PRODUCTS

Udel® P-1700 NT 11 | Medical & Food Contact Grade PSU

Product Struction

What is Udel® P-1700 NT 11

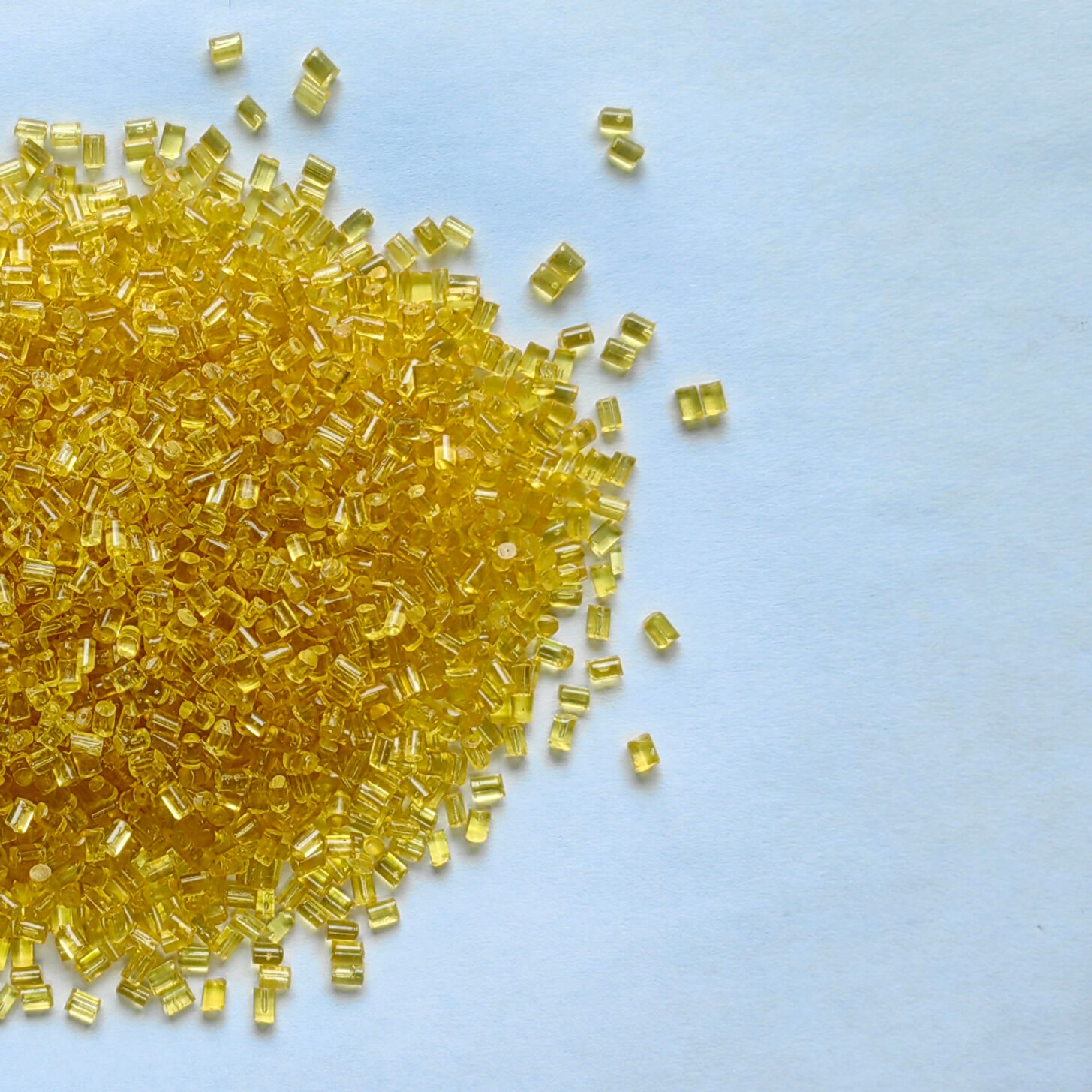

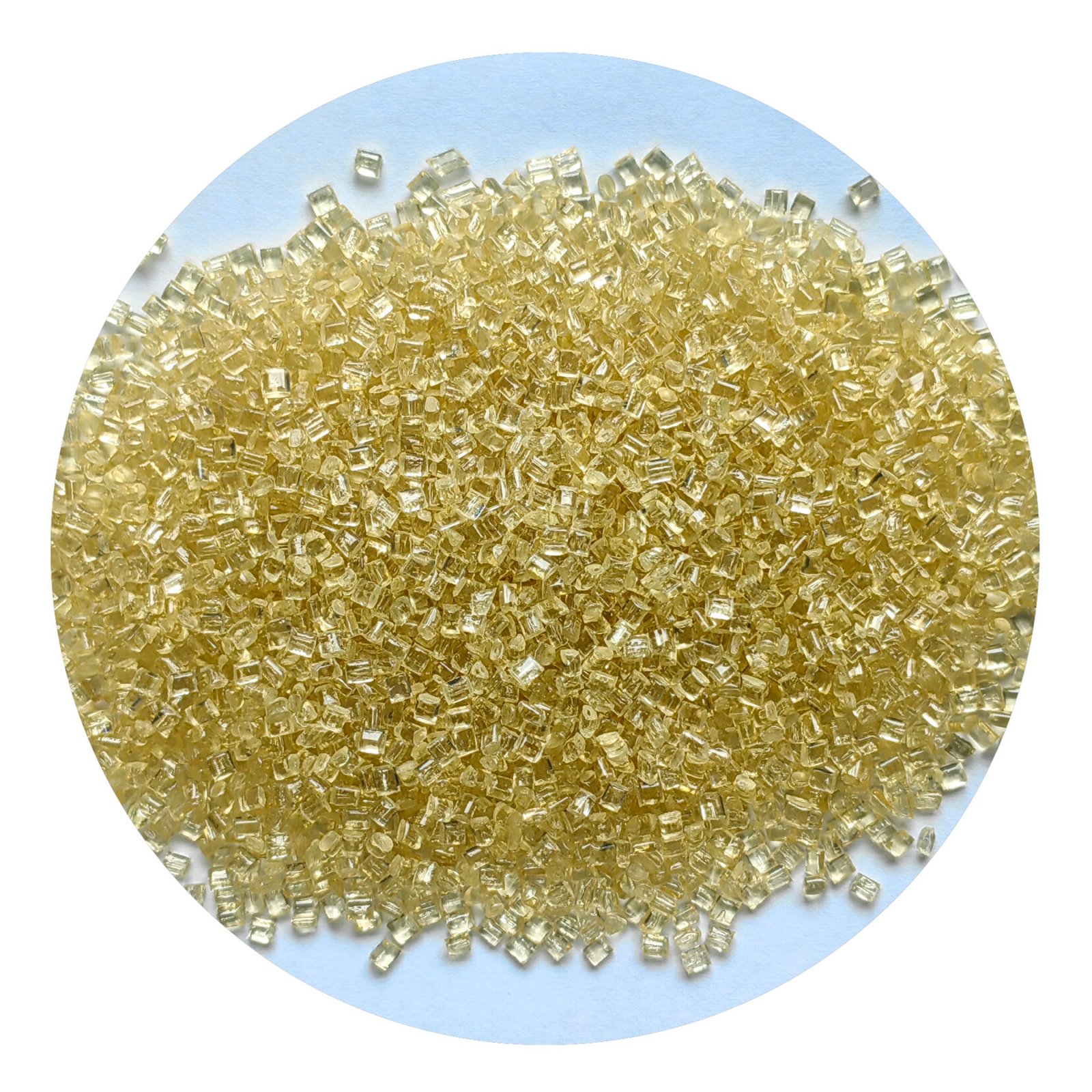

Udel® P-1700 NT 11 is a transparent polysulfone (PSU) resin from Solvay. It combines heat resistance, chemical stability, and electrical insulation, making it suitable for medical and food-contact applications. With balanced toughness and process flexibility, it is widely used in sectors requiring safety and reliability.

01 | Material Properties

Chemical resistance: Stable against acids, alkalis, alcohols, and common chemicals.

Sterilization tolerance: Can handle steam, ethylene oxide, electron beam, and gamma-ray sterilization without degradation.

Biocompatibility: Meets standards for medical devices and hygiene products.

Dimensional stability: Maintains shape and accuracy under high temperature or mechanical load.

Appearance: Semi-transparent with smooth surface, suitable for visible parts or devices requiring light transmission.

High-temperature durability: Keeps mechanical strength and toughness in hot or hydrocarbon environments.

Cleaning resistance: Compatible with repeated cleaning and disinfection.

Mechanical balance: Combines toughness and structural strength for reliable performance.

02 | Typical Applications

Household appliances: Microwave oven components, cookware, and heat-resistant parts.

Electronics: Electrical components needing insulation and dimensional precision.

Automotive electronics: Control modules and functional parts in vehicles.

Medical devices: Dental tools, surgical instruments, and nursing consumables.

Food contact: Containers, valves, and pipes that comply with drinking water standards.

Industrial components: Parts exposed to chemicals or high temperature.

Piping systems: Drinking water pipelines and valve assemblies.

03 | Processing Adaptability

Methods: Injection molding, extrusion, blow molding, thermoforming, CNC machining.

Flame retardancy: Grades from HB to V-0 for various safety requirements.

Multi-form use: Suitable for films, plates, and profiles without compromising performance.

04 | Udel® P-1700 NT 11 Data Sheet

| UL | Condition | Standard | Value | Unit | |||

| CTI | IEC 60112 | 4 | PLC | ||||

| GWFI | 0.8mm | IEC 60695-2-12 | 850 | °C | |||

| GWFI | 1.5mm | IEC 60695-2-12 | 960 | °C | |||

| GWFI | 3.0mm | IEC 60695-2-12 | 960 | °C | |||

| GWFI | 6.0mm | IEC 60695-2-12 | 960 | °C | |||

| GWIT | 0.8mm | IEC 60695-2-13 | 875 | °C | |||

| GWIT | 1.5mm | IEC 60695-2-13 | 850 | °C | |||

| GWIT | 3.0mm | IEC 60695-2-13 | 850 | °C | |||

| GWIT | 6.0mm | IEC 60695-2-13 | 850 | °C | |||

| HAI | All Color 1.5mm | UL 746A | 4 | PLC | |||

| HAI | All Color 3.0mm | UL 746A | 4 | PLC | |||

| HVTR | UL 746A | 4 | PLC | ||||

| HWI | All Color 1.5mm | UL 746A | 3 | PLC | |||

| HWI | All Color 3.0mm | UL 746A | 3 | PLC | |||

| RTI | Elec All Color 1.5mm | UL 746B | 160 | °C | |||

| RTI | Imp All Color 1.5mm | UL 746B | 140 | °C | |||

| RTI | Str All Color 1.5mm | UL 746B | 160 | °C | |||

| RTI | Elec All Color 3.0mm | UL 746B | 160 | °C | |||

| RTI | Imp All Color 3.0mm | UL 746B | 140 | °C | |||

| RTI | Str All Color 3.0mm | UL 746B | 160 | °C | |||

| Arc Resistance | ASTM D495 | 7 | PLC | ||||

| Flame Rating | All Color 1.5mm | UL94 | HB | ||||

| Flame Rating | All Color 3.0mm | UL94 | HB | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Break | ASTM D638 | 50~100 | % | |||

| Flexural Strength | ASTM D790 | 106 | MPa | ||||

| Flexural Modulus | ASTM D790 | 2690 | MPa | ||||

| Izod Notch Impact | ASTM D256 | 69 | J/m | ||||

| Tensile Impact Strength | ASTM D1822 | 420 | kJ/m² | ||||

| Tensile Strength | ASTM D638 | 70.3 | MPa | ||||

| Tensile Modulus | ASTM D638 | 2480 | MPa | ||||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | Unannealed 1.8MPa | ASTM D648 | 174 | °C | |||

| CLE | Flow | ASTM D696 | 5.6E-5 | cm/cm/°C | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 24hr | ASTM D570 | 0.30 | % | |||

| Shrinkage | Flow | ASTM D955 | 0.70 | % | |||

| Density | ASTM D792 | 1.24 | g/cm³ | ||||

| Melt Index | 343°C 2.16kg | ASTM D1238 | 6.5 | g/10min | |||

| Electrical properties | Condition | Standard | Value | Unit | |||

| Dielectric Constant | 60Hz | ASTM D150 | 3.03 | ||||

| Dielectric Constant | 1KHz | ASTM D150 | 3.04 | ||||

| Dielectric Constant | 1MHz | ASTM D150 | 3.02 | ||||

| Volume Resistivity | ASTM D257 | 3E+16 | Ω.cm | ||||

| Dielectric Strength | ASTM D149 | 17 | KV/mm | ||||

| Dissipation Factor | 60Hz | ASTM D150 | 0.0007 | ||||

| Dissipation Factor | 1KHz | ASTM D150 | 0.001 | ||||

| Dissipation Factor | 1MHz | ASTM D150 | 0.006 | ||||

| Flammability | Condition | Standard | Value | Unit | |||

| GWFI | 0.8mm | IEC 60695 | 850 | °C | |||

| GWFI | 1.6~6.0mm | IEC 60695 | 960 | °C | |||

| GWIT | 0.8mm | IEC 60695 | 875 | °C | |||

| GWIT | 1.6~6.0mm | IEC 60695 | 850 | °C | |||

| Flame Rating | All Color 1.5mm | UL94 | HB | ||||

| Flame Rating | All Color 3.0mm | UL94 | HB | ||||

05 | Industry Trends

Metal and glass replacement: Lightweight and semi-transparent Udel® P-1700 NT 11 is gradually replacing traditional materials in visible and functional parts.

Medical and food safety upgrades: Increasing regulations drive demand for PSU materials that meet FDA and NSF standards.

Cost and environmental efficiency: Reusable and disinfectable, reducing maintenance and replacement costs.

06 | Similar Recommendations

| Manufacturer | Product Model | Specific Gravity | Melt Flow Index | Tensile Strength | Elongation | Shrinkage | Tensile Modulus | Heat Deflection Temperature | Notched Izod Impact | Flexural Modulus | Coefficient of Linear Expansion | Flexural Strength |

| Solvay | P-1700 WH 6417 | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | – | 106 MPa |

| Solvay | P-1700 BK 937 | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 50~100 % | 0.70% | 2480 MPa | 174 ℃ | 7.04 kJ/m² | 2690 MPa | 5.6E-5 cm/cm/°C | 106 MPa |

| Solvay | P-1700 NT-11 | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 50~100 % | 0.70% | 2480 MPa | 174 ℃ | 7.04 kJ/m² | 2690 MPa | 5.6E-5 cm/cm/°C | 106 MPa |

| Solvay | P-1700 NT 06 | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | – | 106 MPa |

| Solvay | P-1700 CL 2611 CMP | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 75% | 0.70% | 2480 MPa | 174 ℃ | 69 J/m | 2690 MPa | – | 106 MPa |

| Solvay | P-1700 WH 7047 | 1.24 g/cm³ | 6.5 g/10min | 70.3 MPa | 50~100 % | 0.70% | 2480 MPa | 174 ℃ | 7.04 kJ/m² | 2690 MPa | 5.6E-5 cm/cm/°C | 106 MPa |

07 | FAQ

Q1: How many steam sterilization cycles can Udel® P-1700 NT 11 withstand?

A1: Over 1,000 cycles at 134℃ while maintaining performance.

Q2: How does it compare to polycarbonate (PC)?

A2: Offers higher heat and chemical resistance; transparency slightly lower.

Q3: Is it suitable for food contact?

A3: Yes, it meets regulatory requirements for food and drinking water applications.

Q4: Can it replace PPSU?

A4: In cost-sensitive projects, PSU can be used as an alternative, though PPSU performs better at very high temperatures.

08 | Why Choose Juyuan

Juyuan, with 24 years of experience in plastic raw materials trading, provides:

・Stable supply: Reliable access to Udel® P-1700 NT 11 through multiple channels.

・Material advice: Recommendations tailored to different industry and process needs.

・Market insights: Updates and cases from healthcare, electronics, and automotive sectors.

・Flexible services: Fast response and worldwide delivery support.

Partnering with Juyuan ensures not only a consistent supply of Udel® P-1700 NT 11 but also guidance throughout material selection and application.

【Related Recommendations】

Medical-Grade PSU P-1700 LCD | Medical-Grade Udel® PSU Learn more>

PSU GX07409H for Medical Care Products | PSU Supplier Guide Learn more>

PSU GF20 | 20% Glass Fiber Reinforced Polysulfone for Medical Learn more>