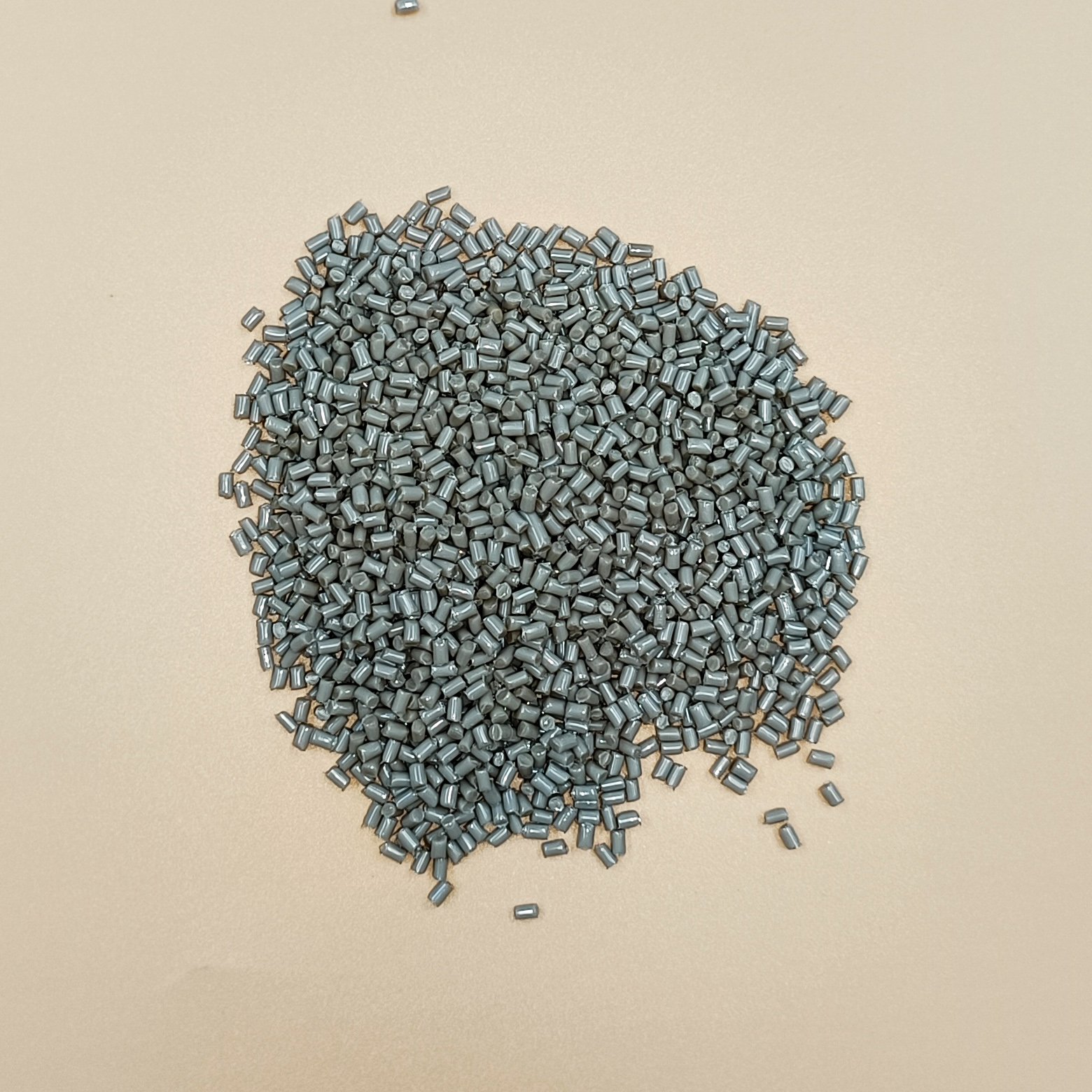

Its natural color (beige) material form can be granular or powder, compatible with injection molding and extrusion molding processes, meeting food contact and medical grade standards, and featuring UL94 V-0 flame retardancy rating.

Key words: PEEK 450G

I. Analysis of Material Properties

Structural features and fluidity

・PEEK 450G is made with a high-purity polyetheretherketone matrix without glass fiber or mineral reinforcement, thus featuring excellent melt fluidity (350 Pa·s, 400 °C), making it suitable for the molding of complex-structured and thin-walled products.

・Its semi-crystalline structure endows the material with both rigidity and toughness after molding, and it can still maintain dimensional accuracy and mechanical strength under high-temperature conditions.

Mechanical property balance

・Tensile strength (yield) : 98 MPa

・Flexural modulus: 3.8-4.0 GPa

・Elongation at break: 45%

PEEK 450G strikes a good balance between high rigidity and high ductility, making it suitable for medical device components that require both mechanical load-bearing and certain flexibility, such as surgical fixtures, pump and valve assemblies, and food processing machinery parts.

Thermal performance and high-temperature stability

・Melting temperature: 343 °C

・Heat distortion temperature (1.8 MPa) : 152 °C

・Glass transition temperature: 143-150 °C

Even at 275 °C, PEEK 450G still retains some mechanical strength (flexural strength of 12.5 MPa), demonstrating excellent heat aging resistance and is suitable for repeated steam disinfection and high-temperature cleaning conditions.

Electrical and insulation performance

PEEK 450G combines high insulation with stable dielectric properties:

・Volume resistivity: 10¹⁶ Ω·cm (23 °C)

・Dielectric constant (1 kHz) : 3.1

・Dissipation factor: 0.004

Its electrical stability and arc resistance performance (ASTM D495:5 PLC) make it suitable for high-precision medical testing equipment and electronic insulating components.

Chemical resistance and cleanliness properties

・Thanks to the stability of the aromatic ketone and ether bonds in the PEEK molecular structure, PEEK 450G can resist acids, alkalis, solvents, steam and various cleaning agents.

・Meanwhile, the material's water absorption rate is only 0.45% - 0.55%, and it can maintain dimensional stability even in humid and high-temperature environments, making it highly suitable for the cleanliness requirements of food and medical environments.

Ii. Suggestions for Processing Techniques

・Processing methods: Injection molding, extrusion molding

・Melting temperature range: 370-400 °C

・Mold temperature: 160-200 °C

・Drying conditions: 150 °C for 3 hours

・Features: High fluidity, low shrinkage rate (0.0%), and high molding dimensional accuracy

PEEK 450G is not prone to decomposition during molding, causes little wear to the mold, and is suitable for processing complex geometric parts and thin-walled parts. It is an ideal material choice for medical consumables and high-cleanliness parts.

Iii. Typical Application Fields

PEEK 450G is widely used in fields where there are strict requirements for cleanliness, chemical resistance and mechanical strength

🩺 Medical devices and nursing supplies: surgical instruments, dental accessories, infusion connectors, sterilization components

🍽️ Food contact and packaging equipment: valve bodies, guide parts, heat-resistant seals, cleaning nozzles

⚙️ Electronic and electrical insulators: sensor brackets, high-temperature connectors, insulating gaskets

🔩 Structure and load-bearing components: pump casing, bearing cage, wear-resistant bushing

Its V-0 flame retardant rating and repeatable disinfection performance make it a long-term reliable material for medical and food-grade applications.

Iv. Summary of Performance Highlights

| Property Category | PEEK 450G Performance | Typical Advantages |

| Material Base | Pure PEEK polymer | Clean and suitable for food and medical contact environments |

| Mechanical Properties | High strength, high rigidity, 45% elongation | Withstands continuous load and impact |

| Thermal Properties | Melting point 343°C, HDT 152°C | Suitable for high-temperature processing and repeated sterilization |

| Chemical Stability | Resistant to acids, alkalis, and solvents; low moisture absorption | Stable and reliable with minimal dimensional change |

| Electrical Properties | High insulation and low dielectric loss | Ideal for electronic and medical device applications |

| Chống cháy | UL94 V-0, Oxygen Index 24 | Safe and compliant with regulatory standards |

V. Equivalent-Use Alternatives

The following materials are similar in performance and application to PEEK 450G and can be used as alternative or complementary solutions under different application conditions:

| nhà chế tạo | Mô hình sản phẩm | Tỉ trọng | Độ bền kéo | Độ giãn dài | co ngót | Nhiệt độ nóng chảy | Mô đun kéo | Độ cứng bờ biển D | Nhiệt độ lệch nhiệt | Notched Izod Impact | Mô đun uốn | Unnotched Izod Impact | Linear Expansion Coefficient | Độ bền uốn |

| Victrex | 450GL30 | 1.51 g/cm³ | 185 MPa | 2.80% | – | 343 ℃ | 11.5 GPa | 87.5 | 328 ℃ | 12 kJ/m² | 11 GPa | 65 kJ/m² | 1.8E1 μm/m/℃ | 275 MPa |

| Victrex | 150GL30 | 1.52 g/cm³ | 200 MPa | 2.70% | – | 343 ℃ | 12.0 GPa | 87 | 335 ℃ | 10.5 kJ/m² | 11.5 GPa | 60 kJ/m² | 2E1 μm/m/℃ | 290 MPa |

| Victrex | 450GL30 BLACK | 1.51 g/cm³ | 170 MPa | 2.50% | 0.30% | 343 ℃ | 11500 MPa | 88 | 328 ℃ | 9 kJ/m² | 11000 MPa | – | 1.8E-5 cm/cm/℃ | 260 MPa |

| Victrex | 450G903 Black | 1.26 g/cm³ | 100 MPa | 30% | 1% | 343 ℃ | 3700 MPa | 85 | 152 ℃ | 6.5 kJ/m² | 4100 MPa | – | 4.5E-5 cm/cm/℃ | 160 MPa |

| Victrex | 450GL20 | 1.43 g/cm³ | 160 MPa | 3.40% | – | 343 ℃ | 8.8 GPa | 85.5 | 315 ℃ | 10 kJ/m² | 8.3 GPa | 65 kJ/m² | 2E1 μm/m/℃ | 250 MPa |

| Victrex | 450GL15 | 1.38 g/cm³ | 145 MPa | 4.00% | – | 343 ℃ | 7.5 GPa | 86 | 298 ℃ | 7.0 kJ/m² | 7.2 GPa | 60 kJ/m² | 2.5E1 μm/m/℃ | 240 MPa |

| Victrex | 150GL30 BLACK | 1.52 g/cm³ | 190 MPa | 2.40% | 0.30% | 343 ℃ | 12000 MPa | 87 | 335 ℃ | 7.5 kJ/m² | 11500 MPa | – | 2E-5 cm/cm/℃ | 270 MPa |

| Victrex | 150GL20 | 1.43 g/cm³ | 160 MPa | 2.40% | – | 343 ℃ | 9.0 GPa | 86 | 323 ℃ | 7.5 kJ/m² | 8.5 GPa | 35 kJ/m² | 2.5E1 μm/m/℃ | 250 MPa |

These materials can be flexibly selected according to the target application, such as higher rigidity, stronger wear resistance or lower coefficient of friction.

Vi. Frequently Asked Questions (FAQ)

Q1: What are the main differences between PEEK 450G and reinforced PEEK?

A: PEEK 450G is not reinforced with glass fiber or carbon fiber, thus featuring better fluidity and surface quality, making it suitable for high-cleanliness and thin-walled products. Reinforced PEEK is used for structural components with higher rigidity requirements.

Q2: Can PEEK 450G be used for food or medical contact?

A: Yes, this model complies with relevant standards such as FDA and ISO 10993, and is suitable for medical and food contact applications.

Q3: Can high-temperature steam disinfection be repeatedly carried out?

A: Yes. PEEK 450G will not experience performance degradation or deformation when repeatedly sterilized in a saturated steam environment at 134°C.

Vii. Supply and Service Advantages of Juyuan

As an international supplier with 24 years of experience in plastic raw material trading, Juyuan is committed to providing reliable engineering plastic solutions for global customers

🌍 offers PEEK 450G and other medical and food grade PEEK materials in stock

📑 supports the provision of technical data sheets, UL certification materials and sample testing services

⚙️ provide selection suggestions and process matching guidance

🚚 global logistics system, supporting multi-region delivery and small-batch purchasing

Phần kết luận

With its high fluidity, chemical resistance, thermal stability and clean properties, PEEK 450G has become the preferred material for medical devices, food processing and electronic insulation components.

For manufacturing enterprises that pursue high precision, high reliability and safety compliance, it is not only a material, but also the core support for stable production and quality assurance.

【Khuyến nghị liên quan】

Blow Molding Defects & Solutions|Quality Plastic Materials Supplier Tìm hiểu thêm>

High-Flow Reinforced PEEK Plastic Material Series Tìm hiểu thêm>

ARLON® 1330 | PEEK For Semiconductor Molding Applications Tìm hiểu thêm>