PRODUCTS

UBE PA6 Material Overview | PA6 1013B for Structural Components & Electrical Parts

Product Struction

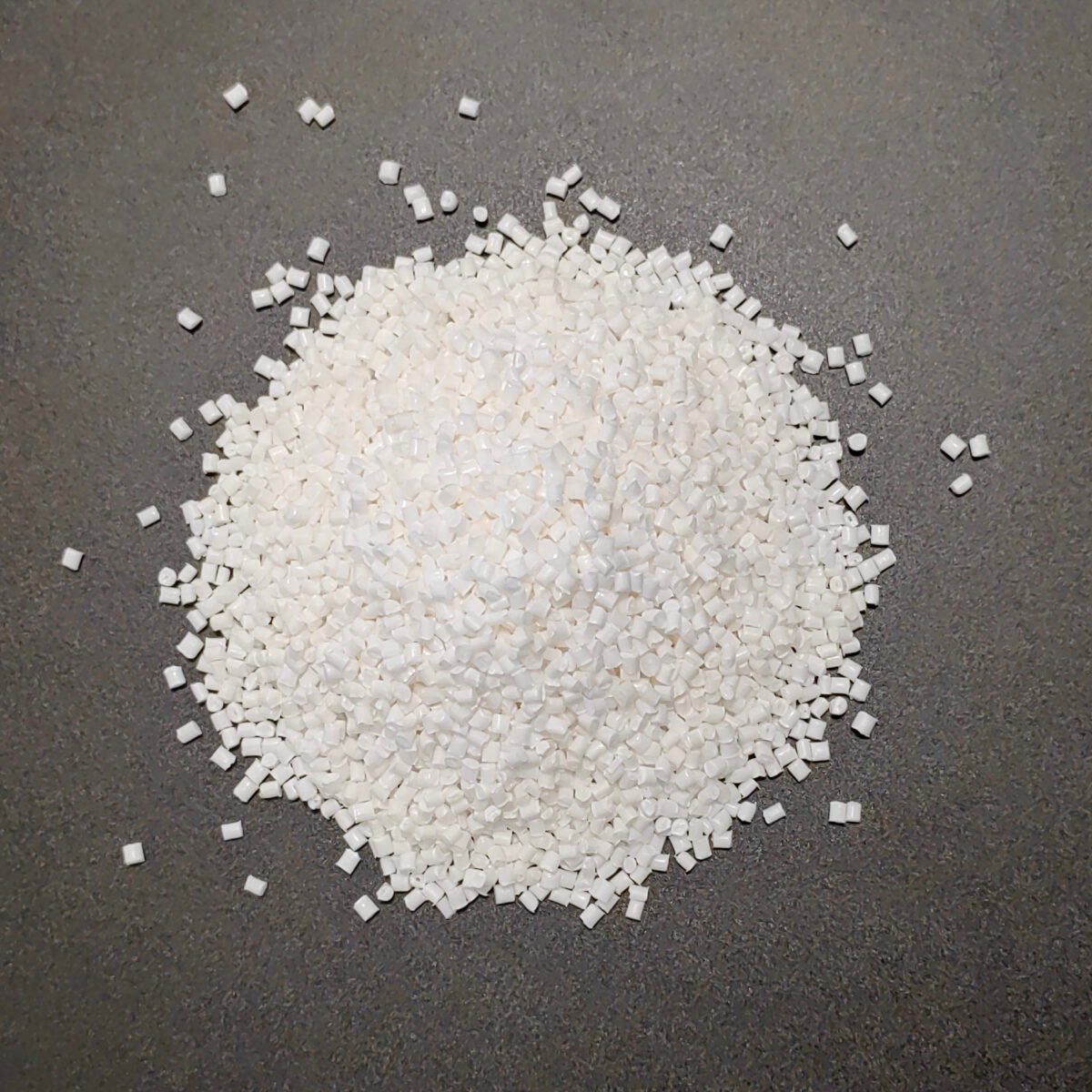

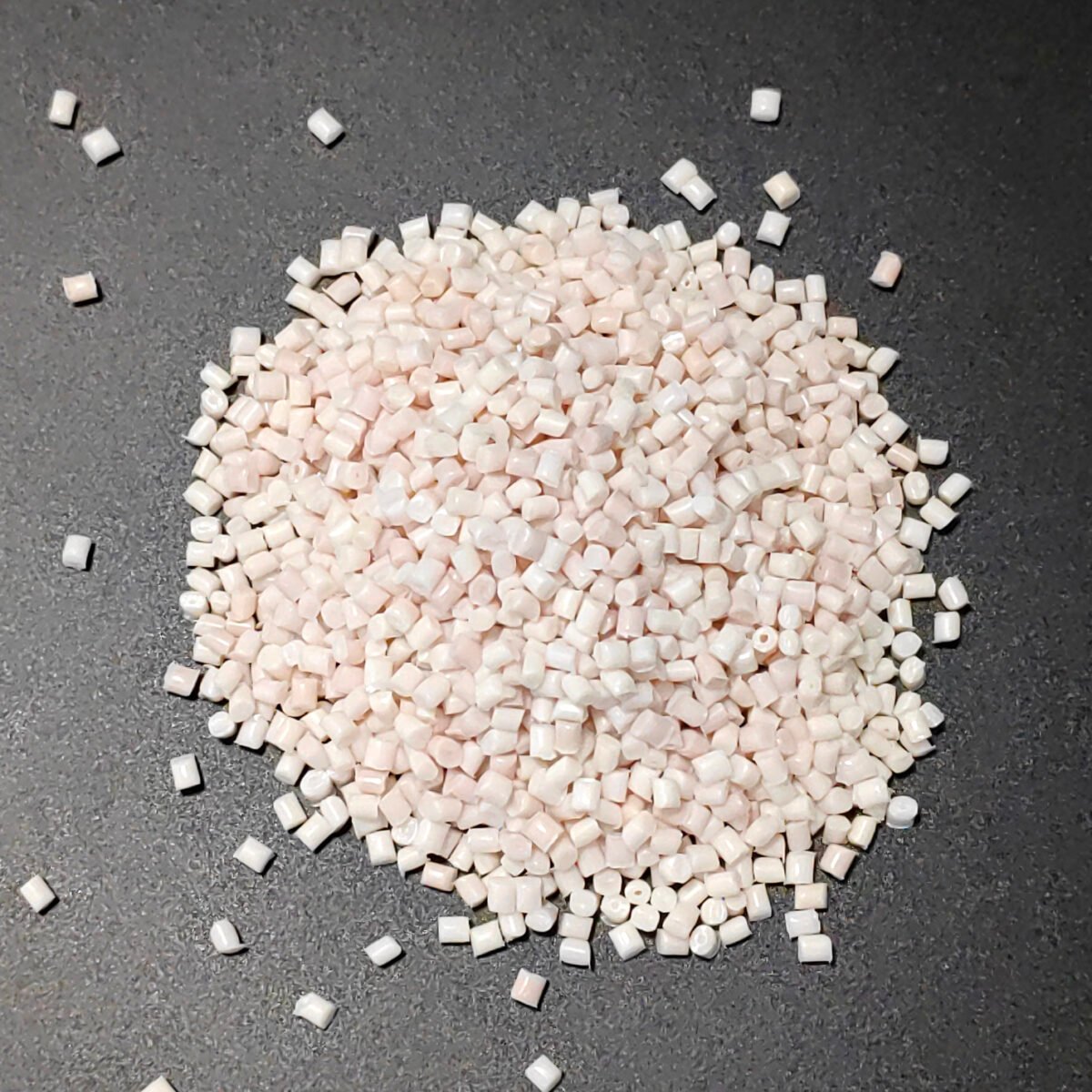

What is PA6 Material - 1013B

In the field of industrial manufacturing, nylon materials are widely used due to their high strength and good heat resistance. However, in electronic and electrical structural components, PA6 materials that take into account mechanical properties, dimensional stability and electrical insulation are not common. Ube PA6 1013B, as an engineering-grade PA6 resin launched by Ube Corporation, was developed precisely to meet such composite requirements.

01 | Material Positioning: Not just nylon, but also injection-grade engineering solutions

Compared with ordinary PA6 materials, PA6 1013B has made formula adjustments based on the material to address the typical challenges of structural components and electrical parts:

High electrical leakage resistance performance: CTI grade reaches PLC 0, suitable for high-voltage components;

Comprehensive flame retardant certification: UL94 V-2 (0.75-6.0mm) passed, in compliance with multiple national security regulations;

Low dimensional shrinkage rate: The shrinkage rate in the flow direction is only 1.4%, effectively controlling deformation.

Comprehensive mechanical equilibrium: Tensile strength reaches 80 MPa, with good rigidity and toughness.

Long-term stable thermal performance: The electrical, shock and structural performance of RTI is all at 65°C, meeting the requirements of long-term use.

This material is positioned for injection molding processing technology, suitable for conventional nylon molding conditions, and does not require complex adjustments.

02 | Typical Application Scenarios: How does PA6 1013B stand out in the "difficult material selection" working conditions?

Many designers often encounter the following problems in the development of electrical structural components:

1) The material has sufficient rigidity but poor electrical performance, and is prone to potential leakage hazards.

2) The flame retardancy meets the standard but the strength is insufficient to withstand the structural load.

3) It has strong thermal stability but large shrinkage deformation, and the assembly accuracy is difficult to guarantee.

PA6 1013B materials shows a high degree of adaptability to this type of problem. Take the electrical control box connector as an example. The requirements for this type of component are:

1) Passed the V-2 flame retardant certification under the condition of small wall thickness;

2) It does not deform or leak electricity when operating for a long time in a humid or hot environment.

3) It has a certain degree of toughness to withstand insertion and extraction as well as impact loads.

The use of PA6 1013B materials not only ensures basic electrical safety, but also achieves a balance in terms of accuracy, heat resistance and processing adaptability.

03 | Summary of core performance parameters (concise version)

| Electrical properties | Condition | Standard | Value | Unit | |||

| Arc | Resistance | ASTM D495 | 119 | s | |||

| CTI | Rating | UL 746A | 0 | PLC | |||

| Dielectric | Strength | IEC 60243 | 20 | KV/mm | |||

| Dielectric | Constant | IEC 60250 | 3.5 | ||||

| Volume | Resistivity | JIS K6911 | 1E15 | Ω.cm | |||

| Flammability | Condition | Standard | Value | Unit | |||

| Flame | Rating All Color 0.75mm | UL94 | V-2 | ||||

| Flame | Rating All Color 1.5mm | UL94 | V-2 | ||||

| Flame | Rating All Color 3.0mm | UL94 | V-2 | ||||

| Flame | Rating All Color 6.0mm | UL94 | V-2 | ||||

| Hardness | Condition | Standard | Value | Unit | |||

| Rockwell | Hardness R(Scale) | ISO 2039 | 120 | ||||

| Rockwell | Hardness M(Scale) | ISO 2039 | 80 | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Charpy | Notch Impact 1eA | ISO 179 | 6 | kJ/m² | |||

| Elongation | Break | ISO 527 | 30 | % | |||

| Flexural | Strength | ISO 178 | 110 | MPa | |||

| Flexural | Modulus | ISO 178 | 2.7 | GPa | |||

| Tensile | Modulus | ISO 527 | 2.9 | GPa | |||

| Tensile | Strength Yield | ISO 527 | 80 | MPa | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ISO 1183 | 1.14 | g/cm³ | ||||

| Shrinkage | Flow 30x100x3mm | INTERNAL METHOD | 1.4 | % | |||

| Shrinkage | xFlow 30x100x3mm | INTERNAL METHOD | 1.5 | % | |||

| Water | Absorption 23°C 50RH | INTERNAL METHOD | 3 | % | |||

| Thermal | Condition | Standard | Value | Unit | |||

| CLE | ISO 11359 | 8E-5 | cm/cm/°C | ||||

| HDT | 0.45MPa | ISO 75 | 155 | °C | |||

| HDT | 1.8MPa | ISO 75 | 60 | °C | |||

| Melting | Temperature | ISO 11357 | 215~225 | °C | |||

Click here to download TDS for PA6 1013B

04 | Comparative Analysis: UBE PA6 1013B VS Common Nylon Grades

| Material | Flame Retardancy | Dimensional Stability | Electrical Insulation | Processability | Application Fit |

|---|---|---|---|---|---|

| Standard PA6 | HB | ★★ | ★★ | ★★★★ | Not recommended for electrical components |

| Glass-Fiber PA6 | V-2/V-0 | ★★★★ | ★★ | ★★ | Strong but warps easily |

| UBE PA6 1013B | V-2 | ★★★☆ | ★★★★★ | ★★★★ | Balanced, first choice |

05 | Who is suitable for using Ube PA6 1013B?

The following customer suggestions will be given priority:

Electrical structural component manufacturers: such as plugs and sockets, relay housings, inductor frames, etc.

Automotive electronic component enterprises: electronic control enclosures, wiring harness connectors and other occasions where there are requirements for heat, electricity and force;

Export manufacturing enterprises: Injection molded products that comply with flame retardant and electrical safety regulations such as UL and IEC;

Medium and high-end injection molding manufacturers that have requirements for the stability of processing techniques.

06 | Processing and Forming Suggestions: Master several key points to achieve twice the result with half the effort in efficiency

Although PA6 materials generally have good processability, if the advantages of PA6 1013B in terms of dimensional accuracy and electrical properties are to be fully exerted, there are still several points that need special attention during injection molding:

Drying conditions: It is recommended that the pretreatment temperature be 80℃ and the time be more than 4 hours to prevent moisture absorption from causing silver threads or bubbles on the surface of the workpiece.

Melting temperature range: It is recommended to be 250-270℃. If the temperature is too high, decomposition may occur.

Mold temperature control: Maintaining the mold temperature between 70 and 90℃ helps improve the crystallinity of the workpiece and enhance dimensional stability.

Injection molding speed and holding pressure control: High-speed filling should be avoided to prevent shear overheating and flow marks, which is particularly important in electrical housing components.

In addition, as 1013B contains no glass fiber and has good fluidity, it is suitable for manufacturing thin-walled products or precision components with complex structures, and is applicable to standard hot runner or cold runner systems.

07 | Frequently Asked Questions: Issues You May Encounter during Material Selection and Usage

Q1: Which is more suitable for structural components, Ube PA6 1013B or glass fiber reinforced nylon?

A1: If the structural components mainly bear higher loads (such as brackets, gears), glass fiber reinforced PA6 might be more suitable; However, if there are requirements for electrical performance, warpage control and appearance at the same time, PA6 1013B performs better in the overall performance.

Q2: Can PA6 1013B materials be applied in a high-humidity environment?

A2: OK. This material has excellent moisture absorption stability and dimensional control ability, making it suitable for working conditions such as kitchen appliances and outdoor connectors that are exposed to moist air for a long time.

Q3: Does this PA6 material have environmental protection certification?

A3: The Ube PA6 series not only complies with UL standards but also offers ROHS and REACH compliance declarations, supporting customers in achieving global market access.

Q4: Can color masterbatch coloring be carried out?

A4: PA6 base color masterbatch can be used for coloring. It is recommended to handle it uniformly during the drying process to prevent moisture from affecting performance.

08 | Get in touch with us

If you need detailed TDS, MSDS or sample support, please feel free to contact us through the contact information on the right side of the page. We will provide a prompt response and professional matching suggestions.

【Related Recommendations】

PET 850H 80: High-Strength Polyethylene Terephthalate for Premium Packaging Learn more>

PET HY1000 by Eastman: Engineered for Flexible, Strong, and Sustainable Packaging Learn more>

PET 8050:Halogen-Free Flame Retardant PET Resin for Structural and Electrical Parts Learn more>