PRODUCTS

Udel® PSU Series Comparison & Selection

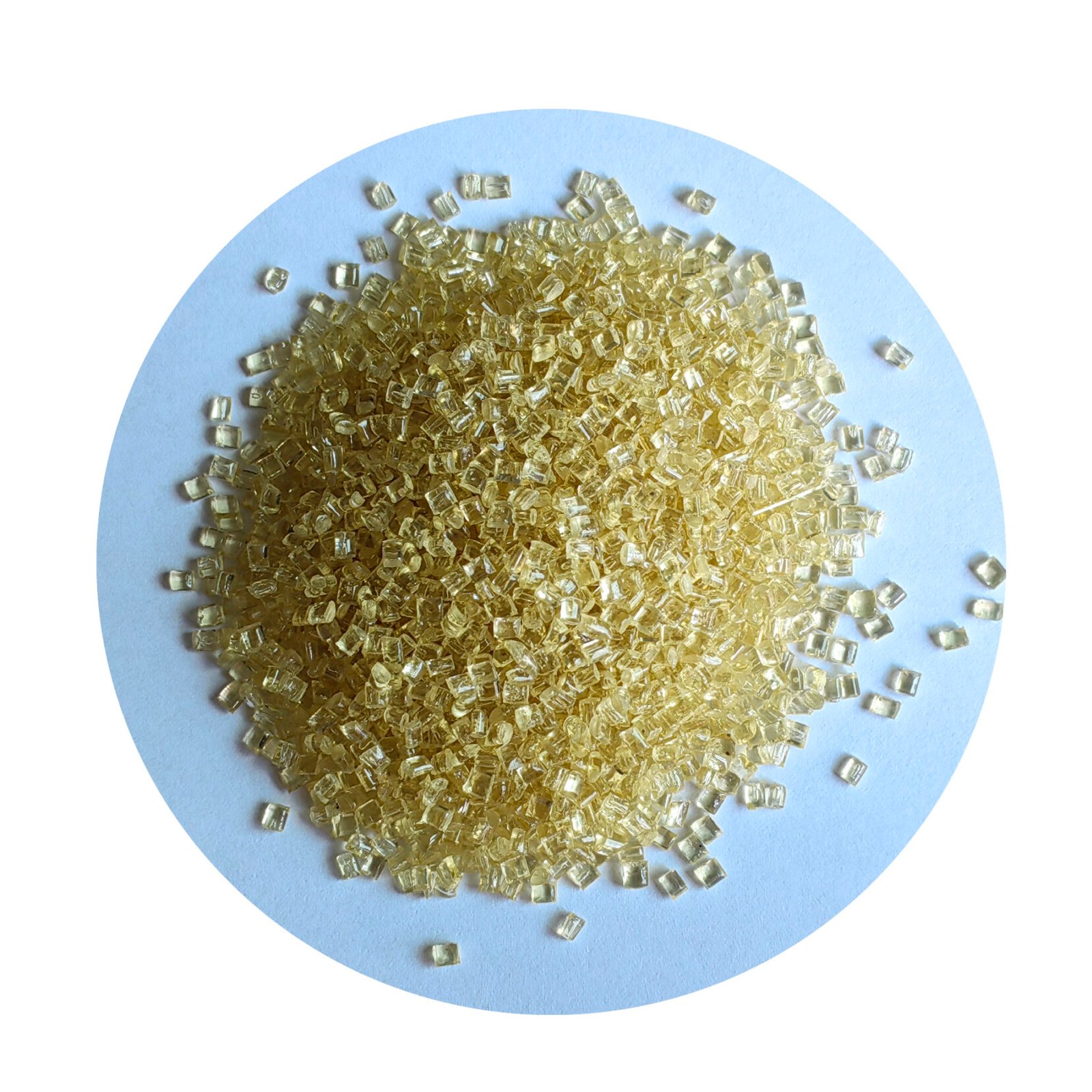

Product Struction

1. Introduction: What are buyers most concerned about?

When selecting plastic raw materials, buyers frequently ask:

・Can this material withstand high temperatures? Is it flame-retardant certified?

・Can it be used in electrical and electronic applications? Is the molding performance good?

・Will it cause mold defects?

・Which model is best for my application?

To address these questions, this article systematically compares the Udel® PSU series, using star ratings and labels to help you quickly identify the right model.

2.Series advantages of Udel® PSU

Udel® PSU stands out in the following aspects:

・High strength: Tensile strength reaches 70.3 MPa, with strong long-term structural stability.

・High-temperature resistance: The heat distortion temperature can reach up to 174 ℃, and the melting point of some models can even reach 357 ℃.

・Flame retardant safety: Some models have passed UL94 V-0/V-1 certification.

・Dimensional stability: The shrinkage rate is only 0.7%, ensuring the formation of high-precision products.

・Toughness and durability: Excellent impact performance, with a bending strength as high as 106 MPa.

👉 These characteristics make Udel® PSU widely used in medical devices, electrical and electronic products, automotive parts, and drinking water systems.

3. Detailed Datasheet

| Product Model | Value Summary | Description | Specific Gravity | Melt Flow Index | Tensile Strength | Elongation | Shrinkage | Melting Temperature | Tensile Modulus | Heat Distortion Temp | Izod Notched Impact | Flexural Modulus | Coefficient of Thermal Expansion | Flexural Strength |

| P-1835 | 1.24 g/cm³ | 4 g/10min | 70.3 MPa | 75% | 0.70% | — | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 5.6E-3 cm/cm/℃ | 106 MPa | ||

| P-1800 | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | — | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 5.6E-3 cm/cm/℃ | 106 MPa | ||

| P-3703 NT 200 | 1.24 g/cm³ | 17 g/10min | 70.3 MPa | 75% | 0.70% | — | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | — | 106 MPa | ||

| P-1720 BK 935 | Flame Retardant: V-1 • V-0 | UL Compliant | 1.24 g/cm³ | 7 g/10min | 70.3 MPa | 75% | 0.70% | 357 ℃ | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 5.6E-3 cm/cm/℃ | 106 MPa |

| P-1720 NT 13 | Flame Retardant: V-1 • V-0 | UL Compliant | 1.24 g/cm³ | 7 g/10min | 70.3 MPa | 75% | 0.70% | 357 ℃ | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | 5.6E-3 cm/cm/℃ | 106 MPa |

| P-3703 BK 937 | 1.24 g/cm³ | 17 g/10min | 70.3 MPa | 75% | 0.70% | — | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | — | 106 MPa | ||

| P-1750 NT MR | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | — | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | — | 106 MPa |

4. Udel® PSU series Performance Comparison

| Model | Strength | Heat Resistance | Toughness | Flame Rating | Application Tags |

| P-1835 | ★★★★★ | ★★★★☆ | ★★★☆☆ | — | Medical parts / Drinking water components |

| P-1800 | ★★★★★ | ★★★★☆ | ★★★☆☆ | — | Home appliance housings / Structural parts |

| P-1750 NT MR | ★★★★★ | ★★★★☆ | ★★★☆☆ | — | General-purpose / Stable supply |

| P-3703 NT 200 | ★★★★☆ | ★★★★☆ | ★★★☆☆ | — | High flowability / Thin-wall parts |

| P-3703 BK 937 | ★★★★☆ | ★★★★☆ | ★★★☆☆ | — | Precision electronic components / Thin-wall structures |

| P-1720 BK 935 | ★★★★★ | ★★★★★ | ★★★★☆ | V-0 / V-1 | Electrical & electronic parts / Automotive electrical |

| P-1720 NT 13 | ★★★★★ | ★★★★★ | ★★★★☆ | V-0 / V-1 | High-temperature parts / Connectors |

5. Product Highlight Analysis

Udel® PSU P-1835

・Label: Strength first/Excellent stability/Medical application

・Advantage summary: Strength ★★★★★ ★; Heat resistance ★★★★☆; Toughness ★★★☆☆

・Application scenarios: Medical device shells, drinking water parts

Udel® PSU P-1800

・Label: Injection-molded general-purpose/High-strength/Home appliance shell

・Advantage summary: Strength ★★★★★ ★; Heat resistance ★★★★☆; Toughness ★★★☆☆

・Application scenarios: Home appliance casings, structural components

Udel® PSU P-1750 NT MR

・Tags: General Model/Stable Supply/High Cost Performance

・Advantage summary: Strength ★★★★★ ★; Heat resistance ★★★★☆; Toughness ★★★☆☆

・Application scenario: Structural components, suitable for purchasers who need long-term supply guarantee

Udel® PSU P-3703 series (NT 200 / BK 937)

・Labels: High fluidity/Preferred for thin-walled parts/High molding efficiency

・Advantage summary: Strength ★★★★☆; Heat resistance ★★★★☆; Toughness ★★★☆☆

・Application scenarios: Electronic components, automotive interior parts, complex molds

Udel® PSU P-1720 series (BK 935 / NT 13)

・Label: High Flame Retardancy/UL Certified/High-temperature components

・Advantage intuitive conclusion: painted painted painted painted painted strength u u | heat painted painted painted painted painted u | toughness u do | 0 flame retardant grade V/V - 1

・Application scenarios: Electrical switches, automotive electrical components, connectors

6. Summary of recommended scenarios

Medical & Drinking Water → P-1835 / P-1800

Household appliances & Structural Components → P-1800 / P-1750

Thin-walled & high-flow molding → P-3703 series

High flame retardant electronics & High-temperature environment → P-1720 series

7. Why choose the Udel® PSU provided by Juyuan?

Complete range of models → One-stop coverage of the entire series including P-1835, P-1800, P-3703, P-1720, and P-1750

Certification Assurance → Compliant with UL, drinking water, and medical-related regulations

Fast supply → Global channels, stable delivery time

Professional support → Material selection consultation + technical guidance, reducing trial-and-error costs

Conclusion

If you are looking for engineering plastics that are high-strength, heat-resistant, flame-retardant and compliant, the Udel® PSU series will be your best choice.

Contact Juyuan immediately for a quote and the most suitable model recommendation.

【Related Recommendations】

RTP Engineering Plastics Series Comparison | Juyuan Learn more>

Plastic Material Data Sheet Explained: Key Properties, Test Methods & Value Guide Learn more>

RTP 2000 Series: Flame-Retardant Plastics Comparison Learn more>