PRODUCTS

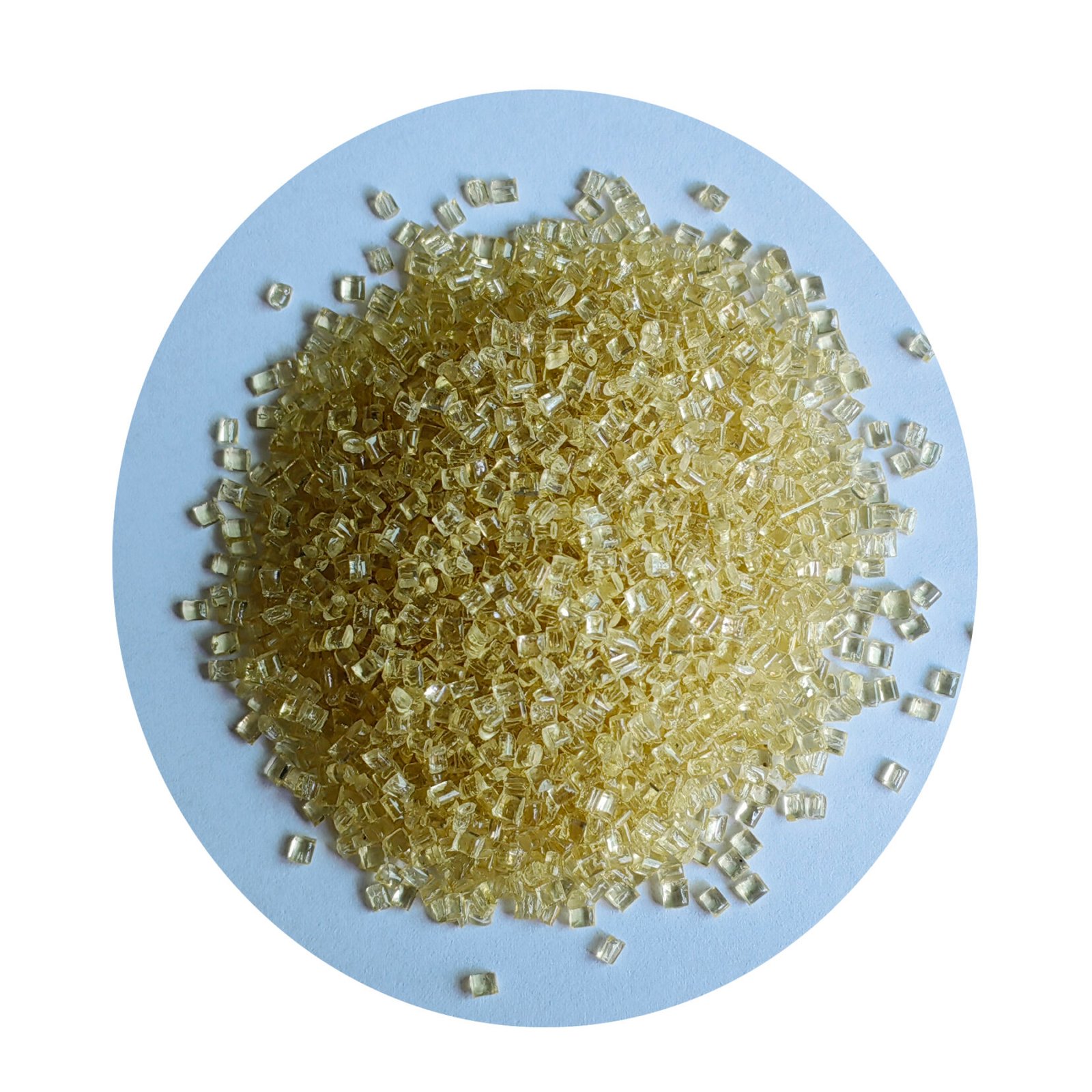

Techmer PPSU GF25 LE Polyphenylsulfone with Low Extractables Material

Product Struction

What is PPSU Polymer

Tycoma PPSU GF25 LE (Polyphenylsulfone) is a 25% glass fiber-reinforced, V-0 flame-retardant thermoplastic. Its low extractables, high heat resistance, and mechanical stability make it a preferred material for medical devices, electrical and electronic equipment, and high-temperature industrial parts. When selecting a material, buyers must consider not only basic performance but also long-term reliability, processability, and supply chain stability. PPSU GF25 LE excels in these areas.

01 | Material Core Properties

It takes into account both mechanical properties and toughness

Polyphenylsulfone itself has good toughness, while glass fiber reinforcement provides high rigidity, ensuring that the parts will not crack when subjected to stress and impact. It is particularly suitable for parts with complex structures and thin walls.

Thermal performance and dimensional stability

The high heat distortion temperature and low coefficient of linear expansion enable PPSU GF25 LE to be used for a long time in high-temperature environments, maintain shape stability, and reduce the risk of failure caused by thermal cycling.

Low extract and safety

The low extract characteristics meet the strict hygiene requirements of medical devices, food contact parts, etc., while the flame retardant grade V-0 ensures the safety of electrical and high-temperature applications.

Chemical tolerance and environmental adaptability

It has a good tolerance to a variety of chemicals and disinfectants, is suitable for medical, chemical and high-temperature industrial environments, and can extend the service life of parts.

02 | Process Adaptation and Processing Guide

Processing Method: Injection Molding

Processing Advantages: Excellent flowability, adaptable to complex geometries and thin-walled part designs.

Note: At high fill rates, mold temperature and injection speed must be optimized to balance molding accuracy and mechanical properties.

03 | Industry Application Analysis

Medical Devices

Low extractables and high heat resistance are suitable for syringes, surgical instrument handles, and sterilized reusable parts. V-0 flame retardancy ensures safe operation and meets FDA and ISO medical standards.

Electronic and Electronic Applications

High-temperature connectors, switch housings, and motor components require high insulation strength and heat resistance.PPSU GF25 LE's stable electrical properties and heat deflection temperature ensure increased reliability over long-term operation.

High-temperature industrial parts

For applications such as chemical equipment and corrosion-resistant structural components, PPSU GF25 LE offers high mechanical strength and dimensional stability, enabling it to withstand complex working conditions.

04 | Polyphenylsulfone PPSU GF25 LE Data Sheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Yield | ASTM D638 | 3.0 | % | |||

| Flexural Strength | ASTM D790 | 172 | MPa | ||||

| Flexural Modulus | ASTM D790 | 6890 | MPa | ||||

| Izod Notch Impact | 23℃ 3.20mm | ASTM D256 | 110 | J/m | |||

| Tensile Strength | Yield | ASTM D638 | 118 | MPa | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | Unannealed 0.45MPa | ASTM D648 | 216 | ℃ | |||

| HDT | Unannealed 1.80MPa | ASTM D648 | 216 | ℃ | |||

| CLE | Flow | ASTM D696 | 3.6E-5 | cm/cm/℃ | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 24hr | ASTM D570 | 0.70 | % | |||

| Shrinkage | Flow 3.20mm | ASTM D955 | 0.50 | % | |||

| Density | ASTM D792 | 1.43 | g/cm³ | ||||

| Electrical properties | Condition | Standard | Value | Unit | |||

| Volume Resistivity | ASTM D257 | 1E16 | Ω.cm | ||||

| Dielectric Strength | Short Time | ASTM D149 | 19 | KV/mm | |||

| Hardness | Condition | Standard | Value | Unit | |||

| Rockwell Hardness | R(Scale) | ASTM D785 | 120 | ||||

| Flammability | Condition | Standard | Value | Unit | |||

| Flame Rating | 1.6mm | UL94 | V-0 | ||||

05 | Selection and purchasing suggestions

Performance-first application: When mechanical strength, heat resistance and flame retardancy are the core requirements, PPSU GF25 LE is the preferred choice.

Resilient priority applications: For medical or precision electronic components that require higher impact toughness, low glass fiber or fiber-free grade Polyphenylsulfone can be considered.

Supply chain stability: It is recommended to choose suppliers with multi-source procurement capabilities and technical support to ensure continuous supply of materials and technical services.

06 | Reference for comparison of similar materials

| Material Model | Reinforcement Type | Density | Key Properties & Application Scenarios |

| PPSU GF25 LE | 25% Glass Fiber | 1.43 g/cm³ | Balanced rigidity and toughness, low extractables. Suitable for medical devices, electrical parts, and high-temperature industrial components. |

| PPSU GF30 LE | 30% Glass Fiber | 1.47 g/cm³ | Higher stiffness, ideal for load-bearing structural parts such as high-performance electrical connectors. |

| PPSU GF30 TL10 LE | 30% Glass Fiber + 10% PTFE | 1.50 g/cm³ | Enhanced with PTFE for better lubricity and flowability. Recommended for high-temperature electronic and industrial components with wear resistance needs. |

| PPSU GF10 | 10% Glass Fiber | 1.36 g/cm³ | Higher impact toughness, easy to process. Suitable for thin-wall medical parts and precision small components. |

| PPSU GF20 | 20% Glass Fiber | 1.43 g/cm³ | Balanced stiffness and toughness, suitable for medium-load parts such as medical instruments and electronic housings. |

| PPSU GF40 | 40% Glass Fiber | 1.63 g/cm³ | Very high stiffness and dimensional stability. Ideal for heavy-duty, high-temperature environments such as industrial structural components. |

07 | Juyuan supply advantage

Global multi-source procurement: Ensuring a continuous supply of Polyphenylsulfone materials

Technical support: Assist customers in model selection, process optimization and application implementation

Flexible delivery: Supports small-batch sample production to large-scale mass production

Customized service: Color, batch and special requirements can be adjusted according to customer needs

【Related Recommendations】

Radel® D-3000 PPSU: Crack Resistance and Thin-Wall Application Material Learn more>

Radel® R-5000 PPSU Material for Medical, Food & High-Temperature Applications Learn more>

Evonik PPSU P Material: Transparent and Heat-Resistant PPSU Polymer Learn more>