PRODUCTS

Solvay PSU HTS-2600 | Heat-Resistant Transparent PSU Polymer

Product Struction

What is HTS-2600

PSU HTS-2600 is a polysulfone (psu polymer) material developed by Solvay. It combines optical transparency, mechanical strength and thermal stability, and is suitable for applications with strict requirements for high-temperature resistance and dimensional stability. It has performed outstandingly in the fields of electronic appliances, medical equipment, membrane separation and automotive parts.

01 | Material highlights and characteristics

Solvay PSU HTS-2600 belongs to the psu polymer series of materials. It is renowned for its excellent heat resistance, transparency and dimensional stability, and is a representative among engineering plastics that combines mechanical strength and electrical performance. Its main highlights include:

・High heat resistance stability: It can maintain structural strength in high-temperature environments, and the heat distortion temperature can cover the demanding application requirements.

・Outstanding mechanical toughness: Balanced tensile and bending strength, capable of withstanding long-term stress and impact.

・Excellent electrical insulation performance: stable dielectric constant, high insulation strength, suitable for electronic and electrical equipment.

・Excellent optical transparency: With a moderate refractive index, it is suitable for application in components that require a transparent appearance or optical performance.

・Dimensional stability and moisture resistance: Low water absorption rate and low shrinkage rate ensure the long-term reliability of precision structural components.

02 | Typical application scenarios

Due to the fact that psu polymer possesses properties such as heat resistance, transparency and electrical insulation simultaneously, PSU HTS-2600 has been widely applied in multiple fields:

・Electronic and electrical: Electrical appliance casings, insulating components, connectors, ensuring long-term electrical safety.

・Medical industry: High-temperature resistant disinfection, suitable for surgical instruments, laboratory consumables and reusable equipment.

・Automotive industry: Headlamp lenses, sensor housings and precision structural components, balancing appearance and functionality.

・Water treatment and membrane separation: Preparation of hollow fiber membranes and filtration elements to meet the long-term chemical corrosion resistance requirements.

・Optics and industrial fields: transparent parts, protective covers, industrial inspection equipment casings.

03 | PSU HTS-2600 Data Sheet

| Optical performance | Condition | Standard | Value | Unit | |||

| Refractive Index | ASTM D542 | 1.66 | |||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | 23°C | ASTM D638 | 20 | % | |||

| Elongation | Yield 23°C | ASTM D638 | 7.5 | % | |||

| Flexural Strength | 23°C | ASTM D790 | 93.1 | MPa | |||

| Flexural Modulus | 23°C | ASTM D790 | 2210 | MPa | |||

| Izod Notch Impact | 23°C | ASTM D256 | 13.57 | kJ/m² | |||

| Tensile Strength | 23°C | ASTM D638 | 79.3 | MPa | |||

| Tensile Modulus | 23°C | ASTM D638 | 2340 | MPa | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | Annealed 1.8MPa | ASTM D648 | 255 | °C | |||

| Melting Temperature | 400 | °C | |||||

| Glass Transition Temperature | 265 | °C | |||||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 23°C | ASTM D570 | 1.5 | % | |||

| Water Absorption | 23°C 24hr | ASTM D570 | 0.5 | % | |||

| Shrinkage | Flow | ASTM D995 | 0.7 | % | |||

| Density | ASTM D792 | 1.31 | g/cm³ | ||||

| Melt Index | 400°C 5kg | ASTM D1238 | 6.5 | g/10min | |||

| Electrical properties | Condition | Standard | Value | Unit | |||

| Dielectric Constant | 1KHz | ASTM D150 | 4 | ||||

| Dielectric Constant | 1MHz | ASTM D150 | 3.9 | ||||

| Dielectric Strength | ASTM D149 | 17 | KV/mm | ||||

| Hardness | Condition | Standard | Value | Unit | |||

| Rockwell Hardness | R(Scale) | ASTM D785 | 127 | ||||

04 | Advantages of technological processing

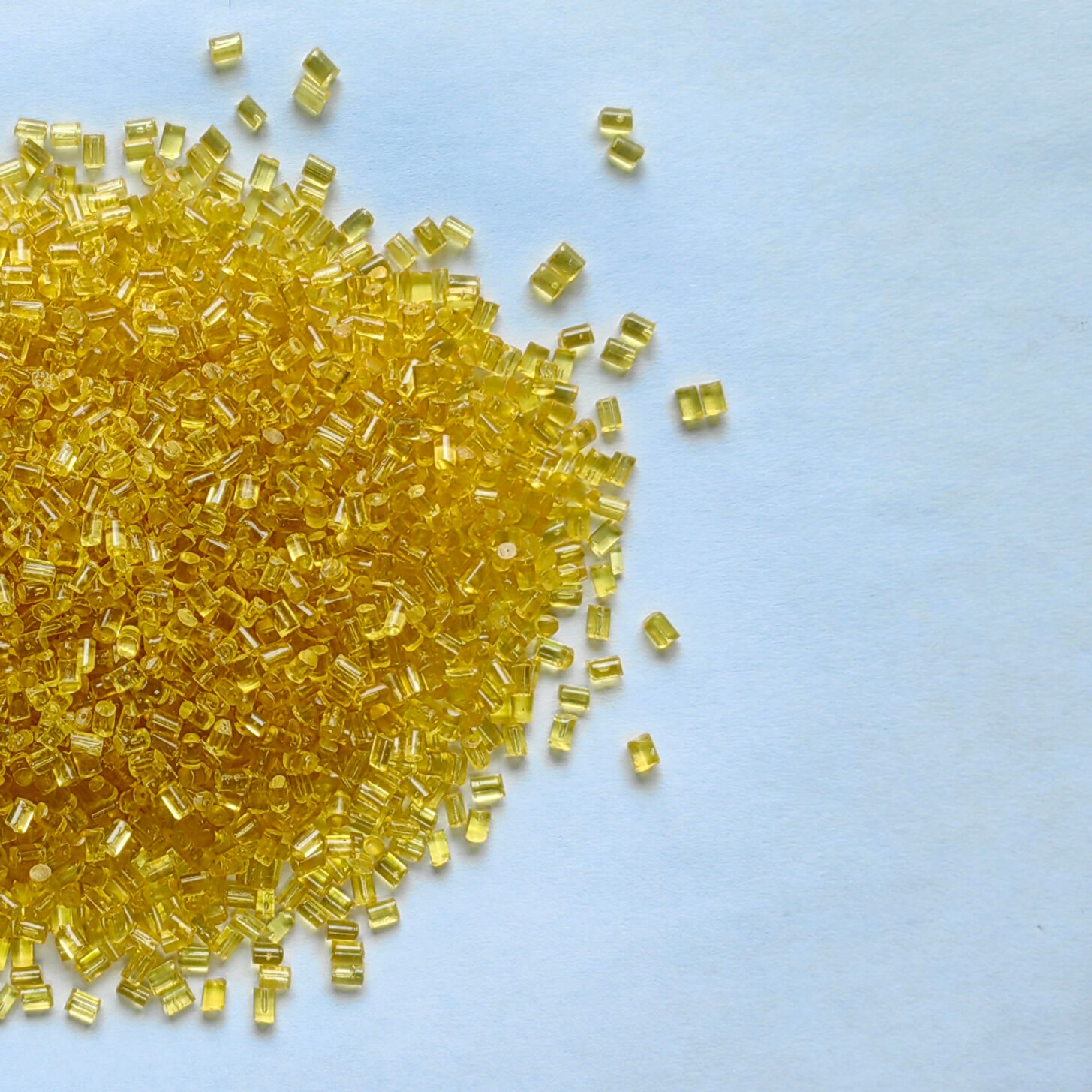

PSU HTS-2600 is supplied in granular form and injection molding process is recommended.

・Moderate flow performance: While maintaining high heat resistance, it still has good processability and is suitable for complex mold designs.

・High dimensional accuracy: Low shrinkage rate, almost no deformation of the processed parts, meeting the requirements of high-precision assembly.

・Strong process compatibility: It can be combined with glass fiber reinforced and flame-retardant systems to develop multi-functional modification solutions.

05 | Innovation and industry competitive advantage

In the high-performance engineering plastics market, the competitors of psu polymer include polycarbonate (PC) and polyetherimide (PEI). In contrast, the PSU HTS-2600 has:

・Higher heat distortion temperature, suitable for long-term high-temperature environments;

・Better transparency and chemical stability, especially with unique advantages in membrane separation and medical disinfection environments;

・Lower hygroscopicity, reducing warpage and dimensional errors of the workpiece.

This enables the PSU HTS-2600 to have stable market competitiveness in fields such as medical care, automobiles, electronics and electrical appliances.

06 | Customer feedback

Purchasers from the medical and electronics industries generally feedback:

・The product performs stably during the high-temperature disinfection cycle, and there are no cracks in the components.

・It demonstrates excellent insulation and durability in electronic components;

・It has good fluidity during the processing, reducing the defective rate and improving production efficiency.

07 | Frequently Asked Questions (FAQ)

Q1: What are the differences between PSU HTS-2600 and PC?

A: PC has high transparency, but its heat resistance and long-term dimensional stability are inferior to psu polymer. Especially in high-temperature disinfection and chemical contact environments, PSU has more advantages.

Q2: Is it suitable for medical devices?

A: Yes. PSU HTS-2600 can withstand repeated high-temperature steam sterilization and has good mechanical toughness. It is a common material for medical devices.

Q3: Are there any special requirements for processing?

A: It is recommended to use high-temperature injection molding equipment, and the mold needs to take into account the relatively high melting temperature of the material.

Q4: Can it be used in food contact applications?

A: Some PSU materials have food-grade certification and can be selected based on specific models and customer requirements.

08 | Similar recommendations

| Manufacturer | Grade | Density | Melt Flow Index | Tensile Strength | Elongation | Shrinkage | Melting Temp. | Tensile Modulus | HDT | Notched Izod Impact | Flexural Modulus | Unnotched Izod Impact | CTE (Linear Expansion) | Flexural Strength |

| Solvay | HTS-2630 | 1.55 g/cm³ | 5.5 g/10min | 112 MPa | 2% | 0.30% | 400 ℃ | 8960 MPa | 260 ℃ | 64.1 J/m | 7580 MPa | 534 J/m | 1.1E-3 cm/cm/℃ | 164 MPa |

| Solvay | HTS-2420 | 1.46 g/cm³ | 11 g/10min | 114 MPa | 3% | 0.40% | 400 ℃ | 6270 MPa | 240 ℃ | 74.7 J/m | 6070 MPa | 694 J/m | — | 176 MPa |

| Solvay | HTS-2620 | 1.46 g/cm³ | 10 g/10min | 110 MPa | 3% | 0.40% | 400 ℃ | 6000 MPa | 260 ℃ | 5.44 kJ/m² | 5650 MPa | 59.89 kJ/m² | — | 163 MPa |

| Solvay | HTS-2601 | 1.31 g/cm³ | 17 g/10min | 79.3 MPa | 15% | 0.70% | 400 ℃ | 2340 MPa | 255 ℃ | 133 J/m | 2210 MPa | — | — | 93.1 MPa |

| Solvay | HTS-2401 | 1.30 g/cm³ | 27 g/10min | 75.8 MPa | 30% | 0.70% | 400 ℃ | 2340 MPa | 235 ℃ | 427 J/m | 2320 MPa | — | 1.1E-3 cm/cm/℃ | 94.5 MPa |

| Solvay | HTS-2430 | 1.55 g/cm³ | 7.5 g/10min | 117 MPa | 2% | 0.30% | 400 ℃ | 8960 MPa | 240 ℃ | 80.1 J/m | 8270 MPa | 587 J/m | — | 174 MPa |

09 | Our supply advantage - Juyuan

As a supplier with 24 years of international experience in plastic raw material trade, Juyuan is committed to providing global customers with:

Stable raw material supply: Direct channels ensure reliable sources of goods;

Rapid delivery system: Responding to customers' urgent production demands;

Professional material selection suggestions: Recommend the most suitable psu polymer according to different application scenarios;

Global service network: Covering the markets of Europe, America, Southeast Asia and the Middle East, meeting the needs of purchasers in different regions.

Summary

Solvay PSU HTS-2600 is a psu polymer that combines heat resistance, transparency, mechanical and electrical properties, and is competitive in fields such as medical care, electronics, and automobiles. For purchasers who require high-temperature stability and long-term reliability, it is a trustworthy choice.

【Related Recommendations】

RTP 900 Series Plastics: Performance & Sourcing | Juyuan Learn more>

EDGETEK™ PF-05GF/000 FR MR PSU Resin for Injection Molding Learn more>

Flame Retardant Plastics Guide | Juyuan Resin Supply Learn more>