CÁC SẢN PHẨM

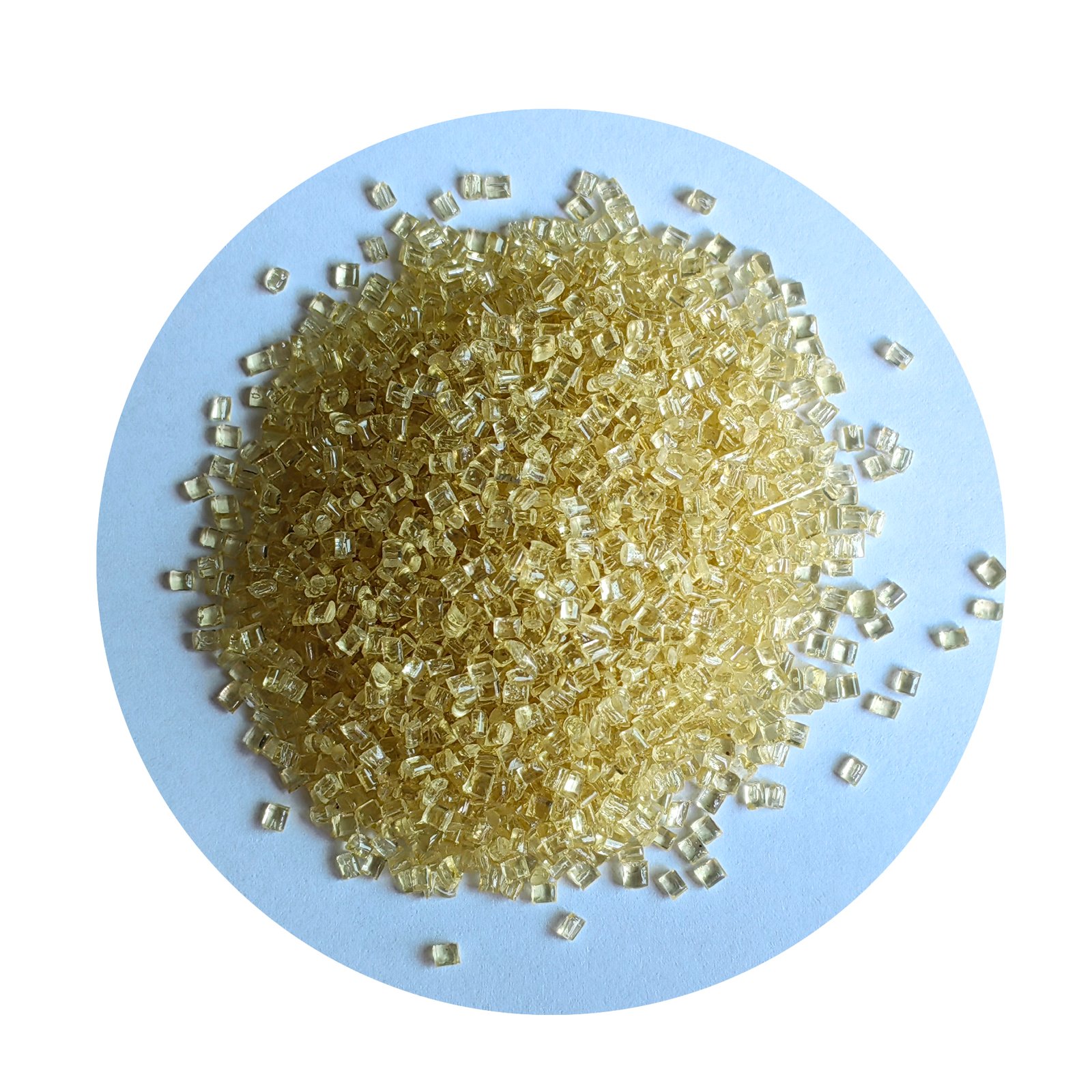

Evonik PPSU P | Transparent & Heat-Resistant PPSU Polymer

Cấu trúc sản phẩm

What is PPSU Polymer

In the high-end application landscape of engineering plastics, ppsu polymer (polyphenylsulfone) has become an important member due to its comprehensive performance. Evonik EUROPLEX PPSU P combines optical transparency, mechanical toughness and thermal stability, making it particularly suitable for industries that require a balance between safety, reliability and aesthetics. From healthcare to new energy, from aerospace to consumer electronics, PPSU P is gradually changing the application landscape of traditional materials.

01 | Performance Analysis: From Materials to Application Logic

Transparency and design freedom

Compared with traditional high-temperature engineering plastics, one of the prominent advantages of EUROPLEX PPSU P is that it maintains high strength while having excellent light transmittance. This enables it not only to replace metals and opaque plastics, but also to offer more design space in terms of product appearance and monitoring visualization.

The balance of mechanical properties

PPSU strikes a balance between rigidity and toughness. Its elongation at break and impact strength exhibit excellent safety redundancy, which means that in structural components, pressure components and frequently used parts, the risk of failure can be effectively reduced.

Thermal stability and long-term durability

PPSU P maintains dimensional stability and mechanical strength at high temperatures and is less prone to thermal deformation. This feature makes it an ideal choice for scenarios involving repeated steam sterilization, long-term operation, or contact with hot fluids.

02 | Process compatibility and processing considerations

At the processing level, EUROPLEX PPSU P has good thermal stability and melt fluidity, making it suitable for injection molding and extrusion processes. Its wide processing window makes the production of complex parts, thin-walled components and transparent products more controllable. Compared with PEI and PSU, PPSU has a shorter processing cycle and less internal stress in the workpiece, which can reduce the risk of cracking or warping in the later stage.

03 | Application scenarios and industry practices

Medical and laboratory equipment: Can withstand hundreds of high-temperature steam sterilizations, preventing transparent materials from yellowing or cracking. Typical applications include surgical instrument casings and transparent containers for analyzers.

Aviation and transportation: Transparent cabin interior parts, window covers and lightweight structural components, meeting the requirements of high safety and durability.

New energy and electrical: Used for charging components of new energy vehicles, high-voltage connectors, and protective covers, taking into account both arc resistance and transparency.

Food and drinking water systems: Due to its BPA-free and excellent stability, it is widely used in drinking water equipment, coffee machines, and food containers.

04 | Evonik PPSU P Data Sheet

| Hiệu suất quang học | Tình trạng | Tiêu chuẩn | Giá trị | Đơn vị | |||

| Độ truyền dẫn | ISO 13468 | 90 | % | ||||

| Hành vi cơ học | Tình trạng | Tiêu chuẩn | Giá trị | Đơn vị | |||

| Độ giãn dài | 23℃ | ISO 527 | 50 | % | |||

| Độ bền kéo | 23℃ | ISO 527 | 70 | MPa | |||

| Mô đun kéo | 23℃ | ISO 527 | 2340 | MPa | |||

| mô đun | 2900 | MPa | |||||

| mô đun | 4400 | MPa | |||||

| Charpy Un-notch Impact | 23℃ | ISO 179 | NB | kJ/m2 | |||

| Charpy Un-notch Impact | ISO 179 | 50 | kJ/m2 | ||||

| Charpy Un-notch Impact | ISO 179 | 45 | kJ/m2 | ||||

| Tác động của Charpy Notch | ISO 179 | 31.2 | kJ/m2 | ||||

| nhiệt | Tình trạng | Tiêu chuẩn | Giá trị | Đơn vị | |||

| Nhiệt độ làm mềm Vicat | 50℃/giờ 10N | ISO 306 | 207 | ℃ | |||

| Tài sản vật chất | Tình trạng | Tiêu chuẩn | Giá trị | Đơn vị | |||

| Tỉ trọng | ISO 1183 | 1.29 | g/cm³ | ||||

05 | Industry trends and material competitiveness

With the increasing demand for lightweight, sustainable and safe design, ppsu polymer is accelerating its entry into the new energy and medical industries. In some fields, it has become an alternative material to glass: it not only provides transparency but also has toughness and processing flexibility. Meanwhile, compared with metal parts, the weight reduction effect brought by EUROPLEX VPPSU P is particularly crucial for the transportation industry.

Future trends include:

・Functionalized modification: Glass fiber reinforced and flame-retardant modified versions have been widely applied in the market, further expanding engineering scenarios.

・Sustainability requirements: In the context of green manufacturing, the recyclability and long lifespan of PPSU have become advantages.

・Emerging applications: Especially in the casings of power batteries and medical visual diagnostic components, the demand continues to grow.

06 | Similar recommendations

PPSU GF10 / GF20: Enhanced rigidity, suitable for load-bearing and electrical components.

PPSU GF30 LE: Combines strength with dimensional stability.

PPSU GF40: Extreme Applications for High-load environments.

07 | Frequently Asked Questions by Purchasers (FAQ)

Q1: What are the differences between PPSU P, PEI and PSU?

PPSU has better impact resistance and hydrolysis resistance, making it more suitable for long-term high-temperature and humid environments.

Q2: Can it meet the repeated sterilization demands of the medical industry?

Yes, PPSU P still maintains stable performance under sterilization conditions of steam, gamma rays and ethylene oxide.

Q3: Can Juyuan offer small-batch or customized supply?

Sure. Juyuan supports small-batch trial production, batch delivery and modification solution coordination.

08 | The supply advantage of Juyuan

As a partner deeply engaged in the international trade of plastic raw materials for over 20 years, Juyuan can provide purchasers with:

・Covering a wide range of PPSU and modified materials, it is suitable for different application requirements.

・A global supply network ensures continuous supply and delivery time.

・Professional selection support helps customers quickly lock in the suitable ppsu polymer.

・Flexible supply mode, taking into account both small-batch R&D and large-batch production.

【Khuyến nghị liên quan】

Radel® D-3000 PPSU: Crack Resistance and Thin-Wall Application Material Tìm hiểu thêm>

Radel® R-5000 PPSU Material for Medical, Food & High-Temperature Applications Tìm hiểu thêm>

XENOY™ 5220U with PC+PBT Low-Temperature Toughness Tìm hiểu thêm>