In fields such as food packaging, catering utensils, and food processing equipment, the safety of plastics is directly related to consumers' health. FDA food grade plastics refer to plastic materials that have been certified by the U.S. Food and Drug Administration (FDA) and can be safely in contact with food. Due to its strict regulatory system, this certification has become an important reference standard for international buyers when choosing food contact materials. For purchasers, correctly understanding and choosing compliant food-grade plastic raw materials not only concerns product quality and consumer safety, but also the market competitiveness of the brand.

1. What are FDA Food-Grade Plastics?

FDA food-grade plastics refer to plastic materials that meet U.S. Food and Drug Administration (FDA) standards and are safe for contact with food or beverages without releasing harmful substances.

Core criteria for determining food grade include:

・Material and additive compliance: Must be on the FDA-approved list.

・Migration limit compliance: Ensures that no excessive substances are released into food.

・Heat resistance and stability: Ensures stable performance in hot and cold environments without decomposition.

・Sensory stability: Ensures that the taste and appearance of food are not affected.

2. Why is food-grade plastic essential?

Compliance Threshold

・For exports to the European and American markets, almost all food contact materials are required to comply with FDA or EU 10/2011 standards.

・Using non-compliant materials can result in product recalls, returns, and customs holdups, resulting in losses far outweighing the cost savings.

Safety Assurance

・Food-grade plastics have low migration rates and do not release BPA, heavy metals, or toxic additives.

・Especially in infant, medical, and drinking water applications, safety is a fundamental barrier to market entry.

Brand Value

・Consumers are increasingly concerned about food safety. Purchasing food-grade plastics can help companies mitigate the risk of negative public opinion and enhance market recognition.

👉 Summary: Food-grade plastics are not only a safe choice, but also a market necessity.

3. Food-grade vs.Standard Plastics: Cost and Value

Many buyers worry: Is food-grade plastic more expensive?

It really depends on the situation:

| Comparison | Regular Plastics | FDA Food Grade Plastics |

| Giá | 10–30% cheaper | Slightly higher, depends on grade and certification |

| chất phụ gia | May contain flame retardants, antistatic agents; not suitable for food contact | Limited to FDA-approved additives |

| Testing/Certification | No food contact testing | FDA compliant statement available; some also meet EU standards |

| Application Risk | Legal risks if used in food-related applications | Safe for direct use, compliant with export standards |

👉 The cost difference is more reflected in long-term risks: If a product is returned or recalled due to non-compliant materials, the loss is often dozens of times greater than the initial savings.

4. Why aren't all plastics food-grade?

Even the same plastic can have significant differences in different grades: Industrial-grade plastics may contain flame retardants, glass fibers, and antistatic agents, making them unsuitable for food contact.

Some materials pose health risks: For example, PVC, ABS, and ordinary máy tính contain potentially harmful monomers or BPA, and can only be used for food contact after special modification.

Certification and Cost: FDA food-grade certification requires testing and a declaration of compliance, which not all manufacturers undertake.

5. Common Types of FDA Food-Grade Plastics

| Vật liệu | Key Properties | Ứng dụng tiêu biểu |

| PE (Polyethylene) | Non-toxic, odorless, excellent low-temperature resistance | Cling film, baby bottles, freezer bags |

| PP (Polypropylene) | Good heat resistance, microwave-safe | Lunch boxes, beverage cups, food containers |

| PET (Polyethylene Terephthalate) | High transparency, strong gas barrier | Beverage bottles, edible oil bottles |

| PPSU/PSU (Polysulfones) | Withstands high-temperature steam sterilization, impact resistant | Baby bottles, medical devices |

| POM (Polyoxymethylene, specific grades) | Excellent wear resistance, high mechanical strength | Food machinery gears, valves |

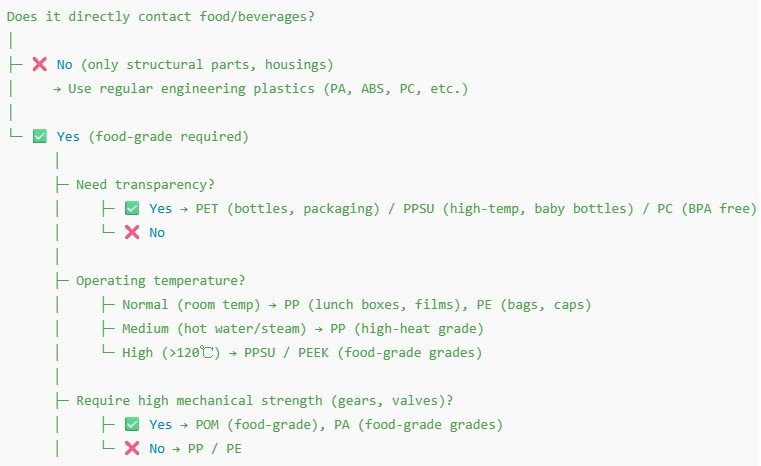

Procurement Insights: Different applications require different materials. For example:

・Beverage bottles → Choose PET

・Microwaveable lunch boxes → Choose PP

・Infant and medical products → Choose PPSU

・Food processing machinery parts → Choose POM

6. Comparison of FDA and International Food-Grade Standards

While FDA food-grade plastics have a significant global impact, they are not the only standard.

・US FDA: 21 CFR regulations, migration limits, and ingredient list management.

・EU EU No. 10/2011: Emphasizes overall migration limits (OMLs) and specific migration limits (SMLs), requiring companies to issue a Declaration of Conformity (DoC).

・China's GB 4806 series: There are specific national standards for food contact materials, such as GB 4806.7-2016 for plastics.

・Japan: The Positive List system will be implemented starting in 2020.

📌 Trend: More and more international buyers are requiring materials to comply with FDA, EU, and China GB standards simultaneously to ensure smooth global market access.

7. Four Top Questions Buyers Concern

Q1: How can I confirm whether a material is food-grade?

👉 Check whether the supplier provides an FDA compliance statement and test reports, and whether they can trace back to specific batches.

Q2: What is the difference between food-grade and industrial-grade materials?

👉 Food-grade materials are subject to stricter material and production regulations, contain fewer impurities, and additives must also comply with food regulations, resulting in a slightly higher price.

Q3: What factors should I consider when purchasing?

👉 I mainly focus on temperature range, transparency, sterilization methods, and compliance with target market regulations (such as FDA and EU regulations).

Q4: Can you provide different specifications based on your needs?

👉 Yes, for example, we have food-grade versions of materials with different melt indexes (MFIs), color masterbatches, and impact ratings.

8. Our Advantages

As a supplier of food-grade plastic granules, we not only sell materials but also help customers solve practical problems:

・A full range of food-grade raw materials: PE, PP, PET, PPSU, POM, and more.

・Complete Compliance Documentation: We provide FDA compliance statements, with some products complying with EU 10/2011 and NSF standards.

・Cost Optimization: We recommend appropriate grades based on customer applications to avoid unnecessary high costs.

・Stable Delivery: We offer long-term partnerships to ensure timely delivery of large-volume orders.

9. Conclusion

Choosing FDA food-grade plastics not only ensures food safety but also serves as a gateway to international market expansion. When selecting materials, buyers should strike a balance between safety, compliance, and cost. A reliable supplier can help you save significant trial and error costs.

If you are looking for stable, compliant food-grade plastic raw material granules, please feel free to contact us. We will provide you with professional material selection advice and flexible supply solutions.