PRODUCTS

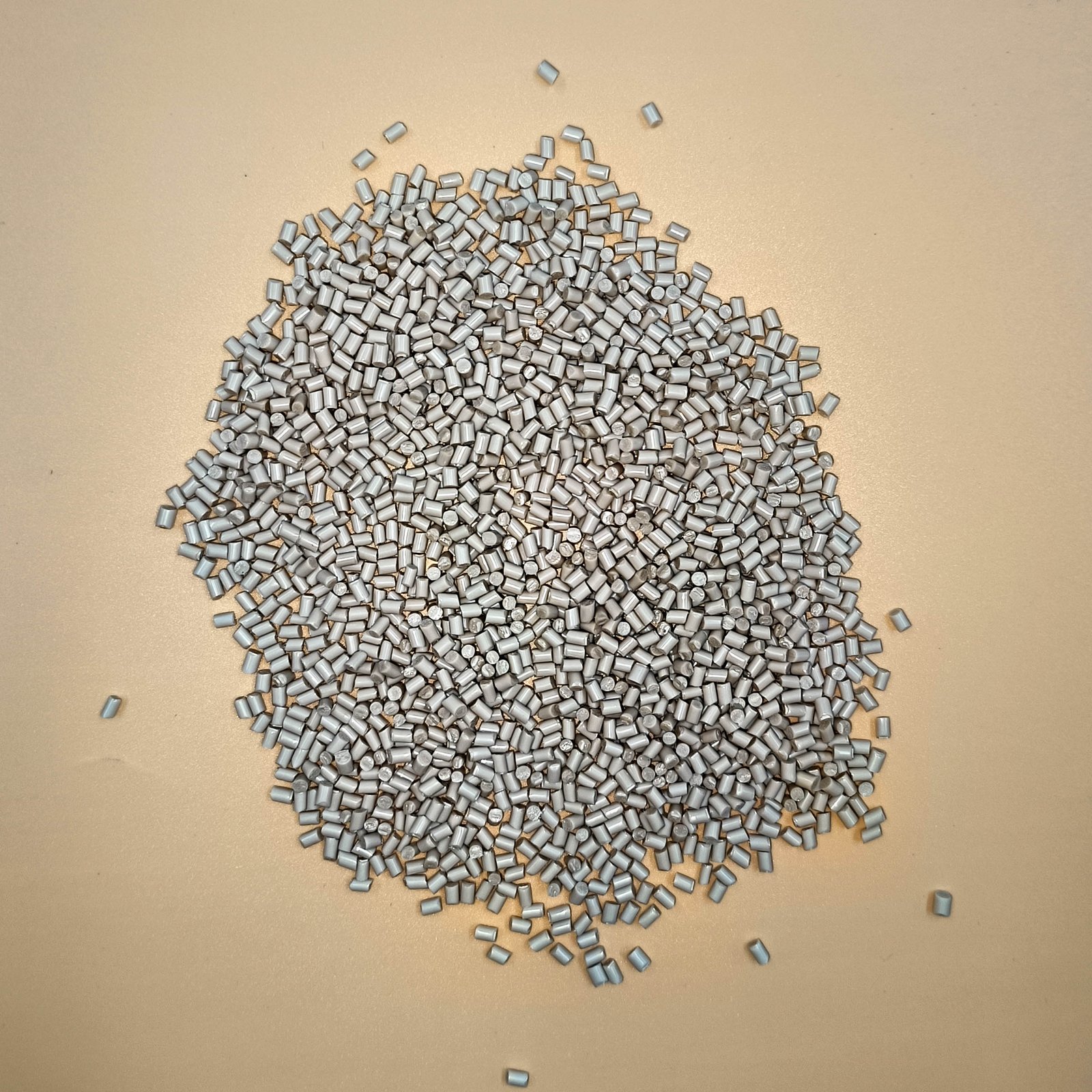

VESTAKEEP® 2000G | Flame-Retardant Medium-Viscosity PEEK

Product Struction

Why Choose VESTAKEEP® 2000G

Among engineering plastics, PEEK is renowned for its heat resistance and chemical stability, but the processability varies significantly among different grades.

VESTAKEEP® 2000G precisely controls the molecular weight distribution, enabling the material to maintain mechanical toughness and flame retardancy while also having ideal flow performance and demolding performance.

For manufacturers who pursue dimensional accuracy, cleanliness and flame retardant safety, it is a highly balanced material choice.

01 | Core Characteristics of Materials

Non-reinforced system: Maintains the cleanliness of pure resin, with no glass fiber precipitation or mold wear issues;

Medium viscosity formula: Balancing fluidity and mechanical strength, suitable for injection molding of medium and thin-walled parts;

Flame retardant safety: UL94 V-0 is achieved at a thickness of 0.8-1.6mm.

Clean and free of precipitates: Meets the requirements of semiconductor and medical contact components;

Stable shrinkage control: Approximately 0.7% flow direction, with high dimensional repeatability accuracy.

02 | Processing Technology Performance

Wide Processing Temperature Window: Melting temperature is approximately 340°C, and the resin remains stable at 370°C.

Smooth demolding: The non-reinforced system avoids the problem of mold adhesion caused by fiber breakage.

Flow balance: Suitable for multi-cavity molds and fine flow channel designs;

Mold temperature control suggestion: A mold temperature range of 170-200°C can achieve a denser crystalline structure.

Reprocessing friendly: The proportion of recycled material mixing can be controlled within 20% without significantly affecting performance.

03 | Applicable Fields and Formed Value

Semiconductor components: Heat-resistant and non-precipitating, suitable for high-cleanliness parts such as vacuum chambers and wafer fixtures;

Medical device structural components: Compatible with multiple sterilization methods (EO, steam, gamma rays);

Precision motion mechanism: Friction-stable, low-noise operation, suitable for gears, sliders, and bearings;

General mechanical parts: Maintain dimensions and strength for a long time in harsh environments.

04 | VESTAKEEP® 2000G Data Sheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Yield 50mm/min | ISO 527 | 5 | % | |||

| Elongation | Break 50mm/min | ISO 527 | 30 | % | |||

| Tensile Strength | Yield 50mm/min | ISO 527 | 100 | MPa | |||

| Tensile Modulus | ISO 527 | 3700 | MPa | ||||

| Friction Coefficient | 0.1MPa 23°C | INTERNAL METHOD | 0.4 | ||||

| Friction Coefficient | 2MPa 23°C | INTERNAL METHOD | 0.35 | ||||

| Specific Wear Rate | 0.1MPa 23°C | INTERNAL METHOD | 0.000091 | mm³/N.m | |||

| Specific Wear Rate | 2MPa 23°C | INTERNAL METHOD | 0.0001668 | mm³/N.m | |||

| Charpy Un-notch Impact | 23°C | ISO 179 | NB | kJ/m² | |||

| Charpy Un-notch Impact | -30°C | ISO 179 | NB | kJ/m² | |||

| Charpy Notch Impact | 23°C Complete Destruction 1eA | ISO 179 | 6 | kJ/m² | |||

| Charpy Notch Impact | -30°C Complete Destruction 1eA | ISO 179 | 6 | kJ/m² | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | 0.45MPa | ISO 75 | 205 | °C | |||

| HDT | 1.8MPa | ISO 75 | 155 | °C | |||

| Melting Temperature | DSC Secondary Temperature Rise | INTERNAL METHOD | 340 | °C | |||

| CLE | xFlow 23~55°C | ISO 11359 | 6E-5 | cm/cm/°C | |||

| Vicat Softening Temperature | 10N | ISO 306 | 335 | °C | |||

| Vicat Softening Temperature | 50N | ISO 306 | 310 | °C | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 23°C | ISO 62 | 0.5 | % | |||

| Shrinkage | Flow | ISO 294 | 0.7 | % | |||

| Shrinkage | xFlow | ISO 294 | 1.2 | % | |||

| Density | 23°C | ISO 1183 | 1.3 | g/cm³ | |||

| Melt Index | 380°C 5kg | ISO 1133 | 70 | cm³/10min | |||

| Electrical properties | Condition | Standard | Value | Unit | |||

| CTI | IEC 60112 | 200 | V | ||||

| CTI | 100Drops SolutionA | IEC 60112 | 175 | V | |||

| Dielectric Constant | 1KHz | IEC 60250 | 2.9 | ||||

| Dielectric Constant | 1MHz | IEC 60250 | 2.8 | ||||

| Dielectric Constant | 50Hz | IEC 60250 | 2.8 | ||||

| Volume Resistivity | IEC 60093 | 1E15 | Ω.cm | ||||

| Dielectric Strength | K20/K20 | IEC 60243 | 21 | KV/mm | |||

| Dielectric Strength | K20/P50 | IEC 60243 | 25 | KV/mm | |||

| Dissipation Factor | 1KHz | IEC 60250 | 0.003 | ||||

| Dissipation Factor | 1MHz | IEC 60250 | 0.005 | ||||

| Surface Resistivity | IEC 60093 | 1E14 | Ω | ||||

| Flammability | Condition | Standard | Value | Unit | |||

| Limiting Oxygen Index | 3.20mm | ISO 4589 | 38 | % | |||

| GWFI | IEC 60695 | 960 | °C | ||||

| GWFI | 2mm | IEC 60695 | 875 | °C | |||

| Flame Rating | 0.8mm | UL94 | V-0 | ||||

| Flame Rating | 1.6mm | UL94 | V-0 | ||||

05 | Forming Precautions and Process Optimization Suggestions

Drying management: It is recommended to dry the material at 150°C for 3 hours before processing to avoid air bubbles and silver streaks.

Injection molding parameters: The screw speed should be moderate, and the back pressure should not be too high to prevent degradation.

Mold material selection: It is recommended to use polished surfaces or chrome-plated mold cavities to prevent resin adhesion.

Demolding Angle: It is advisable to be greater than 0.5° to enhance the surface quality of the workpiece and the stability of molding.

Holding pressure strategy: Controlling the crystallization rate during the holding pressure stage can reduce warpage and shrinkage differences.

06 | Supply and Technical Support Advantages of Juyuan

Original factory channel guarantee: Long-term cooperation with Evonik to ensure material traceability.

Process support services: Provide suggestions for mold debugging and injection molding parameter optimization.

International logistics system: Multi-country export experience, quick response to customer demands.

Complete technical documentation: Provide physical property tables, MSDS, RoHS and FDA certification documents.

07 | Recommendations for Similar Materials

| Product Model | Description | Specific Gravity | Melt Flow Index | Tensile Strength | Elongation | Shrinkage | Melting Temperature | Tensile Modulus | Heat Deflection Temp. | Vicat Softening Temp. | Flexural Modulus | Coefficient of Linear Expansion | Flexural Strength | Summary |

| 3300G | Material Features: Non-reinforced Applications: Industrial use • Electrical wires & cables | 1.30 g/cm³ | 20 cm³/10min | 98 MPa | 5% | 0.70% | 340 °C | 3600 MPa | 205 °C | 335 °C | — | 6E-5 cm/cm/°C | — | Viscosity: MediumFlame Rating: V-1 • V-0 Notched Impact: 6 kJ/m² |

| ZV7402 | — | 1.30 g/cm³ | 65 cm³/10min | 80 MPa | 7% | — | — | 3500 MPa | — | — | 3500 MPa | — | 150 MPa | Notched Impact: 5 kJ/m² |

| L4000G | Material Features: Non-reinforced Applications: Gears • Mechanical parts • Medical applications • Films • Sheets | 1.30 g/cm³ | 11 cm³/10min | 96 MPa | 5% | 1.10% | 340 °C | 3500 MPa | 205 °C | 335 °C | — | 6E-5 cm/cm/°C | — | Viscosity: HighFlame Rating: V-1 • V-0 Notched Impact: 7 kJ/m² |

| ZV7401 Natural | — | 1.30 g/cm³ | 83 cm³/10min | 75 MPa | 6% | — | — | 3800 MPa | — | — | 3500 MPa | — | 150 MPa | Notched Impact: 5 kJ/m² |

| ZV7403 | — | 1.30 g/cm³ | 18 cm³/10min | 80 MPa | 7% | — | — | 3600 MPa | — | — | 3300 MPa | — | 140 MPa | Notched Impact: 7 kJ/m² |

08 | Conclusion: PEEK selection that emphasizes both stable processing and high cleanliness

VESTAKEEP® 2000G does not win by its extreme performance, but has established a reliable reputation in the medical and semiconductor fields with its three characteristics of "stable molding, flame retardant safety, and clean controllability".

For manufacturers seeking high-precision injection molding materials, it is not merely a raw material but also a long-term and stable process solution.

Juyuan will continue to provide customers with the most competitive PEEK supply and application guidance through global channels and professional support.

【Related Recommendations】

ColorRx® PEEK-3000RX: Medical-Grade peek raw material for Advanced Healthcare Learn more>

VESTAKEEP® PEEK 2000GF30: Natural PEEK for High-Rigidity Structural Applications Learn more>

The Role of Plastic Raw Materials in Fishing Nets: A Deep Dive into PA6 Learn more>