PRODUCTS

TECASON P MT Polyphenylsulfone for Medical & Industrial Use

Product Struction

TECASON® P MT

In the fields of medical devices, food processing and high-end industries, materials are not merely components but also crucial to the lifespan, safety and compliance of products. As the industry's demands for high-temperature resistance, flame retardancy, biocompatibility and other properties continue to rise, traditional materials are gradually revealing their limitations: although metals are strong, they are heavy and prone to corrosion; Although ordinary plastics are lightweight, they are difficult to withstand high-temperature steam disinfection or complex chemical environments.

Against this backdrop, TECASON® P MT Polyphenylsulfone launched by Ensinger stands out. This material combines the lightness of engineering plastics with medical-grade reliability, making it the preferred choice for medical, food and industrial customers seeking high-performance solutions.

1. Material Highlights and Characteristics

High-temperature resistance: It still maintains mechanical strength in an environment exceeding 200℃ and is suitable for long-term high-temperature scenarios.

Outstanding disinfection resistance: It can withstand hundreds of high-pressure steam sterilizations while still maintaining transparency and toughness.

High strength and flame retardancy: With UL94 V-0 grade, it ensures flame retardancy while maintaining excellent impact strength.

Biocompatibility: Meets medical-grade application standards and can be directly used in products that come into contact with the human body.

Dimensional stability: Low water absorption rate and good chemical resistance ensure long-term stable performance in complex environments.

2. Typical Uses

Medical field: surgical handles, dental equipment, transparent shells, reusable consumables.

Food and drinking water: Valves, joints, pump bodies and other parts that come into contact with food and drinking water.

Aviation and transportation: High-strength lightweight structural components, meeting the requirements of flame retardancy and impact resistance.

Electrical and Electronic: Insulating components, electrical enclosures and high-performance connectors.

3. TECASON® P MT Polyphenylsulfone Data Sheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | 23℃ | ASTM D638 | 60 | % | |||

| Compressive Strength | ASTM D695 | 98.94 | MPa | ||||

| Flexural Strength | 23℃ | ASTM D790 | 91 | MPa | |||

| Flexural Modulus | 23℃ | ASTM D790 | 2410 | MPa | |||

| Izod Un-notch Impact | ASTM D256 | 694 | J/m | ||||

| Tensile Strength | Yield 23°C | ASTM D638 | 69.6 | MPa | |||

| Tensile Modulus | 23℃ | ASTM D638 | 2340 | MPa | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | Unannealed 0.45MPa | ASTM D648 | 220 | ℃ | |||

| HDT | Unannealed 1.80MPa | ASTM D648 | 216 | ℃ | |||

| CLE | Flow | ASTM D696 | 3.1E-4 | cm/cm/℃ | |||

| Vicat Softening Temperature | ASTM D1525 | 218 | ℃ | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 23℃ 24hr | ASTM D570 | 1.1 | % | |||

| Density | ASTM D792 | 1.29 | g/cm³ | ||||

| Electrical properties | Condition | Standard | Value | Unit | |||

| Dielectric Constant | 60Hz | ASTM D150 | 3.44 | ||||

| Volume Resistivity | ASTM D257 | 1E15 | Ω.cm | ||||

| Dielectric Strength | ASTM D149 | 14.2 | KV/mm | ||||

| Hardness | Condition | Standard | Value | Unit | |||

| Rockwell Hardness | R(Scale) | ASTM D785 | 123 | ||||

| Flammability | Condition | Standard | Value | Unit | |||

| Flame Rating | UL94 | V-0 | |||||

Technical Data Overview of TECASON® P MT Polyphenylsulfone

4. Technology and Processing Techniques

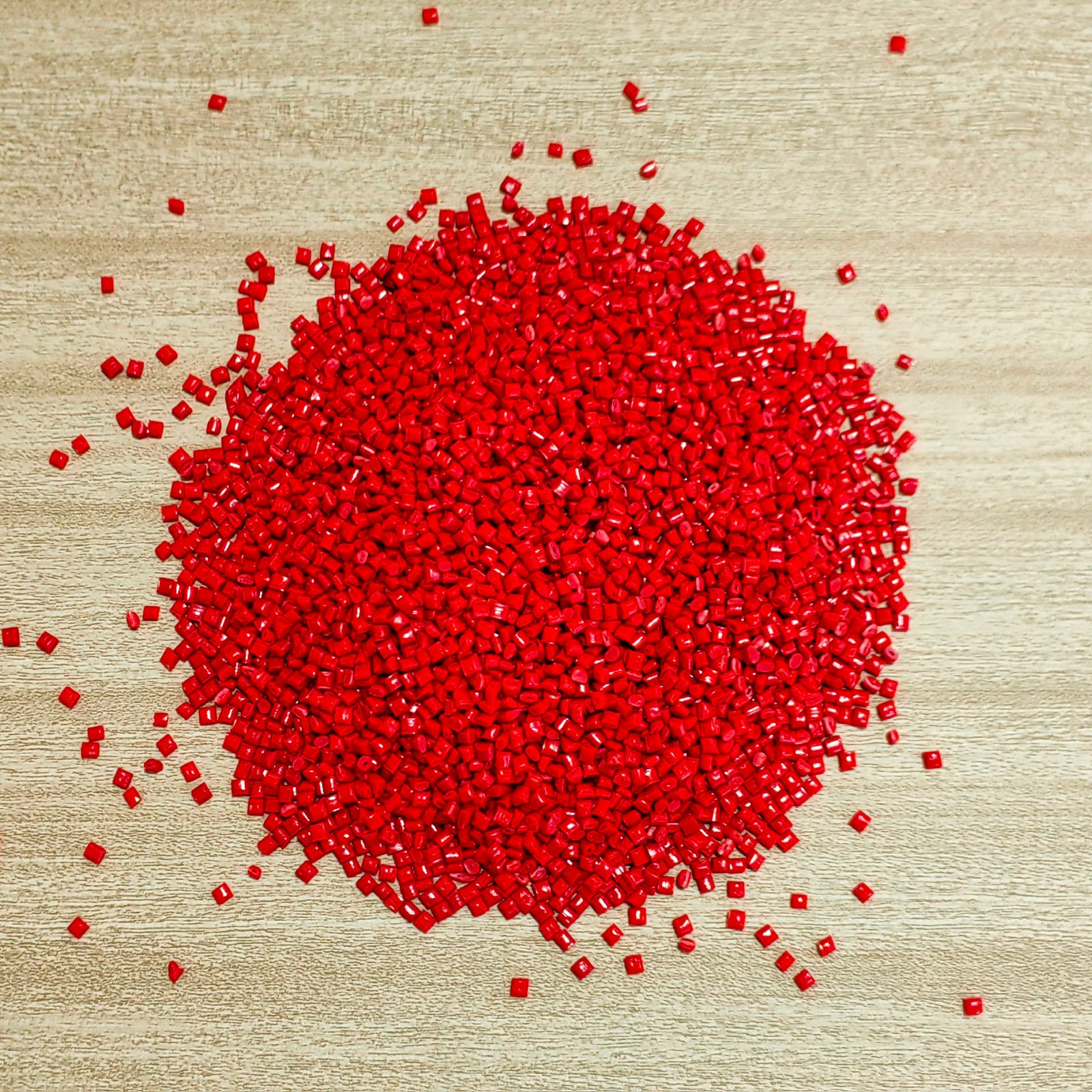

TECASON® P MT Polyphenylsulfone is produced by injection molding process and can produce granular raw materials, compatible with standard thermoplastic processing equipment.

・Injection molding: Suitable for complex medical components and precision parts.

・Machining: Suitable for small-batch and high-precision parts customization.

・Transparency and natural color features: They offer design flexibility and can be used in medical and industrial scenarios that require visualization.

5. Innovation and Industry Competitive Advantage

Compared with traditional materials:

・Compared with metals: It is lighter, more corrosion-resistant and easier to process.

・Compared with engineering plastics such as PSU and PEI, it has stronger heat resistance and disinfection resistance, and more outstanding impact resistance.

・Compared with general plastics, it has significant advantages in mechanical strength, flame retardancy and compliance.

This differentiated characteristic makes TECASON® PMT Polyphenylsulfone the preferred alternative material for the medical and high-end industries.

6. Customer Feedback

European medical device manufacturers: After using this material, the lifespan of the devices has increased by 40%, significantly reducing the cost of consumable replacement.

Food processing enterprises: In high-temperature cleaning environments, the performance of components remains stable, ensuring food safety.

Aviation parts supplier: By adopting this material, lightweight design has been achieved while meeting flame retardant regulations.

7. Frequently Asked Questions (FAQ)

Q1: How many times of high-temperature steam sterilization can this material withstand?

A1: It remains transparent and resilient even after hundreds of repeated autoclaving cycles.

Q2: Does it comply with international medical and food contact standards?

A2: Yes, TECASON® PMT Polyphenylsulfone complies with multiple medical and food safety regulations.

Q3: What are the advantages compared with PSU and PEI?

A3: This material is superior in terms of high-temperature resistance, hydrolysis resistance and impact strength, making it suitable for more demanding application scenarios.

8. Similar Recommendations

In addition to TECASON® PMT Polyphenylsulfone, Enxingge also provides:

| Grade / Model | Tensile Strength (MPa) | Tensile Modulus (MPa) | Flexural Strength (MPa) | Notched Impact Strength | Heat Deflection Temp (℃, 1.8MPa) | Continuous Use Temp (℃) | Medical Suitability |

| Radel 5500 Black | 79 | 2340 | 91 | 160 J/m | 207 | 149 | ✓ (Food contact / Medical) |

| P Polyphenylsulfone | 69.6 | 2340 | 91 | 694 J/m (unnotched) | 216 | — | — |

| P MT XRO Bone | 79 | 2900 | 124 | 85 J/m | — | 149 | ✓ (Medical grade, bone color) |

9. Our Advantages as an Export Supplier

Selecting materials is just the first step; choosing a reliable supply partner is the key.

Multi-category coverage: We not only supply TECASON® PMT Polyphenylsulfone, but also offer a variety of high-performance engineering plastics.

In-stock and fast delivery: Always in stock, shorten delivery time, and meet urgent orders.

Technical support: Provide material selection guidance, processing suggestions and industry application solutions.

International service network: Supports multilingual communication and global logistics to ensure worry-free cross-border transactions.

Competitive pricing: Relying on stable channels and large-scale supply, we help customers reduce costs.

10. Conclusion

In high-demand medical, food and industrial applications, TECASON® PMT Polyphenylsulfone is not merely a material, but a systematic solution to help customers address core issues such as short lifespan, safety risks, compliance difficulties and high costs.

Choosing us as a partner means choosing reliable materials, perfect services and a stable supply chain.

【Related Recommendations】

RADEL® 5500 Black – Multi-Color Medical-Grade PPSU Material Learn more>

RTP PPSU 1400 Series – Durable, Heat & Food Safe Resin Learn more>

FDA Food Grade Plastics: A Must-Read for Purchasing Food-Grade Plastics Learn more>