CÁC SẢN PHẨM

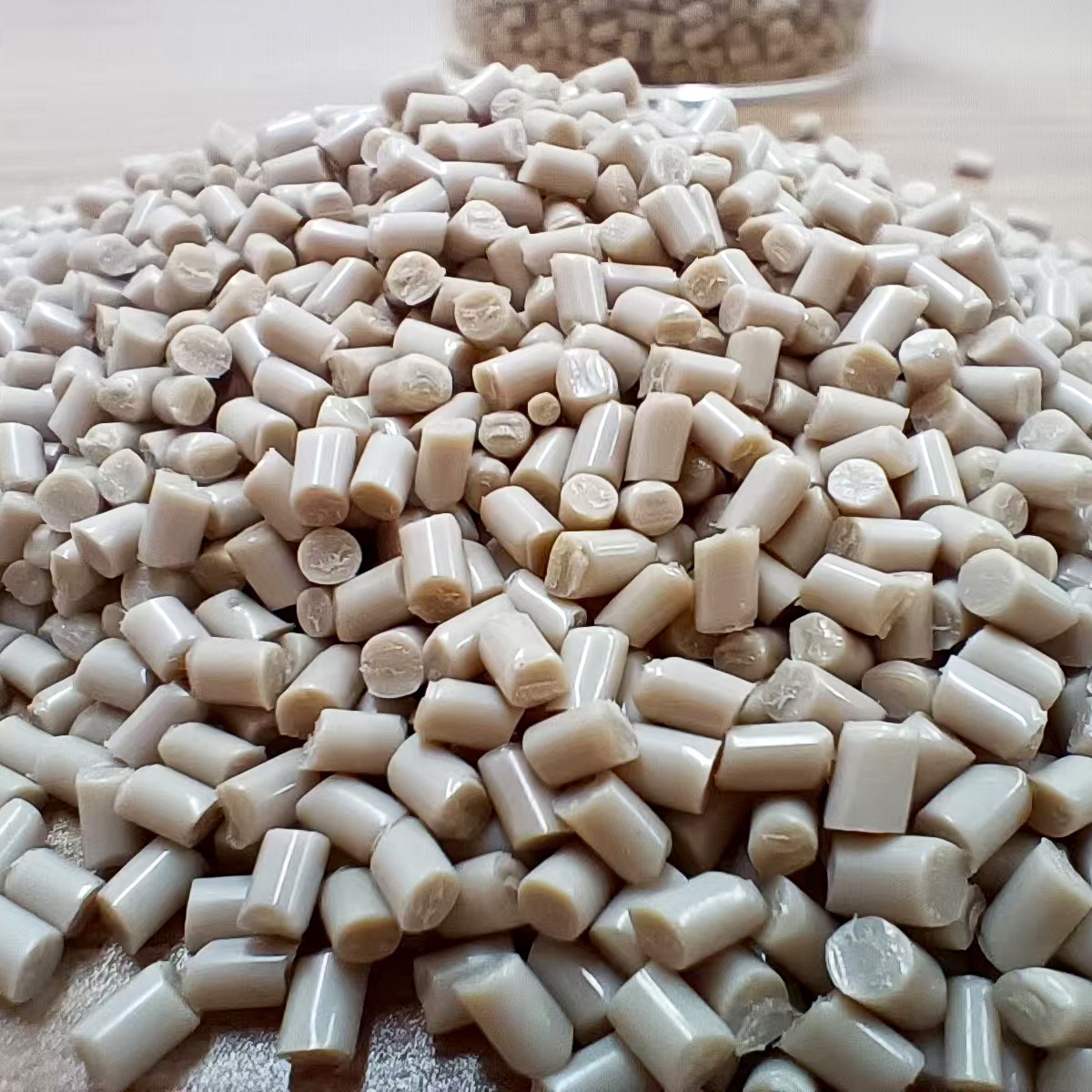

Evonik PEEK DC 4430 G | PEEK Granules for Dental Applications

Cấu trúc sản phẩm

What are PEEK Granules - DC 4430 G

In modern dental restorations, material choice directly impacts patient comfort and surgical precision. Evonik PEEK DC 4430 G, a peek granule specifically designed for dental applications, features a unique barium sulfate-modified formula that achieves a balance of imaging visibility, biocompatibility, and processing stability. Whether used for digital denture fabrication, image-guided positioning, or prototyping short-term restorations, it is the ideal material for dental manufacturers striving for precision and safety.

1. Material Highlights and Characteristics

Dental imaging visibility

・Barium sulfate filling enables PEEK DC 4430G to have excellent X-ray visibility. Doctors can clearly identify the position of the repair piece or guide plate in the image, improving intraoperative accuracy.

Reliable biocompatibility

・It has passed the ISO 10993 medical standard test and can be safely used for short-term dental restorations, oral guides and tool components, avoiding tissue irritation and allergic reactions.

Chemical and Sterilization Resistance

・It can withstand high-temperature and high-pressure steam sterilization, multiple chemical cleanings, and disinfectant treatments, making it suitable for repeated use in dental labs and clinics.

Độ ổn định kích thước tuyệt vời

・Its low water absorption rate and stable coefficient of thermal expansion enable it to maintain high precision and consistency in dental precision processing.

2. Typical Dental Application Fields

・Dental imaging guide plates and positioning components: They are used as positioning materials in preoperative scanning and digital navigation, and can be precisely developed under X-rays.

・Temporary restoration of dental crowns and bridge frame prototypes: used for the trial fitting and structural testing in the early stage of restoration.

・Dental drill bit handle and support insert: Resistant to chemicals and heat, capable of withstanding frequent disinfection.

・Denture processing rods and digital model materials: Suitable for CNC cutting, hot pressing and digital denture processing procedures.

These applications focus on short-term oral contact and medical auxiliary uses, not long-term implants.

3. PEEK DC 4430G Data Sheet

| Hành vi cơ học | Tình trạng | Tiêu chuẩn | Giá trị | Đơn vị | |||

| Độ giãn dài | Năng suất | ISO 527 | 4.8 | % | |||

| Độ giãn dài | Phá vỡ | ISO 527 | 20 | % | |||

| Độ bền kéo | ISO 527 | 95 | MPa | ||||

| Độ bền kéo | Phá vỡ | ISO 527 | 73.8 | MPa | |||

| Độ bền kéo | Năng suất | ISO 527 | 95 | MPa | |||

| Mô đun kéo | ISO 527 | 4100 | MPa | ||||

| Charpy Un-notch Impact | 23°C | ISO 179 | NB | kJ/m2 | |||

| Tác động của Charpy Notch | 23°C Completely disruptive 1eA | ISO 179 | 6.8 | kJ/m2 | |||

| nhiệt | Tình trạng | Tiêu chuẩn | Giá trị | Đơn vị | |||

| HDT | 0,45MPa | ISO 75 | 210 | °C | |||

| HDT | 1,8MPa | ISO 75 | 155 | °C | |||

| Nhiệt độ nóng chảy | ISO 11357 | 337 | °C | ||||

| Nhiệt độ chuyển thủy tinh | ISO 11357 | 153 | °C | ||||

| SẠCH | Lưu lượng 23~55°C | ISO 11359 | 4.5E-5 | cm/cm/°C | |||

| Nhiệt độ làm mềm Vicat | 50°C/giờ 10N | ISO 306 | 335 | °C | |||

| Nhiệt độ làm mềm Vicat | 50°C/giờ 50N | ISO 306 | 305 | °C | |||

| Tài sản vật chất | Tình trạng | Tiêu chuẩn | Giá trị | Đơn vị | |||

| Sự hấp thụ nước | ISO 62 | 0.4 | % | ||||

| Tỉ trọng | ISO 1183 | 1.5 | g/cm³ | ||||

| Chỉ số tan chảy | 380°C 5kg | ISO 1133 | 11 | cm³/10 phút | |||

4. Processing and Process Compatibility

PEEK DC 4430 G is supplied as high-viscosity peek granules, suitable for a variety of molding methods:

・Ép phun: Used for the production of positioning guides, drill handles, and temporary crowns.

・Đúc đùn: Suitable for preparing dental rods, thin sheets and blanks for digital cutting.

・CNC and thermoforming processing: It features excellent dimensional stability and surface polishing performance, meeting the requirements of digital dental laboratories.

Its melting temperature (337°C) and high heat distortion temperature (210°C) ensure the thermal stability and surface uniformity during the processing.

5. Innovation and Industry Advantages

Image recognizability

・Containing 6% barium sulfate, the material is clearly visible in X-rays and CT scans, and is suitable for dental guides and positioning components.

Processing adaptability

・Compatible with injection molding, extrusion and CAD/CAM processing, it features stable molding and precise dimensions.

Medical alternative

・As a non-metallic material, it can replace some metal dental components and has both strength and biocompatibility.

6. Customer Feedback

The visibility of PEEK DC 4430G greatly improves the accuracy of the image guide plate and makes the surgical simulation process more efficient.

"The peek granules batch we purchased through Juyuan is stable, with consistent molding fluidity, and the surface is smooth and bubble-free after CNC machining."

7. FAQ

Q1: Can PEEK DC 4430 G be used for permanent implants?

A: Not recommended. It is intended for dental prosthetic aids and short-term contact components, such as guides and temporary crowns, but not for long-term implants.

Q2: Can it be repeatedly sterilized?

A: Yes. The material can withstand multiple 134°C steam sterilizations or chemical disinfection with stable performance.

Q3: Can it be used in digital denture fabrication?

A: Absolutely. PEEK DC 4430 G can be used as a raw material for processing digital dental models, denture blanks, and restoration guides.

8. Recommended Dental Products

| Mô hình sản phẩm | Tỉ trọng | Melt Flow Index | Độ bền kéo | Độ giãn dài | Nhiệt độ nóng chảy | Mô đun kéo | HDT | Nhiệt độ làm mềm Vicat | Notched Izod Impact Strength | Mô đun uốn | CLTE |

| DC 4470 R | 1.36 g/cm³ | 110MPa | 4.5 % | 4400 MPa | 210 °C | 335 °C | 5.4 kJ/m² | 4400 MPa | 4.5E-5 cm/cm/°C | ||

| DC 4430 G | 1.5 g/cm³ | 11 cm³/10min | 95 MPa | 4.8 % | 337 °C | 4100 MPa | 210 °C | 335 °C | 6.8 kJ/m² | 4.5E-5 cm/cm/°C | |

| DC 4420 R | 1.51 g/cm³ | 110MPa | 4 % | 4800 MPa | 210 °C | 335 °C | 5.2 kJ/m² | 4700 MPa | 4.5E-5 cm/cm/°C | ||

| DC 4450 R | 1.52 g/cm³ | 110MPa | 4.2 % | 4800 MPa | 210 °C | 335 °C | 5.1 kJ/m² | 4900 MPa | 4.5E-5 cm/cm/°C | ||

| DC 4470 G | 1.36 g/cm³ | 11.1 cm³/10min | 95 MPa | 5 % | 340 °C | 3600 MPa | 210 °C | 335 °C | 7.5 kJ/m² | 4.5E-5 cm/cm/°C | |

| DC 4430 R | 1.51 g/cm³ | 110MPa | 4.2 % | 4800 MPa | 210 °C | 335 °C | 5.4 kJ/m² | 4700 MPa | 4.5E-5 cm/cm/°C | ||

| D 4 G | 1.3 g/cm³ | 12 cm³/10min | 96 MPa | 5 % | 340 °C | 3500 MPa | 210 °C | 335 °C | 8 kJ/m² | 4.5E-5 cm/cm/°C | |

| D 4 R | 1.3 g/cm³ | 110MPa | 4.8 % | 4000 MPa | 5,5kJ/m² | 4050 MPa | 4.5E-5 cm/cm/°C | ||||

| DC 4420 G | 1.49 g/cm³ | 11 cm³/10min | 95 MPa | 4.8 % | 336 °C | 4100 MPa | 210 °C | 335 °C | 6.8 kJ/m² | 4.5E-5 cm/cm/°C | |

| DC 4450 G | 1.51 g/cm³ | 11 cm³/10min | 95 MPa | 4.8 % | 337 °C | 4100 MPa | 210 °C | 335 °C | 6.8 kJ/m² | 4.5E-5 cm/cm/°C |

9. Juyuan's Advantages in Foreign Trade Supply

As an international supplier with 24 years of experience in plastic raw material trading, Juyuan is committed to providing complete engineering plastic solutions for the dental manufacturing industry

Focus on the supply chain of medical and dental materials

・Provide Evonik medical-grade PEEK series and corresponding certificates (COA, USP Class VI, ISO 10993).

Professional Technical Selection Support

・Recommend suitable grades and processing solutions based on dental manufacturing needs.

Stable International Delivery Capabilities

・Our global logistics network covers Asia Pacific, Europe, and the Americas, providing dental facilities with a continuous and stable supply of peek granules.

Juyuan makes dental restorations lighter, more stable, and more precise—making every peek granule a core material for dental medical innovation.

【Khuyến nghị liên quan】

PEEK TK4600 – High-Rigidity FR PEEK Pellets Tìm hiểu thêm>

Global Plastic Raw Material Market Update — October 2025 Tìm hiểu thêm>

The Global Journey of a Plastic Pellet: From Crude Oil to New Life Tìm hiểu thêm>