CÁC SẢN PHẨM

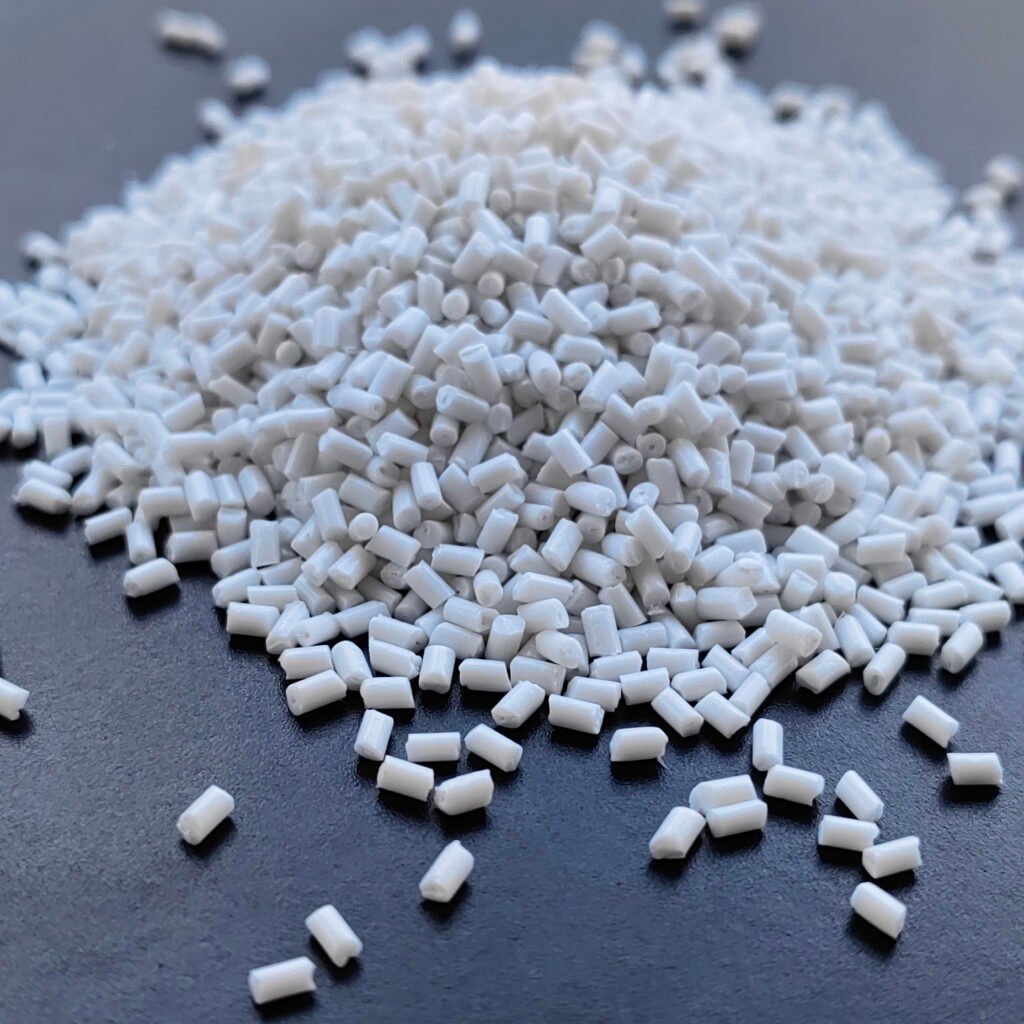

Nguyên liệu nhựa LUCEL POM GB-325

Cấu trúc sản phẩm

Polyoxymethylene (POM), còn được gọi là acetal hoặc Delrin, là một loại nhựa kỹ thuật nhiệt dẻo có mật độ cao, độ kết tinh cao được trùng hợp từ formaldehyde và các nguyên liệu thô khác. Vật liệu POM được chia thành homopolymer (POM-H) và copolymer (POM-K), cả hai đều có các tính chất vật lý, cơ học và hóa học tuyệt vời, đặc biệt là khả năng chống ma sát.

Polyme tinh thể mật độ cao này, không có chuỗi bên, có bề mặt nhẵn và bóng, cứng và đặc, và thường có màu vàng nhạt hoặc trắng. POM có thể được sử dụng lâu dài trong phạm vi nhiệt độ từ -40°C đến 100°C, mang lại khả năng chống mài mòn và tự bôi trơn vượt trội. Ngoài ra, khả năng chống dầu và peroxide của POM vượt trội hơn hầu hết các loại nhựa kỹ thuật. Bằng cách thêm chất ổn định tia cực tím (tác nhân UV), khả năng chống tia cực tím của nó được cải thiện đáng kể.

Trong số các loại khác nhau, POM GB-325 nổi bật với hiệu suất đáng chú ý. Ở 23°C, độ bền kéo của nó là 64 MPa, với hệ số ma sát tĩnh và động lần lượt là 0,15 và 0,21, và tốc độ giãn dài là 10%. Vật liệu này hoạt động xuất sắc trong thử nghiệm mài mòn Taber, với tốc độ mài mòn chỉ 22 mg trên 1000 chu kỳ. Ở cùng nhiệt độ, POM GB-325 có mô đun uốn là 3900 MPa, độ bền uốn là 98 MPa và độ bền va đập Izod có khía là 35,71 kJ/m². Ngoài ra, nhiệt độ biến dạng nhiệt của nó, ở trạng thái không ủ, là 165°C dưới 0,45 MPa và 150°C dưới 1,8 MPa, với trọng lượng riêng là 1,59 g/cm³. Tỷ lệ co ngót theo hướng dòng chảy và hướng vuông góc lần lượt là 1,6% và 1,9%, và có độ cứng Rockwell theo thang M là 80.

Những đặc tính tuyệt vời này làm cho POM GB-325 hoạt động cực kỳ tốt trong các ứng dụng đòi hỏi độ bền cao và khả năng chống mài mòn, chẳng hạn như bánh răng, ổ trục, ròng rọc và nhiều bộ phận cơ khí khác. Các đặc tính vượt trội của POM đảm bảo ứng dụng rộng rãi trong ngành công nghiệp và chứng minh những lợi thế độc đáo của nó trong nhiều ứng dụng hàng ngày.

| Hành vi cơ học | Tình trạng | Tiêu chuẩn | Giá trị | Đơn vị | |||

| Độ bền kéo | Nghỉ 23°C | ASTM D638 | 64 | MPa | |||

| Hệ số ma sát | Tĩnh | Tiêu chuẩn ASTMD3702 | 0.15 | ||||

| Hệ số ma sát | Năng động | Tiêu chuẩn ASTMD3702 | 0.21 | ||||

| Độ giãn dài | 23°C | ASTM D638 | 10 | % | |||

| Tiber hao mòn | Tiêu chuẩn ASTMD1044 | 22 | mg/1000cy | ||||

| Mô đun uốn | 23°C | ASTM D790 | 3900 | MPa | |||

| Độ bền uốn | 23°C | ASTM D790 | 98 | MPa | |||

| Tác động của Izod Notch | ASTM D256 | 35.71 | kJ/m2 | ||||

| Tác động của Izod Notch | 23°C | ASTM D256 | 4.08 | kJ/m2 | |||

| nhiệt | Tình trạng | Tiêu chuẩn | Giá trị | Đơn vị | |||

| HDT | Không ủ 0,45MPa | ASTM D648 | 165 | °C | |||

| HDT | 1.8MPa không được ủ | ASTM D648 | 150 | °C | |||

| Tài sản vật chất | Tình trạng | Tiêu chuẩn | Giá trị | Đơn vị | |||

| Tỉ trọng | ASTM D792 | 1.59 | g/cm³ | ||||

| co ngót | Chảy | Tiêu chuẩn ASTMD995 | 1.6 | % | |||

| co ngót | xFlow | Tiêu chuẩn ASTMD995 | 1.9 | % | |||

| độ cứng | Tình trạng | Tiêu chuẩn | Giá trị | Đơn vị | |||

| Độ cứng Rockwell | M(Tỷ lệ) | ASTM D785 | 80 | ||||