PRODUCTS

Versatile Metallocene LLDPE 3518CB Properties Uses and TDS

Product Struction

MLLDPE 3518CB Introduce

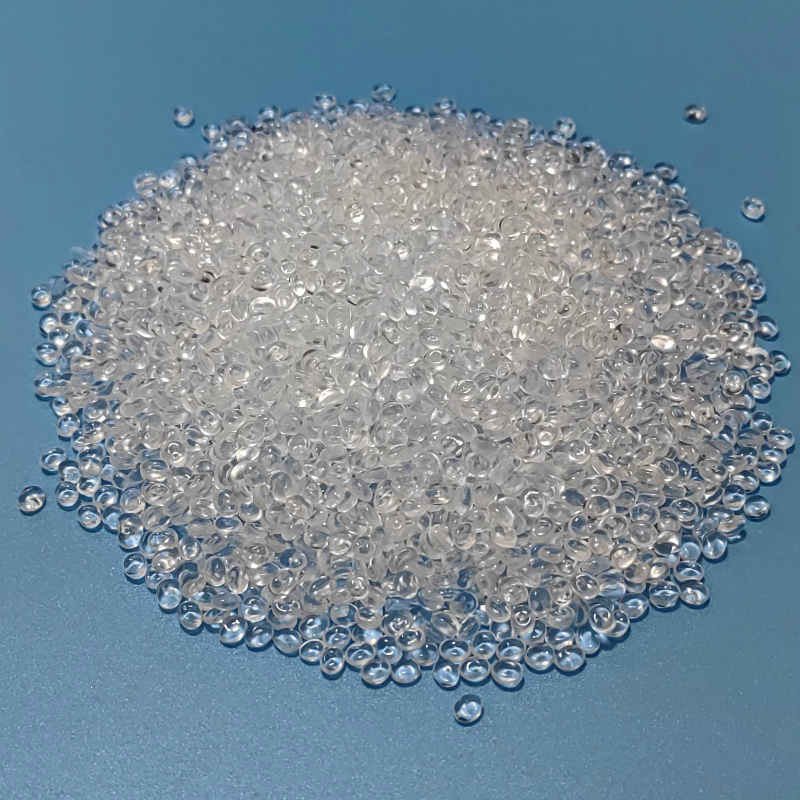

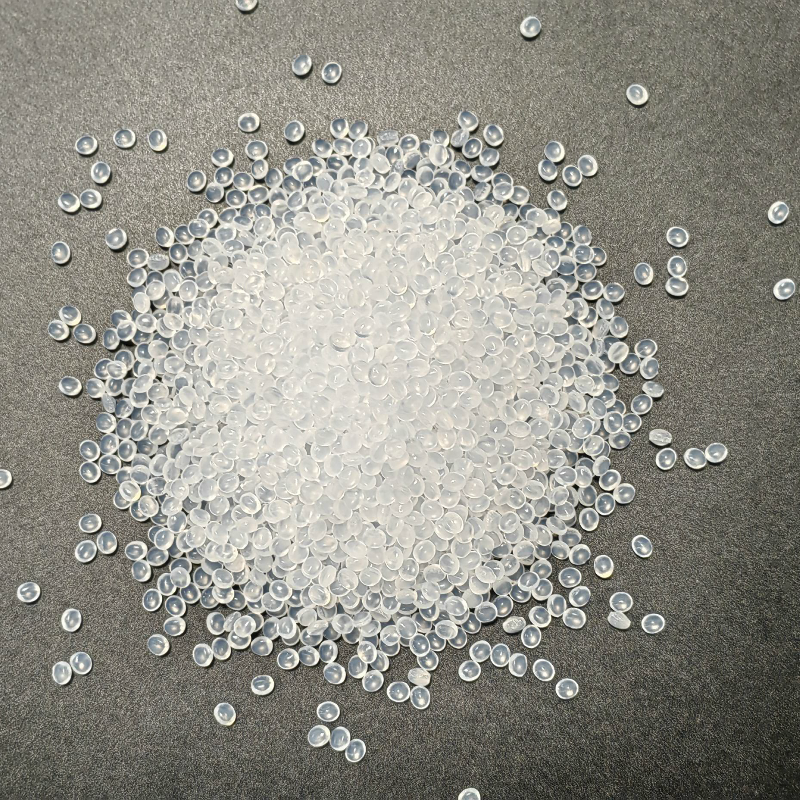

mLLDPE 3518CB plastic pellets are a metallocene linear low density polyethylene (mLLDPE) copolymer designed for extrusion and blow molding processes. They are naturally colored, have film grade properties, do not contain opening agents, and use six carbon copolymers.

1、The Properties of MLLDPE XP9100

Metallocene LLDPE 3518CB does not contain slip enhancers and exhibits good tensile properties, high impact strength and excellent puncture resistance, giving it excellent durability and reliability in thin film applications. The ethylene-hexene copolymer structure gives it better flexibility and processing adaptability, while the metallocene catalytic technology ensures the uniformity and controllability of the material.

2、Metallocene Linear Low Density Polyethylene Applications

mLLDPE 3518CB is suitable for a wide range of packaging and film applications, including box lining bags, barrier food packaging, food packaging film, sanitary film, packaging film, sealed packaging, diaper interlining, personal care products, blow molded film, cast film, cast film and multi-layer cast film. The material contains heat stabilizers that ensure excellent thermal stability and durability in processing and final applications.

3、Metallocene LLDPE 3518CB Parameters

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elmendorf | Tear Strength Flow | ASTM D1922 | 160 | g | |||

| Elmendorf | Tear Strength xFlow | ASTM D1922 | 460 | g | |||

| Elongation | Flow Break | ASTM D882 | 500 | % | |||

| Elongation | xFlow Break | ASTM D882 | 750 | % | |||

| Falling | Weight Impact Strength | ASTM D1709 | 180 | g | |||

| Puncture | Resistance | INTERNAL METHOD | 90 | N | |||

| Secant | Modulus 1% Flow | ASTM D882 | 110 | MPa | |||

| Secant | Modulus 1% xFlow | ASTM D882 | 130 | MPa | |||

| Tensile | Strength Flow Break | ASTM D882 | 90 | MPa | |||

| Tensile | Strength xFlow Break | ASTM D882 | 60 | MPa | |||

| Optical performance | Condition | Standard | Value | Unit | |||

| Gloss | 60° | ASTM D2457 | 14 | ||||

| Haze | ASTM D1003 | 2.0 | % | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | INTERNAL METHOD | 0.918 | g/cm³ | ||||

| Melt | Index 190°C 2.16kg | ASTM D1238 | 3.5 | g/10min | |||

Click here to download TDS for mLLDPE 3518CB

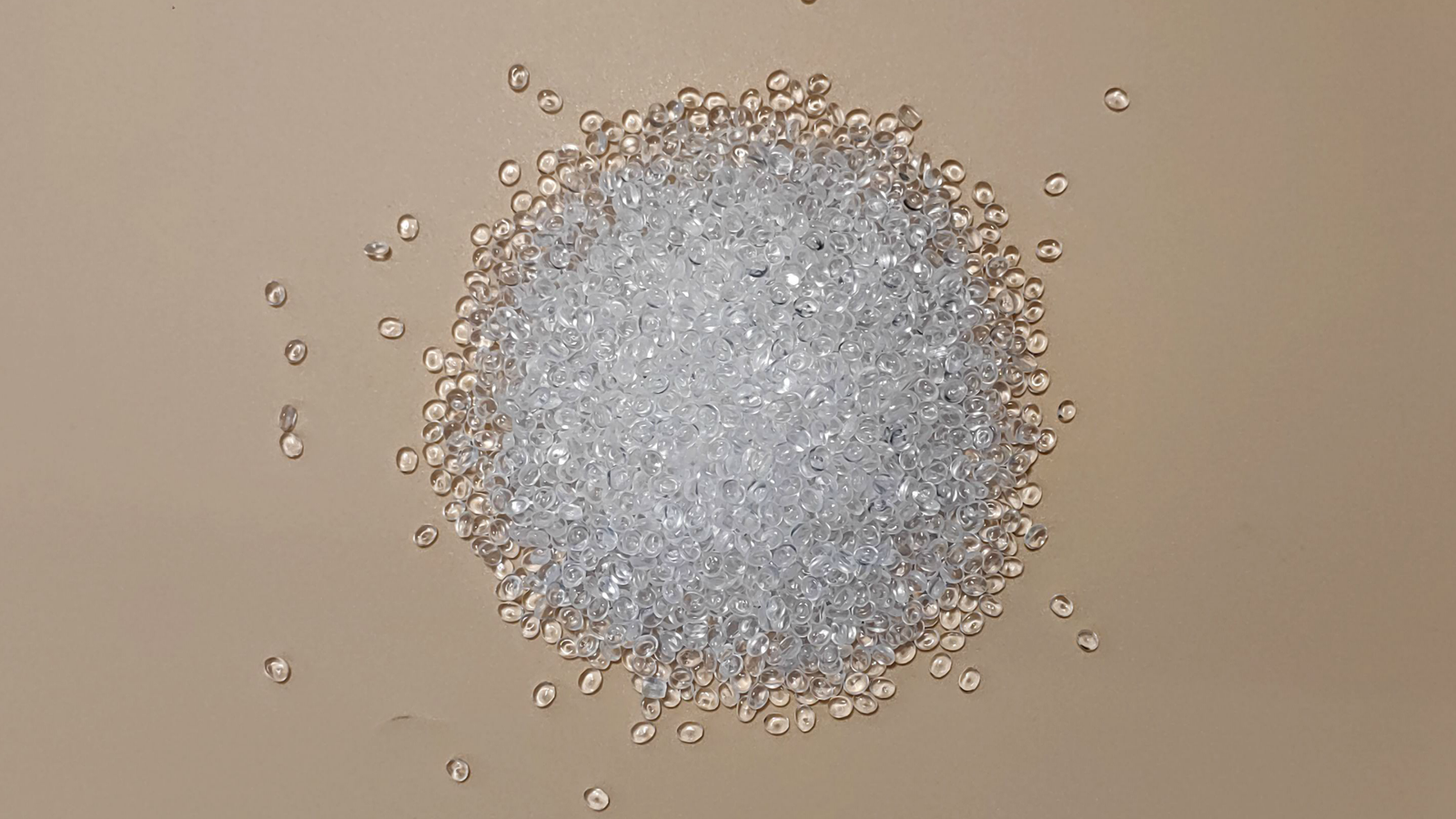

4、MLLDPE 3518CB Granule Display

Have questions or need custom solutions? Get in touch with us for personalized advice!

【Related Recommendations】

mLLDPE 8784MK: High-Performance mLLDPE for Barrier Films & Liquid Packaging Learn more>

mLLDPE SP0540: High-Performance metallocene LLDPE for Film Extrusion Learn more>

mLLDPE 1327MD: High-Performance Film-Grade mLLDPE for Food Packaging Learn more>